Does Size Matter?

Let us begin with two anecdotes to set the stage.

Anecdote 1 – While visiting a premier company in the region of Mumbai, I spoke to the receptionist while waiting for my appointment and asked, Do you know the reason these windows with handles are provided?

I do such awareness tests now and then to understand how much the occupant really knows about their safety in a premises.

Back to the story, she replied, No, I am not aware. Is it for natural ventilation? I replied, We are in an Air-Conditioned building, so think again. She replied, is it to escape out of the building in some emergency? I said, you are on the 6th floor, would you make it if you escaped out of this? Then, explained to her the importance that the humble ‘SmokeVent’ plays in any Glass Façade Building, when no other form of exhausting toxic gases, and hot, thick black smoke is present.

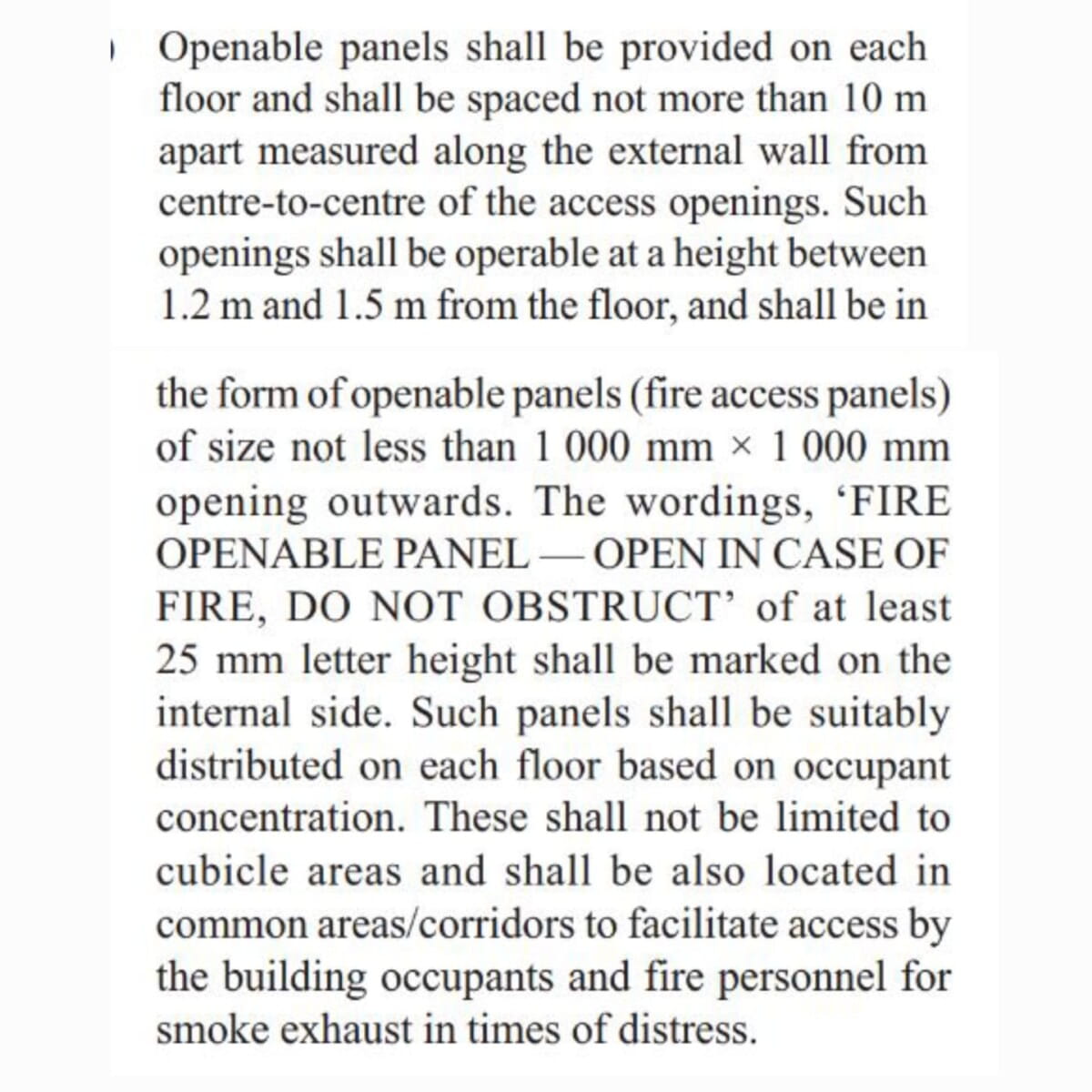

Below is a snippet of the ‘SmokeVent’ section, presently in the National Building Code published in 2016.

If you notice the last line, it drops the onus of opening these vents to the ‘Fire Personnel’ or YOU, the ‘Building Occupant’.

Ask yourself, as a reader of this article, or if you work in a glass façade building in our region, would you open that window/vent before you escape and make it to the ‘Assembly Area’, or would you just escape and run for your LIFE?

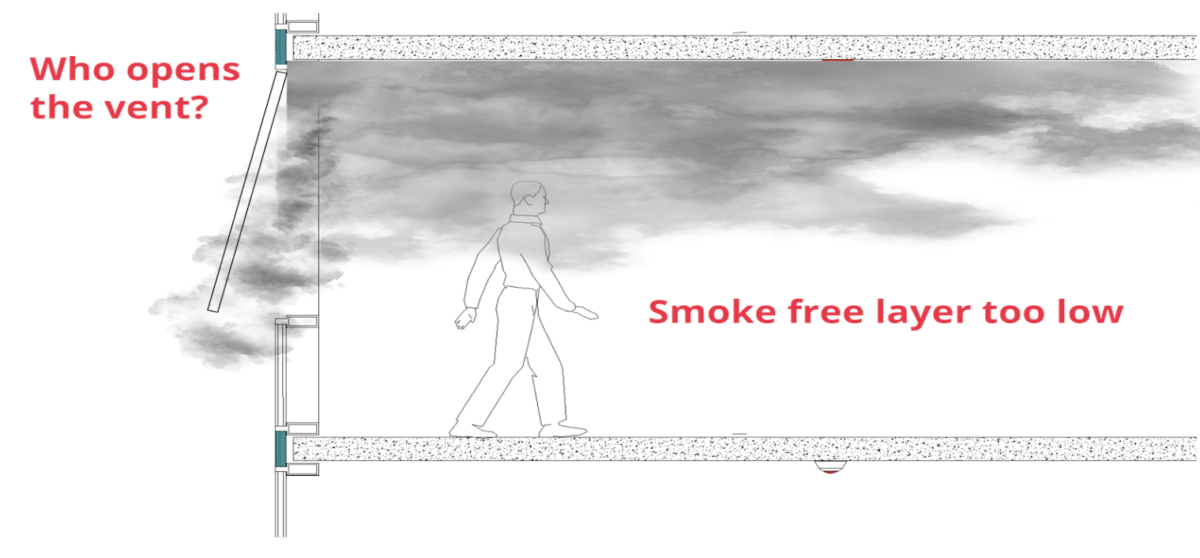

Anecdote 2 – While visiting a building in Ahmedabad, I saw the vent was 2m x 2m, very large and openable with a handle. The same awareness test was done, and similar replies came back; however, the vent here did not even budge beyond 10 degrees as it was stuck and not maintained. Most of the vents are designed to not open more than 200-250mm.

This now becomes a ‘Very High Risk’ high-rise, where there is a lack of awareness or training for the occupants and/or systems that do not function as designed. In a residential project with a glass façade, the vents, top hung or parallel or sliders will be opened/closed frequently, so eventually they will be maintained by the owner, not the case in large IT/Commercial parks, it’s more fit, handover and forget here.

Also, when we speak to the concerned, their goal is to have very large panels, predominantly to provide fabulous views of the outside. As it’s said, bring the outside in. We are talking of openable with sizes of 1.5m wide x 2.2m and taller, humanly hard, or rather cumbersome to open, and the question is, why should we?

The Challenges

Large vents without automation bring about a lot of challenges,

- The fabricators of these glass buildings need to deal with millimetre-level tolerances to make these large panels function & pass Performance Mock-up.

- Hardware supplies are usually expensive as the vents/windows get larger with a greater number of moving parts.

- We are all aware that precision and workmanship that can be achieved in a factory condition cannot be achieved at the site. Alignment issues are a concern, too.

- The interior fit-out team often opens the vents during their scope, and during rains, this causes flooding inside or even causes the vents or the hardware to get damaged, which is, mind you, under warranties from the supplier.

- For this, provide interior contractors with fans or some cooling systems, as these vents/windows are for ‘SmokeVentilation’ only.

- On handover, if you have a site with over 500 vents, imaging opening and closing each one of them 5 times to prove it works, there is no SOP for this today in the market when vents are manual.

- Handles are removed in some data secure projects owned/leased by large Global and/or Indian companies, which is as good as not having a system.

- Lastly, no awareness is given to the occupants of the system, so they are not aware that something like this even exists.

The Solution – And Points To Consider:

Modulation, Automation, Testing

- Rather than provide a large openable vision, shift the openable slightly higher towards the false ceiling, and the rest below becomes your vision

- This helps to extract the smoke out, as smoke tends to rise due to its buoyancy

- Vents are to be BHOO – Bottom Hung Open Out

- Making the vent shorter allows for a greater angle of opening, as the taller the vents, the shallower the opening & which will not allow for effective smoke exhaust

- Parallel is possible with automation; however, it starts to add costs to the system, and opening is limited

- Automation must be by Actuators, which are to be of chain type tested to EN12101-02 CE/UKCA.

- Size, weight, Opening Angle, and Wind Loads play a crucial role and need to be taken care of. If wind loads cannot be sustained by just the Actuator, a suitable Multi-Point Locking (MPL) Actuator needs to be used here with Locking Points, should the performance standards be much higher.

- Keeping the vent shorter also allows for fewer moving parts internally, thereby making the system less prone to failures

- Wide vents like in airports or some cases IT/Commercial parks need to have multiple Actuators based on the width, to allow for the necessary clamping/holding with a minimum of 4000N / Actuator.

- To govern the weight, during its operations, care to be taken to understand the forces applied, where Actuators must have a minimum of 400N / Actuator open/ close force.

- Calculations must be verified and certified by a project Consultant.

- Lastly, with glass façades tending to move towards fire-rated systems, it is important to not only have a tested Actuator but also to test the entire ‘SmokeVent’ and its components to EN12101-02/IS21927-02.

Reach us to know more.

The Side Less Spoken About

There is a notion that the ‘SmokeVent’ is a façade-related hardware system; this is partially correct. However, the system is on the Glass Façade but forms part of the building’s ‘Fire Strategy’, ‘Active Fire Systems’, and ‘HVAC Designs’ as well. 80% of the work lies here, in system design, approvals, proper execution, commissioning with fire alarm systems, and the proper Handover to the End User/CareTaker/Owner

- Having smaller AMP controllers allows for shorter cable runs, controllers and MCP are to be tested to EN12101-10 CE/UKCA.

- The longer the cable runs, the thicker the diameter/size of the cables, and eventually, the costs increase.

- In large public space buildings, we can proceed with larger panels of 30/60/90/120 AMPS as space is less of a restriction here, or cable draws.

- However, for offices and commercial buildings, an 8AMP will take care of points 1 and 2 stated here.

- Voltage drop calculations are a must here to be provided by the vendor to the consultants for approvals.

- Locations of controllers play a crucial role too, can be placed at HVAC, ELV, or Fire Command Rooms and must be zonal/local and not centralised, due to cable runs with access to be provided.

- Manual Override or a Manual Control Point must be provided at all stair locations, create an awareness program for the occupants to not tamper with any fire systems, don’t change the norm, change the mindset.

- Now, since the system is installed and is automatic, the Owner/End-User will and must maintain it via the manufacturer or authorised partners of the vendor providing the system.

In Conclusion, “Size Does Matter”

- Shallower the vent more than the opening.

- The higher the placement of the vent, the better for smoke exhaust.

- Cable diameter/size goes up as distances increase, so propose smaller AMP controllers for Office/IT spaces placed zonally or floor-wise controls, do not centralise them and drag cables from floor to floor.

- Bear in mind to receive all calculations and drawings on wind loads, force, cable types, voltage drops, installation details, vent details, SLDs, and BOQ by break-up of systems proposed.

- It is recommended to have smaller vents spaced evenly rather than fewer large vents, as they are easier to maintain and care for in the long run of the building life cycle and have fewer moving parts internally.

- Stick to a maintenance schedule and do not sublet maintenance to an untrained professional, and later call the system manufacturer.