When you look at a modern building, whether it is a towering skyscraper, a smart commercial space, an airport, or a luxurious home, what stands out first is the façade. It is the face of the building, a blend of design and functionality. Alongside, fenestrations (like windows and glazed openings) play a vital role in allowing light in, providing ventilation, and ensuring comfort indoors. While we often focus on the aesthetics and glazing materials, there is one part that quietly holds everything together – the hardware.

From hinges and handles to brackets and locks, hardware might be small in size, but it plays a massive role in how well a façade or window system performs over the years. If chosen wisely and tested properly, the right hardware can ensure your façade system works smoothly, resists weather, and stands strong for decades.

Let’s break down why choosing the right hardware and proper testing is critical and how it all works in real-life applications.

Why Hardware Matters More Than We Think

Hardware is the hidden backbone of any façade or window system. Think of it like the joints in a human body. Just like our joints help us move, open, close, and bear weight, hardware allows glass panels, aluminium frames, louvres, and windows to function efficiently and safely.

Poor Hardware Choices Can Lead To:

- Windows that do not shut properly, letting in water or air.

- Loose panels or cladding during strong winds.

- Difficulty in operation over time.

- Safety and security risks.

- Higher maintenance or replacement costs.

That is why the selection of hardware should never be an afterthought. It should be planned right from the design stage.

Key Design Factors When Choosing Hardware

While selecting hardware, we need to think beyond just fit and finish. Here are some essential design factors that guide the selection:

- Load Capacity: Hardware must support the weight of the glass or panel. For example, operable windows with large glass panels need heavy-duty hinges and friction stays.

- Movement And Expansion: Buildings expand and contract due to heat, cold, and wind. Hardware should accommodate this without getting loose or jammed over time.

- Wind Pressure: In high-rise buildings or coastal areas, wind pressure is intense. Hardware should be capable of holding the structure in place even under storm conditions.

- User Experience: Hardware should be easy to use, especially in residential and public buildings. Smooth handles, simple locking systems, and accessible designs are essential.

- Compatibility With The System: It is important to use hardware that is compatible with the framing system, glass thickness, and overall façade engineering. Otherwise, it may fail even if it is high quality.

Material Matters: Choosing The Right Hardware Material

The environment in which the building is located has a huge impact on the kind of materials we should use in hardware.

- Stainless Steel (SS 304 or SS 316): Ideal for coastal areas due to its corrosion resistance. SS 316 has even higher resistance, making it suitable for harsh environments.

- Zinc Alloys: Often used for locks and handles. Cost-effective but needs protective coatings for durability.

- Anodized or Coated Aluminium: Lightweight and rust-resistant, but not as strong as steel. Good for small to medium loads.

- Engineered Plastics (Nylon, Polyamide): Used in rollers, bushings, and weather seals. Reduces friction and noise.

In most cases, manufacturers combine different materials based on function and exposure. For example, a hinge might have a steel core and nylon bushings.

Testing For Long-Term Performance

Testing is what separates assumption from assurance. Even the best-looking hardware might fail if not tested under real-world conditions.

Common Tests For Hardware And Façade Systems

- Cycle Testing: Hardware is repeatedly operated (e.g., opened/closed 25,000 times) to test durability.

- Salt Spray Test (ASTM B117): Used to check corrosion resistance, especially for coastal or polluted zones.

- Air & Water Infiltration Test (ASTM E283/E331): Checks if the system resists air leaks and water entry under pressure.

- Thermal Cycling: Hardware is exposed to extreme temperatures to check expansion, contraction, and durability.

- Impact Testing: Especially for high-security areas or cyclone zones where resistance to sudden impact is crucial.

Hardware that passes these tests gives peace of mind that the system will perform reliably for 20–30 years or more.

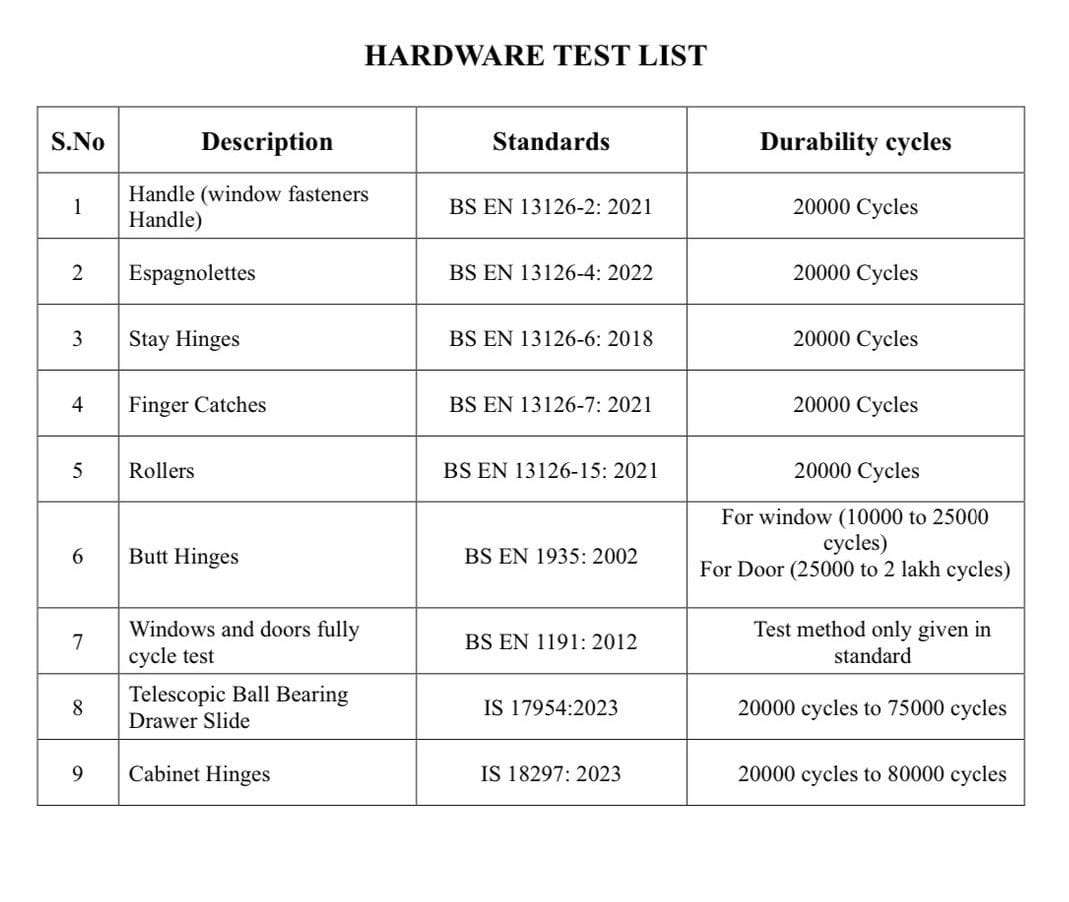

Hardware Test List:

Sustainability And Energy Efficiency

You may wonder, how does a small piece of hardware contribute to sustainability? The answer lies in energy efficiency and lifecycle durability. Good-quality hardware ensures:

- Windows seal tightly, reducing air leakage.

- Reduced energy bills due to better insulation.

- Lower replacement frequency means less material waste.

- Durable systems that do not need frequent fixes or upgrades.

Some manufacturers also offer eco-friendly hardware made with recyclable or low-carbon materials, aligning with green building certifications like IGBC, LEED, or GRIHA.

Maintenance, Safety, And Smart Features

Selecting the right hardware also affects long-term maintenance and safety.

- Ease Of Maintenance: Hardware should be easy to access, lubricate, or replace without disturbing the whole system.

- Safety Features: Restrictors, child locks, and anti-lift mechanisms help in public buildings and homes.

- Smart Hardware: Some advanced hardware comes with sensors that notify facility managers about usage, faults, or even attempted break-ins. These can connect with building management systems (BMS) for smarter operation.

Conclusion: It Is Not Just About Looks – Performance Is Key

When designing or installing a façade or fenestration system, never underestimate the role of hardware. While it may seem like a small component compared to glass or aluminium, it holds everything together and keeps it functioning smoothly.

Choosing the right hardware – based on design needs, environment, material compatibility, and usage pattern – and ensuring proper testing leads to a system that performs efficiently for decades. It improves energy performance, reduces maintenance hassle, and, most importantly, ensures safety and durability.

In a world where buildings are becoming smarter, greener, and more complex, hardware is no longer just a mechanical add-on – it is an essential part of the building’s long-term success.