With the improvement of people’s aesthetics in the architectural style of buildings, the colouration of uPVC window profiles is increasing continuously, thus leading to an increasing demand for uPVC window fabricators. However, the current colouration process for doors and windows, such as lacquering, colouring, co-extruding, etc., is not the best solution due to the limitation proved for years.

Co-extrusion

For example, co-extrusion is the most popular colouration process for uPVC window profiles suppliers in the Asian area nowadays. It proves that the outside single coloured uPVC window is the strongest demand in the market. The advantage of co-extrusion is the low cost, but there are lots of disadvantages, such as not only single colour and higher mould investment but also the bad feedback from various regions, especially in extreme climate areas, after the application in recent years. It performs different weather resistance. The profile will release its internal co-extrusion stress and cause deformation when the climate changes between hot and cold, which will even lead to the cracking of the fillet weld.

Lacquering

When it comes to lacquering, although there is more colour diversity, it is very difficult to keep a small colour difference between producing batches. Furthermore, the anti-scratch and weather resistance will be determined by the binding strength of the spraying paint layer and profiles. The truth is, this strength is always weaker than estimated. Because of the above, lacquered uPVC profiles are very rare to be used in the market.

Colouring

To use pigment to colour the whole uPVC profiles when extruding, we call it colouring. Because the base material is PVC, the problem with this process is low weather resistance.

Lamination

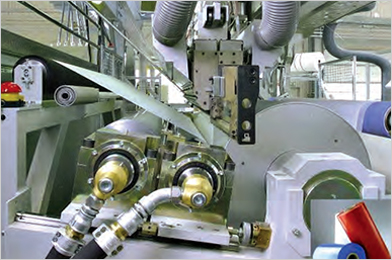

In Europe, lamination is always the most popular process for colourful uPVC windows, but lamination hasn’t been accepted by the main market in the Asian market because of the high cost. Lamination relies on excellent quality of branded film, which can not only solve the weather resistance problem but also fully meet the demands of personality and colouration for uPVC windows. In brief, lamination is nothing but wrapping a high weather resistance foil on the uPVC profiles with highly efficient and high weather resistance adhesive through a laminating machine.

The profiles just need to be kept for some time to get the adhesive solidified, and can be used for the next process. The outstanding advantages of lamination mainly appear in the following aspects: the surface of colourful profiles won’t bend or have deformation because of zero internal stress; different single colour and wood grain colour will have more design diversity; profiles’ colour can be easily and quickly changed during lamination; flexible small batch production; environment-friendly and no pollution.

Films for Lamination

With more and more window film companies coming to the market and putting effort into research and promotion, lots of window film products with different characteristics and functions have emerged in the market.

According to the division of the base layer, it can be divided into PVC, PMMA, ASA, etc., which can also fundamentally decide the basic weather resistance ability of window film. And also, we can get different levels of weather resistance films to adapt to different climatic regions by the method of different technologies on the surface layer treatment.

RENOLIT, as the earliest window film company entered in Asian market, has a series of products now. It can not only achieve different surface effects for the single colour and wood grain colour films, but also can develop different levels weather resistant films like MX, PX, FX through the combination of base layer and surface layer material.

Skai film from Hornschuch, Germany and LG film from Korea also have their own characteristics. For example, Hornschuch is the first company to come up with the cool colour concept, its anti-infrared technology of the pigment can reduce the thermal effect of near-infrared solar radiation, then reduce the heat build-up of the windows.

Additionally, LORIKA window film from Austria, with its innovative use of SABIC Geloy ASA as a base layer, successfully transplants the perfect weather-resistant property of Geloy resin to the application of window films. And also with its appropriate price, it is highly rewarded and respected in the market once it is launched in the market. Geloy ASA resin is a special ASA resin that has proven to be applied to exterior applications such as fences, vehicles, boats, roofs, and co-extruded uPVC window profiles for more than 10 years without fading.

Future Colouration Process

In the expected future, with the different levels of window films continuously launched in the market, there is a big hope that the lamination process can replace the current co-extrusion process in large scale. In the trend of more and more enhancements on the internal quality of uPVC profiles industry, proven better performance of the lamination process will win the future for sure.

Contact: Mr Tracy

E-mail: india@lorikafilm.com

Phone: +91 9886621130

Website: www.hkfar-star.com

www.lorikafilm.com