Exterior Cladding: Design Principles and Material Choices

By:

Cladding is one of the most important elements which ensures that the exterior of a building is protected from the elements of nature and potential sources of damage. Cladding extends the longevity and lifespan of the building. It also provides the other important benefits that include providing strength to the structure and thermal insulation to the buildings. Cladding not only protects the building envelope but also enhances the appearance of the building. It is also very important that the cladding design and the right choice of cladding material should have the right balance of aesthetics and efficiency.

We interviewed the experts in the construction sector who have provided their thoughts on the cladding sector, the trends in cladding technologies & materials, the role of fire safety in external cladding systems, etc. Here are the views of experts presented in this cover story

The Latest Trends In Cladding Materials

AbdulGhani Dallal, Operations Manager (KSA), Comelite Architecture, Structure & Interior Design says, in so many ways, the façade of a building reflects the nature of architecture in a given period. It demands as much aesthetic quality as it requires functional excellence. By empowering the user with technology that can bring a paradigm shift in terms of comfort while being energy-efficient, designers are indeed looking at new ways to innovate.

Among all the solutions dotting the market, dynamically tinting electrochromic glass is a game-changer in the sector. It not only maximises natural light, but also cuts glare significantly – thereby enabling better thermal and visual comfort, and greater well-being. He further explains, electrochromic glass (i.e. smart glass or dynamic glass) is an electronically tintable glass used for windows, skylights, façades, and curtain walls. Electrochromic glass, which can be directly controlled by building occupants, is popular for its ability to improve occupant comfort, maximise access to daylight and outdoor views, reduce energy costs and provide architects with more design freedom.

When the beauty of the stone is desired on a façade, the ultra-thin, large-format porcelain slabs in the Kalesinterflex range works best. With a flexibility radius of 5.5m, the tiles can be clad on buildings that have concave and convex surfaces. The 3mm thickness makes the slabs light in weight, making them an ideal façade material even for tall structures. Highly resistant to weather changes, wear and tear, they do not require extra care or maintenance – routine cleaning will ensure the façade always looks as good as new.

He believes that the fibre cement is an innovative material. In less than 10 years, fibre cement – consisting of cement, water, cellulose, textile fibres, and air – has emerged as an innovative material. Thanks to it, the weight of the external skin of a house has been cut by a factor of 9! That’s 90 tonnes for a house built with traditional materials (bricks, concrete, etc.), compared to 10 tonnes of fibre cement. The result is fewer raw materials, less energy, and less waste, in return for better performance and better insulation.

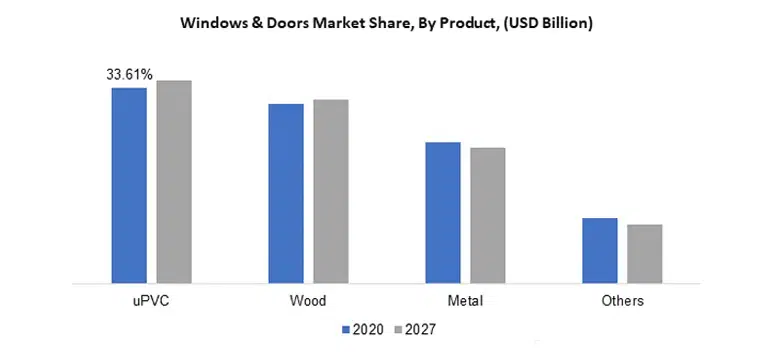

Asad Ahmed Khan, Marketing Manager – Cladding Division, NAFFCO believes, in recent times, the market has taken a turn towards the use of metal, stone, ceramic & fibre cement to some extent. Metal cladding or aluminium composite panels with wooden or ceramic finishes have also seen more frequent use nowadays, due to the near-identical aesthetic and given the prolonged lifetime of the façade. Ventilated façades as well, have been a subject of discussion in the region due to huge temperature differences between the internal and external environments of buildings.

According to Tamer Nezha, Senior Project Manager/Façade Specialist, Target Engineering Construction Co LLC, the latest trends in cladding materials are using the 3D printing technology. The 3D printing opens up design possibilities that were unthinkable in the past. We can take advantage of this freedom to integrate functions such as ventilation, shading and air conditioning.

The Major Challenges In The Industrial Cladding Segment In The Middle East

Cladding dictates how a building appears and how it forms part of an overall urban environment, so the right choice of materials and appropriate design are the deciding factors in whether it is ultimately fit for purpose, say design and build professionals. Thermal, acoustic, and fire resistance requirements are vital factors and challenges to take into account, from concept design through to maintenance, and the more ambitious the project, the greater the need for attention to detail, explains Dallal.

Khan says, the Middle East market has always been a challenging arena due to its central geographical location, which means that access to various cladding materials from across the world has never been a hindrance. However, changing the mindset of developers and consultants due to the use of traditional insulation materials for buildings by default has been a challenge; albeit, there has been a paradigm shift in the understanding of the building’s thermal dynamics more recently, resulting in newer and more efficient material being made available in the market. Detailing of the design façade model requires an interactive process developed by different team members, architects, engineers, and manufacturers with constantly updated and common detailed design information under design and build process, says Nezha.

Smart Cladding Technologies For Sustainable Buildings

Dallal says, cladding is getting smarter. It is also contributing to more energy efficiency. For many years, architects have been using precast concrete panels, metal screens, and timber panels as the main cladding materials, but the focus has shifted more towards sustainability, so those materials that provide cost savings to the client and help reduce the carbon footprint of a building are one of the primary considerations for designers.

Recently architects in this region have been experimenting with different materials and we have seen a few new types of cladding materials such as perforated screens, WPC panels and timber panels being used in low rise built forms and we are also starting to see an increase in the use of mineral fiber panels replacing the old traditional metal panels.

Fritted glass double glazing is also seeing a resurgence as it offers versatility and the fact that not only does it provides transparency to the building, it also helps reduce the solar gain of the built form thus reducing operational costs. He adds, since the introduction of the new building and fire safety codes earlier this year, the only source alternative options such as rockwool or glass mineral wool to replace polystyrene-based EIFS – which has been removed from the list of approved cladding materials.

The choice of non-flammable and code-approved materials applies also to retrofit as does the need to ensure the energy efficiency of the building. The selection of materials can contribute hugely to the overall insulation of the built form to reduce infiltration which is one of the main causes of increases in HVAC loads and any measures taken to reduce the infiltration would reduce the HVAC loads which in turn reduce the overall electricity usage.

According to Khan, impending concerns over the increased power consumption of the economy has led the local authorities across the UAE to introduce certain ‘Green Building’ regulations, which encourage the use of sustainable façades which tick the boxes when it comes to how environmentally friendly, carbon-neutral or how recyclable the material is. Sustainably resourced metal cladding, solar fitted cladding, and even stone faced GRC have been emerging options for Sustainable cladding in the Middle Eastern market.

Nezha says, there is a researcher from the Technical University of Munich (TUM) who has designed the multi-functional façade elements to be digitally fabricated to allow for complete design freedom and the easy realisation of innovative concepts. The new façade, characterised by its translucency and fluid surface texture, is one of the first functionally integrated façade elements from a 3D printer, providing the interior with ventilation, insulation, and shading.

Key Factors To Consider While Designing And Selecting Cladding Materials

When it comes to choosing a cladding system, there is often a misunderstanding between design working life and service life. Service life can be longer or shorter than design working life, explains Dallal. He described it below: • The design working life of a cladding system is the fixed period during which it will meet prescribed design parameters, subject to specified maintenance, without abuse or repair. • The service life is the period during which it can be used economically, without abuse, with or without maintenance and repair.

The key factors to be considered while designing and selecting cladding materials are structural performance, corrosion resistance, water tightness, air permeability, thermal resistance (by conduction/ convection/ radiation), aesthetic intent and artistic finish, and reduction in carbon footprint. He adds, there are 7 factors also that influence the design working life are: Temperature, dust, wind, rain, and other weather factors are a key challenge in the Middle East region; environment; ancillary items; fasteners; workmanship; temporary conditions during construction; and maintenance.

According to Khan, aesthetics, sustainability, thermal performance, façade life, and ease of maintenance are the key factors that should be considered while designing and selecting the cladding materials. Tamer believes that the functionality, durability, and stability of each project element depend on the selection of materials and quality of the detailing during the analysis and design.

Role Of Cladding In Controlling The Internal Environment

Dallal notes, the primary function of the cladding is to split the indoor environment of a building from the outside in such a way that the outdoor environment will not affect the indoors. It is also best for regulating the light penetration and controlling the radiation and conduction of heat from the sun and prevents interiors from getting faded and dull. Additionally, sunshades and louvered panels allow for the reflected light to enter the building that enhances the comfort, rather than direct sunlight.

The insulation and thermal properties of the cladding decide how efficient the building’s temperature control can be. The United Arab Emirates, for instance, has a regulation as to the minimum performance parameters of an external façade, which needs to comply with the green building code when it comes to thermal transmission of a façade.

Khan elucidates that the insulation and thermal properties of the cladding decide how efficient the building’s temperature control can be. The United Arab Emirates, for instance, has a regulation as to the minimum performance parameters of an external façade, which needs to comply with the green building code when it comes to thermal transmission of a façade.

Nezha explains, the external envelope of a building is of prime importance when considering the environmental impact of a building. In particular, the external walls provide the main element of the aesthetic impact of the building on its surroundings. They are also key elements of the envelope as a climate modifier affecting the flow of both heat and light and consequently the resulting energy required to maintain comfort conditions within the building. In the case of cladding systems, the importance of environmental issues is complemented by the fact that they can represent up to 20% of the cost of the building project.

Rainscreen Cladding And Its Advantages

Dallal describes, a rainscreen cladding is the most efficient cladding system for construction envelope purposes nowadays. A building solution that perfectly fits into the current sustainable architecture trends; whose installation is easier than it seems. Poor façade insulation entails a significant energy loss in private homes and other buildings. On the contrary, the rainscreen cladding system favours energy saving thanks to its air cavity on the exterior façade of the building. When combining the rainscreen cladding system with an exterior insulation system, we provide the building with numerous advantages such as the increase of thermal and acoustic insulation.

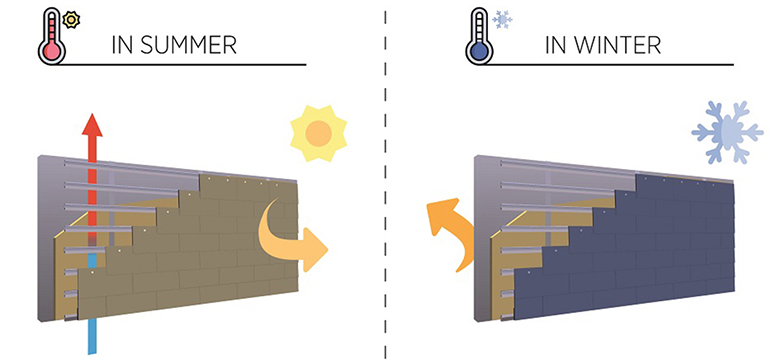

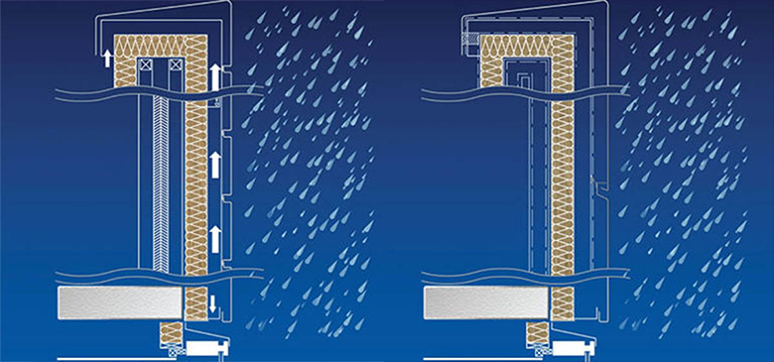

Rainscreen cladding’s function in summer and in winter

Rainscreen cladding’s function in summer and in winter

Avoids condensation and humidity: This façade system reduces condensation and humidity coming both from inside and outside the building. The continuous circulation of air inside the air cavity works as an extra protection layer and removes the possible water filtrations that can slip through the cladding joints.

One of the major reasons for which rainscreen cladding is generally adopted by building designers is the aesthetic flexibility to match any sort of shape, colour or dimension required. Apart from this, thermal performance, extended lifetime, ease of installation, sustainability, etc. are just a few other added benefits that a rainscreen system can provide, says Khan.

A rainscreen cladding is the most efficient cladding system for construction envelope purposes nowadays. A building solution that perfectly fits into the current sustainable architecture trends; whose installation is easier than it seems, says Nezha. He explains the advantages of rainscreen cladding systems that include: avoiding condensation & humidity, extends the façade’s lifetime, reduces structural movements, improves thermal and acoustic insulation, increases energy efficiency, requires virtually no maintenance, and adds value to the building or home.

Advantages of Rainscreen Cladding

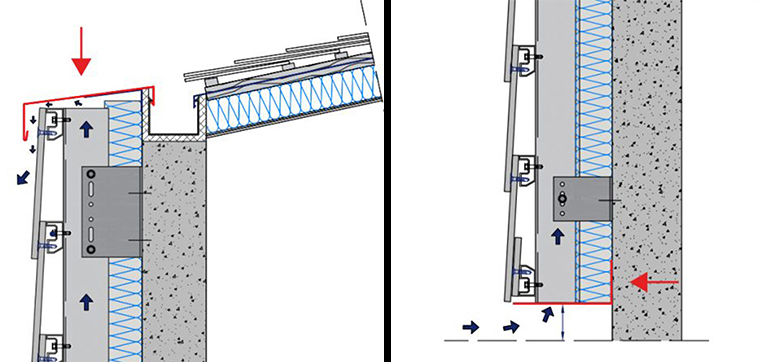

Image 6A: Upper opening rainscreen cladding | Image 6B: Rainscreen lower opening ventilated façade

Image 6A: Upper opening rainscreen cladding | Image 6B: Rainscreen lower opening ventilated façade

- Extends the façade’s lifetime: The constant ventilation inside the air cavity improves the durability of the exterior cladding material since it keeps it dry. The façade’s lifetime is even longer when using a durable and resistant material like natural slate.

- Reduces structural movements: As we mentioned at the beginning, the air cavity allows maintaining a more stable temperature in the building construction envelope. This helps to prevent the risk of cracks and other structural issues. Since the structure is not subject to extreme temperature changes, it is less liable to suffer expansion or contraction movements.

- Improves thermal and acoustic insulation: The insulation layer is optional, but when we combine it with the rainscreen cladding system, the thermal and acoustic insulation of the building improves significantly. This has a huge impact on health since environmental pollution is diminished and therefore are the health issues derived from the excess of noise such as stress or fatigue. Additionally, this system removes thermal bridges.

- Increases energy efficiency: The rainscreen cladding makes cooling the building easier during summer and provides better control of the heating during winter, favouring both thermal comfort and energy saving. Thanks to the rainscreen cladding system, energy bills can be reduced between 30 and 40%.

- Requires virtually no maintenance: Rainscreen cladding systems require almost zero maintenance, especially if you choose a cladding material that withstands adverse weather conditions like a high-quality natural slate.

- Adds value to the building or home: The extra initial investment is recovered thanks to the durability, energy efficiency, and low maintenance cost of the façade. So rainscreen cladding is an excellent choice both for new construction sites and refurbishment projects. These systems are a very advantageous solution in terms of energy and money-saving. It is a stand for a sustainable future that allows, at the same time, reducing your heating bills and increasing your home’s thermal comfort.

AbdulGhani Dallal, Operations Manager (KSA), Comelite Architecture, Structure & Interior Design

Effect Of Fire Safety Norms & Standards In The Cladding Industry

Khan observes that increased fire outbursts and flammability of façades over the last decade have led to the introduction of regulations that drastically revolutionised the cladding industry in the region. The norms have shifted towards façades bound by fire-safe regulations and minimum flammability in an attempt to safeguard buildings in the case of accidental fires. Most external façades must now mandatorily classify as Class A following European Standard EN-13501-1, which classifies building materials based on flammability and likeliness to spread the fire. The current fire safety Code in the UAE is the most updated norm & standard in the Middle East and given solution to stop the extent of lateral & vertical fire spread and stop the extent of smoke and droplets emissions, says Nezha.

Ventilated Cladding & Energy Conserving Facades

A ventilated façade is a façade construction with an air gap between the insulation and the façade cladding. This gap is open at the top and bottom and the cladding has small open joints, thus creating a way for natural ventilation of the façade. A ventilated façade can be viewed as a raincoat: it protects a building against the weather, while at the same time creating a healthy indoor climate. This is why it is often referred to as rainscreen cladding.

Scientific research shows that a ventilated façade has multiple benefits compared to other building techniques. When a brick or concrete wall is exposed to continuous rain, it will act as a sponge, due to the porous nature of the materials. Ventilated façades, however, allow for the water to be drained in the cavity and any other humidity to evaporate through the air gap. The façade may get wet in the cavity because of the open joints, but this moisture will evaporate quickly thanks to the ventilation flow within the air cavity.

A ventilated façade reduces the direct solar impact on the building and reduces the thermal movement of the structure itself. With a well designed/ constructed façade, condensation inside the façade build-up can be prevented. Algae and moisture problems do not occur in that case, because the façade is ‘self-breathing’. Khan notes, ventilated façades are an option being explored currently and have already been implemented in a few projects in the UAE. These façades prioritise the movement of air between the façade and the external wall of a building to boost the thermal performance and energy efficiency of the building. Simultaneously, due to an obvious chance for fire spread in ventilated areas, Cavity barriers with expandable fire stop systems have also been developed to prevent the risk of fire spreads in such systems.

Nezha explains, ventilated façades are an outdoor cladding building solution that can be applied to both new build and refurbished buildings. It is of special interest to architects for several reasons such as:

- Improved thermal insulation.

- Improves the façades’ continuous finish

- Faster to install and to clean

Ventilated façades allow for the circulation of air between the supporting wall and the cladding material, such as marble, ceramic tiling, metallic panels, etc. In this manner, the supporting wall is protected from both the cold and heat resulting in energy savings.

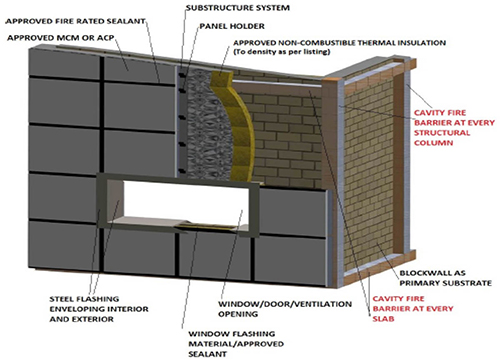

Materials & Methodologies For Fire-Safe Cladding

Calorific value is the amount of energy that is produced by the complete combustion of a material. This amount of energy determines how much heat a certain material contributes to a fire. More heat simply means a faster spreading of the fire. The calorific content of a panel is indicated by its PCS (an abbreviation of the French term ‘Pouvoir Calorifique Supérieur’) value. The higher a PCS value is, the more calorific content a panel has. Noncombustible façade material has a very low calorific value and thus a very low contribution to the fire. The classification of these non-combustible materials has an upper limit on the PCS values.

Ventilated systems vented – Pressure equalised

Ventilated systems vented – Pressure equalised

In general, the lower the calorific value of a product, the better it is when it comes to fire safety. But what does this imply? When it comes to PCS value, two panels distinct themselves, for example, fiber cement and stone wool (Rockpanel). They both have very low caloric content. Stone wool, for example, is made from natural volcanic rock basalt, which can withstand extremely high temperatures by nature. However, to be sure of a totally fire-safe solution, it is strongly advised to use non-combustible panels and does not risk the somewhat dodgy performance of panels that include fire retardants to ‘mask’ their high calorific value.

Certain test standards based on EN (European) & ASTM (American) standards with regards to fire performance of façades have been made compulsory by the local civil defence authorities. In general, there are 2 test methodologies when it comes to cladding materials; first being the material fire reaction test and the second being a system test which determines the product’s fire performance as part of a façade system, says Khan.

Nezha says, currently, there are too many fire-safe materials and large-scale fire testing still remain the only possible route to gain knowledge about the flammability of exterior façades. However, these assessments are very costly, destructive, and often impossible due to many practical constraints. Even when a large-scale test is performed, it is currently done on a perfectly constructed system. In reality, the systems installed onto buildings may be vastly different from the testing standards. Therefore, numerical simulations based on computational fluid dynamic (CFD) techniques are a cost-effective tool to bridge the knowledge gap and explore the system sensitivity to some of the parameters such as the gap widths and material thickness.

Importance Of Fire Safe Design, Materials And Technologies in Building Facades

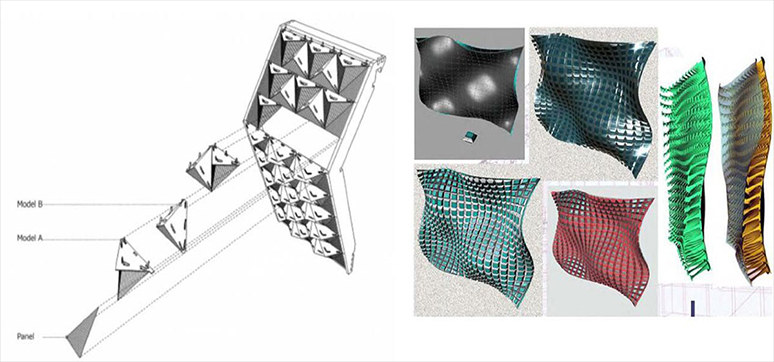

Parametric design and digital fabrication – Rhino & Revit

Parametric design and digital fabrication – Rhino & Revit

Khan says, “As a fire & a life safety company, we have a deep understanding of the impact that fire-safe designs & materials can have when protecting lives, properties, and the environment. If anything, recent times have shown the market that fire safety should be one of the primary priorities when designing or implementing façades and building materials”. Façade materials play a key role in fire safety, as it would be extremely difficult to control the building fire on the exterior. Hence, more focus is needed in selecting appropriate materials, and this requires designer knowledge on material behaviour and performance, opines Nezha.

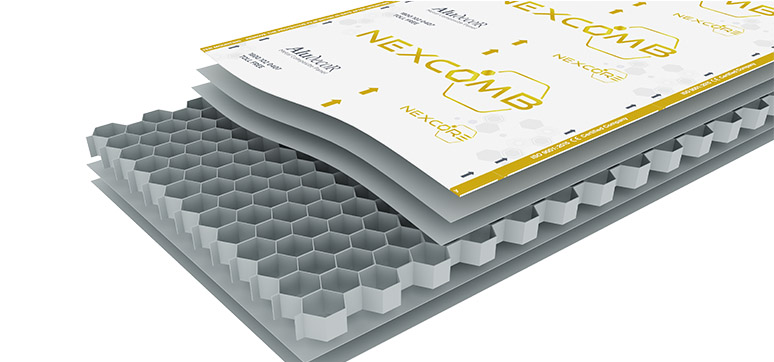

Fire Resistant Cladding Materials : Market & Its Way Forward

At this point, there is no turning back to flammable materials, even for budgetary purposes. The shift towards the use of fire-resistant has led to a chain of events for the better of the industry. NAFFCO for instance, has introduced TUF panel, aluminium composite panels and is the only company in the Middle East to manufacture the composite nonflammable core, in-house. Due to increase in fire outbreaks and huge quality control discrepancies for materials arriving from South East Asia, TUF panel introduced a methodology that would allow 100% control over the quality of the aluminium composite panels, which have been one of the major causes for fire spreads in buildings, explains Khan.

The rapidly increasing utilisation of advanced lightweight materials, including light alloys, polymers, and fiber-reinforced composites that are highly flammable poses significant fire risks impacting people, environment, and the economy, notes Nezha. They can be often found in exterior cladding systems, otherwise known as exterior insulation finishing systems (EIFS) or external thermal insulation composite systems (ETICS). These systems are designed to be cost-effective solutions for thermal insulation, weather resistance, and aesthetic external wall finishes, he adds.

In the Middle East and UAE specially the most basic exterior cladding system consists of:

- An insulation layer, often a polymer such as a polystyrene (EPS), polyisocyanurate (PIR) or polyurethane (PU);

- A surface finish layer that can be a surface coating or a sandwich panel (such as an aluminium composite panel (ACP)).

Future Trends For Industrial Cladding In The Middle East

Dallal sees a good scope for textile façades in the Middle East. He explains fabric façades are a new trend of screens and fabric architecture used on the exterior surfaces of buildings. Both old and newly built buildings can be quickly and simply clothed. It can be used for many buildings from industrial buildings to shopping centers, stadiums to residential buildings. Textile façade coating applications are made of textile materials using static (closed) PVC, mesh (mesh), PTFE (Teflon) laminates and/or mesh and aesthetic materials and imported textile products with guaranteed aluminium construction for the steel construction, And/or by applying special design tensioning apparatuses.

These systems, which are used in the direction of sunlight breaker function, shading and thermal insulation as well as light permeability (night and day, inside-out, far-away view) which must be perceived differently from the inside by the inside, besides their contribution to architectural appearance and aesthetics, ease of application and economic, he adds.

Khan presumes, mobile or moving façades are a trend that is currently in an experimental stage in the region and are being closely studied. Solar-based cladding is also being developed as sustainable options become more viable with an increased demand for sustainable products. The future trends for industrial cladding in the Middle East using the software as Rhino & Revit for parametric design and digital fabrication, says Nezha.

Top Stories

Façade Systems Market Size is Estimated to Reach USD 398.8 Billion by 2029

By: Abdul | April 16, 2024

Improving Sustainability Alongside Fire Safety – Can We Deliver?

By: Abdul | April 16, 2024

Foster + Partners Wins the Competition the New Xicen Science & Technology Centre

By: Abdul | April 9, 2024

A Symbol of Architectural Brilliance & Cultural Significance

By: Abdul | April 8, 2024