In today’s fast-changing architectural landscape, façade glazing has become a defining feature, merging form with function. Beyond aesthetics, glazed façades boost energy efficiency, occupant comfort, and overall building performance.

With sustainable practices, innovative materials, and smart technologies on the rise, expectations for façade systems are higher than ever. Yet developers and contractors face tighter budgets, rising costs, and fast-track schedules—forcing cutting-edge design to coexist with financial discipline.

This article explores the balancing act between innovation and cost in façade glazing, showing how value engineering, technology adoption, and smarter collaboration can deliver high-performance, visually striking façades—without compromising budget or buildability.

The Demand For Innovation In Façade Glazing

As buildings become more complex and performance-driven, the demand for innovation in façade glazing has intensified. Today’s building envelopes must deliver far more than aesthetic appeal—they are expected to meet stringent thermal insulation, acoustic performance, and structural resilience standards, along with sustainability benchmarks such as LEED and Estidama certifications.

Architects and clients are pushing design boundaries with complex geometries, free-form surfaces, and expansive transparent façades that blur the divide between indoors and outdoors. These striking concepts require advanced engineering solutions and precise fabrication-often under tight deadlines and budget constraints.

To meet these demands, the industry is embracing innovative systems and advanced technologies for their adaptability to environmental changes. While often costlier, correct specification and optimal use of these solutions are crucial to achieving both high performance and cost efficiency.

Financial Constraints & Market Realities

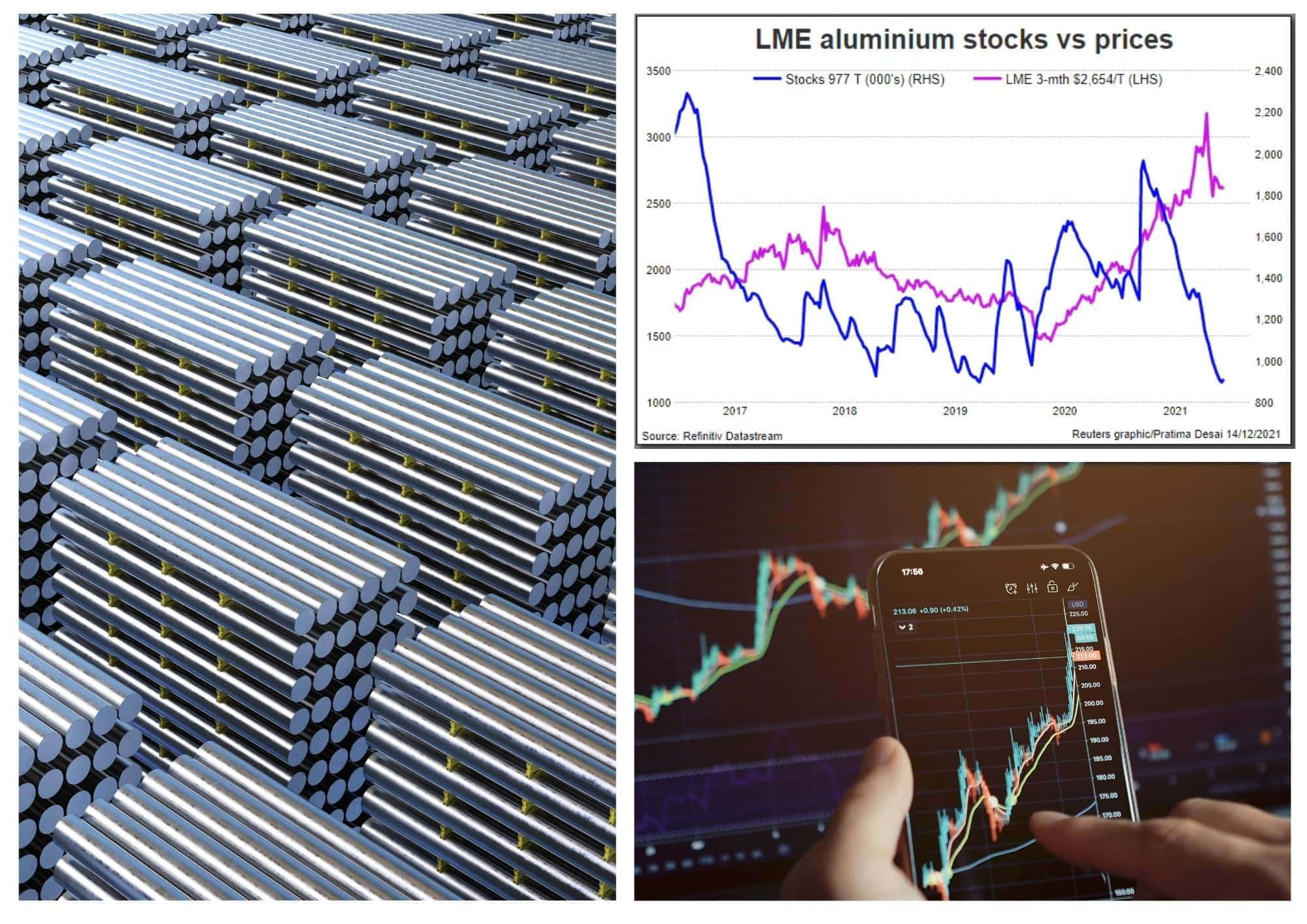

While innovation in façade glazing continues to advance, financial constraints remain a constant challenge. The construction industry is grappling with steadily rising costs driven by a combination of factors—surging raw material prices, increased transportation and logistics expenses, and a shortage of skilled labour, particularly in specialised trades such as glazing and cladding.

Simultaneously, developers and contractors face mounting pressure to deliver projects faster, more efficiently, and within increasingly tight budgets. With accelerated timelines becoming the norm, there is little room for delays or cost overruns, placing significant strain on the design, procurement, and installation phases.

Global inflationary pressures have further exacerbated façade pricing and availability. The unpredictable London Metal Exchange (LME) rates for aluminium profiles, along with fluctuating costs and inconsistent availability of accessories, often result in spikes in project budgets and extended lead times. This volatility forces project teams to adapt quickly or seek alternative solutions.

In this context, achieving design intent while maintaining budget discipline becomes a constant balancing act. Façade engineers and fabricators must look beyond traditional methods to identify smarter, more flexible approaches that deliver high-performance systems without compromising cost-effectiveness or project timelines.

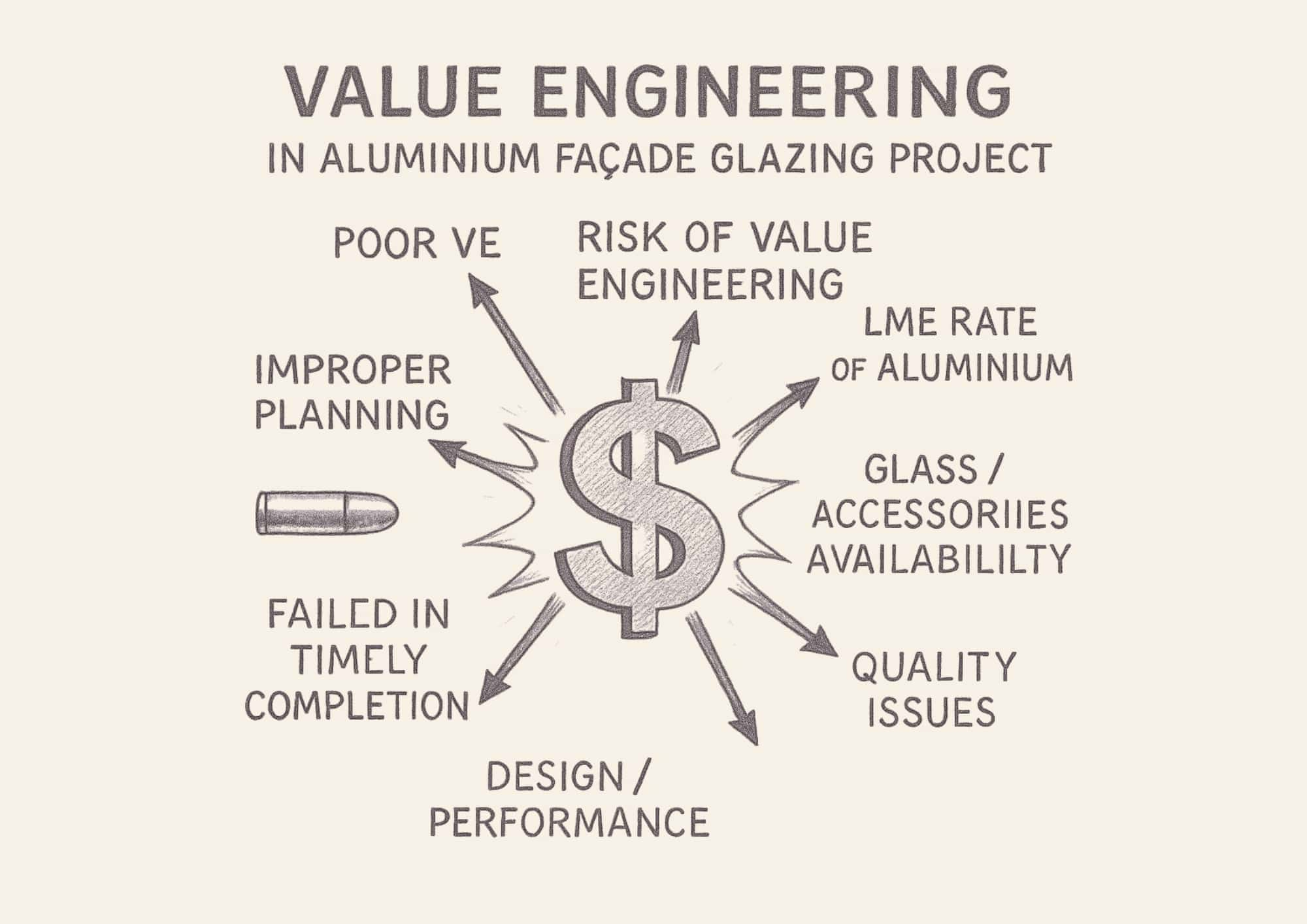

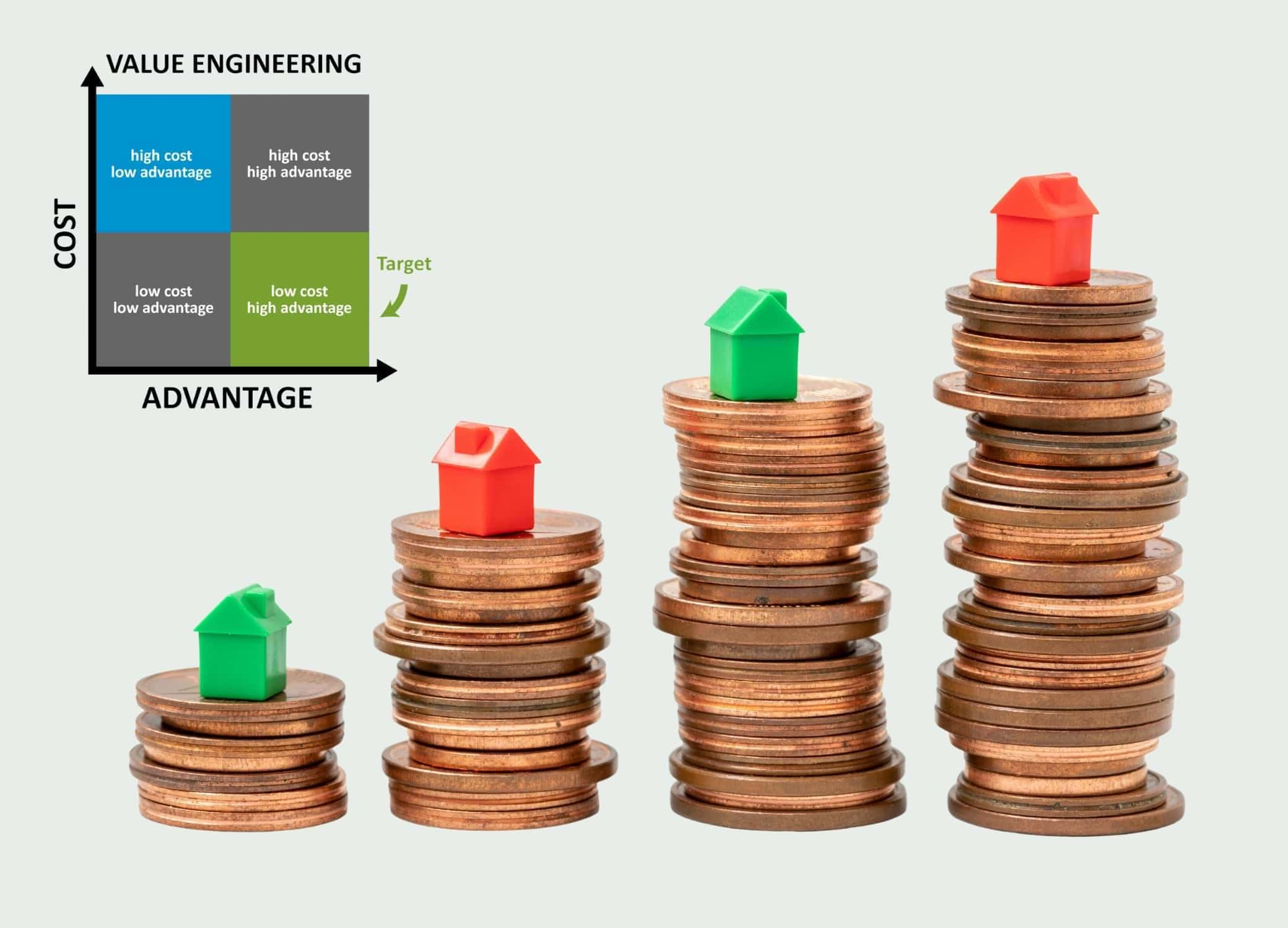

Value Engineering: Smart Design Decisions, Not Just Cost-Cutting

In the face of rising costs and tighter project margins, value engineering (VE) has become a crucial strategy in façade glazing. However, it is often misunderstood as a mere cost-cutting exercise. In reality, true value engineering is about optimizing performance, constructability, and aesthetics—while maintaining budgetary control.

Effective VE starts with a deep understanding of the project’s design intent and performance goals. It involves evaluating alternative materials, glazing systems, and fabrication methods that deliver equal or better outcomes at lower costs or improved efficiency. For example, replacing custom profile systems with standardised extrusions, or substituting laminated glass with performance-coated monolithic glass where possible, can result in significant savings without compromising safety or visual quality.

Early collaboration between architects, façade consultants, contractors, and fabricators is critical to successful value engineering. It allows teams to identify smart trade-offs, reduce material waste, and avoid rework or redesign later in the process. The goal is not to reduce quality but to ensure that every element of the façade delivers maximum value.

When done thoughtfully, VE becomes a tool for innovation, enabling the delivery of elegant, high-performance façades that meet both design vision and financial reality.

Practical Cost Optimisation Strategies In Façade Projects

Effective cost optimization in façade works starts with understanding the complete project scope and technical requirements. By analysing the specifications in detail, fabricators can propose practical, compliant alternatives without compromising performance or aesthetics.

Key Strategies Include:

- Aluminium Profiles: Propose the correct profile size and thickness through proper structural analysis, avoiding unnecessary material overuse.

- Labour Efficiency: Streamline fabrication through effective internal planning, proper labour allocation, and strong engineering to minimise waste and time delays.

- Glass Performance: Reduce the performance grade of high-spec glass if the project location does not require extremely low U-values.

- Glass Thickness: Perform structural calculations to determine the actual thickness needed. Reducing oversized glass panels or divisions can cut costs.

Challenges In Implementation

While cost optimisation brings clear benefits, implementing it in façade projects often uncovers real-world challenges:

- Stakeholder Misalignment: Architects focus on design, contractors on time and cost-without alignment, quality and performance suffer.

- Poorly Managed Value Engineering: Unreviewed changes to glass or profiles can harm structural integrity and thermal performance.

- Material Availability: Specified high-performance materials may be hard to source, causing delays or costly substitutions.

- Skilled Labour Shortage: Even the best designs fail without experienced façade installers.

- Site & Installation Constraints: High-rise access, tight logistics, and trade coordination can add unexpected time and cost.

Overcoming these challenges requires early coordination, realistic planning, and transparent communication-ensuring that cost-saving strategies are both technically sound and practically executable.

Embracing Smarter, Leaner Façade Strategies For The Future

The future of façade glazing lies in smarter, integrated approaches that balance innovation with cost-efficiency. In today’s environment, seamless collaboration between architects, engineers, fabricators, and system suppliers is essential, not optional deliver high-performing façades that are both inspiring and economically viable.

Leading trends include the adoption of slimline aluminium profiles from established system suppliers, paired with cost-effective glazing solutions, and precision-engineered accessories that further support cost-effective yet high-quality façade construction.

These advancements not only reduce initial costs but also improve ease of installation, durability, and long-term performance. The focus is increasingly shifting from upfront expenditure to total lifecycle value, considering energy efficiency, thermal performance, maintenance needs, and environmental impact.

Clients now prioritise solutions that offer long-term returns, both financial and ecological. As a result, digital tools, BIM integration, and data-driven design are becoming standard practices in value-focused façade execution.

To succeed in this evolving landscape, the façade industry must continue to push boundaries while staying grounded in real-world constraints—by embracing lean thinking, early coordination, and sustainable engineering.

Conclusion

The evolving demands of architecture require façades that are visually striking, high-performing, cost-effective, and sustainable throughout their lifecycle. Striking the right balance between innovation and affordability is essential. Effective cost optimisation relies on practical strategies such as precise material specification, structural accuracy, consideration of material availability, and upfront design focused on cost control, without compromising quality. Real-world challenges must be addressed through transparent communication and realistic planning.

By embracing value-driven engineering, advanced technologies, and lifecycle performance, the façade industry can deliver smarter, leaner, and more resilient building envelopes.

Avoid comparisons with low-cost, substandard fabricators; true cost control comes from intelligent engineering and quality-driven decisions, ensuring lasting value for both clients and contractors.