We see glass being used all around us – curtain walls, elegant balustrades and expansive skylights – but do we critically evaluate the role it plays in ensuring safety? Glass is beautiful. Yet, when not selected and installed correctly, it can become a serious hazard. A single failure can lead to serious injuries and even catastrophic accidents.

This article explores the different types of safety glass, where they should be used, and the key considerations for architects, engineers, and contractors to ensure compliance and safety in modern buildings.

Definition Of Safety Glass

For a glass product to be classified as safety glass, it must meet specific performance standards, which include:

- Impact Resistance (e.g., ANSI Z97.1, EN 12600, or BS 6206)

- Breakage Pattern (reducing risk of severe injury upon failure)

- Post-Breakage Performance (retaining fragments and preventing collapse)

Types Of Safety Glass And Their Applications

- Toughened (Tempered) Glass: Toughened or Tempered Glass is processed by controlled thermal and chemical treatments on annealed glass, which increase its strength. The process called toughening increases tensile strength, thermal shock resistance, heat withstanding capacity and safety of normal glass. The high load resistance capacity of toughened glass makes it an ideal choice for areas requiring high load resistance.

Image courtesy – Glass Genius, Kratos Glass Another important characteristic of the glass is its breakage pattern: Toughened glass shatters into small, blunt fragments, rather than large, sharp pieces as seen in annealed and heat-strengthened glass. This makes it an ideal choice as the outer lite for shop front glazing, doors, and windows at low heights, as well as for internal partitions. If the glass breaks, toughened glass minimises the likelihood of severe injury or fatality for occupants.

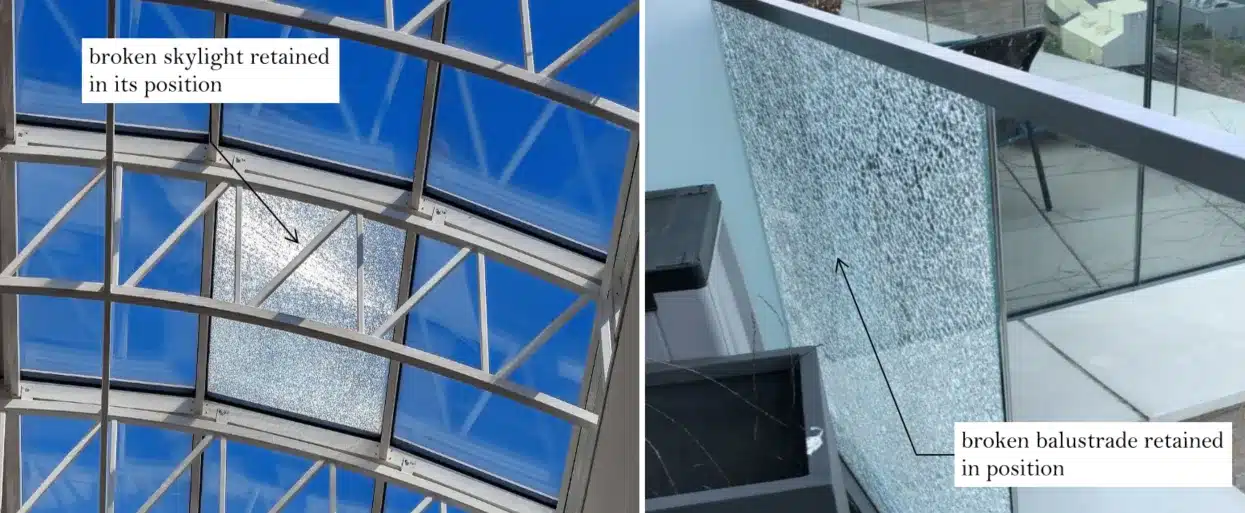

However, the same breakage characteristic of toughened glass could pose a serious safety concern when used at height. Even a small fragment falling from a great height can gain enough energy to cause fatal injuries. Additionally, the toughening process can introduce nickel-sulfide impurities into the glass, causing it to break spontaneously, without any external force. Hence, monolithic toughened glass is not considered “safety glass” when installed for glazing at height.

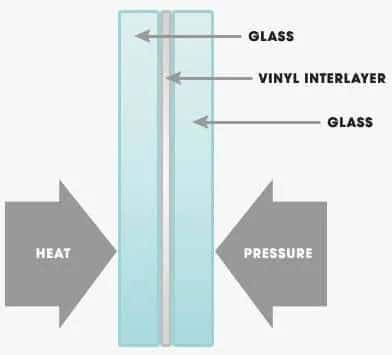

- Laminated Glass: Laminated glass is simply two or more glass layers bonded with an interlayer (PVB, SGP, etc.). The key advantage of laminated glass is that it is held together even when broken. Hence, it is most suited for applications such as skylights, balustrades, overhead glazing and high-security applications (bullet-resistant and blast-resistant glass).

While laminated glazing holds broken fragments together, it is important to note that not all laminated glass is true “safety glass.” The choice of interlayer, support system, and post-breakage behaviour determines whether it can effectively protect against injuries and structural failure. Hence, it is important to consider the following conditions when specifying laminated glass as safety glazing.- Annealed laminated glass is not considered “safety glass” because it has very low strength. When it breaks, it forms large, sharp shards that can potentially tear through the interlayer, increasing the risk of injury.

- Standard PVB is flexible and weak, leading to sagging of the panel after breakage. If the glass sags or detaches from its frame, it creates serious hazards, especially in overhead glazing, balustrades, or point-supported systems.

- Frameless or minimally supported laminated glass is vulnerable to failure if the interlayer lacks sufficient strength. The entire glass panel can lose structural integrity and collapse under its own weight, behaving like a heavy, flexible sheet – a “wet blanket”. In overhead glazing, balustrades, or façades, this failure mode can be deadly, as an entire panel falls from height, potentially injuring people and damaging property.

- When laminated glass is used in balustrades and façades, it is required to perform as a protective barrier. However, if the panel collapses, it fails to act as a barrier, compromising occupant safety.

- Laminated heat-strengthened glass is the optimal safety glazing solution that combines high strength, improved breakage safety, and compliance with building regulations. HS glass has much larger strength than annealed glass, making it more resistant to mechanical loads, wind pressure, and thermal stress. After breaking, the laminated interlayer holds the glass pieces together, preventing full collapse and providing post-breakage load-bearing capacity.

- Where a higher design load necessitates the use of FT glass, a structural interlayer such as SGP can be used, providing post-breakage support.

- Annealed laminated glass is not considered “safety glass” because it has very low strength. When it breaks, it forms large, sharp shards that can potentially tear through the interlayer, increasing the risk of injury.

- Wire-Glass: Wire-reinforced glass includes an embedded metal mesh that holds the fragments together upon impact. It is often used in fire-resistant applications due to its ability to withstand high temperatures.

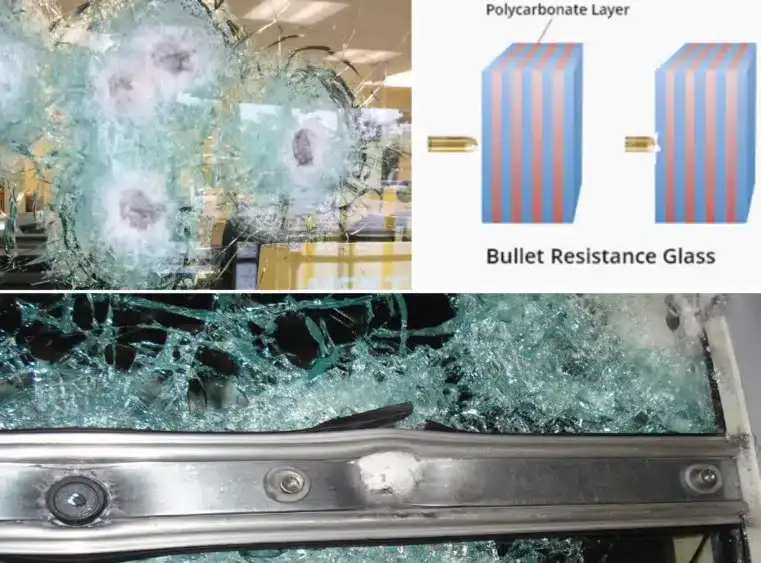

- Bulletproof Glass: Bulletproof or ballistic glass is a specialised form of laminated glass with multiple interlayers, providing high resistance against projectiles. It is used in banks, government buildings, and high-security areas. A ballistic-resistant glass panel alone is ineffective if the frames, mullions, transoms, and connections are weak points. Design of ballistic-resistant glass requires a holistic approach, integrating reinforced framing and impact-resistant connections.

Conclusion

Glass is a defining element of modern architecture, bringing transparency, elegance, and structural innovation to our built environment. However, its safety cannot be an afterthought. The consequences of improper glass selection and installation can be severe, leading to injuries, structural failures, and even fatalities. By making informed choices and adhering to best practices, we can ensure that glass remains a symbol of innovation without compromising safety.