Perimeter fire barriers are critical to the passive fire safety of glazed façades, including sealing off the movement gap/perimeter joint to prevent the floor-to-floor spread of flames, smoke, and heat. In June 2023, the Bureau of Indian Standards (BIS) released IS 18190: 2023 – Fire Resistance of Perimeter Fire Barrier Joint System to help define the performance requirements for these life safety-critical systems across the nation. However, many industry stakeholders are not yet fully aware of this new standard, what it considers, or the benefits that it can bring to the long-term safety of our buildings.

Passive Fire Protection Measures For Safe Curtain Wall Systems

In curtain wall systems, the spandrel zone is, as defined by BS EN 13119: 2016 – Curtain walling – Terminology, “the area of a curtain walling between two horizontal zones, normally between glazing and concealing the edge of the floor slab”, whilst the spandrel panel assembly is, as defined by ASTM E2874-23 – standard Test Method for Determining the Fire Test Response Characteristics of a Building Spandrel-Panel Assembly Due to External Spread of Fire Using Intermediate-Scale, Multi-Story Test Apparatus, “the portion of a building’s exterior wall assembly, which is comprised of the spandrel-panel, fasteners, structural supports, and any glazing, located between the top of the window opening in one story and the sill of the window opening in the adjacent story immediately above”.

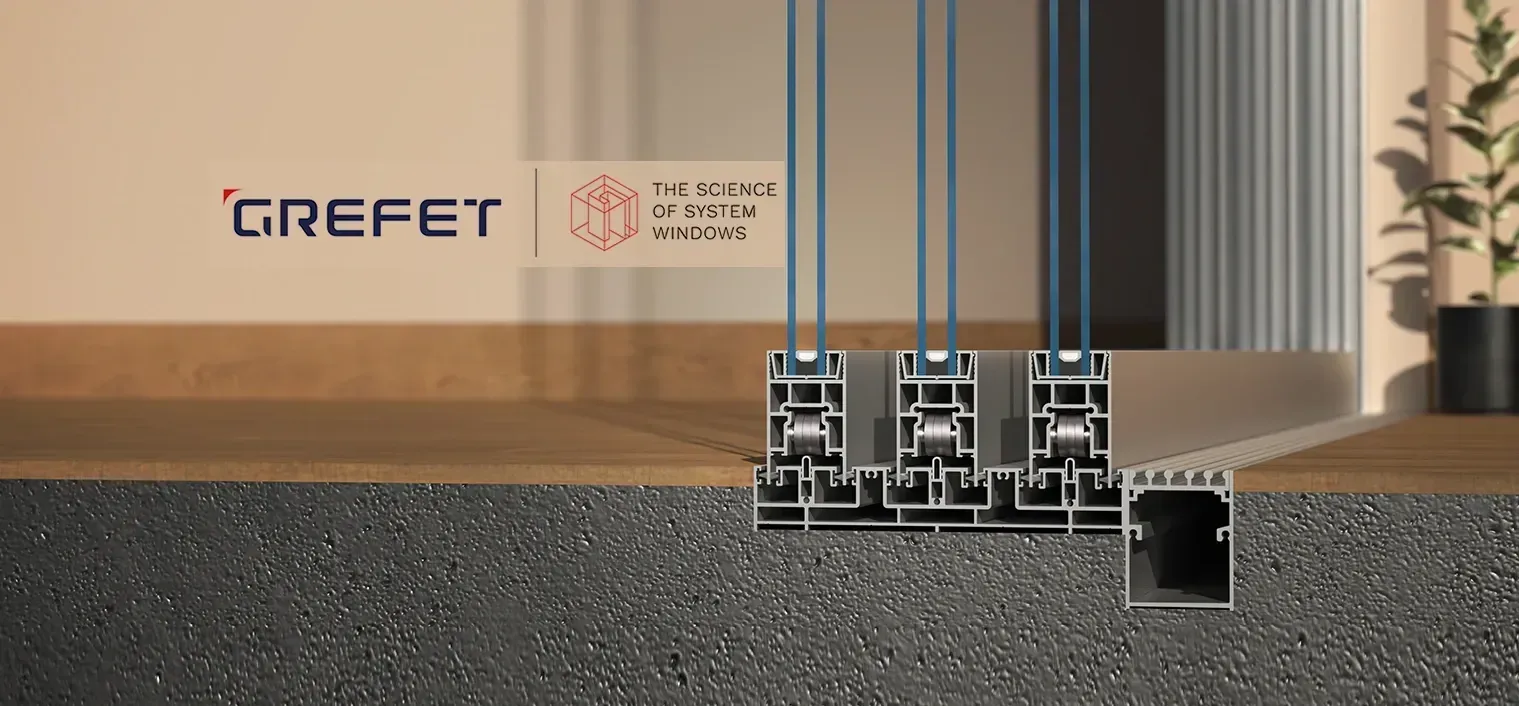

At the perimeter joint between the edge of the floor slab and the glazing, a gap is left to enable the façade to accommodate movement caused by factors such as thermal, wind, and rain loads; seismic sway; and occupancy loads on the floor slab.

If left unprotected, there are two main ways fire can spread within this construction:

- Internal Vertical Propagation: Due to pressure differences between the interior and exterior of the façade, the flames, smoke, and heat can be drawn upwards, through the movement gap and into the space on the floor above.

- Leapfrog Effect: The heat generated by a fire burning on a lower story can exit the vision glazing through an opening, such as an open window or broken pane of glass, allowing the flames and hot smoke to reach up the exterior of the façade and over the spandrel panel. The flames may then break back through the glass and re-enter the building at a higher floor level. Additionally, with the fire now burning on both sides of the façade, the ferocity can cause the framing system to deform in the heat.

To inhibit both of these potential pathways, it is vital to ensure compartmentalisation is achieved using proper passive fire protection solutions. The National Building Code (NBC) 2016 states in clause 3.4.10.2 that “All gaps between floor slabs and façade assembly shall be sealed at all levels by an approved fire-resistant [sic] system of equal fire rating as that of [the] floor slab to prevent fire and smoke propagation from one floor to another.” 2 Historically, this fire resistance rating has been determined by various test standards developed by bodies in different regions, such as Europe (EN) and the USA (ASTM). However, in 2023, the BIS introduced its standard, IS 18190: 2023.

What Is IS 18190:2023?

IS 18190:2023 is a fire test standard that outlines how to carry out fire resistance tests to assess the performance of perimeter fire barrier assemblies installed within the spandrel zone. It draws on widely used standards ASTM E2307-20 (now superseded by ASTM E2307-25)—Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-Scale, Multi-Story Test Apparatus—as well as UL 2079 – Tests for Fire Resistance of Building Joint Systems—to create a robust approach that demonstrates how the chosen solution performs with respect to the floor-to-floor spread of flames, toxic gases, and heat. It does this by assessing three key elements:

- Movement Cycling: Before the test begins, the perimeter fire barrier system is subject to movement cycling between the minimum and maximum joint width at a rate designated by the test applicant 24 hours before fire exposure. This is to simulate the dynamic movement of the curtain wall system. Once complete, the assembly is checked to ensure no gaps have opened. (Note—a perimeter joint is considered ‘static’ when its maximum and minimum joint widths are equal because it will not move. A perimeter joint is considered ‘dynamic’ when the maximum joint width is greater than the minimum joint width because it is capable of movement.)

- Fire Resistance: The test uses an intermediate-scale multi-story apparatus (ISMA) to better replicate a fully developed curtain wall fire. The system is exposed to fire from both inside and outside the test compartment to simulate the room where the fire started, as the fire plume exits the room of fire origin through a window opening and attempts to leapfrog to the next floor.

The first 30 minutes of the test follow the time-temperature curve defined in the NFPA 285 standard, which evaluates the “fire propagation characteristics of exterior wall assemblies containing combustible components.” The test then follows the fire curve defined by ISO 834-1: 1999 – the international standard for fire-resistance tests. The perimeter fire barrier system then receives T- and F-ratings.

Its F-rating, or fire resistance rating (sometimes referred to as ‘integrity’), is determined when flames penetrate through the perimeter firestop system or around its boundaries, or when the cotton pad applied to the opposite side of the fire gets hot enough to ignite. (An additional failure criterion to ASTM E2307-20/25 is failure through openings within the upper spandrel section of the curtain wall above the perimeter firestop system.)

Its T-rating or temperature rise (sometimes referred to as ‘insulation’), is set at the time when the average temperature recorded by any of the thermocouples installed on the unexposed surface of the perimeter fire barrier system and the interior face of the curtain wall rises more than a defined temperature determined by the joint width being tested, e.g. +180°C for joint widths ≥100 mm and +139°C for joint widths >100 mm.

- Air Leakage: As well as looking at fire performance, and while not mandatory but highly recommended, the test also measures air leakage (determined as the L-rating) by UL 2079. This tests the perimeter firestop at the maximum joint width and joint length of 1 m. It is conducted within a sealed box with an open side where the test assembly is mounted. The box is supplied with constant airflow at the specified test pressure difference and temperature for a time sufficient to obtain readings of airflow.

L-ratings can assist authorities in determining the suitability of firestopping systems for the protection of floor openings and smoke barriers for the purpose of restricting the movement of smoke in accordance with the NFPA (National Fire Protection Association) 101 Life Safety Code.3

References:

Is 18190:2023 And ASTM E2307-20/25 – Key Differences

Many perimeter fire barriers available on the Indian construction market carry ASTM E2307-20/25 testing to verify their fire performance. While this is a robust and valid test in itself, it is important to understand how it differs from IS 18190:2023 and that it is not an equivalent standard.

While both tests use the same testing apparatus and methodology, ASTM E2307-20/25 has been developed to assess specifically the performance of the perimeter fire barrier, not the perimeter fire barrier system that includes the spandrel. The IS 18190:2023 standard also more closely aligns with international standards by using the ISO 834-1:1999 time-temperature curve.

Another key difference is the provision for testing air leakage rates. In a fire, more casualties and deaths occur due to inhalation of the smoke generated from burning building contents than from burns, especially as smoke can travel much faster than the fire itself. Ensuring that the chosen perimeter fire barrier system maintains a tight floor-to-floor seal is therefore crucial to safeguarding the safety of building occupants.

Notwithstanding the above, it is important to note that any test results apply only to the specific perimeter fire barrier system used, and changing any of the components within a project specification means that the system no longer meets the requirements of the test standard.

The Need For The Façade Industry To Adopt Is 18190

IS 18190 is an Indian standard developed specifically to protect buildings and people from the effects of fire. Whilst it is still only a recommendation at this stage, its holistic, system-based approach goes beyond both current Indian standards and those developed elsewhere in the world. Adopting the standard and sourcing passive fire protection systems that have been tested to it can not only help preserve the integrity of curtain wall assemblies and ensure effective compartmentation in the unfortunate event of a fire, but also set India at the forefront of global efforts to improve curtain wall fire safety. The standard will be reflected in the upcoming version of the NBC (National Building Code), thereby ensuring that all current and ongoing constructions are future-proofed and aligned with the code.

What’s Next

Buildings with curtain wall façades have been the focus of the authorities in recent years, and this standard is one of the positive outcomes. It is now time for equal consideration to be given to passive fire protection in other façade types – cladding systems in particular – as they have been under intense scrutiny and subject to increased legislation in other jurisdictions following several high-profile, devastating building fires.

References:

- UL Solutions—Firestop and Joint Application Guide