Benefits Of Positive Full Mechanical Retention Brackets Over ‘Push-To-Fit’ Brackets

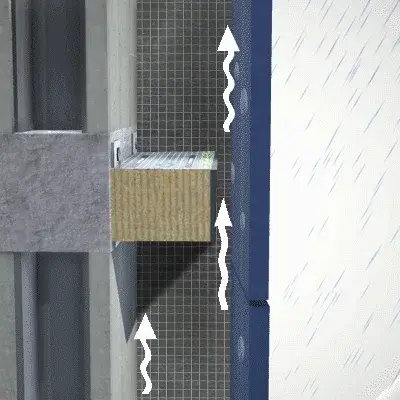

Horizontal open state cavity barriers (OSCBs) are vital to ensuring the passive fire safety and effective moisture management of ventilated building façade systems with a cavity. In general use (sometimes referred to as the ‘cold state’), they allow any moisture that penetrates the ventilation cavity between the inner wall and external cladding to drain away or evaporate, which is important in zones with high relative humidity or relentless monsoons. However, in the event of fire, the intumescent layer on the exposed edge of the barrier activates at approximately 266°F/130°C, causing it to ‘exfoliate’ and close the concealed cavity, creating a robust fire and smoke seal.

To ensure they can provide this performance for the designed life of the building, OSCBs must be securely and appropriately fixed to the internal substrate with a retention method that prevents barrier displacement. Façade designers, engineers, consultants, specifiers and installers need to understand the different types of fixing methods, the risks posed by insecure fixings and inadequate retention, and the requirements for ensuring their projects adhere to best practice.

How Can The Fixing Method Impact The Performance Of Open-State Cavity Barriers?

Buildings and their façades are constantly subjected to forces that can cause them to move, such as wind loads, settlement and temperature changes. In a fire, heat-induced air pressure and thermal expansion place further stress on brackets and fixings. If these lack sufficient tensile strength or retention capability, these factors can all potentially cause them to fail and the OSCBs to completely or partially detach from the internal construction.

In addition to the possibility of thermal and moisture management issues resulting from fallen cavity barriers obstructing ventilation and drainage flow in the cavity, which can lead to damp-related problems such as condensation, corrosion and mould growth, barrier displacement can severely compromise the building’s compartmentation. Any gaps that form between the substrate and the rear of the barrier can allow fire and smoke to spread vertically through the unseen cavity – the ‘chimney effect’. Meanwhile, severe misalignment of the OSCB can lead to its intumescent layer not exfoliating within the limits of its stated air gap range, thus failing to form a complete seal against the opposing surface by not fully closing the width of the void.

To mitigate these risks, OSCBs must be selected with support brackets and fixings that are designed to keep them securely in position even when subjected to differential movement or fire-induced stresses, and that allow for the intumescent to fully exfoliate when exposed to the heat of a fire.

Fixing Approaches For Open State Cavity Barriers

There are several common approaches to mechanically fixing cavity barriers:

- Direct through-fix to substrate using non-combustible fixings (small voids): Usually stainless-steel countersunk head screws with a washer that sits flush with the intumescent face and that is screwed at a sufficient depth into the substrate.

- Mechanically fixed partial penetration brackets (large voids): Usually stainless-steel spikes that penetrate the width of the barrier by typically 50-75% and are fixed to the backing wall using non-combustible stainless-steel fixings, sometimes with pigtail screws piercing through the intumescent into the barrier.

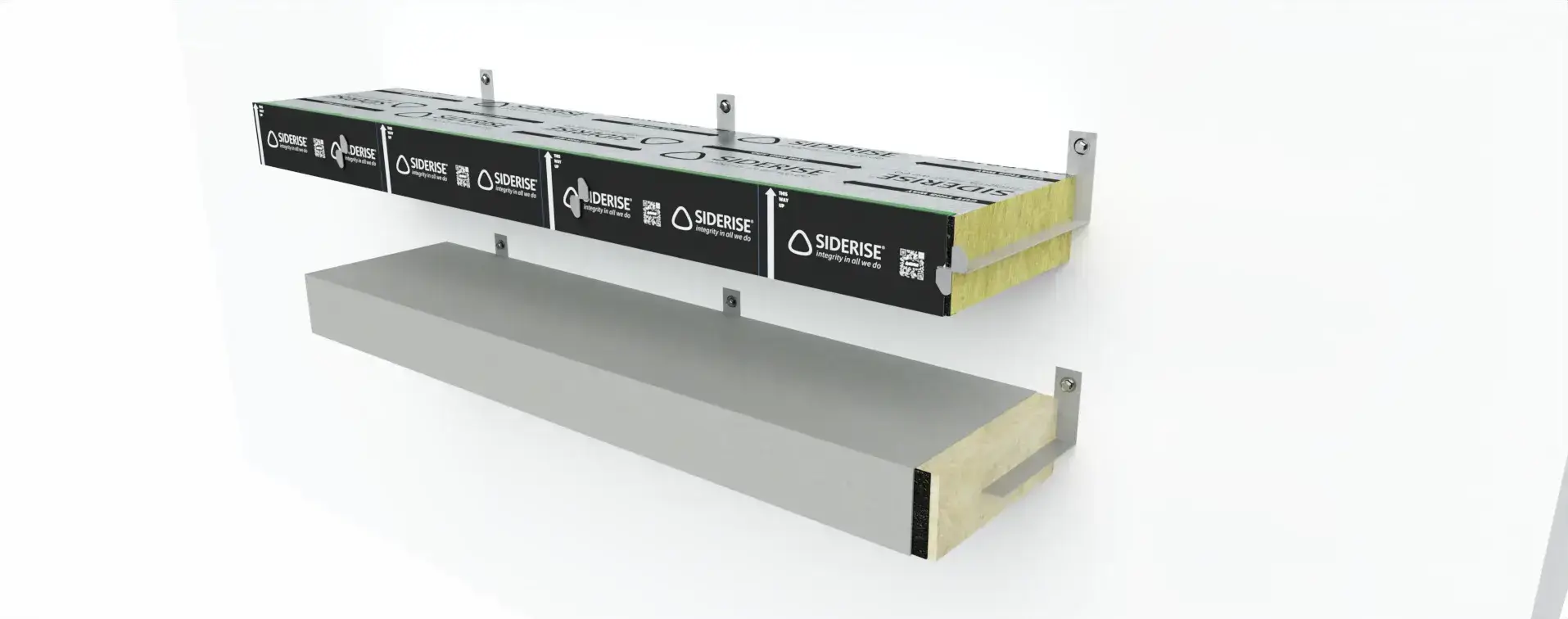

- Mechanically fixed full penetration brackets with bent tails (large voids): As above, without pigtail screws but with ‘tails’ piercing through the intumescent on the leading edge of the barrier that faces the open airspace of the cavity. These are bent flat, or ‘counter-folded’, to the outer face to positively retain the barrier and the intumescent.

Advice from the industry-led Centre for Window and Cladding Technology (CWCT) based in the UK reinforces the need for barriers to be tightly fitted to a rigid construction and mechanically fixed in position so that their performance is not rendered ineffective by failure of the barrier fixings during a fire, building and external envelope movement, or the collapse of penetrating services or failure of abutting construction.

It advocates more specifically for open state cavity barriers used within ventilated façades to be fixed with brackets that penetrate the full thickness of the barrier with tails bent over to positively retain the barrier in position.

For instance, Section 6.6.3.2.3 of Guidance on Built-up Walls (CWCT (2017) Guidance on Built-up Walls: https://www.cwct.co.uk/products/built-up-walls) that focuses on cavity barriers in rainscreen constructions states:

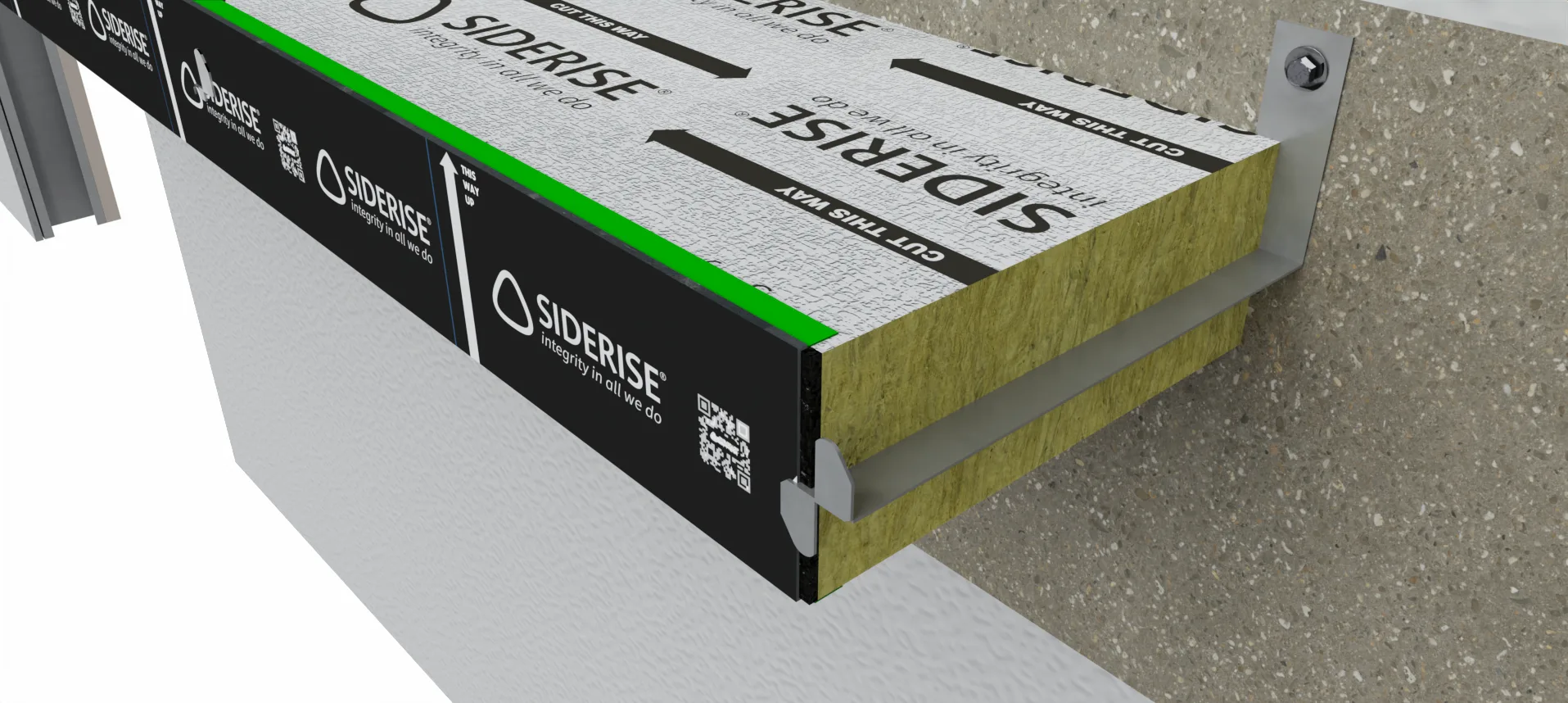

“To be effective, these should be securely fixed to the face of the back wall or preferably, for cavity barriers on the line of compartment floors, the concrete slab edge. This will require a break in the thermal insulation in the rainscreen cavity… Steel spikes are used to fix the barriers, and these should penetrate the full thickness of the barrier with the tails turned over to positively hold the barrier in position. Failure to do this may allow the barrier to fall into the cavity, making it ineffective as a fire barrier and possibly blocking drainage.”

In section 4.24 of the guidance, it cites instances where this issue has been encountered, demonstrating that this is a very real potential problem: “Cavity barriers should be positively fixed in position to ensure their effectiveness. Cases of barriers sliding off spikes and collecting at the foot of the cavity have been reported.”

Furthermore, CWCT places specific emphasis on the difference in effectiveness between full penetration and partial penetration brackets in its Technical Note 98: “Spikes which penetrate the full width of the fire barrier with tails that can be bent over are likely to be more effective than spikes that only penetrate partway through the barrier but without support from the envelope.”

Positive Full Penetration Mechanical Retention Brackets Vs Partial Penetration ‘Push-To-Fit’ Brackets

Using OSCBs with full penetration brackets that have retaining bent tails can support effective compartmentation and firestopping in several ways. They firstly enable the cavity fire barrier to be firmly secured to the substrate, preventing it from moving laterally during its service life. This enables it to maintain contact with the backing wall to provide an effective cavity barrier.

Full penetration brackets can also help to support the structural strength of the cavity barrier by allowing the weight of the barrier to be supported by the inner leaf, instead of relying on the tensile strength of the bracket alone. Additionally, an equilibrium is created between the barrier’s outer face and the bent tails when the bracket is fixed to the substrate above the OSCB, which can increase the structural strength of the OSCB to prevent sagging.

These types of brackets also offer benefits during the installation stage. Whilst bending the bracket is a small step to accommodate build tolerances such as deviations in the cavity’s dimensions, these types of brackets are often supplied with pre-engineered features that not only save time but also help to ensure an accurate installation and that the product is fit for purpose. For example, they are typically available in a range of lengths to suit different void sizes and with fixed-length tails, eliminating the need to cut them to size on-site. They also often feature pre-drilled fixing holes, as well as a notch feature to make them easy to bend to the right shape, and the use of bracket-bending tools helps expedite the bending process.

Additionally, as they do not rely on the external wall covering for retention, they can be fitted at an earlier stage of the construction process, reducing scheduling stresses. They are also much less likely to be dislodged or disrupted during the installation of the external envelope. Some types of open state barriers, on the other hand, require hand-screwed pigtail screws to be wound out until they touch the inside face of the cladding – after the cladding has been installed.

Ensuring Installation Quality Of Positive Full Penetration Mechanical Retention Brackets On-Site

The CIOB-RIBA Guide to Managing Safety-Critical Elements in Building Construction (CIOB-RIBA (2023) Guide to Managing Safety-Critical Elements in Building Construction: https://www.architecture.com/knowledge-and-resources/resources-landing-page/a-riba-guide-to-managing-safety-critical-elements?srsltid=AfmBOopjXgmQMHs3DDUkZWj3cjcHjYwdqmWiPcCLIu4bRT2Cg91YMLB9) stresses the importance of inspecting cavity barriers as safety-critical elements, stating that: “[F]or all Elements that contribute towards fire and smoke compartmentation of a building – The compartmentation must be assumed to be part of a considered design, so there could be a significant risk of a serious injury or fatality if it was compromised by incorrect installation and there was a fire. Therefore, the compartmentation in its totality is a Safety-Critical Element.”

Cavity barriers whose retention is reliant on the external façade being installed can present a challenge when it comes to inspection, requiring a section of the all covering to be deconstructed to check how they have been fitted. Meanwhile, full penetration brackets with bent tails can simplify this process as their visible tails eliminate the need for destructive inspections in build-ups where the thermal insulation abuts the OSCB from both above and below.

It is worth noting that some manufacturers of OSCBs offer both in-person and remote inspections via specifically developed inspection apps. Suitable for standard systems, the apps allow users to capture images as each area/element is installed and update the data input fields using their smartphone or tablet. These can then be reviewed off-site by the manufacturer’s technical team to ensure the installation meets recommendations and quickly identify any potential issues with the fixing methods. Where a manufacturer inspection has taken place, either by app or in-person, the final report can be included in the handover information, providing a clear record of exactly what passive fire protection measures are in the building and how it was installed. This helps to maintain a thread of product information and can be a useful reference point for any future modifications to the project that may affect the building envelope.

Testing And Certification To Consider

As the fixing method is so integral to the performance of OSCBs, it is important to look out for products that have been subjected to testing with their fixing methods. This includes identifying products with a measured and defined design life, and that have been put through tests that replicate their intended application – demonstrating that they maintain integrity in real-world thermal and mechanical conditions.

The Association for Specialist Fire Protection (ASFP) Technical Guidance Document TGD 19 (Association for Specialist Fire Protection (2017) Technical Guidance Document TGD 19: https://asfp.site-ym.com/store/viewproduct.aspx?id=19779888) and the recently published European standard EN 1364-6: 2025 standard both outline the test configurations and failure criteria for the testing of OSCBs.

Whilst these tests can determine standalone cavity barrier performance, and therefore general suitability for the purpose it is marketed for, it is only through large-scale testing that we can fully understand how complete assemblies might perform in a real-life fire scenario. Such testing examines all the system components together, providing data on how the different products interact, along with the impact of details such as fixings, joints, gaps, and penetrations on the overall fire performance. Therefore, data from large-scale systems tests such as NFPA 285 and BS 8414-1 & 2 that evaluate the performance of a complete external wall assembly can be invaluable when considering any type of cavity fire barrier.

It is important to note that, even with the inclusion of positively retained cavity barriers, systems can fail if the exterior wall covering allows the fire to spread up the outside of the building, causing the panels to move, break down or detach and fall. Any malfunction with the cladding would likely leave a path for the flames to spread up and over the cavity barrier and up the cavity. Therefore, it is vital to always refer to the latest specialist advice for façade design and specification, and to ensure high-quality workmanship at every stage.

Positive Process, Positive Results

People know the value of fire safety and the importance of compartmentation, and whilst the use of cavity barriers within India’s buildings that have cavities behind external cladding systems is not yet mandated, it is increasingly becoming standard practice and with that needs to be a widespread understanding of not only what they do but also how they must be used to achieve the appropriate compartmentation. Properly designed OSCBs, that use mechanically fixed, full penetration brackets with bent tails that can withstand the rigours of environmental changes, serviceability movement and thermal stress, are key to upholding industry best practices and standards – ensuring buildings remain protected throughout their lifecycle.

For Further Information,

Please Contact

Siderise’s Fire Safety Technical Support Team

Email: smetech@siderise.com