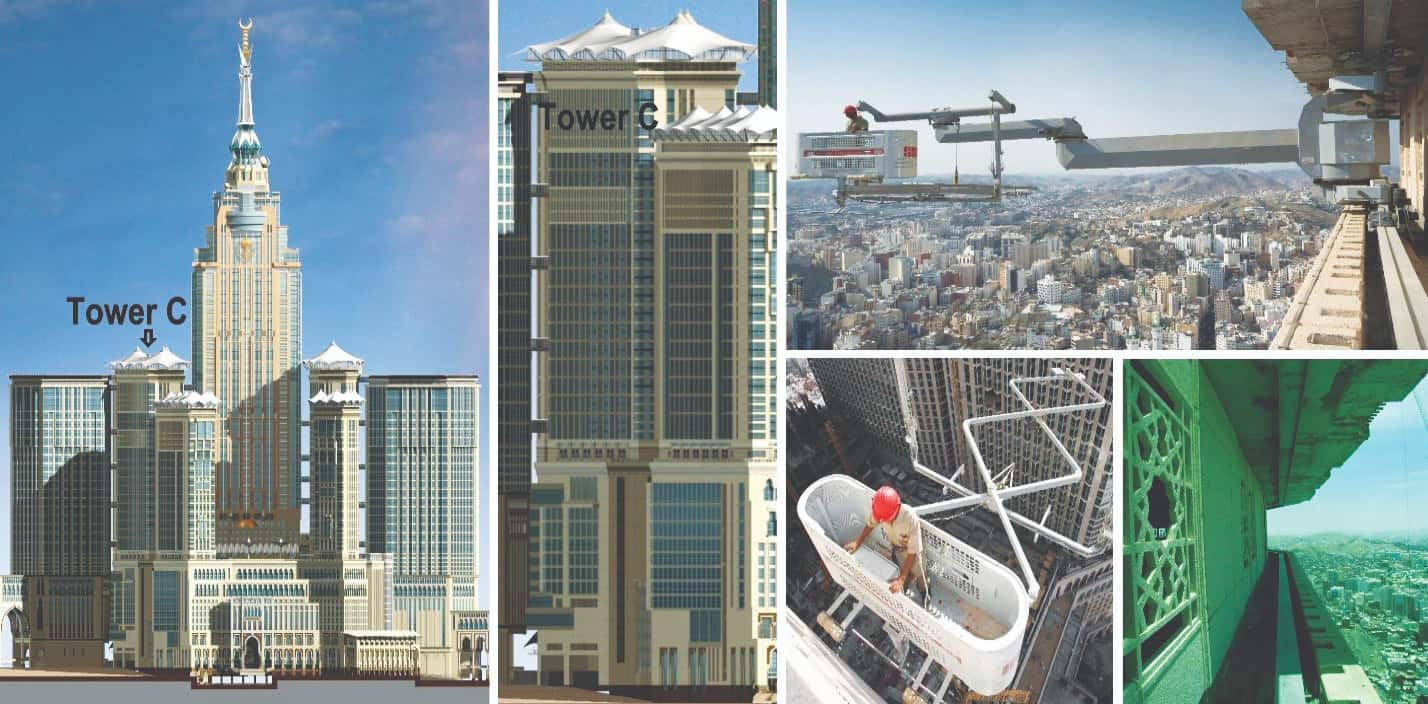

Clock Tower, Abraj Al Baith (King Abdul Aziz Endowment Project), Mecca, Saudi Arabia

Façade access systems for this iconic complex were executed by the teams of Farra and Sky Steel Systems, directly managed by the author. This iconic US$15 billion government-owned complex of seven skyscrapers in Mecca, Saudi Arabia, besides the world’s largest and Islam’s holiest Mosque, is part of the King Abdulaziz Endowment Project.

There was a space constraint to place BMUs on these towers since there was no open roof available. A 1 m wide corridor was provided on the service level under the roof to place the BMU. The space was so limited that placing the BMU in that space was highly challenging. Special BMU was designed and developed by Farra Engineering Ltd, New Zealand and Sky Steel Systems LLC, Dubai, with the following features:

Vertically opposed tracks with the upper track under the roof slab at the service level and the lower track on the floor are placed to accommodate the BMU in the service level corridor.

No counterweights due to the non-availability of space. The track system takes the complete overturning moment.

Complete system squeezed into a 1 M wide space in the service level corridor.

While most of the BMU sticks out of the building during operation, the parking area is coordinated and provided to hide the BMU while not in use, screened from view.

Special scissor pantograph cradles are provided with the BMU for the cage to project into the recess to access the recessed elevations.

While working out appropriate solutions, it is essential to determine the quantity of the equipment required to perform the cleaning and maintenance of systems. While material hoisting normally occurs occasionally, and since there is a dedicated crane, it is not included in the calculations here. The cleaning cycle time and equipment required are calculated as follows.

Quick Facts:

|

Cleaning cycle calculations and BMU quantity determination

| No | Description | Quantity | Unit |

|---|---|---|---|

| 1 | Perimeter length of the building | 237.2 | M |

| 2 | Building height | 237.7 | M |

| 3 | Elevation cleaning area to be accessed | 56,382.4 | SQ.M |

| 4 | Cleaning time required for 2 operators at 2.5 sq. ft. per minute per operator | 188 | Hours |

| 5 | Working hours per day | 8 | Hours |

| 6 | Pre-operative inspections and daily routine maintenance | 0.5 | Hours |

| 7 | Time available per day for system operation and cleaning | 7.5 | Hours |

| 8 | No of times 2.5M long Cradle climbs up and down over 237.2M perimeter length | 95 | times |

| 9 | Time required for 237.7M ascent and descent 95 times at 10 M per minute speed | 75.3 | Hours |

| 10 | Time required for 237.2M horizontal movement of the BMU at 6 M per minute and return to the garage | 1.3 | Hours |

| 11 | Pantograph operation per cleaning cycle, 2 times per fall x 95 falls x 5 minutes each | 15.9 | Hours |

| 12 | Lateral restraint pin engagement and disengagement on elevations per cleaning cycle for 95 falls x 10 levels x 2 engagement x 2 disengagement x 1 minute each | 63.4 | Hours |

| 13 | Total time required for one full cleaning cycle 1 + 3 + 4 + 5 + 6 | 343.9 | Hours |

| 14 | Total time required for one full cleaning cycle at 80% efficiency and 10% weather, and other interruptions | 477.6 | Hours |

| 15 | Number of working days required for one full cleaning cycle at 7.5 hours per day | 63.7 | Days |

| 16 | Scheduled quarterly maintenance of the BMU before every cleaning cycle | 2 | Days |

| 17 | Considering 6 6-day work week in Saudi Arabia and considering holidays, weeks required for 1 cleaning cycle at 5.5 days per week (65.7÷5.5) | 12 | Weeks |

| 18 | For a quarterly cleaning cycle, 4 times in a year, the maximum number of weeks available | 13 | Weeks |

| 19 | Number of BMU systems required for a quarterly cleaning cycle | 1 | Unit |