Advanced Interlayers for Versatile Façades

By:

Glass has become an inevitable construction material for any modern-day building. It is hard to imagine any new building coming in our locality, be it commercial, residential, retail, hospitality, airport, hospital, not making use of glass. This is because Glass façades directly or indirectly enhance the functionality of all these types of buildings. However, glass is still not well accepted as a structural material by a community of structural engineers in our country as they fear about its brittleness and the consequences of a sudden failure which are in sharp contrast to conventional structural materials i.e., concrete and steel.

Some good news for them! The standards for usage of glass in buildings in India have been evolving steadfastly in recent years under the aegis of the Bureau of Indian Standards (BIS). The inclusion of an exclusive chapter on glazing by the National Building Code of India (NBC) -2016 and Indian Standards (IS) 16231. Use of Glass façades in India (Parts 1-4) is a big leap taken by BIS. Kuraray, the leading manufacturer of interlayers for laminated glass has been actively contributing to the development of standards on the use of glass in buildings, with a major focus on the structural analysis of laminated glass. Creating awareness of these standards is the next challenge BIS is working on. Enforcement and compliance with these standards, penalty on developers for any noncompliance, would require the state legislatures to make suitable acts.

Laminated glass is one of the types of safety glass that is required in buildings to safeguard the occupants of the building against the risk of injuries from broken glass shards. Skylights, canopies, balustrades are few applications requiring laminated safety glass. “Safety” is the basic function of laminated glass that can be attained through the use of standard PVB interlayers. Advanced interlayers can be made use of to enhance the functional versatility of the Glass façades.

Thinner, Lighter & Stronger Façades: Advanced Interlayer SentryGlas® enhance the design freedom of the engineers to design façades that are not only much stronger for the same given design loads but can also sustain larger loads even at elevated temperature conditions like 50°C. Alternatively, now they can design Glass façades that are making use of large glass panels that goes very well with the general concept of the architecture of providing “large unobstructed views” to the building occupants. Additionally, reduced weight of the glass makes the installation of panels much easier that speeds up the installation rate, especially for super tall buildings.

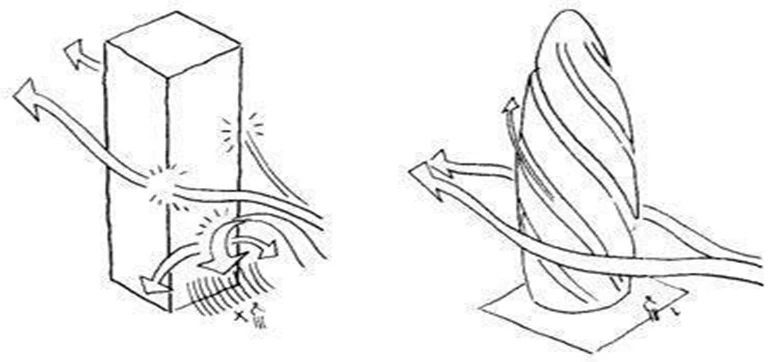

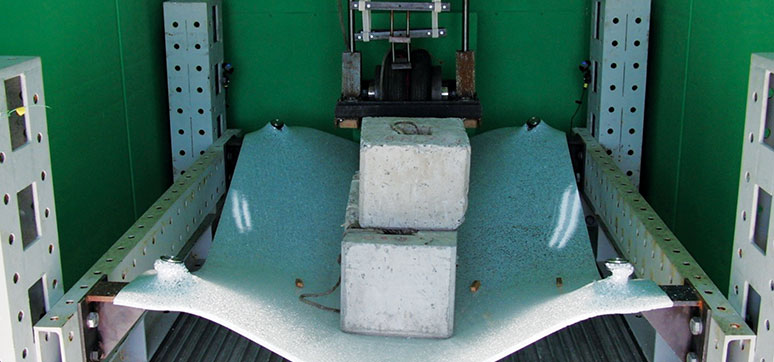

Thereby, bringing in some other intangible benefits. There won’t be any exaggeration in saying manufacturing thinner glass leaves fewer carbon footprints compared to a thicker one. Shanghai Tower, standing tall at 632 m in China (Fig. 1) is a classic example that demonstrates the versatility of its façade. The tower has used around 200,000 Sq m of SentryGlas® in combination with annealed glass to ensure there are no optical distortions for its double skin façades. The concept of lighter, thinner and stronger façades is best highlighted in a freestanding balustrade application (Fig. 2). It has been structurally analysed through finite element techniques for the imposed design live loads as necessitated by NBC 2016 of India.

Durability: Durability of laminated glass with exposed edges in aggressive environmental conditions (high temperatures and humidity) has been a concern as PVB interlayers are hygroscopic in nature. It is a common practice to “cap” the exposed edges of the laminated glass. However, exceptionally high edge stability of laminates made with SentryGlas® has been proven in natural weathering tests running for more than 20 years now in Florida in the US.

Cyclone Resiliency: In the year 2018, Hong Kong witnessed Typhoon Mangkhut, which has been called as one of the severest typhoons to have struck the country ever, causing catastrophic damage to some of the important buildings. The impact caused by wind borne debris was one of the strong reasons behind it and this has to lead to an “introspection” by the Hong Kong Building Department on the existing façade design practices. Our country too has few regions like the coastal areas of Orrisa, Andhra Pradesh, TamilNadu that are vulnerable to cyclones. On 6 December 2016, cyclone Vardah wreaked havoc in coastal Tamil Nadu causing widespread damages to glass façade buildings, especially in Chennai. A study conducted by IIT Chennai cited wind borne debris impact as one of the reasons for the failure of façades. Missile impact tests followed by pressure cycling tests as required by ASTM standards in the US are required to make our Glass façades more resilient and thus keep the buildings functional post any such calamity.

Structural Applications: Even a small glass window that has all four edges framed can be called a structural application. However, the imagination of architects has always put to test the creativity of structural engineers to use glass with minimal structural supports. Often the glass is required to be used in applications like balustrades, floorings, where conventional materials like wood, steel or stone have been used since ages.

Mumbai has several media to high end condominiums making use of free-standing balustrades in the balconies and terraces, safely withstanding humongous wind loads.

Glass bridges or skywalks have become almost a rage in countries like China, Malaysia. The glass is not only expected to bear safely the imposed loads but also ensure a high redundancy in the event of accidental breakage. Zhangjiajie Glass Bridge in China (Fig. 3 & 4) makes use of SentryGlas® laminates to sustain the weight of 800 people at a time.

Post Breakage Strength: In overhead glazing applications like skylights, it is important to ensure that there is sufficient design redundancy to ensure the safety of not only people underneath but the maintenance workers over the top. DIN 18008-6 in 2015, brought a new regulation in Germany requiring the broken glass to be strong enough to sustain a load of 100 Kg for a period of atleast 30 minutes post the breakage of all glass layers. Kuraray pursued this new development with Bureau of Indian Standards and it was readily adopted by BIS in the National Building Code of India – 2016. Kuraray also ran a research project at University of Armed Forces in Munich, Germany with the objective of exploring the post breakage strength of laminates as a function of interlayer stiffness and temperature (Fig. 5).

Blast Resistant Glazings: Growing incidents of terrorism across the globe have resulted in governments of countries, even like Singapore which is considered safe, to have building façades that can withstand a certain level of the blast. Important buildings in the US such as federal courthouse in Miami has a Glass façade that is designed to withstand bomb blasts and hurricanes. In Singapore, the upcoming terminal 5 of the Changi Airport shall make use of blast resilient glazing.

Laminated glass panels made with Trosifol Clear® and SentryGlas® were tested in a shock tube at ATI Laboratories in York, Pennsylvania. Peak pressure of 41 kPa (6 psi) and impulse of 282 kPa-msec (41 psimsec) were chosen to represent performance levels found in the Unified Facilities Design Criteria (UFC) of the U.S. Department of Defense. The test specimens were 126 cm (49.72 inches) x 172 cm (67.75 inches), wet-glazed in a wooden frame. Blast testing was conducted according to ASTM F1642 standard test method for glazing and glazing systems subject to airblast loadings. This standard enables the user to determine a hazard rating for the glazing or system utilising either a shock tube or arena test.

ASTM hazard ratings are expressed differently than those of the U.S. General Services Administration (GSA). GSA Condition 3a equates to the very low hazard level defined in ASTM F1642 where the glass cracks, and fragments land on the floor no further than 1 meter. GSA Condition 2 equates to ASTM F1642 no hazard where glass cracks but is retained in the frame. The results of the test program are presented in Table 2 below, giving a comparison of the blast performances two glass constructions.

Intrusion Resistant/Forced Entry: The glazings can be effectively designed to thwart any attempts by an intruder trying to make a forced entry using commonly used tools e.g stone, sledge hammer, axe etc. EN 356 is very commonly used to rate the intrusion resistance of given glazing. The glazings are given a rating based on the number of impacts, strike required to make an opening. The five low classifications P1A to P5A prevent the glass pane being smashed in, e.g. with a stone.

It does not offer traditional burglary protection. For that reason, it is also called only “impact-resistant glazing. The three high resistance classes P6B to P8B offer higher resistance against burglary and are accordingly called burglarresistant glass, P8B glass offering the highest level of burglary resistance. Bullet Resistant Glazing (BRG) is another segment that is growing due to the increasing number of high net-worth individuals in our country who want to safeguard themselves against any attack, be it at their lavish home, office or even in vehicles. Conventional glass clad polycarbonate solutions are bulky and are vulnerable to delamination when exposed to UV radiations. SentryGlas® and CPET Spallshield® together provide an unmatched solution that is not only significantly lighter and thinner but highly durable. Fig. 6 shows a comparison of weight and thickness of the solutions for NIJ standards.

Decorative Glazings: Few architectural applications require very high clarity of the glass which can be achieved using extra clear glass only. In such applications, if the glass must be laminated for any of reasons, right selection of the interlayer that has a matching clarity with the glass is very important. Otherwise, it would defeat the purpose of using extra clear glass. It must be ascertained the interlayer has a low yellowness index. SentryGlas® and Trosifol® Ultra Clear have the lowest yellowness index compared to other interlayers. The colour element when added to the glazing, give design freedom to the architects to be used for making the glazings livelier and brighten up space.

Acoustic Glazings: Contrary to the prevalent belief in the industry, laminated glass gives better acoustic performance than an IGU unless the IGU is making use of a large air gap. It is better to use just 12 mm monolithic glass instead of 6+12+6 IGU as it gives better performance (Fig. 7) when noise reduction is the primary design concern. Acoustic PVBs can be used dampening the noise by additional 3-4 decibels compared to regular PVB.

Conclusion: Laminated glass can no longer be called just a safety glass. Unfortunately, the awareness about the influence of interlayer on various types of performances of laminated glass is too less in the industry. Selection of appropriate interlayers can add a lot of value to the façade like enhanced structural and post breakage strength, larger glass panels for maximised view, lighter and thinner glass, reduce environmental impact, acoustic comfort, resiliency against windborne debris impact, forced entry or intrusion resistance, blast and bullet resistance, and aesthetics. With so many different aspects, the interlayers can make the Glass façades truly versatile.

Top Stories

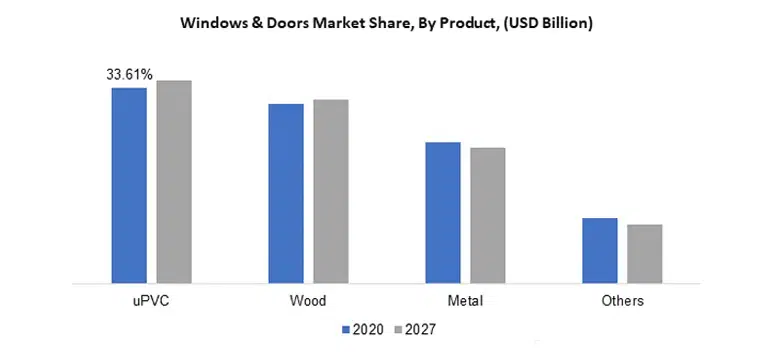

Façade Systems Market Size is Estimated to Reach USD 398.8 Billion by 2029

By: Abdul | April 16, 2024

Improving Sustainability Alongside Fire Safety – Can We Deliver?

By: Abdul | April 16, 2024

Foster + Partners Wins the Competition the New Xicen Science & Technology Centre

By: Abdul | April 9, 2024

A Symbol of Architectural Brilliance & Cultural Significance

By: Abdul | April 8, 2024