Circularity, adaptability, R-strategies, avoided carbon, and many more terms are used frequently nowadays — but what makes sense and what does not? Is tearing down a 20-year-old metal façade and replacing it with a brand-new façade the right thing to do? Should we preserve it, or upgrade it? Can we save carbon emissions during the remaining lifespan of the building to justify that this is the right choice? And what if we recycle the old glass — does that help? Does it even matter what engineers calculate if the building owner is determined to give the building a new look in order to make the office space relevant?

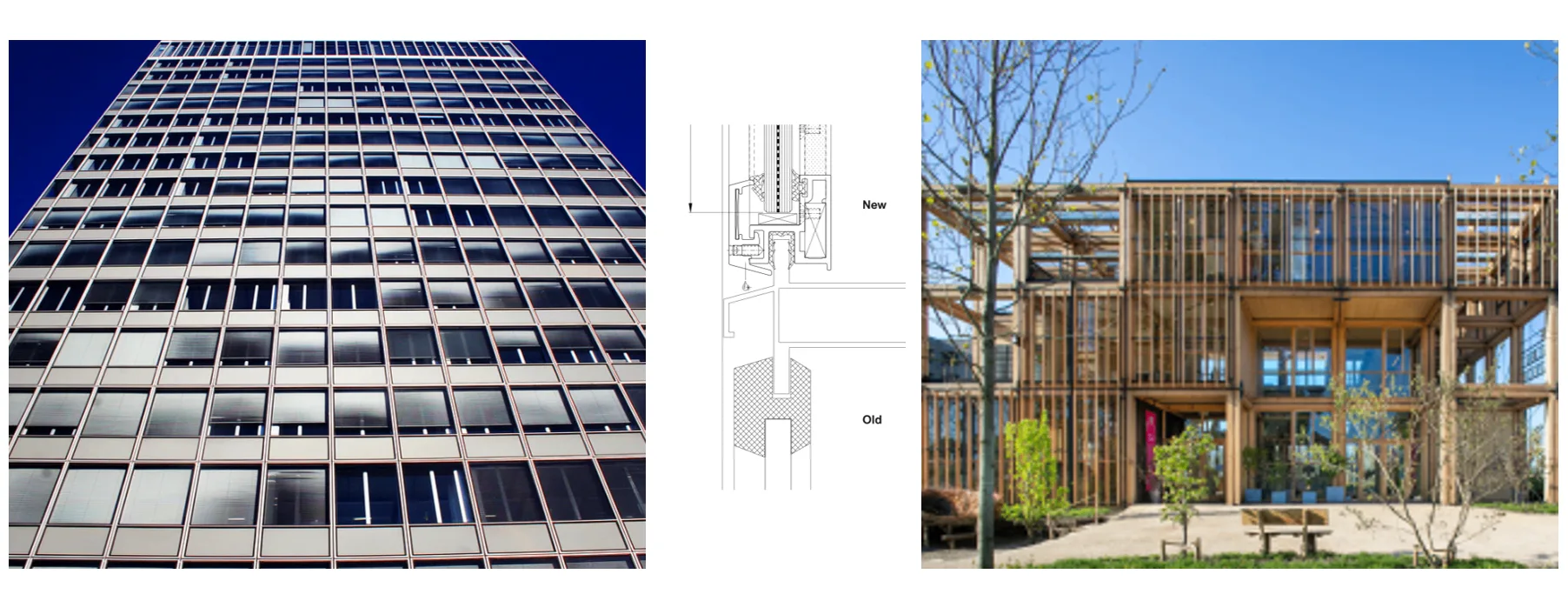

Let’s start at the beginning. The built environment is full of metal façades constructed in the ’80s, ’90s and ’00s and, quite frankly, to me it is unclear how they imagined refurbishment scenarios after 25 or 30 years of service. We can find lifetime expectancy schedules in the O&Ms, but some materials or systems are underestimated, and others are overestimated. The biggest issue is that they do not align. This means that some façades may be considered at the end of life after 30 years because one component is no longer meeting requirements, forcing other materials to be scrapped as a consequence. It breaks my façade heart to see 25-year-old aluminium extrusions being discarded, when we know they can have a lifespan more than twice that. How to avoid scrapping buildings or façades prematurely is another topic that should be discussed separately among building owners and architects.

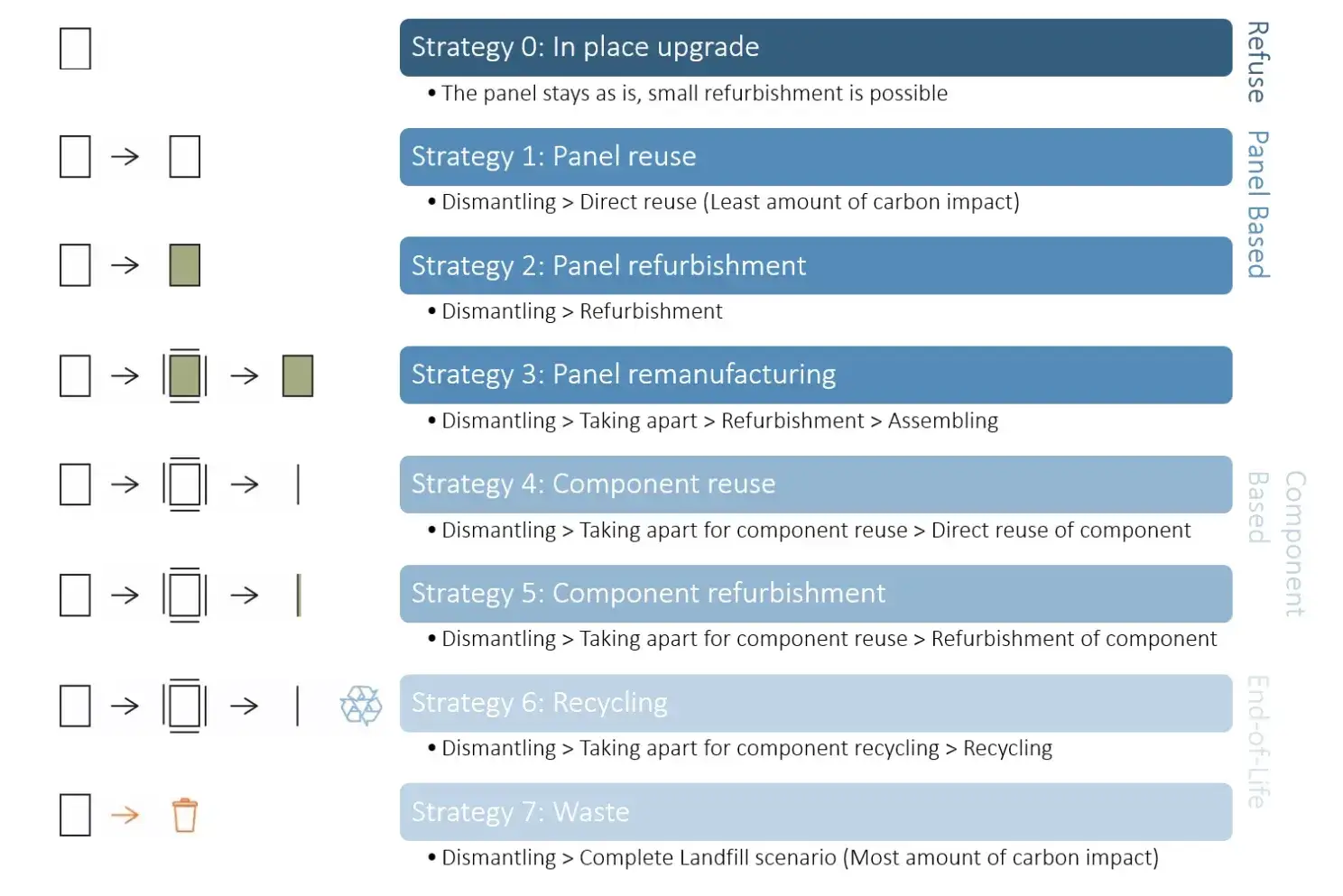

How can we be more environmentally friendly and sustainable when refurbishing the built environment? How can we enhance circular principles and reduce carbon emissions when refurbishing older buildings? This question-initiated research into circularity, which we first began with Rianne Teeuwen, a Master’s student at TU Delft Civil Engineering and Geosciences. She investigated the options available when replacing a façade and analysed the potential carbon impact of different strategies. In this case, we assumed a 25-year-old unitised façade made of aluminium and double-glass. The seven strategies mentioned below were analysed and ranked, with Strategy 0 added as a benchmark.

A literature study highlighted several notable examples across industries of different R-strategies. The most impressive, to me, was Caterpillar’s remanufacturing process for heavy equipment, in which they take back old machines, strip them down to the smallest component, clean and repair them, and subsequently rebuild the machine.

In the façade industry, there are numerous commendable initiatives, such as recycling glass and other materials, as well as component-based strategies like stone re-use or refurbishment.

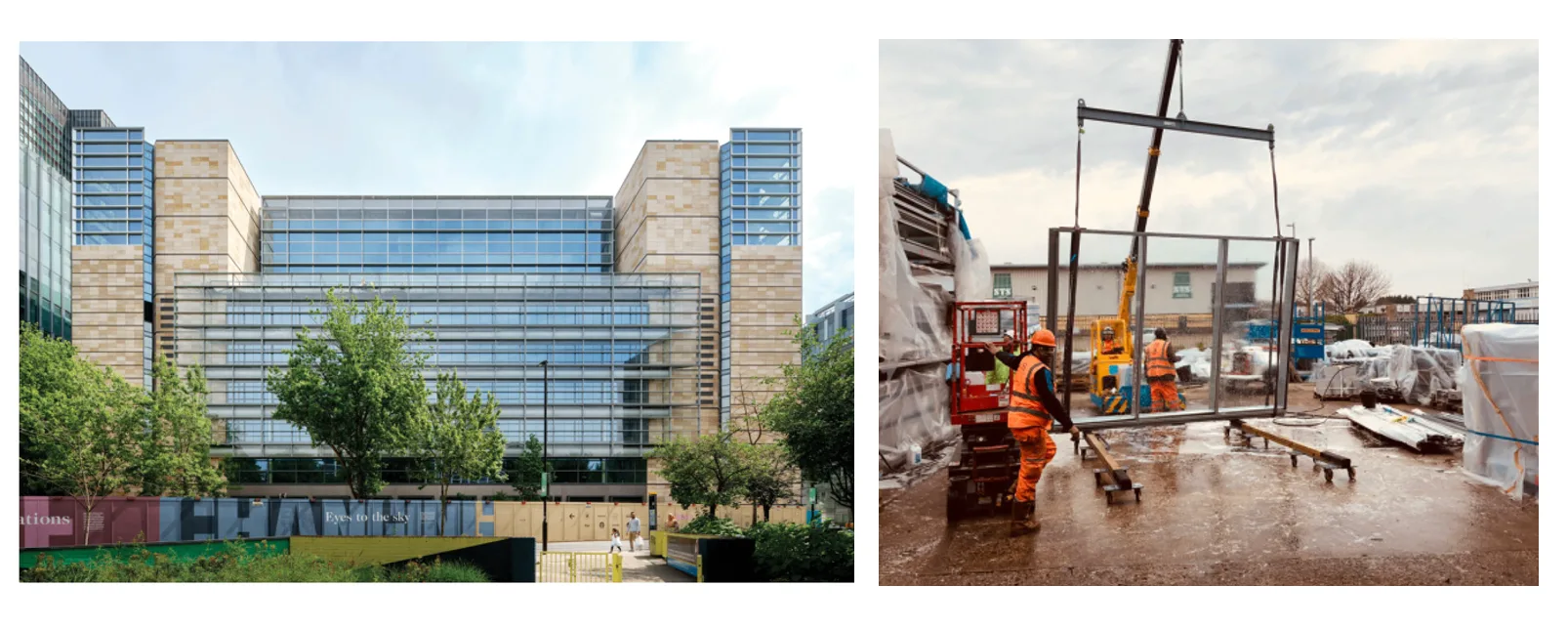

When we examine the Permasteelisa Group’s experience, three examples particularly stand out. The first is Project Koningskade in The Hague, a 60-year-old façade respirante designed by Jean Prouvé. The façade remained in place, but the gaskets holding the single outer glass were replaced with a new system, and the single glass was replaced with laminated glass. The original single glass was reused at the Floriade, in the Natural Pavilion. This demonstrates that aluminium façade systems and glass can last longer than 60 years if designed and maintained well.

Secondly, the project One Triton Square in London involved the temporary removal of the external double skin, followed by cleaning, replacement of the gaskets, and reinstallation of the panels. This demonstrated that unitised curtain wall panels can be dismantled from a building without damage and subsequently reinstated.

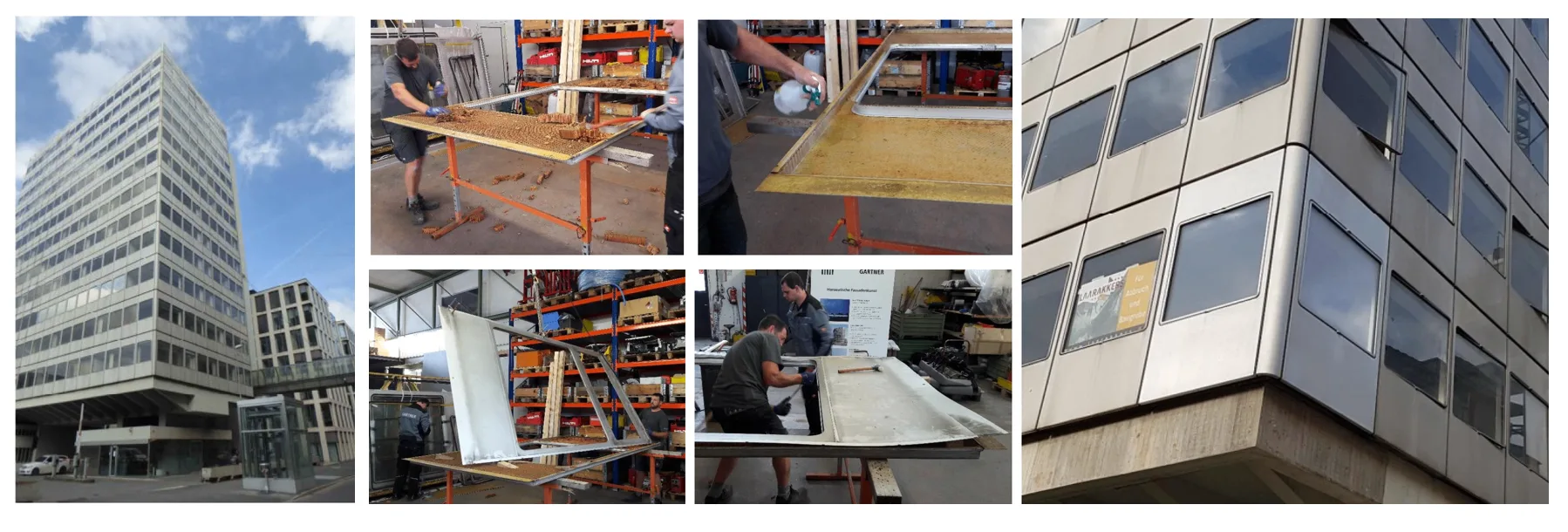

A final example that was analysed was the Commerzbank in Düsseldorf, where old façade units were dismantled from the building, fire-hazardous materials were removed, insulation was added, and the aluminium sheets were cleaned before the panels were reinstalled. This demonstrated not only that the units could be removed and replaced, but also that they could be remanufactured to improve performance.

Let’s return to our 25-year-old façade, which we initially assumed would be replaced, and examine what was actually happening at the time, as well as how to increase circularity and reduce carbon emissions. We identified seven strategies and have observed examples of each. As a façade contracting company, we focus on assembling façade panels and adding value in the process.

At the end-of-life stage for a building façade, when replacement becomes necessary for any reason, we can have the greatest impact by considering R-strategies based on panels rather than components or recycling. When it comes to recycling or reusing individual materials or components, the relevant industries are far better equipped and achieve greater efficiency by handling larger volumes; therefore, we did not focus on these in our research. Take the glazing industry, for instance, which is making significant improvements in the re-use and recycling of insulated glass.

We also excluded the direct re-use scenario—similar to a second-hand marketplace—where we do not add value to reused façades. Instead, we focused on refurbishment and remanufacturing scenarios. The potential savings in embodied carbon that we, as façade contractors, can achieve by refurbishing and remanufacturing old façades are substantial compared to waste and recycling scenarios, making it our moral duty to investigate further.

The amount of embodied carbon that can be saved through refurbishing or remanufacturing façades can be expressed as what we call avoided embodied carbon. In this example, we state that we can avoid embodied carbon when comparing a baseline scenario, in which a façade reaches the end of its life, is discarded, and a new façade is built from scratch. Carbon emissions can be avoided if we do not discard the façade but reuse it. The effort required for reuse varies depending on the R-strategy.

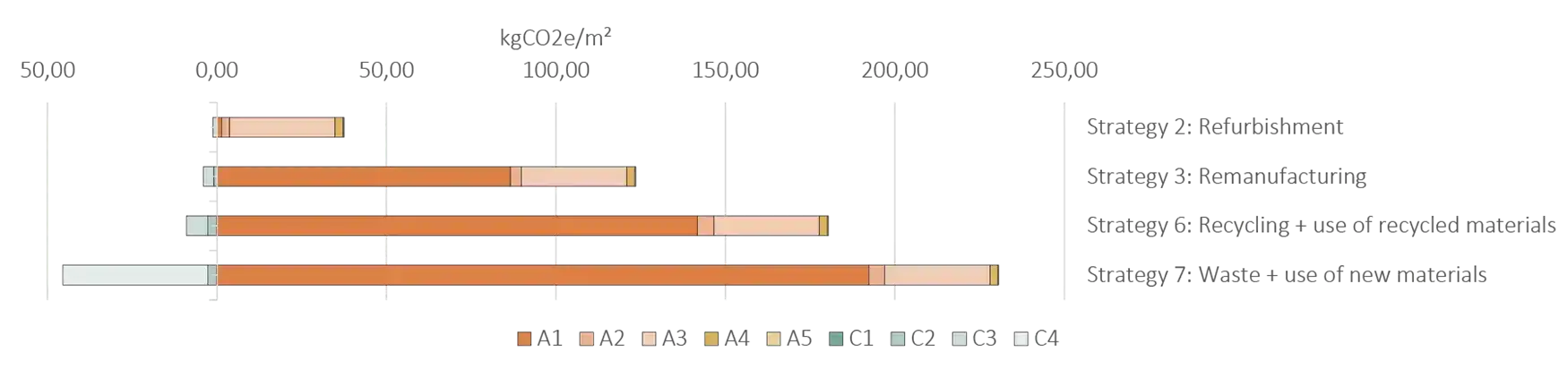

It requires more carbon emissions to dismantle a façade panel, recycle the materials, and build a new façade than it does to refurbish it. The graph below illustrates the potential carbon savings at the different stages. To the left of zero, we show the carbon emissions for the C stage of the old panel, and to the right, the A1–A5 stages.

Now, the service life needs to be considered, and B-stages for existing façades also need to be taken into account. We will elaborate on this complexity another time. The concept of avoided carbon, as shown above, clearly demonstrates that discarding façades that are not at the end of their life after 25 years is a missed opportunity to save carbon. This is because the main components-such as aluminium framing, steel sheets, stainless steel, single glass, laminated glass, internal gaskets, brackets, and insulation not at the end of their life after 25 years, but rather after 60 years. Yes, the insulated glass might be at its theoretical end-of-life, like the exposed gaskets, but we still need to reconsider the value of the remaining service life of a used façade. This is why our research into the remaining service life of materials is so important: it proves how long materials can still be used.

This brings us to the core of the avoided carbon method: assessing the possibilities when a façade is regarded as redundant or underperforming in a building. Can we upgrade it in situ? What is required to achieve energy performance class A+++, and is that even possible? Should we replace it partially or fully, and if we replace it, what can be done with the old façade? Can it be reused or remanufactured for another building?

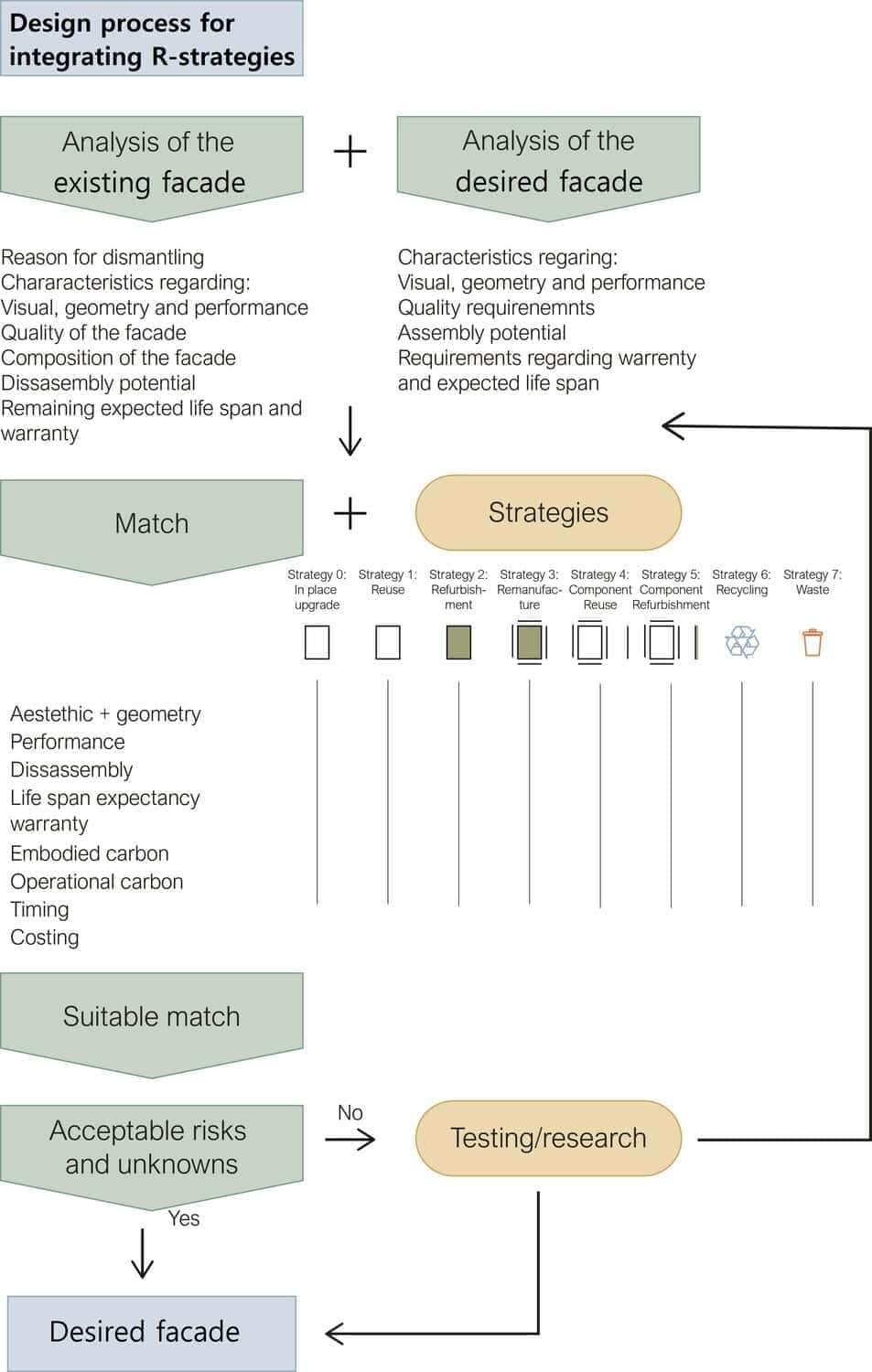

Through this approach, we can assist building owners, architects, and engineers with our knowledge of façades. Our method, or Circular Flow Chart, starts with the analysis of the existing façade and the desired façade. The desired façade could be on the same building, for example, in an in-situ refurbishment, but it could also be a reused façade on a receiving building. In both cases, the analysis will quickly indicate whether R-strategies are worth investigating. If they are, these should be compared to determine which provides the best value for the client, not only in monetary terms but holistically.

Comparing avoided embodied carbon, as shown above, is one parameter, but not the only one. Other parameters should be agreed upon and include, but are not limited to, aesthetics, operational carbon improvements, service life, warranty, cost plan, and programme.

So, finally, imagine that we have redundant windows that are not at the end of their life, and we have five potential projects to which these windows could be allocated. We could assess the best possible scenario to determine the destination for these windows, where the most carbon could be avoided. Or imagine that we could convince a client to upgrade their façade, rather than discarding it and purchasing a new one. That, in my humble opinion, is something worth striving for. This is how I believe circularity, R-strategies, or simply common sense, whichever term you prefer, will transform the façade industry. Because, ultimately, it is the right thing to do.