A Leader with the Belief of Leading by Example

By:

Please tell us about your company Greenlam Industries, and yourself? How long you have been in this business and in the Indian market?

Greenlam laminates is among the world’s top three, Asia’s largest and India’s number one surfacing solutions brand. With its presence in over 100 countries, Greenlam has focussed on developing quality products with great passion for innovation. We offer end to end surfacing solutions to customers with the varied range of product offerings, which consist of laminates, compacts, interior and exterior cladding solutions, restroom and locker solutions, decorative veneer, engineered wooden floors and engineered wooden doors.

Our manufacturing units, based at Behror, Rajasthan and Nalagarh, Himachal Pradesh, are best in class, using the latest technologies along with R&D centers to deliver unparalleled products to our customers. Across product segments, Greenlam laminates has the largest production capacities with 14.02 million laminate sheets, 4.20 million Sq m decorative veneer, 1.00 million Sq m engineered wood floor and 0.12 million doors annually.

Greenlam also boasts of the largest and widest distribution network of over 14,000 distributors, dealers and retailers across the country. In the international market, Greenlam is present in over 100 countries with its own marketing and distribution setup in 13 countries. With an 18 per cent share in the organised domestic market, Greenlam laminates is the largest laminate player in the country.

We started our business in the year 1993 with just one-production line plant in Alwar, Rajasthan. We initiated commercial production of laminates in 1993 and started commercial production of decorative veneer in 2002. In the year 2014, we started the commercial production of engineered wooden floors and MFC and we are India’s only manufacturer of the same. In the year 2015, we started the commercial production of engineered wooden doors at Behror and became India’s first organised manufacturer of the same (doorsets and frames).

Tell us briefly about your journey with the company over the years, also about your major success stories in India?

I started my journey with Greenlam in 1997 and since then, I have not looked back. Greenlam forayed into the laminates industry in 1993 and changed the outlook of the market, today completing 25 years of excellence.

Greenlam Laminates Industries is a pioneer in innovating the laminates market in India. We were the first company who commenced the advertising of products, especially textures, which was never done before.

In other words, marketing has been one of our biggest strength. From introducing compact and unicore laminates to presenting scratch resistant laminates, we are the first company to offer anti-bacterial cubicles and lockers. Not just the quality, we offer technically advanced products and have an exclusive warranty of 10 years for our products. Not only laminates, today, Greenlam Industries has become an integrated manufacturer of all surfacing needs with solutions for façades, restrooms and cubicles, doors and frames, laminates, decorative veneers and flooring.

What are the exterior cladding product categories offered by Greenlam Industries?

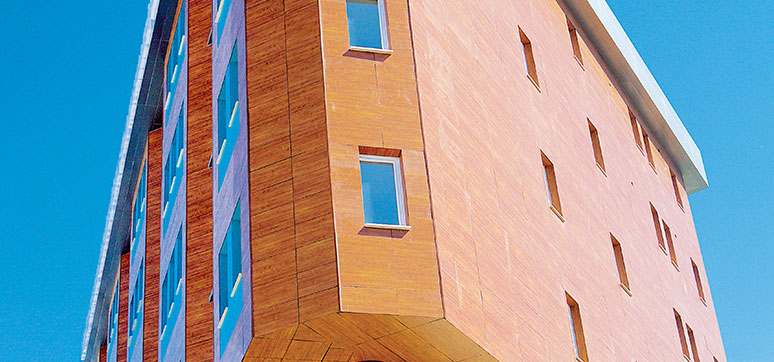

Exterior wall cladding has reached to new heights over the past decade and can be made from all kinds of materials like ACP, glass, real wood, metal, ceramic, concrete, etc. However, taking into account the effects of global warming, we as manufacturers need to think of sustainable ways in which we can do our bit for the environment. At Greenlam Laminates industry, sustainability is very critical for us and therefore in the quest of creating sustainable places we offer smart and sustainable façade options.

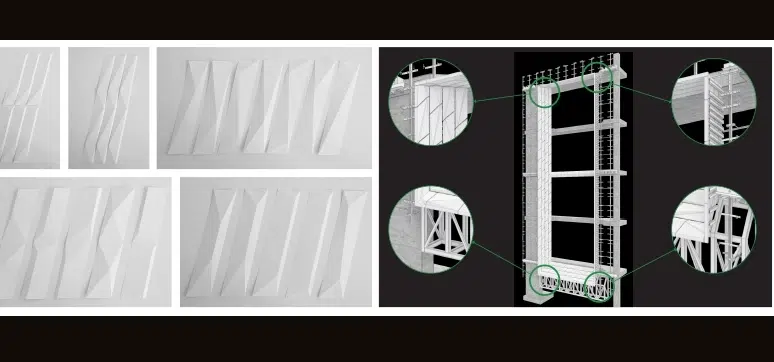

Greenlam’s exterior grade compact laminates are a duo of style and character and are specially designed to beautify your exteriors. They come with a revolutionary GLE Technology that offers three layers of protection that makes them resistant to UV light, microbial threats, weatherproof and fire-resistant, hence apt for exteriors.

Claddings come with special fasteners which are made using non-corrosive materials that offer better colour fastening properties. The exterior clads allow you to decorate your home, office or entire building structures These façades are anti-graffiti, chemical resistant and can withstand extreme temperature conditions from -60°C to +80°C. Façades activate space, drawing out relationships between light, environment and view. They also accommodate varying levels of privacy. Besides saving up to 30 per cent energy, they add warmth and elegance.

Owing to the recent fire accidents, the demand for fire retardant façades has increased. Since it is extremely difficult to control a fire from the exteriors, fire retardant façades play a key role in fire safety. Greenlam clads comes with fire retardant property due to which it minimises smoke emission and delay the temperature rise, making it more resistant to fire and ill effects. The beauty and endurance of the clads enhance the look of your exteriors and last for a lifetime.

Please tell us about your doors and frame products?

Mikasa Doors, from the house of Greenlam Industries, come as a single, factory-finished unit. The complete doorset is a natural progression over the outdated carpentry methods where the door and frame were provided separately. The final product is ready-to-install, unlike the current method in which the door is installed early and suffers damage during the later stages of construction.

Mikasa doors are easy to maintain. The cost for these doors and frames is known upfront unlike traditional methods where it is disaggregated. Being factory finished, they require no polishing or regular maintenance. It is important to know that aesthetics, fir and finish of these doors are extremely premium and superior.

Additionally, UV lacquer and polishing line is used in the process following the latest European practices. Mikasa provides superior quality locks, latches, door handles which provides the perfect solution to make the house secure. Mikasa also produces fire rated doors which provide a safe exit, in case of emergency, by preventing the spread of fire and smoke and limiting it to a certain level. Nonfire rated doors are made of five layers with a solid core which are sturdy and can bear a heavy load.

The different layers of a door make it durable, strong and provide protection to the house. Also, specialty doorsets are constructed for areas exposed to high levels of radiation, such as hospitals and laboratories. These are designed to achieve optimum levels of sound reduction of up to 45RwdB with a minimum thickness of doors being 44 mm.

Mikasa Real Wood doors provide a wide range of wooden doors which are durable as well as stylish. The weather in India varies from region to region and it is difficult to choose doors which can resist all weather conditions. Mikasa’s all-weather doors can be used anywhere without thinking about the weather of a place. Just like a perfect package, Mikasa gives a complete door solution as doors, frames and accessories which are shipped from the factory as a fully furnished single doorset to suit every room and purpose.

All the components – door leaf, frame and architectural ironmongery – work together as a unified product, meeting certified performance levels. With Mikasa Doors, customers also get the choice of surfacing material ranging across veneers, laminates or paint.

In the door’s space, we recently launched Mikasa DURA collection. Mikasa’s Dura doorsets come with a comprehensive 6-side protection which provides extremely high impact resistance. These doors are designed to stand the test of time. Dura doorsets is a function of 5 layers of tubular core and a 6-side protection that shields the doors from the hostile weather and makes them apt for both, residential and commercial ecosystems.

Throw some light on your company facilities and structure?

Greenlam’s products are produced in the world class state-of-the-art manufacturing facilities situated at Behror in Rajasthan and Nalagarh in Himachal Pradesh. Greenlam is an environmentally responsible company that takes the role of a leader with the belief of leading by example. Greenlam exports to over 100 countries worldwide with 13 international offices.

That being said, Greenlam Industries was awarded the largest laminates exporter from India from last eight years consecutively by ‘The Plastics Export Promotion Council’. Today, Greenlam is one of the most preferred global brand in the building material space.

From the very first step in the manufacturing process to the final product, everything is carefully monitored and meticulously scrutinised for quality. The idea is to develop a range of products that last for years while minimising environmental pollution. Our superior design, quality, systems and environmental commitment have been awarded the ISO 9001, ISO 14001, OHSAS 18001, Green Label, Green Guard, FSC and PEFC certifications.

The company is structurally well placed to deliver strong growth.

Backed by an established distribution network and brand value in the surface décor industry, we strive to strengthen our corporate citizenship through engagements with various NGOs working in the fields of health, education, environment and vocational training. Greenlam has currently identified some priority projects to be undertaken by the CSR Committee, which are, promoting education, including special education, health care and gender equality.

How do you see the cladding industry evolving in India?

The Indian cladding industry has undergone a dramatic change in the last 10 years. The primary two reasons because of this would be – one, the increase in demand of smart cities, sustainable buildings and green projects and, two, an aware consumer who is constantly on the lookout for unconventional options. This is where Greenlam exterior cladding comes in because the end product is sustainable and green as well as has a Green Guard Gold Certificate.

According to a study by Grand View Research, Inc, the global façades market size is expected to reach USD 339.46 billion (Rs. 1.7 lakh crore) by 2024. The fact that industrialists and consumers have shifted towards advanced ecofriendly façades, which is estimated to fuel the market growth in the coming years as well.

We look forward to catering this demand and serving our customers the best of our offerings. To give a brief, Greenlam clads have a wide range of solid, wood and abstract patterns. The variety of colours and designs make it possible to use it for innovative applications like – on main gates, pergolas, fencing, router cut entrance gates, balconies, etc. They are ISO certified and come with an advanced and revolutionary GLE technology that makes them fade resistant, resistant from microbial threats, waterproof and fireresistant, hence ideal for exteriors.

What has been your or your organisation’s contribution in bringing about the current revolution in the façade cladding and the fenestration sector?

If we look at the traditional methods of cladding, the most commonly used materials were bricks, glass or ACP. While these materials did serve the purpose of protecting a building, it was a rare occurring that the cladding would last through the years. Today, the cladding industry has moved forward where we have smart products that guarantee protection for your walls and simultaneously give you bold and beautiful exteriors.

Greenlam’s exterior grade compact laminates come with an unmatched GLE technology that makes them fade resistant, microbial proof, weather-proof and fire-resistant, hence apt for exteriors. Claddings from Greenlam come with special fasteners which are made using non-corrosive materials that offer better colour fastening properties. As mentioned above, Greenlam introduced the concept of innovative cladding materials such as fire-resistant exterior cladding. We also were the first company to conduct training sessions and workshops for various architects, interior designers and installers, on the benefits of cladding, what is involved in the process of cladding installations, etc.

With the expansion of technology, we are yet to see the apex for the outer covering of the building. Architects and façade designers are experimenting with all kinds of façade products, which takes care of dust, sun, extreme winters, heat, apart from adding beauty to the overall structure. One primary reason why compact laminates are gaining importance is due to its eco-friendly material. Greenlam clads is the preferred choice as they are all eco-friendly and are ISO certified.

Please tell us about a few of your iconic and innovative projects?

Some of our most innovative projects have been Hotel Sarvana Bhavan in Chennai, Andhra Pradesh Industrial Infrastructure Corporation, Command Control Center in Vijaywada, the NHAI’s Highway Nest which is ongoing for pan India among many other projects. Along with these, Chief Minister Secretariat Receiving Counter in Patna was an exemplary project. Like so, we also decorated filmmaker Upendra Rao’s house which is situated in Bengaluru. Some of our major assignments have been in Lucknow as well, such as, Charbagh Metro Station and LMRC Training Center.

With these iconic projects, it is evident that there is an increased awareness for laminates, veneers and engineered wood floors among people when it comes to beautifying their houses.

We have also done various residential and commercial cladding projects in many countries other than India like COOP network of supermarkets at Slovakia; a residential project, Kharkov, Ukraine; another residential colony project, Vilnius, Lithuania; Municipality of Kucukcekmece Semt Konagi; Marka Yapi, Istanbul; Pirlanta Villas, Kisikli, Istanbul; Sunset Park, Istanbul, and many more.

As per your view, how important is the role of right cladding in achieving system performance, optimum acoustic and thermal insulation as well as in achieving the desired aesthetics?

We believe that it is important to understand that different types of wall cladding complement different structures. Therefore, without the correct combination, the external cladding might not work best for your home or building.

Since exterior cladding is prone to external factors like water, wind, heat, dust and rain, etc., it is essential that the panels act as a protective outer shell of your building. Greenlam exterior clads come with a 10-year warranty with an exclusive range, which is fire retardant, making them highly durable. Plus, being easy to maintain, they also help reduce the cost of maintenance needed for a building.

Greenlam Clads offer interior wall cladding as well. While interior clads are water resistant, antibacterial, anti-graffiti, scratch, solvent, energy saving, abrasion and impact resistant, they come with 10 years of warranty. As Greenlam clads are equipped with a modular system, they can be easily installed and are low maintenance which makes them an ideal refurbishment option.

How well aware do you think the decision makers are in general about the availability of the cladding products, its functionality and categories?

In India, when we talk about decision makers such as architect, consultants, clients, PMC, contractors and builders, they are partially aware of our cladding products. When I say partially, it means that they know the product, but are not acquainted with its details.

However, those who are located in metro cities, they are relatively familiar with the products but are not informed of its benefits. On the other hand, decision makers who are in non-metro cities, may be unaware of the products entirely. Whichever the case is, there is a clear opportunity for us. The Indian market is highly cost conscious and there are natural materials available too like stone and more. Hence, as a brand we need to be competitive in terms of our pricing.

Cladding is bifurcated into two categories, dry and wet. We also supply dry cladding materials with which breathable façades are made. The fact that the majority of our present sites are nonmetro cities, there are numerous opportunities in these areas.

What is the emphasis laid on R&D, especially for the Indian market?

In our business space, new product development is more to do with the design and changing décor trends. While our products are technologically advanced, sustainable and offer smart solutions, it is important to know that we have not compromised on the design aspect.

For Greenlam Exterior Clads, the designs we offer are all inspired from natural elements such as stone, wood and more.

We keep a close track on the predictable trend in interiors through market research, with designers and architects across the globe. The international exhibitions and furniture fairs give a broad perspective to the forecast design and colour trend. Having said that, we are constantly working towards improving our product quality. With an endeavour being the best in the industry, we are making sure that our customers get the best of our products.

What do you see as the main challenges faced by the cladding industry?

When we first started our journey for Greenlam Exterior Clads, the initial challenge was to create awareness about the concept and usage of the product in the Indian market. However, in the cladding industry, the price and aesthetics of the product are considered to be the highlight of the purchase and amidst that functionality takes a back seat.

Our clads are all-weather proof and fire-resistant, which makes them apt for exteriors. When we came up with the idea of breathable façades, our aim was to reduce power consumption and protect a building from all sort of weathering break downs. If we compare the façade applications with countries like Europe, the relevance goes beyond aesthetics. The primary concern lies in whether the product is providing protection from all kinds of weather inclusive of the power it consumes.

Tell us about your channel expansion strategies in the market.

Entering into new products is greenlam laminates strategy for future growth. With a product portfolio, which includes laminates, compact laminates, decorative veneers, engineered wood floor and engineered wood doors and door sets, we offer a one stop solution for customers. There is a huge opportunity to explore. This will also help us to balance the business during any downturn in the decorative surface business.

For channel expansion, we focus on increasing our network of distributor and dealers in new cities and interior towns of the country. We have also opened our display centres in various cities to make it easier for the consumers to choose from a variety of products available in the market.

What keeps your company ahead of its competitors in terms of products and services offered?

Simply put, we are distinguished through our unique and differentiated products and manufacturing practices. Greenlam laminates offer integrated decorative solutions to cater to the needs of customers across price segments. While launching new products, an extensive research goes behind the making of them, so that our customers get the best of our creations.

We have introduced technologically advanced products in the market under all brands such as anti-fingerprint laminate, HD gloss, VRB, Synchro Collection (synchronised embossed laminates) in Greenlam laminates. Furthermore, Decowood Veneers and Mikasa Floors both feature a unique Herringbone Collection.

With over two decades of experience in the surface décor space, we have been the pioneers in introducing décor trends in India and the international markets as well. As the largest producer of laminates in Asia, Greenlam has managed to stay ahead due to its robust strategies of product innovation, design, marketing, distribution and efficient manufacturing.

We at Greenlam Laminates offer a vast portfolio, which includes laminates, compact laminates, decorative veneers, engineered wood floor and doors and doorsets, making us a one-stop solution in the industry. Innovative technology and creative solutions have been our guiding principles from day one.

That being said, we have always ensured that superior quality is available to our customers with timely delivery of products due to our wide network and swift service. Additionally, we have a wide network of distribution centres, channel partners and regional distribution centres which are always stocked and ensure timely product delivery. Greenlam laminates has managed to stay ahead due to its robust strategies of product innovation, design, marketing, distribution and efficient manufacturing.

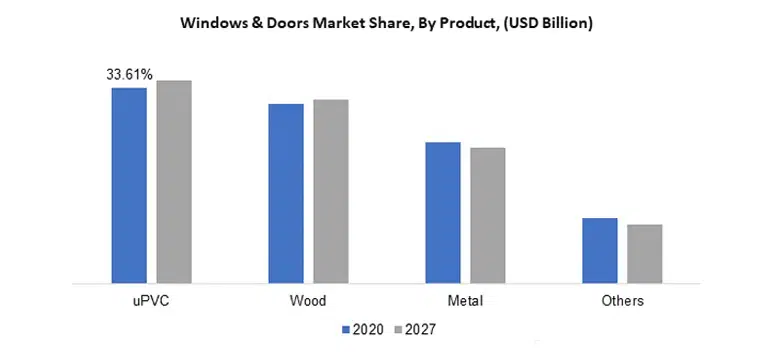

How do you see the cladding and door industry evolving over the next 5 years?

Owing to the recent years, the market is gradually turning from un-organised sector to organised sector. This means there is an advent of positive changes in terms of systematic working in the construction industry, which truly starts from identifying materials and putting the same into a tender. For cladding, since the awareness of the products is increasing, the purchasing power of the individuals is on the rise too making the future of clads extremely huge. Though when we talk about natural resources, they are not available in most of the locations and bringing them to a desired location may not be cost effective as well.

Given our India and global presence, we see this as an opportunity to disperse the product worldwide. For us, the door industry too has an optimistic future since Mikasa gives a complete door solution as doors, frames and accessories which are shipped from the factory as a fully furnished single door sets to suit every room and purpose. Additionally, these doors can be installed even after the construction of a building.

Top Stories

Façade Systems Market Size is Estimated to Reach USD 398.8 Billion by 2029

By: Abdul | April 16, 2024

Improving Sustainability Alongside Fire Safety – Can We Deliver?

By: Abdul | April 16, 2024

Foster + Partners Wins the Competition the New Xicen Science & Technology Centre

By: Abdul | April 9, 2024

A Symbol of Architectural Brilliance & Cultural Significance

By: Abdul | April 8, 2024