Construction, as an industry and a craft, is one of the oldest and most transformative elements of human civilisation. From early shelters built using mud and straw to towering skyscrapers made from steel and glass, the development of construction materials and techniques has always played a crucial role in shaping societies. Among the earliest significant milestones in human construction history are the large-scale buildings of ancient Mesopotamia, considered by many experts as the birthplace of urban construction.

In Mesopotamia, construction extended beyond simple dwellings. The people of this early civilisation built impressive structures such as temples, palaces, and ziggurats. These buildings were often constructed using intricate bricklaying methods that laid the groundwork for future architectural and engineering advancements.

Ancient Egypt, Greece, Rome, and China each contributed their innovations – be it the pyramids, aqueducts, amphitheatres, or complex wooden and stone structures. As urban populations grew, so too did the demand for larger, more durable, and aesthetically pleasing buildings. This led to the birth of professional architecture and engineering. By the 16th century, with increasing urbanization and the emergence of modern science, the construction industry began taking a more structured form.

The Industrial Revolution in the 19th century marked a turning point, as new materials like iron, steel, and concrete emerged. The period was defined by rapid technological advancement and mass production, which significantly transformed how buildings were constructed. In this period of innovation, new building materials also began to appear, one of the most pivotal among them being drywall.

The Rise Of Drywall In Modern Construction

The desire to build faster, cheaper, and safer structures led to the invention of drywall, also known as gypsum board or plasterboard. This material is mainly composed of gypsum plaster sandwiched between two sheets of paper or fibreglass. First introduced in the early 20th century, drywall quickly gained popularity due to its cost-efficiency, ease of installation, and fire-resistant properties. It revolutionised interior construction and is now standard in most residential and commercial projects.

As its success indoors became undeniable, the construction industry began to explore the possibility of using drywall in exterior applications. This led to the development of exterior drywall systems, which maintain the benefits of traditional drywall while introducing new qualities such as weather resistance and structural durability. These systems now offer a viable alternative to conventional brick and block walls.

Advantages Of Exterior Drywall

Exterior drywall systems are designed for use in façades, external walls, and even high-rise construction. These systems are often built using light-gauge steel frames, cement boards, jointing compounds, and water-resistant coatings. Below are several key advantages:

- Faster Installation: Compared to traditional brick or block walls, exterior drywall can be installed significantly faster – up to three times as quickly in some cases. This accelerated timeline can reduce construction project durations and associated labour costs.

- Labour Efficiency: Exterior drywall requires fewer labourers, which is particularly beneficial in markets experiencing labour shortages. The simplified process allows for faster training and deployment of crews.

- Cost Savings: Thanks to its lightweight nature and quick installation, the overall construction cost is often lower than that of masonry. The savings extend to transport and structural costs as the building requires lighter foundational support.

- Sound and Thermal Insulation: Modern drywall systems incorporate insulation layers that offer excellent soundproofing. They also support thermal regulation, which helps maintain comfortable indoor environments and reduces energy costs.

- Fire Resistance: Gypsum’s inherent fire-resistant properties make drywall systems safer in case of a fire, especially when used with fire-rated boards and assemblies.

- Superior Aesthetics: Exterior drywall provides a flat, smooth surface with sharp edges and corners, resulting in a high-quality finish. This makes it particularly attractive for architects and designers seeking modern, clean façades.

- Greater Height without Beams: Using steel frames, drywall systems can reach heights of up to 8 metres. without intermediate support beams – something challenging to achieve with conventional masonry.

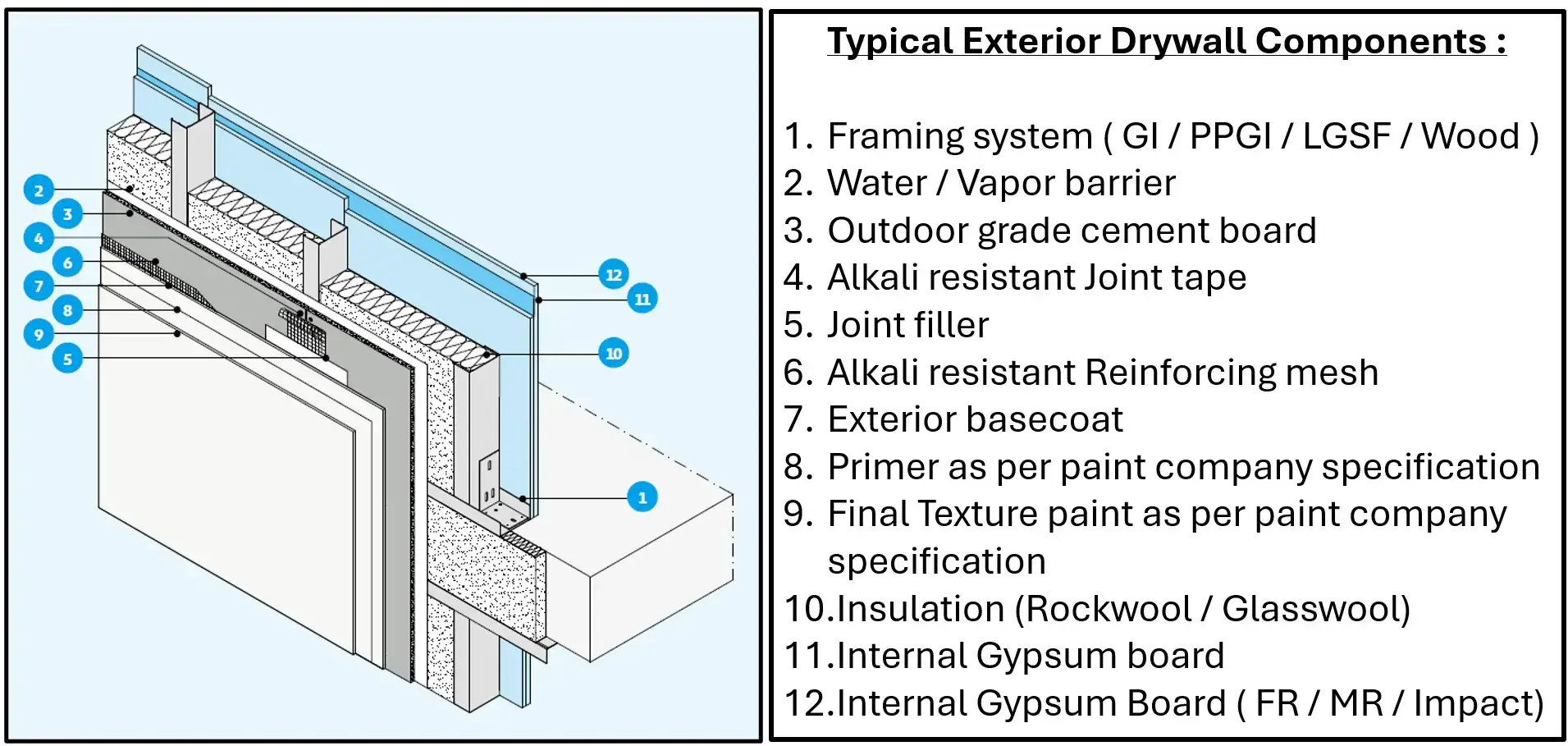

Key Components Of An Exterior Drywall System

An exterior drywall system is a multi-layered structure that must meet specific environmental and structural demands. Each component is essential in delivering overall performance:

- Framing System: The structural backbone of any drywall installation is the frame. Typically made from galvanised light-gauge steel, the frame must be resistant to moisture, rust, and pests. Important considerations include:

- Corrosion Resistance: Steel or treated wood framing should resist environmental damage. Frames made using PPGI (Pre-Painted Galvanised Iron) have very high protection against corrosion and weathering.

- Load-Bearing Capacity: Must support the weight of boards, insulation, and cladding.

- Wind Load Resistance: Critical for high-rise and coastal buildings.

- Seismic Compliance: Must include reinforcements in earthquake-prone areas.

- Stud Spacing: 400mm centre-to-centre is the standard for better structural support.

- Weather Barriers: Proper wrapping and waterproofing prevent water intrusion.

- Sustainability: Steel is highly recyclable, supporting green building standards.

- Exterior Cement Boards: The exterior boarding is the most critical layer exposed to the elements. These boards are usually made from cement, sand, and fibreglass mesh, offering a robust, weather-resistant surface.

Key Features:

- Water Resistance: Prevents swelling, warping, and mould development.

- High Durability: Withstands impact, compression, and structural shifts.

- Fire Safety: Most boards meet Class A fire ratings.

- Fungal Resistance: Non-organic components resist mould and mildew.

- Freeze-Thaw Tolerance: Especially important in colder climates.

- Ease of Installation: Boards should be lightweight, pre-scored, and adaptable.

- Certifications: Look for ASTM C1325 and eco-labels like LEED or GreenGuard.

- Basecoat (Finishing Layer): The basecoat serves as a preparatory surface between the cement board and the final aesthetic finish (such as textured paint or tile).

Important Properties:

- Adhesion: Must strongly bond with both the cement board and topcoat (usually a textured paint).

- Waterproofing: Should form a barrier against rain or humidity.

- Crack Resistance: Durable against temperature expansion and building movement.

- Impact Resistance: Protection from environmental or mechanical damage.

- Vapour Permeability: Allows moisture to escape while preventing water ingress.

- UV & Weather Resistance: Should not degrade under sun exposure or freezing cycles.

- Workability: Easy to spread and compatible with trowel or spray application.

Common basecoat types include cement-based, acrylic-based, polymer-modified, and lime-based products.

- Interior Gypsum Boards: The interior side of the drywall system can be customised depending on the room’s function. Common types include:

- Moisture-Resistant (Green Board): Ideal for bathrooms or kitchens.

- Type X Fire-Rated Board: For added fire protection.

- Mould-Resistant Board: Used in humid environments.

- Impact-Resistant Board: Best for high-traffic areas.

- Paperless Boards: Offer top-tier mould and water resistance.

Vapour barriers are crucial for moisture control, especially between interior and exterior wall environments.

Benefits include:

- Moisture Prevention: Blocks water Vapour migration that could lead to rot.

- Mould Mitigation: Keeps inner wall cavities dry.

- Energy Efficiency: Helps insulation perform better by limiting moisture.

Vapour barriers can be membranes or coatings applied over or behind the drywall, depending on local climate zones.

The Future Of Exterior Drywall

The construction industry is embracing rapid innovation, and exterior drywall systems are no exception. Here’s what the future holds:

- Sustainability: More manufacturers are adopting eco-friendly practices, such as using recycled materials or reducing emissions in production. Boards and coatings are being developed with lower VOCs (volatile organic compounds), contributing to healthier buildings.

- Smart Technology Integration: Future drywall systems may include embedded sensors that monitor structural integrity, humidity, temperature, or even seismic activity. These innovations could provide real-time data on building health and performance.

- Enhanced Insulation and Resilience: New research is focused on improving drywall’s ability to withstand extreme weather, such as hurricanes, high winds, or heat waves. Products are emerging with improved thermal insulation and impact resistance without sacrificing weight or installation speed.

- Modular Construction Compatibility: Exterior drywall systems are well-suited for modular and prefabricated construction, where building parts are manufactured off-site and assembled rapidly on-site. This method promises speed, cost-efficiency, and reduced waste.

- Regulatory Evolution: As governments and industries adopt stricter building codes for energy efficiency, fire safety, and environmental impact, drywall systems will continue evolving to meet these standards.

Case Study – 1

Oberoi Flight Kitchen Services, Sahar – Mumbai

The OFS building is a pre-engineered building with varying exterior wall heights. The steel structure joints between the masonry wall and Steel members were a major concern for both architects and clients. Wall heights varying from 3m to 5m were another challenge for construction.

Akash Impex provided a double board solution with specially imported exterior-grade PVC reveal beads to create an elegant-looking exterior drywall. By using TYVEK Vapour barrier walls were well protected against any seepage and leakage issues.

Quick Facts:

|

Case Study – 2

Oberoi Maxima, CTRLS Data Centre – JVLR, Mumbai

This is a 2-hour fire-rated exterior drywall project. The client wanted to build an exterior drywall to envelop a fire chute, which was constructed using MS structures outside on a fire staircase. The fire chute starts from the 4th floor and extends up to the 29th floor. The detailing of drywall termination on the stair wall and termination on every floor I beam was carefully planned to make sure there is no water leakage/seepage. An additional layer of Vapour barrier was used just behind exterior cement boards to make sure there is no water/vapour ingress inside the drywall cavity.

Quick Facts:

|

Case Study – 3

CTRLS Data Centre, JVLR – Chennai

The client wanted to quickly pack up the transformer room openings on an exterior wall. A major part of the exterior wall had already been done in AAC blockwork, and for the transformer room openings, the client was looking for a fast installation. The exterior drywall solution was designed specially for a 2.8 KPA wind load and 4.8 m height for Chennai. After the final painting, it is very hard to find the difference in appearance between block work and drywall. The drywall seamlessly blends with blockwork to give a uniform look to the façade.

Quick Facts:

|