The envelope of every major building needs to be accessed, maintained and cleaned to an immaculate finish and appearance. This becomes all the more important when we deal with complex geometries in modern architecture, high-rise structures, Power Skin enclosure and its components. With contemporary architecture growing more and more complex, accessing the building envelope has become an extremely difficult task. To access and maintain them, it is quite often necessary to have custom-designed and engineered systems in addition to the standard equipment available from the manufacturers. Barring some straightforward buildings, it requires special knowledge of the available system options to be applied. The architects and building envelope designers need to have adequate knowledge of façade access systems available and required for their buildings, which is essential for them to use the best possible choices. This article endeavours to study, illustrate and determine the importance of planning façade access systems, selection criteria and application for building façade access and maintenance.

Why Do We Need To Plan Façade Access BMU Systems For A Building At The Design Stage?

Ideally, the best stage to plan façade access requirements for a building is the design stage. Determining façade access requirements and incorporating them in the building design results in the most appropriate, functional and cost-effective result.

The following need to be taken into account in the selection and application of appropriate façade access systems for the buildings.

- Cleaning cycle requirements.

- Other maintenance, frequencies and durations.

- Material hoisting requirements with weights and sizes, and frequency.

- Architectural considerations, equipment visibility and whether screening equipment from vision is required.

- Provision of space for equipment and structural load-bearing capacity at an available location to support equipment.

- Availability of electric power supply, cleaning water supply, wastewater disposal and BMS connection if required at the equipment location.

The above information, which will define system requirements, needs to be obtained from building designers, architects, structural designers, consultants, MEP engineers, façade engineers and facility managers.

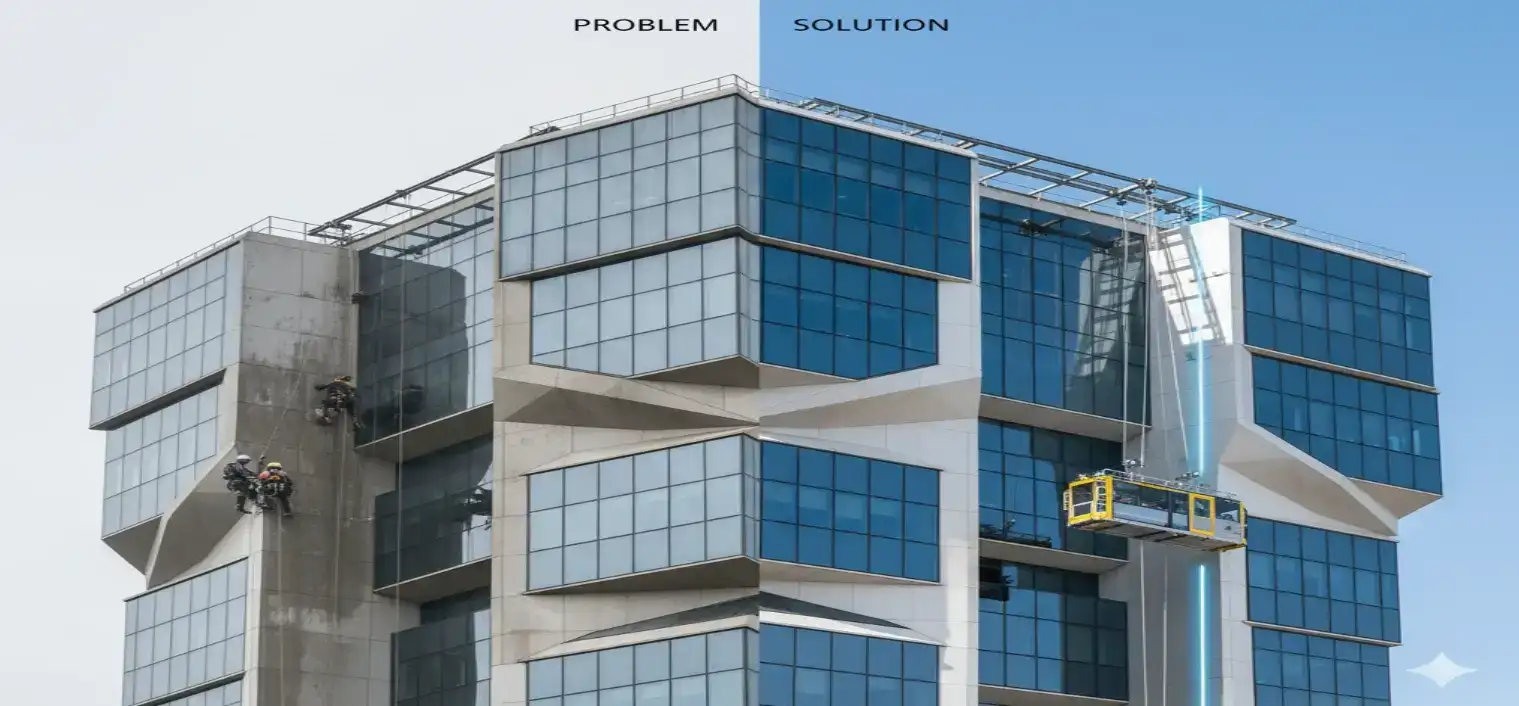

There are instances where façade access provision is not taken into account during the design stage and considered later during building construction, or even worse, after construction. In such a situation following difficulties occur in most cases:

- Building may require redesign and modification to accommodate a façade access system that had not been taken into account in the original design.

- The options to have an appropriate façade access system may be limited, and one may need to settle for an option that may be an inferior solution compared to the choices available at the design stage.

- The cost of having a façade access system may be substantially higher since redesigns and modifications may be required.

It is best to avoid this scenario.

Most Commonly Used Façade Access Systems

Building Maintenance Units (BMU): These are the most commonly used systems and are roof-based, most practical, cost-effective and easy to use.

Davit System: When installation of BMU is not possible on the roof, Davit systems are frequently used, though handling and operating the davits is labour-intensive manual work. This, however, is not suitable for heights above 100m due to the utilization of traction hoists and suspended electric cables, both unsuitable for heights.

Monorail System: Whenever installation of BMU or davits is not possible on the roof, monorail systems are the most frequently used system, which mounts on elevations. This, however, is not recommended for heights above 100M due to the utilisation of traction hoists and suspended electric cables, both unsuitable for heights.

Cradle Systems: There are various cradle systems, also known as gondolas and cages. These are suspended from BMUs, davits and monorail trollies for carrying operators with tools and materials for cleaning and maintenance.

Ground-Launched Systems: When building a skin to be covered that is a low rise, it can be covered by ground-launched systems. Mobile Elevating Work Platforms (MEWPs) are easy to use and effective. Their light weight and compactness make them suitable for use in building exterior and interior elevations and skylights. With MEWPs capable of operating with outrigger footing on different levels, climbing staircases and passing through narrow doorways, these have multiple applications.

Rope Access System (Abseiling): Whenever conventional means of human access are not possible to reach building skin, rope access is the solution we arrive at, which enables vertical climb and horizontal manoeuvring for cleaning and maintenance.

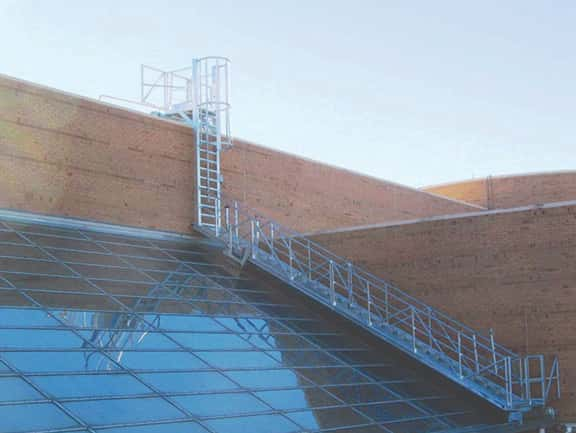

Traversing and Revolving Gantry Platforms: Several types of traversing and revolving gantry platforms are being used mainly on roofs, skylights and domes. Their advantages are simplicity, effectiveness, economy and easy usage covering areas where BMU is normally unsuitable. These can be simple, small manual gantries or fully powered large units. Some of the popular versions of these gantries are horizontal, inclined, curved and revolving units for exterior and interior access.

Robot Systems: Robot access systems have a trolley on a twin-track system on the roof, with a hoist carrying suspended robots. The robot does automatic cleaning of building façades using vacuum cups for secure positioning on the façade. The cleaning robots are hoisted automatically by the roof trolley, which carries the Robot and moves horizontally along the façade. The entire façade cleaning is programmed and fed into a control system to drive the operation automatically. The Robot cleaning system cleans the façade using purified and recycled water with minimal human effort. They cross obstacles like mullions, transoms, sunscreens, etc., covering elevations, and navigate automatically. Advantages of Robot Systems are easy usage, high-speed cleaning, cleaning water recovery, purification and recycling. These are ideal where human access is impossible or dangerous. The disadvantages include a higher cost and limited use. A robot does only the programmed operation. Does not consider an actual situation where more cleaning or less cleaning is required. These do not provide human access and are only for façade cleaning.

Lateral Restraint Systems For Use With Suspended Cradles

This system stabilises the suspended platform against the wind. It is mandatory to use lateral restraint systems for heights over a certain limit, which varies in different places as per various local standards. Relevant standards for the respective geographic region should be verified and applied.

It is important for façade and structural designers to take this into account since restraint sockets need to be installed on the elevations at the required locations, taking the required loads.

The most widely used European standards EN1808 and comparative critical values of US and Australian standards are:

| No | Description | Standards | ||

| European Standards EN1808; 2015 |

American Standards OSHA 1910.66 |

Australian Standards AS1418.3-1996 |

||

| 1 | Minimum height of the building above which a lateral restraint system is required | 40m | 22.9m | 40m |

| 2 | A level above ground for the first embedded restraint socket to start | 40m | 22.9m | 40m |

| 3 | Vertical spacing between restraint socket levels | 20m | 15.3m or 3 floors, whichever is lesser | 12m above 45m height 15m below 45m height |

| 4 | Horizontal spacing between restraint sockets | To suit cradle length | To suit cradle length | To suit cradle length |

| 5 | The minimum load that the embedded restraint socket is required to take in all directions | 1 KN | 1.34 KN | 0.45 KN |

There are three types of lateral restraint systems.

- Mullion Guides: The mullion guide track runs vertically on the elevations in parallel lines all around with coordinated spacing for two mullion guides to be reachable from the cradle at a time for engagement and disengagement of guides secured to the suspended cradle. Guide rollers from the cradle run into the mullion guide tracks, restraining horizontal movement due to wind.

- Intermittent Stabilisation System: In this widely used system, restraint sockets are embedded on the elevations at required heights and spacings with load-bearing capacity as stipulated by the relevant standards to restrain lateral movement of the cradle. The restraint lanyards from the cradle suspension wire ropes are secured to embedded restraint sockets. Different types of restraint sockets with quick-release pins and sockets are available from different manufacturers. The most popular types are the sockets that are flush-mounted to the façade. These are generally cylindrical in shape and made of SS316. Another type of restraint used sometimes is a protruding plate type that gets hooked by the restraint lanyard from the cradle suspension wire ropes. This is generally not preferred since visible by projecting out on elevation. These are normally painted to the background colour for minimum visibility when an embedded restraint socket is not possible.

Image Credit – Farra – A typical restraint socket with Farra’s adjustable restraint lanyard and quick-release pin - Intermittent Stabilisation System with Soft Rope Restraint Lines: This is intermittent stabilisation with additional independent soft rope restraint lines from the BMU down through the elevation to the reelers in the suspended cradle. This is used when suspension ropes cannot be secured to restraint anchors when the cradle reach is to be extended and retracted, negotiating steps and slopes on the elevation.

Selection Of Systems

The selection of the right façade access systems that will suit the specific requirements of a building can be a simple task for straightforward buildings. For complex architectural structures with difficult geometries, it can be a highly challenging task to find a solution and select the right systems. In such cases, it takes a great deal of knowledge, innovation, creative thinking and extraordinary engineering skills. Façade access equipment suppliers normally provide three solutions: the most economical, the best possible and the one that suits the requirement best. This suits sellers best since they are there whichever way the procurement process goes. It is the buyer’s prerogative to choose the right one. A techno-commercial viability check may also be required by comparing the investment in equipment and employing manpower versus subcontracting the cleaning and maintenance with hired equipment if possible.

The following requirements are to be met in the selection and application of façade access systems

- Requirements from architects, building designers, façade designers, building facility managers, consultants, structural engineers and MEP engineers as indicated earlier.

- Full coverage of the system wherever access is required.

- Compliance with standards and safety regulations.

- Ease of operation.

- Availability of timely maintenance and timely spare parts supply.

Conclusion

“It is always easy to complicate a design, whereas it is extremely difficult to simplify to make it easy to manufacture, install, use, maintain and sustain economically”. These words from my first design teacher several decades back hold good even today. With most of the contemporary architectures already complicated and getting more so day by day, we are left with limited choices for simplification. A sincere effort should always be made for simplification to the extent possible, since a compromise is mostly not possible on performance. An ideal choice would be to endeavour to have both simplicity and performance complementing each other to the maximum possible extent. The table below gives the information, suitability and comparison of various systems for evaluation, selection and application.

When the requirement gets complex, it is advisable to seek advice from experts related to façade access.

| No | System | Simplicity & Performance | Building Type Suitability | Cost | |||||

| Simplicity level | Performance level | Building heights above 100M | Building heights below 100M | Buildings with straight elevation | Building with recessing, projecting elevations | Initial cost | Operating cost & maintenance | ||

| 1 | BMU on RCC runway | good | good | suitable | suitable | suitable | suitable | medium | low |

| 2 | BMU On Steel Tracks | good | good | suitable | suitable | suitable | suitable | high | low |

| 3 | BMU with drum hoist | good | good | suitable | suitable | suitable | suitable | high | low |

| 4 | BMU with powered cradle | good | average | Not suitable | suitable | suitable | Not suitable | low | high |

| 5 | Davits | good | poor | Not suitable | suitable | suitable | Not suitable | low | high |

| 6 | Monorails | average | average | Not suitable | suitable | suitable | Not suitable | medium | high |

| 7 | Rope Access | average | average | suitable | suitable | suitable | suitable | low | high |

| 8 | Traversing gantries | good | good | suitable | suitable | NA | NA | medium | low |

| 9 | MEWP | good | average | Not suitable | suitable | suitable | suitable | high | high |

| 10 | Aluminium mobile scaffold | good | average | Not suitable | suits height up to 12m | suitable | suitable | low | medium |

| 11 | Telescopic Extension Poles | good | poor | Not suitable | suits height up to 9m | suitable | suitable | low | low |

| 12 | Custom-built systems | average | good | suitable | suitable | suitable | suitable | high | high |