Glass panel used for building enclosure has to be durable, transparent, and resistant to various environmental factors such as heat, pressure, fire, chemical, and breakage. As a response, glass manufacturers do additional treatments to improve its appearance, environmental properties, and integrity to ensure that glass can resist breakage and reduce the risk of injury to occupants or at least break safely with less or no significant penetration.

Regardless, glass breakage would happen anytime, anywhere, and anyhow in the building caused by various factors compromising occupants’ safety, security, and comfort; while adding to building maintenance costs in matching and installing glass replacement. The national average cost for glass panel replacement can be between USD300 to USD900, depending on the damage’s extent, while approximately 2.5 million accident-related injuries are caused by broken glass panels annually. Hence, it is imperative to understand glass breakage, especially for building designers.

Glass Breakage Characteristics.

Glass breakage characteristics depend on the glass type. Annealed glass breaks into sharp edges but remains in to frame depending on the glazing methods. Heat strengthened glass breaks similarly to annealed glass. Tempered glass into small-dice-shaped particles when disintegrated and may fall out of frame. On the other hand, laminated glass can remain to stand as it adheres to laminate. Examining glass breakage requires a thorough investigation to define the causes by understanding the breakage pattern and inspecting the framing design. However, in most cases, common causes of glass breakage are impact, uniform loads, edge damage, thermal stress, and nickel sulphide inclusion.

Theoretically, glass is durable, but because of this microscopic defect present in the bulk material, known as Griffith’s flaw, the glass panel’s strength may vary. It is because stress concentration will allow the crack to start. This crack extension, which would lead to fracture in brittle materials, occurs when there is sufficient elastic strain energy in the crack location to form new surfaces.

Impact

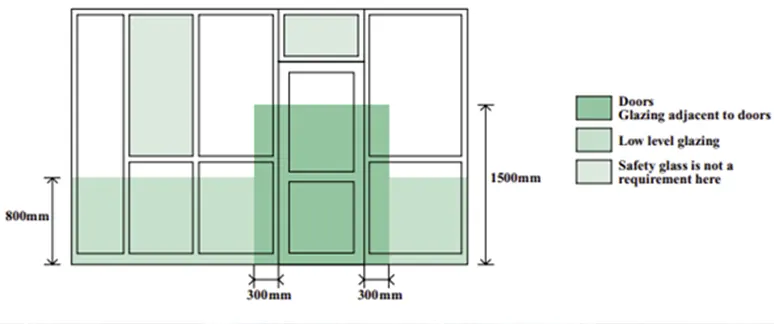

The glass may break due to solid forces acting upon the pane, either accidentally or intentionally. A proper selection of glass thickness related to loads and critical location is vital to prevent such damage and mitigate the risk. The image below shows the safety glass requirements regarding dimensions from the finished floor level. Accordingly, the glass panel, 800mm from the finished floor, has to be considered safety glass, and those around the doors are critical.

Uniform Loads

Wind loads and snow loads are common forms of uniform loads. These lateral loads blow to the building are forces acting on building elevations. That should be absorbed by the structure safely and efficiently. The absorbed loads will be transferred to the foundation to avoid structural collapse. The ability of the glass to withstand the load depends on its pane size and thickness (BS 6262-3 and BS5516- 2). Considering this, the glass panel should be designed adequately enough to resist bending due to excessive uniform loads to prevent glass breakage.

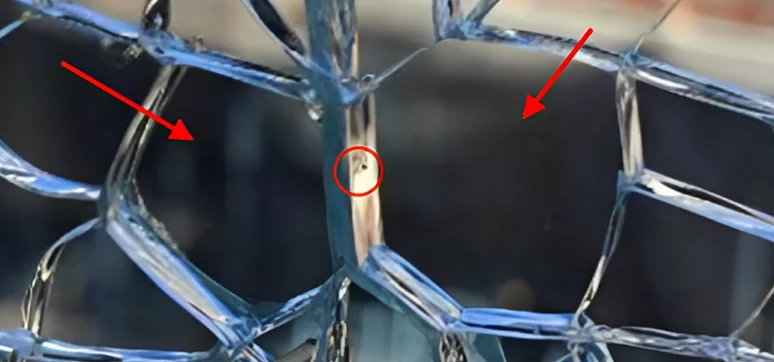

Nickel Sulphide Inclusion. It is a form of small crystal present in glass composition that causes the toughed glass to break spontaneously. These impurities will be frozen at high temperatures when heated during the toughened process, then recover to the original state at the low temperature, but it takes several years. And then, a spontaneous glass breakage would happen as the nickel sulphide at low temperature will occupy the glass surface’s greater volume, generating local stress concentration. Heat soak testing procedures can detect Nickel sulfide failure during the toughening process. It may take five years if the failure rate is high.

In most cases, it could reach up to 30 years after production. Suppose glass breakage due to nickel sulphide inclusion occurs. In that case, a fractured glass panel may fall from height as a platelet of approximately 200-300mm diameter, then separate into dice when impacted to the hard surface.

Uneven Cooling

Also known as uneven toughening. The unevenly toughed glass is vulnerable to breakage even to minor surface abrasion due to surface tensile stress. Uneven-toughed glass can easily be identified when broke; it is shattered into irregular shapes rather than the familiar dice-shaped pieces.

Edge Damage

It is essential to pay attention to the cut edges of the glass panel as it might be the starting point of the breakage pattern. Some may observe glass edges that are severely feathery or have deep and pointed vents are generally unacceptable, especially when the glass panel is exposed and absorbs a high percentage of solar energy. Thermal Stress. The glass may break due to temperature differences between two areas of the pane – usually the edge and center plane resulting from excessive thermal stress. The break pattern usually starts from the edge, around 100mm, extending over time.

Poor Glazing

It is crucial to look through the incorrect glass sizing, deviation of panel sizes, and insufficient clearance between glass edges and glazing frames, as it may not accommodate structural movement and panel expansion. These factors may heavily contribute to glass panel breakage when localized contact happens to the frame or protruding fixing screws.

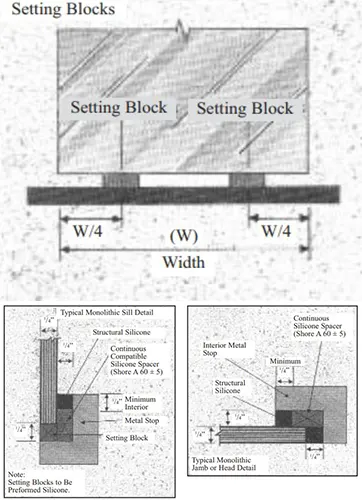

The width and hardness of the glass setting block also contribute to glass breakage. Theoretically, the width of the setting block must equal the sum of the glass unit thickness with rear clearance to ensure full support across the IGU depth. The rigidity of the glass setting block could cause glass damage due to relative movement between the setting block and IGU. However, on the other hand, a softer setting block would cause the glass panel to sink into and would lead to localized frame contact.

Site Damage

The site works such as welding, grinding, and falling debris as the project progresses must be considered during glass panel installation. The glazing installer must be mindful not to allow a hot metal particle to pit on the glass surface, as it will cause the glass panel to expand, inducing high and local stress. The installed glass panel must be protected from dumping local materials such as cement, concrete, or mortar on the glass surface as it will damage the glass panel and impair its appearance. Hence, it would be advised to cover the glass panels with non-flammable blankets to protect them from other trades working in the same area.

Other causes of glass breakage are weather conditions, glazing rebates for debris, and raised/exposed screws on the frame. Prevention. In summary, glass breakage can be mitigated or prevented by properly selecting glass types, thickness, pane size, and heat soak testing for tempered glass. Also, consider the proper storing and handling of the glass panel. And considering adequate clearances and tolerances between glass edges and frames to accommodate the glazing element movement and thermal expansion; hence, glazing rebates, for example, must be free of protrusions.

Safety

During glass breakage, it is crucial to consider these safety notes.

- If a toughened glass breaks and falls, the rest will likely follow anytime; hence, it is mandatory to replace the panel as soon as possible.

- When the external lite breaks, the inner pane and the air cushion in the cavity would have some residual resistance to lateral load but not enough to carry the full wind/impact loads; hence, it is mandatory to replace the panel as soon as possible.

- Additional preventive measures will be needed for a broken laminated glass panel as it might fall like a blanket from above.

- And to ensure that similar cases (broken panels) will never happen again, it is practical to record the evidence by taking photos, preparing sketches, or applying adhesive film to the broken glass panel for further investigation.

Glass breakage is normal, but cases can be mitigated with proper knowledge about glass types, characteristics, limitations, and designs concerning the manufacturing process, production, and site installations. We could save lives, money, resources, and property through it.