In today’s complex construction landscape, cost control stands as one of the most critical pillars of project success. Owners, contractors, and consultants alike depend on robust tracking mechanisms to forecast budgets, optimise resources, and deliver value. From high-rise towers to intricate architectural envelopes, tracking costs accurately throughout a project’s lifecycle is no longer a luxury – it is a necessity.

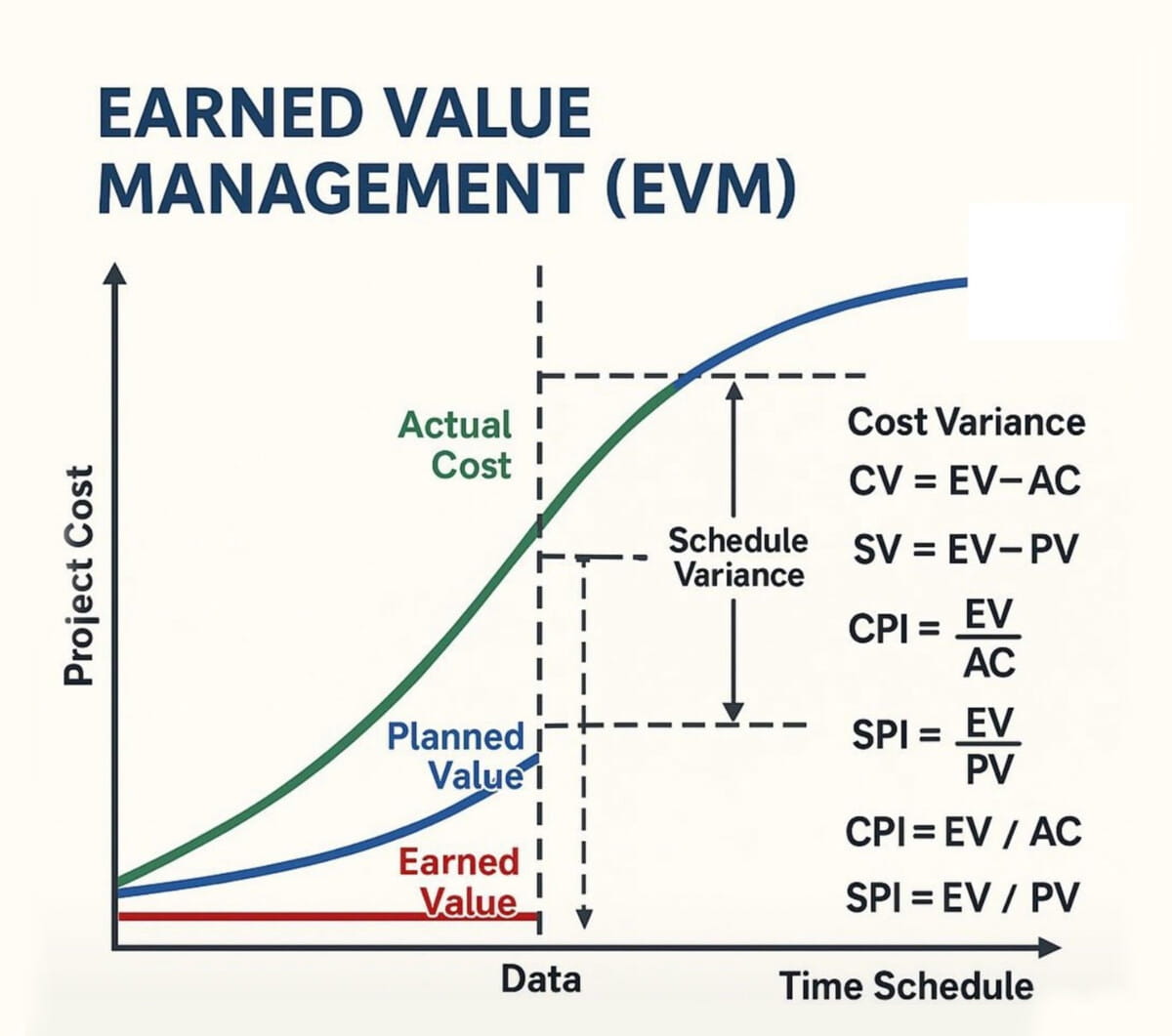

Many cost control measures are deployed across the industry: Earned Value Management (EVM), monthly cost reporting, cost-to-complete forecasts, and productivity benchmarking. These tools aim to track three critical values:

- Planned Value (PV)

- Earned Value (EV)

- Actual Cost (AC)

From these, we derive metrics like Cost Variance (CV), Schedule Variance (SV), and Performance Indices (CPI, SPI).

In this article, we’ll walk through each phase of a typical façade construction lifecycle – from estimation to installation – and examine the cost control challenges at each stage. Along the way, we’ll highlight the kind of coordination, planning tools, and digital systems, such as ERP, that can help close the gap and turn complexity into control. In today’s complex construction landscape, cost control stands as one of the most critical pillars of project success. From the moment a façade package is estimated until the last panel is installed, a wide range of variables can distort even the most carefully crafted budgets.

Estimation & Cost Control Integration

It all begins with the estimation stage, where the foundation for cost planning is laid. However, the traditional role of the cost control department as a post-budget monitoring unit needs to evolve. True integration starts when cost control and estimation teams collaborate early, not only to align on numbers but to review and validate assumptions, break down rates, and assess build-up logic.

This collaboration works in both directions: cost control teams can flag underestimations that could trigger overruns, and overestimations that may hide inefficiencies. This feedback loop, when embedded in the preconstruction process, builds trust in the cost baseline and enhances long-term accuracy. In façade works, where variations in scope and design details are the norm, this integration isn’t optional – it is essential.

Engineering Challenges

Engineering inputs directly affect material quantities, procurement timing, and constructability. Even small missteps – like missing transitions or mismatched dimensions – can ripple into costly fabrication and site delays.

In façade systems, engineering is not just about drawings – it defines the logistical and financial roadmap for the entire lifecycle of the envelope. That’s why engineering accuracy must be treated as a key driver of cost performance.

A critical aspect of this phase is the ability to develop self-contained, independent details wherever possible. The more details are engineered to avoid cascading dependencies, such as tying upper levels to the completion of lower ones, the more flexible and resilient the project becomes.

For example, using one bracket for both the façade fascia and the balustrade can complicate coordination and sequencing. If the shared bracket is embedded in a way that prevents the main contractor from completing their waterproofing or other trade-specific works, it may create delay claims or access issues that disrupt overall progress.

Independent detailing helps ensure uninterrupted workflow on site, allowing multiple zones to proceed simultaneously without interference. This efficiency leads to reduced running costs for site labour, fewer disruptions in sequencing, and tighter control of the critical path – all of which directly impact cost and schedule performance.

But the engineering team’s role goes even further. They are not only responsible for drawings, but also for shaping the ideas, technical solutions, and procurement roadmap of the project.

The engineering team influences:

- Drawings and constructability details.

- Material take-offs and procurement order releases.

- Factory production orders and phasing.

That is why investing in a competent, innovative engineering team must be well-budgeted and prioritised, as it plays a foundational role in long-term savings.

Procurement Complexities

At this stage, ERP systems play a key role in tracking all purchase orders, delivery timelines, and approvals, helping avoid delays and labour downtime. With multiple vendors involved, real-time updates are crucial to managing procurement tied to site readiness and payment terms.

Façade procurement is especially complex because curtain wall systems rely on multiple interdependent components from different sources, like aluminium profiles, coating services, glass, and accessories. These parts must all arrive in sync; if even one is delayed, the entire system can’t be assembled or installed, leading to costly standstills. This phase makes clear how critical it is to coordinate lead times, control schedules dynamically, and ensure that suppliers stay aligned because the full set only works when every piece arrives on time.

Fabrication And Productivity Variations

During fabrication, ERP systems help track productivity by linking material use, work orders, and quality control checks. This allows early issue detection and more accurate forecasting through EVM dashboards.

Curtain wall panels vary in complexity – those with features like spandrel zones, steel insertions, or thermal breaks require more time and labour. Standard productivity rates often don’t reflect these differences, so real production trials and detailed tracking are critical.

To address this, activities should be broken into practical units— detailed enough to reflect real effort, but not overly complex to the point of overwhelming the system. Not all panels are equal, and tracking them under one code can distort performance analysis.

As part of continuous improvement, Value Stream Mapping (VSM) as part of lean tools should be used in case studies to visualise production flow, identify waste, and develop targeted improvements that align with actual labour intensity and material flow.

Site-Specific Realities And Man-Hour Tracking Challenges

Beyond the codes, another huge challenge lies in site manpower tracking. Curtain wall installation is heavily dependent on:

- Site access & Work Fronts.

- Crane or monorail availability.

- Installation sequencing.

- Workforce fluctuations and idle time.

Accurately allocating manpower to activities in real-time is a difficult task. Most site teams rely on general timesheets rather than real-time logs. This undermines the Cost Performance Index (CPI) for installation crews and leads to reactive, not data-driven, decision-making.

This is where modern ERP systems become game-changing. When integrated with mobile tools and daily reporting workflows, ERP can:

- Enable time-stamped resource allocation by task and zone.

- Capture zone-specific productivity variations.

- Compare actual progress vs. planned in real-time.

- Feed clean, reliable data into EVM dashboards for CPI and SPI tracking.

In essence, ERP helps convert fragmented site data into strategic cost control inputs, providing visibility, accountability, and agility to installation teams.

The Role Of ERP In Unifying Project Control

Façade construction involves multiple complex stages, but many issues come from poor integration between them. A strong ERP system can solve this by acting as a central platform that connects all phases and teams in real-time.

ERP Supports:

- Estimation: Share cost data and assumptions with downstream teams.

- Engineering: Tracks design updates to avoid outdated info.

- Procurement: Monitors vendor status and delivery timelines.

- Fabrication: Links production to planning and flags issues early.

- Installation: Enables real-time tracking of labour, progress, and performance.

The true power of ERP lies in its ability to turn disconnected silos into one continuous flow of data. This allows teams to anticipate rather than react, and validate rather than assume.

But ERP success is not just about the system itself – it is about the people using it. Teams must be trained to understand the value of inputting clean data, reading outputs meaningfully, and making decisions with a cross-disciplinary mindset. When implemented properly, ERP isn’t just an IT upgrade – it becomes the foundation for proactive project management in façade construction.

Integration Is The Backbone – But Culture Drives Success

Managing façades across the façade lifecycle requires more than just processes – it demands seamless integration, proactive collaboration, and a shared mindset.

ERP systems provide the backbone, linking estimation, engineering, procurement, fabrication, and installation into a unified workflow. They transform fragmented data into actionable insights, reduce delays, and enable real-time cost and progress tracking. But even the best ERP can’t succeed in isolation.

True control and consistency emerge when engineers, planners, cost controllers, and site teams collaborate actively, validating assumptions, conducting real-world trials, and continuously refining strategies. Innovation also plays a key role. Many cost-saving breakthroughs come not from new tools, but from rethinking old habits – whether through smarter sequencing, leaner detailing, or site-driven logistics improvements.

Ultimately, the biggest enabler is not technology – it is mindset. Curtain wall construction is deeply interdependent, where one weak link can disrupt the whole chain. Teams must recognise their role in the bigger picture. When problems are solved upstream, the site can focus on smooth execution, not damage control.

ERP systems may connect the phases, but it is the team’s awareness, creativity, and accountability that keep the system running right.

We are working with pre-fabricated, detail-sensitive systems. The more complete and precise the preconstruction efforts are, the more margin the site team will have to control labour, time, and quality. That precision upstream is what enables smoother ERP tracking, higher quality installation, and meaningful earned value analysis.

Empowering teams to see the broader impact of their work and minimizing distractions by resolving issues early is what truly enables cost control in façade construction.