Recently, I walked through a stunning high-end bungalow in its final stages of construction. The homeowner had selected one of the world’s most premium brands of system aluminium windows — a wise choice for durability, performance, and aesthetics.

But as I toured the home, disappointment set in.

- Frames were misaligned.

- Sliding panels dragged and juddered.

- Handles operated roughly or got stuck.

Despite the system’s engineering excellence, poor installation had undermined the entire result. Worse, the non-technical client assumed the product itself was defective.

This is a recurring story across project sites today: the best system is only as good as its installation.

System aluminium windows are high-precision products that demand high-precision installation. Without it, even the finest window will fail, leading to client dissatisfaction, warranty issues, and long-term performance problems.

In this article, I’ll explore:

- Why is installation quality critical?

- Correct installation practices.

- Common mistakes to avoid.

- How the industry must elevate installation awareness.

Why Installation Quality Is Non-Negotiable

-

High precision = low tolerance for error

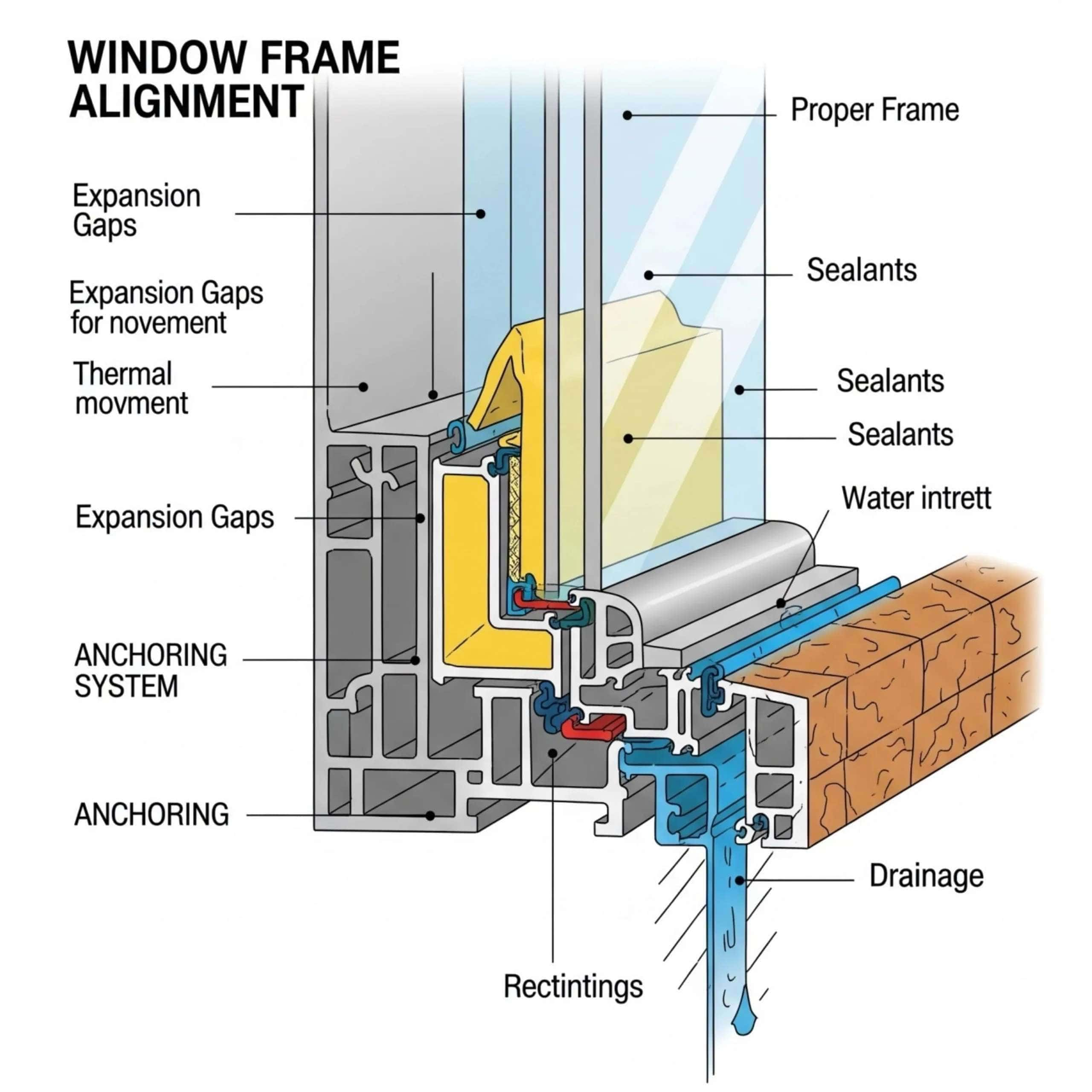

System aluminium windows are precision-engineered products. They feature:

- Tight clearances (under 2 mm tolerance).

- Complex multi-chamber thermal breaks.

- Advanced drainage paths.

- Carefully tuned hardware and gaskets.

These features only work if the frame is:

- Perfectly square and level.

- Properly anchored.

- Installed with correct sealants and tolerances.

Even small installation errors produce large performance failures:

- Air and water leakage.

- Frame distortion.

- Sash binding or poor operation.

- Excessive wear and tear.

- Warranty voidance.

-

The client experience is everything

Clients judge the result by:

- How easily windows slide.

- Whether handles feel smooth and secure.

- Whether there are visible gaps or leaks.

- How the system looks and performs over time.

Poor installation will ruin this experience, no matter how premium the product is. The damage to the brand and builder’s reputation is severe, especially in high-end projects.

Warranties Are Linked To Correct Installation

Most system manufacturers provide performance warranties, but only when their installation protocols are followed exactly.

Deviating from these protocols (even unintentionally) often voids warranty coverage, leaving the client exposed to expensive future repairs.

Correct Installation Essentials

-

Frame Alignment: Plumb, Level, Square

- Why it matters: Misaligned frames cause uneven stress, leaking seals, and operational problems.

- Best practice: Use laser or spirit levels. Check diagonals for squareness at every stage.

-

Expansion Gaps

- Why it matters: Aluminium expands and contracts significantly with temperature changes. Without proper expansion gaps, frames can deform or bind.

- Best practice: Maintain 10–15 mm perimeter expansion gaps, sealed with backer rods and system-approved sealants.

-

Anchoring

- Why it matters: Incorrect anchoring can warp frames or create stress points.

- Best practice: Use anchors at system-specified points (typically every 600–700 mm). Use appropriate fasteners for the substrate.

-

Drainage Paths

- Why it matters: Blocked drainage causes water ingress and frame damage.

- Best practice: Keep drainage paths clear during and after installation. Never block weep holes with foam or sealant.

-

Hardware Installation

- Why it matters: Incorrect torque damages handles and rollers.

- Best practice: Use torque-limited drivers. Follow the manufacturer’s instructions exactly for spindle depth, screw torque, and hardware positioning.

-

Roller and Sash Alignment

- Why it matters: Misaligned rollers cause rough, uneven sliding and excessive wear.

- Best practice: Carefully adjust rollers for even contact and smooth operation. Test the operation multiple times.

Common On-Site Mistakes To Avoid

Overpacking or Underpacking Shims: Result: Frame distortion, leading to leaks or sash misalignment.

- Using Low-Quality Sealants: Result: Cracking, peeling, water ingress, and long-term failure.

- Cutting Thermal Breaks On-Site: Result: Destroyed thermal performance and warranty voidance.

- Ignoring Torque Specifications: Result: Loose or stiff handles, stripped threads, hardware failure.

- Blocking Drainage Paths: Result: Water build-up, frame corrosion, and leaking into interiors.

- Skipping Final Adjustments: Result: Rough operation, air leakage, dissatisfied client.

Why Do These Mistakes Happen?

- Lack of Training: Many installers lack specific training in system aluminium window installation, especially with newer, more complex products.

- Schedule Pressure: Installation often gets rushed at the end of projects. Quality suffers.

- Lack of Awareness: Architects, project managers, and clients often assume that “any window installer” can handle a system aluminium window. This is not true – these systems require specialist knowledge and careful execution.

Best Practices For Raising Installation Quality

- Educate Clients and Professionals: Architects, builders, and clients should understand that system windows are precision products, not commodity windows. They must demand correct installation and be willing to budget for it.

- Specify Installation Requirements: Architects and consultants should specify:

- Required installer qualifications.

- Accepted installation methods.

- Final inspection and testing standards.

- Use Certified Installers: Work with installers who are trained and certified by system manufacturers.

- Supervise and Inspect.

- Conduct pre-installation briefings.

- Use installation checklists.

- Inspect critical points (frame alignment, drainage, hardware function) before handover.

- Promote Awareness in the Industry.

- Publications like this magazine can play a major role in raising awareness among architects, builders, and clients about the importance of correct installation.

Conclusion

System aluminium windows deliver unmatched aesthetics, durability, and performance – but only when installed correctly.

As industry professionals, we must:

- Insist on high-quality installation.

- Educate all stakeholders.

- Follow best practices rigorously.

Treat installation as a critical part of the system, not an afterthought. Let’s move beyond “good enough” and ensure that every premium window system delivers the full value it was designed to provide.

Right product. Right installation. Right results. |