Understanding Codes And Standards, Selecting The Right System, And Navigating Common Pitfalls

The United Nations projects that within the next two decades, about 51% of India’s population will reside in urban areas. This trend, coupled with existing urban pressures, is likely to increase the Floor Space Index (FSI). Rapid urbanisation demands the swift adoption of advanced technologies and faster construction methods. In the last ten years, high-rise buildings have increasingly embraced curtain wall glazing systems, prized for their design flexibility, visual appeal, and energy efficiency. However, these innovations also bring inherent fire safety risks that warrant careful consideration and thorough examination.

When designing and constructing curtain wall systems, adhering to building regulations and national or international testing standards is crucial for fire safety performance. Neglecting or compromising on the design and testing of these systems, especially at the slab opening’s edge, can have severe consequences.

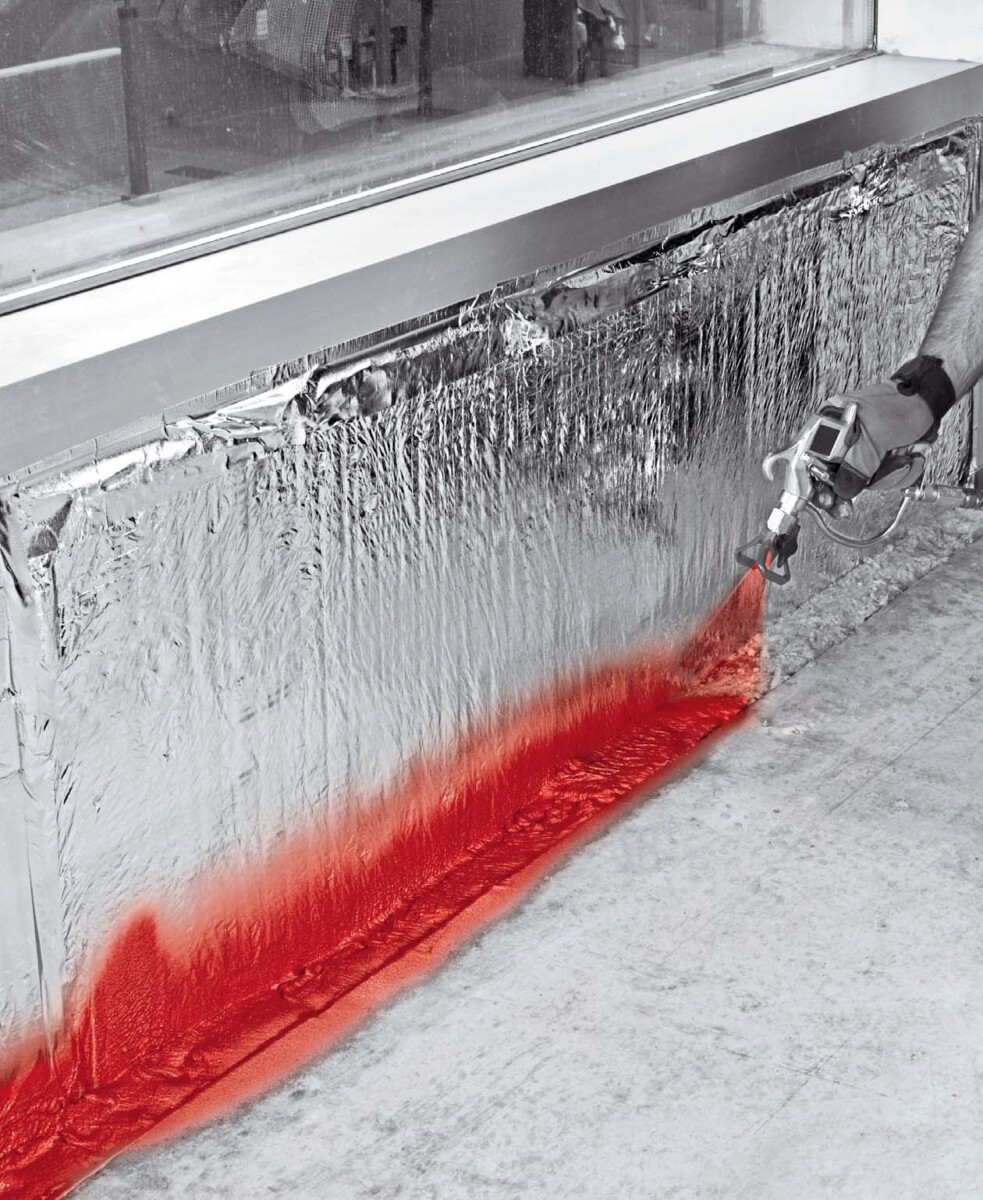

A crucial element in mitigating fire risks is the use of Perimeter Fire Barriers (PFBs). Mandated by various national and international building codes, PFBs effectively inhibit the spread of fire and smoke between floors.

The “chimney effect” and “leap-frog effect” enable fire to spread quickly between floors at a building’s perimeter, emphasising the importance of well-designed, properly installed, and regularly maintained perimeter fire barrier systems. The varying gap between the slab edge and curtain wall, particularly in concrete structures with construction tolerances, highlights the vital role of building codes and standards. These guidelines stress the need for perimeter fire barriers and offer methods to safeguard the space between fire-rated floors and exterior walls, effectively controlling fire and smoke spread across floors.

Codes And Standards:

NBC 2016, Clause 3.4.10.2 (b) mandates that all gaps between floor slabs and façade assemblies be sealed at every level with fire-resistant materials matching the floor slab’s fire rating. This crucial measure prevents fire and smoke from spreading between floors.

In accordance with IS-18190, building codes mandate that all gaps between floor slabs and façade assemblies be sealed at every level with fire-resistant materials matching the floor slab’s fire rating. This crucial measure prevents fire and smoke from spreading between floors. The standard outlines fire resistance testing methods for evaluating perimeter firestop assemblies, drawing significant input from ASTM E2307 and UL 2079.

Assembly Testing: IS 18190 specifies a test setup using a two-story building with the ground floor subjected to a post-flashover fire. The test employs two burners—one inside and one outside- to generate a flame plume along the building’s side. An exterior curtain wall is installed on one side, with fire-resistant materials filling the gap between the curtain wall and the floor slab edge. This testing evaluates the assembly’s ‘F-Rating’ (Fire Rating), ‘T-Rating’ (Insulation Rating), and ‘L-Rating’ (Smoke Rating).

Test Sequence (In Accordance With IS 18190 And ASTM E2307):

- Cycling Test: Perimeter joint systems undergo testing to ensure they can withstand live loads and environmental forces such as wind, thermal, and seismic impacts. This test demonstrates the compatibility of joint system components with the supporting construction. It subjects the joints to 500 or 100 complete movement cycles at a rate of 1 to 10 or 30 cycles per minute before the fire test.

- Fire Test: This test evaluates the performance of the perimeter fire barrier by observing the behaviour of fire and hot gases on the unexposed side of the barrier and any adjacent supporting structures.

- Smoke Rating: IS-18190 also requires evaluating the L-Rating for smoke containment, in addition to assessing fire performance. Fire-resistant joint systems protecting joints in smoke barriers and perimeter fire containment systems shielding voids at the intersection of a horizontal smoke barrier and an external curtain wall must undergo air leakage testing according to UL 2079.

The L-Rating should not exceed 5 cubic feet per minute per linear foot (0.00775 m3/s m) of joint at 0.30 inches (74.7 Pa) of water, for both ambient and elevated temperature tests.

Selection Of The Right System:

Unlike some fire safety elements that primarily require design and specification, perimeter fire barrier systems demand meticulous attention to design, specification, and installation. This necessitates close collaboration among the architect, specifier, and general contractor to ensure proper implementation of each system component.

Some Of The Commonly Seen Curtain Wall Arrangements That Influence The Perimeter Fire Barrier Systems’ Performance In Fire:

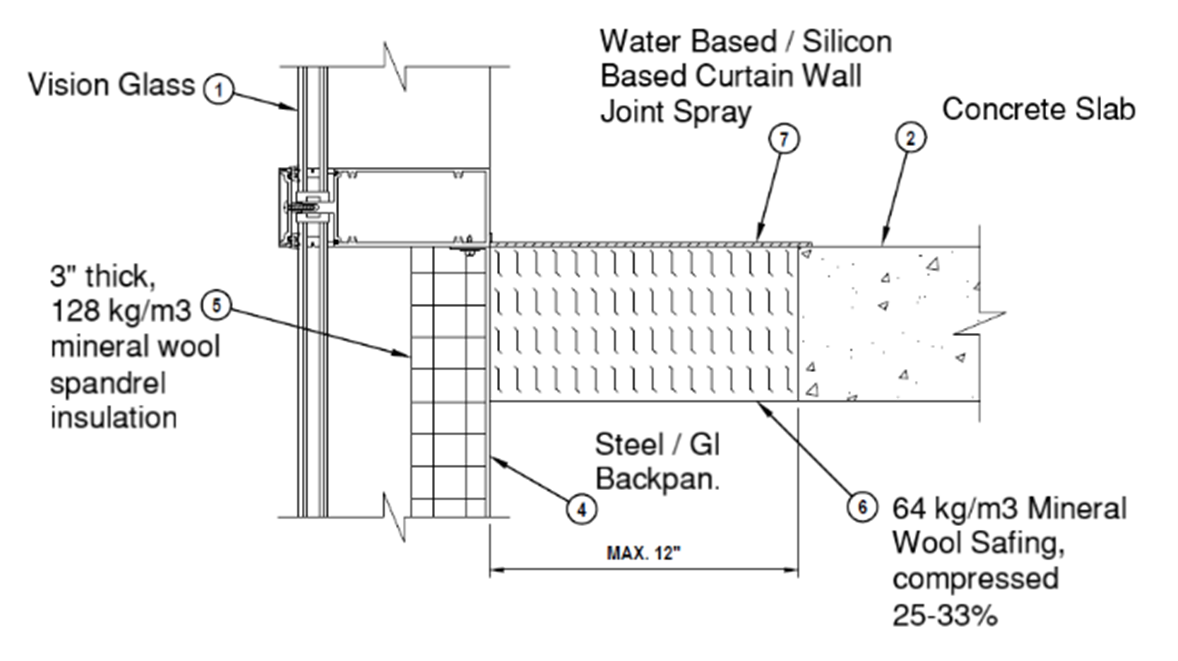

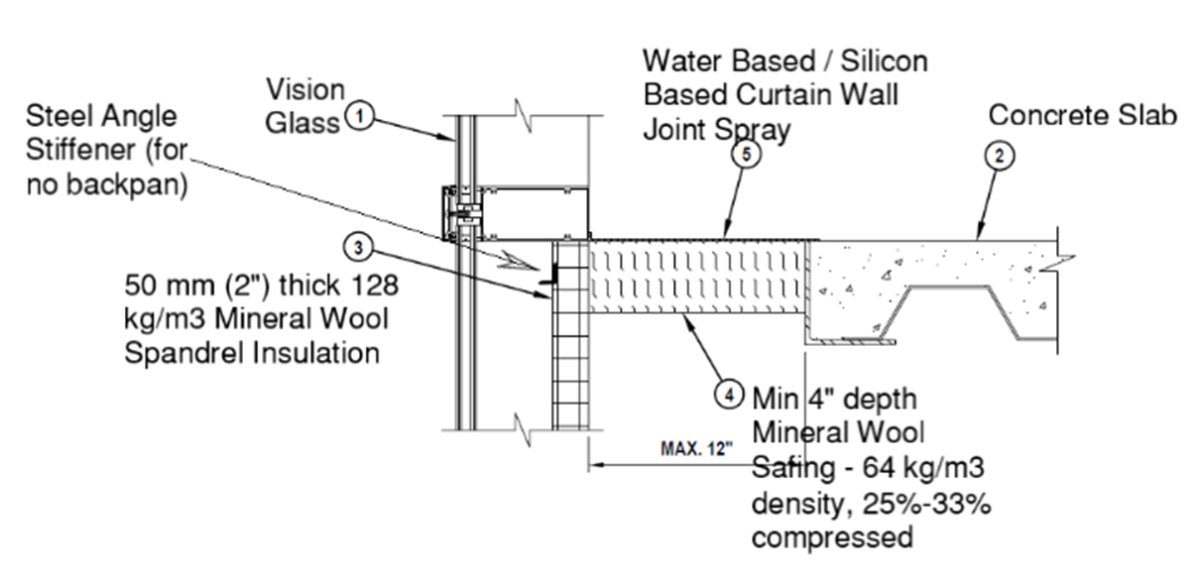

Selecting the right system requires understanding key application details, including:

- Exterior wall composition (e.g., steel studs, aluminium mullions)

- Spandrel glass and backpan material

- Curtain wall insulation

- Gap width

- Hourly rating (F-Rating)

- Smoke rating (L-Rating)

- Joint width

- Movement requirements (static or dynamic)

Navigating Common Pitfalls In Perimeter Fire Barrier Systems

Edge-of-Slab Joints: Deviations from tested construction specifications in curtain wall systems can compromise fire safety. It’s crucial to adhere strictly to firestop system requirements, ensuring the installation matches the tested system precisely. For example, transom heights—measured from the floor to the bottom of the vision glass—must conform to firestop system specifications. Transoms placed closer to the floor than allowed by the tested system can lead to failures. Low transom heights may cause higher temperatures, potentially igniting sealants and resulting in premature fire spread. Design choices that prioritise aesthetics over fire safety can create significant conflicts. To avoid these issues, effective coordination between design professionals and strict adherence to firestop requirements are essential.

Curtain Wall Insulation And Joints:

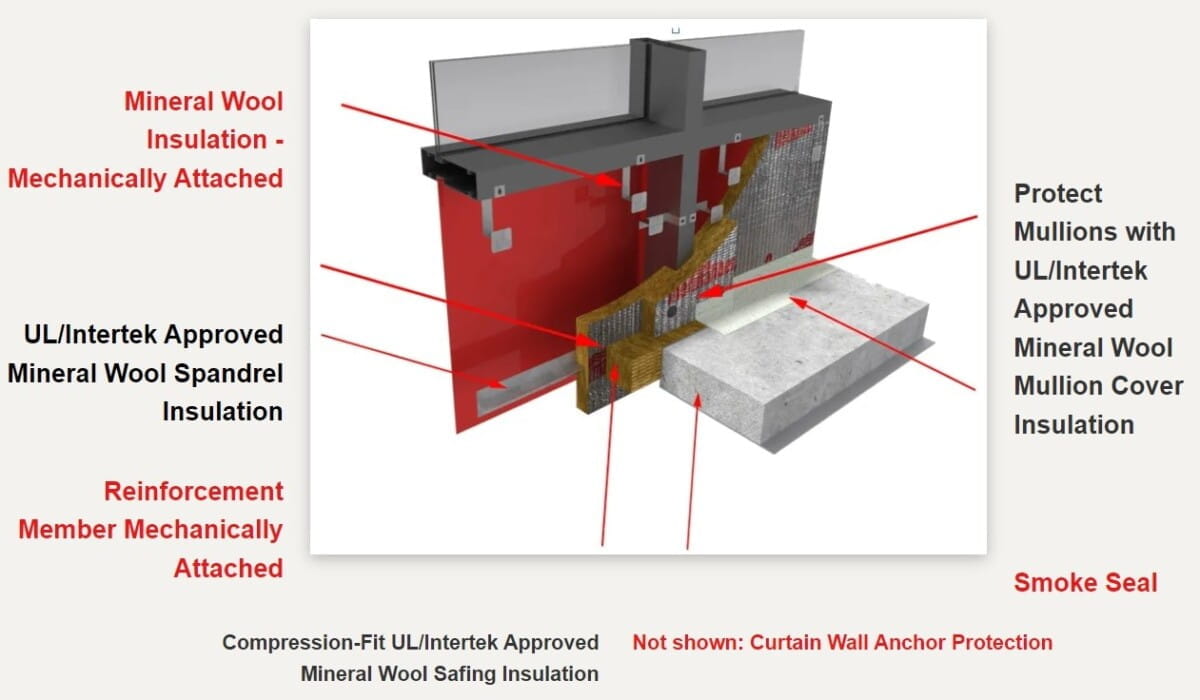

Continuous insulation between mullions is often essential. Vertical seams in the insulation must be firmly secured to prevent gaps that could allow fire or smoke to spread. Maintaining the integrity of mineral wool insulation is crucial for effective firestopping. This may require reinforcing components like welded pins or Z-clips, as specified in firestop systems. Poorly secured insulation can result in insulation failure, compromising the entire system’s effectiveness.

- Reinforcing Steel: For systems using non-stone or non-concrete panels, 20–22 gauge steel angles are often crucial for maintaining stability, as fire can cause aluminium components to soften. These steel angles, when specified in firestop systems, must be installed during construction. Adding them after construction can be impractical and expensive, underscoring the importance of early coordination in curtain wall design.

- Impaling Pins and Z-Clips: Proper function of perimeter firestop systems hinges on keeping insulation in place. Mechanical fasteners-such as impaling pins or Z clips-are crucial for preventing insulation shifts during fires. Neglecting these fasteners can lead to insulation falling out, compromising fire resistance. Past incidents of inadequate securement have resulted in increased fire spread, highlighting the critical need to follow installation requirements precisely.

- Improper Mineral Wool Installation: Install mineral wool with fibres running parallel to the curtain wall studs. Horizontal installation can compromise the wool’s compressive properties and reduce fire resistance. Proper installation is crucial for maintaining the integrity of firestop systems.

- Selecting The Right System: Choose the appropriate perimeter firestop system by consulting third-party certification laboratory directories. UL and Intertek listings offer comprehensive insights into fire containment systems. These directories employ specific nomenclature to identify various firestop systems, aiding in the selection of the right system for your project’s needs.

- Engineering Judgments (EJs): Informative Annexe A of IS-18190 outlines detailed guidelines for Engineering Judgments (EJs). When on-site conditions deviate from the original design or unexpected construction challenges occur, EJs provide alternative methods to preserve the firestop system’s integrity. As redesigning may be impractical, these alternative recommendations must align with the original fire-tested designs. Skilled professionals should formulate Ejs following International Firestop Council (IFC) standards and sound engineering principles.

- Installation: Firestop manufacturers typically offer specific programs and qualification criteria for installers, providing education and training on trade-specific installation methods. As perimeter fire barrier systems are “Listed” systems, they must be installed in accordance with their listing and the manufacturer’s instructions. To ensure the effective functioning of the perimeter fire barrier system, follow this 5-step approach:

- Rating Compatibility: Verify that the perimeter fire barrier system’s rating meets or exceeds the adjacent floor’s rating.

- Accredited Testing And Listing: Confirm that an accredited laboratory has tested and listed the Edge of Slab (EOS) joint system. Ensure the field installation aligns with listing specifications for gap width, curtain wall spandrel insulation (type, thickness, density), and safing insulation (type, depth, %compression).

- Engineering Judgments (EJs): If a tested system matching site conditions is unavailable, obtain an Engineering Judgment from the manufacturer.

- Installer Qualifications: Ensure a trained and qualified installer performs the installation.

- Documentation: Thoroughly document the installed system to facilitate future inspections and maintenance.

By addressing these key aspects, you ensure proper installation and ongoing compliance with safety standards.

Conclusion

The effectiveness of the Fire Barrier System hinges on its correct design, installation, inspection, documentation, and maintenance. Each assembly must display a clearly visible design listing and approval label that matches the construction type, joint gap specifications, and required fire, smoke, and movement ratings.

Product manufacturers or suppliers are responsible for providing comprehensive submittals. These should include system design listings or test certifications from accredited laboratories, complete with illustrations and adherence to applicable standards for each system configuration.

Rigorous compliance with code requirements not only ensures safety but also instils confidence in builders, contractors, architects, inspectors, and occupants. This commitment creates a secure environment and supports firefighters in their rescue and firefighting efforts-ultimately saving lives and safeguarding valuable assets.