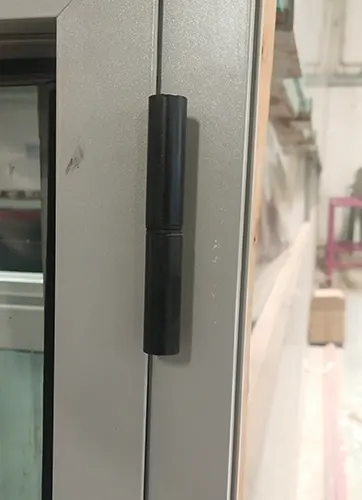

Doors and windows are the kind of product that needs multiple types of materials to complete assembly; hence, hardware is an important component in manufacturing the finished product. In terms of the total cost of material to manufacture the product, it is the third major cost component after aluminium, uPVC, and glass. There are different categories of hardware depending on the product-to-product and material-to-material. For instance, various types of doors and windows will have different categories of hardware. Some hardware is visible, and some is not. Some are metal-based, and some are non-metal-based. One needs to understand all these different variations in hardware before selecting them or deciding upon them.

Secondly, the selection of hardware depends on the product segment and the technical grounds. There are certain kinds of benchmarks from which the suitability of the hardware can be justified. For instance: life cycle, grade of concrete, safety barrier, the weight of the glass, size of the door or window, product segments, etc. For example, the incorporation of the hardware is different in casement windows than in the sliding windows and façades. In recent years, advancements in aluminium window hardware technology have further improved their staging, energy efficiency, and security.

Aluminium windows have been a popular choice for homeowners and businesses due to their durability, robustness, and elegance. Apart from the technical part, aesthetics play a major role in visible hardware; the selection is based on aesthetics and the colour scheme in hardware, which further bifurcates into manual and automatic hardware and modern and traditional style hardware.

Different types of hardware:

- Door & Window Hardware: Hinges, locks, patch fittings, handles, latches, screws, handles, friction stays, side-hung arms, single-point and multipoint locks, woven brush piles (wool piles), limitation arms, parallel arms, stoppers, corner clips, panic door handle, transmission rods, floor springs, door closers, tower bolts, deadbolts, door knobs, door seals, door levers, electrical door locks, doorbells, door chimes, door push/pull plates, window stays, fold-down handles, window pull handles, crank window handles, window folding handles, window latch mechanisms, folding window adjusters, touch locks, pop-up & projected handles, single-wheel nylon & double adjustable rollers.

- Façade: Friction stay, two-way spider, four-way spider, tension rod, nut & bolt, mechanical anchors, chemical anchor, etc.

The manufacturer of the hardware should make sure that their products pass all the necessary test processes and also should get certified by the testing laboratories. For instance: Friction stay hardware passes through certain parameters and tests (as per JG/T 127-2017), like

- Surface Test: The surface of the product has no obvious defects, nicks, pores, concave holes, flash, sharp edges, or burrs. The Joint should be fastened smoothly and without any cracks.

- Designed Friction: The Self-positioning force of the friction hinge can be adjusted and is not less than 40 N (N = Newton).

- Operating Force: The operating force should not be more than 40 N.

- Running Force: The running force should not be more than 80 N.

There are some other parameters for friction stays, like clearance, rigidity when closed, rigidity at maximum position, repeated opening and closing, resistance to damage, etc.

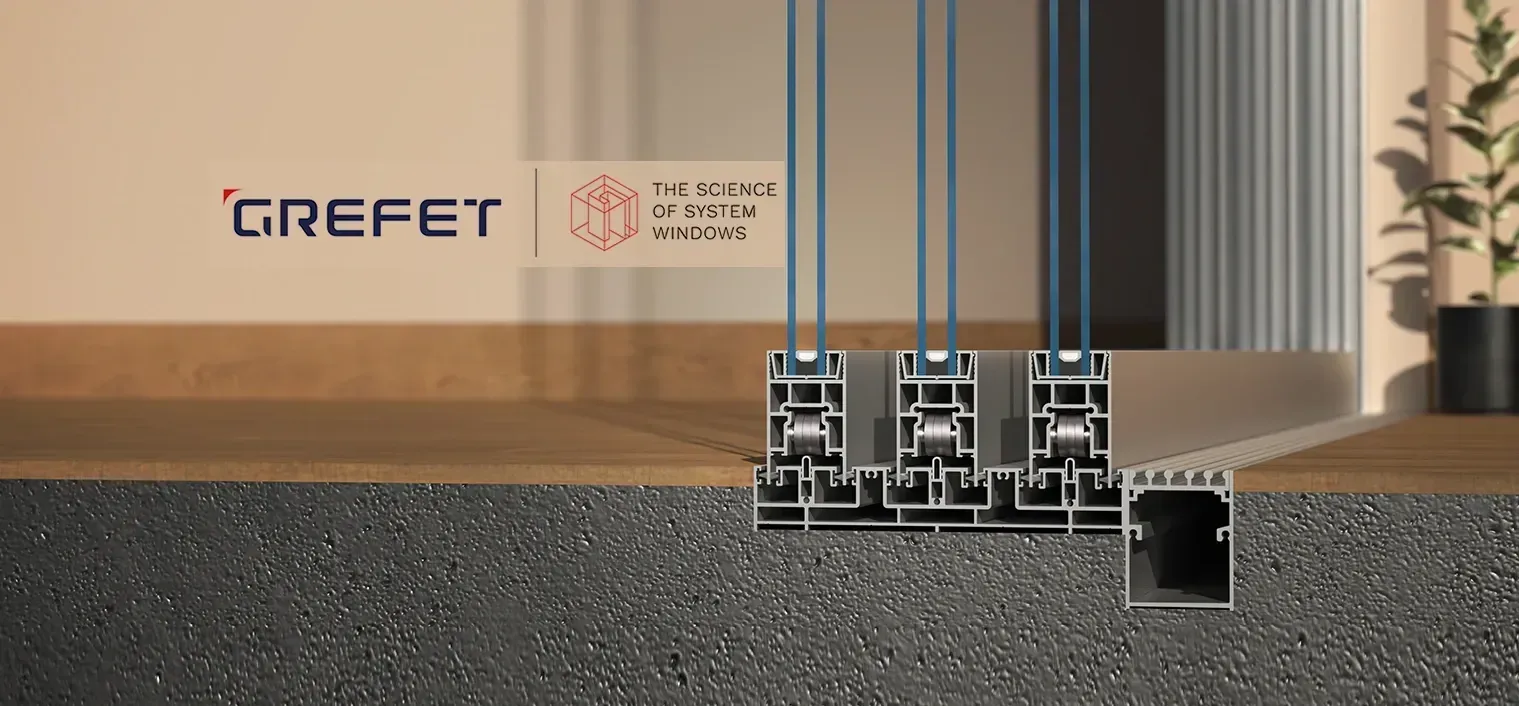

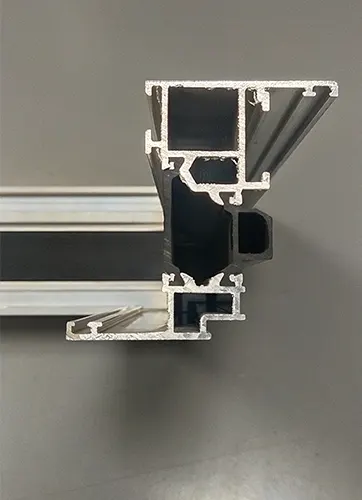

Different standards like ASTM, ISO, BIS, or EN may have different parameters to check the quality and level of strength of hardware to use for different hardware. There are international developments in the hardware industry with advancements in the development of products by experts. One of the most remarkable evolutions in aluminium window hardware apparatuses is the introduction of a thermal break system.

Thermal breaks are barriers made of polyamide materials that are placed between the inside and outside of the aluminium sections. They control and reduce heat transfer between the inside and outside of the building, making the windows more low-carbon and reducing energy costs.

Because the aluminium alloy is a metal, the heat conduction is relatively fast, so when the temperature difference between indoors and outdoors is large, the aluminium alloy can become a “bridge” for transferring heat. The doors and windows made of aluminium alloy have low heat insulation capacity.

If we talk about locking systems in development, then another evolution in aluminium window hardware technology is the introduction of multi-point locking systems.

These locking systems feature multiple locking points along the length of the door and window frame, providing increased security. Some multi-point locking systems also feature anti-lift devices that prevent the window from being lifted out of its frame, further increasing security.

One of the nice features of the tilt-and-turn window is a mechanism that allows the window to be opened in two different ways: tilting from the top for ventilation or turning from the side for full access.

This provides greater elasticity and control over airflow and ventilation. Some new aluminium windows now feature motorized opening and closing mechanisms, which can be controlled remotely using a smartphone or other smart device. This provides greater convenience and control over the window’s operation and can also improve energy efficiency by allowing for automated opening and closing based on temperature or other environmental factors.

Architectural hardware for windows and doors has witnessed many advancements. In general, the entire industry today is more conscious about design. As a direct effect of this, several products provide practical solutions that are technically sound and aesthetically appealing. These products have also evolved to incorporate technological aspects, thereby enhancing their appeal in the eyes of the end consumer.

Case Study: Sejal Siddha – Seabrook, Mumbai

The Project is the talk of the town, situated in a prime location in Kandivali (west), Mumbai. It is the tallest residential tower in the neighbourhood. With an edifice of 57 stories, with 2254 plus numbers of aluminium windows (Khidki) with high-performance solid toughened glasses, more than 800 Wooden Doors for the apartment, six (6) high-speed elevators, and a 77-story automatic car parking system. Also, the project is incorporated with Laminated Armour glass railings at the 3BHK apartment and 8 sky gardens. It also has a staircase at two locations for emergency escape, which is secured with two heavy-duty fire doors on each floor. This premium project has a number of different hardware used for the installation of various products. The electrical panels on each floor also have protection from heavy-duty fire doors to give safety to the residents.

The windows used are from branded aluminium and high-quality hardware like locks, rollers, hinges, and telescopic arms to cater to the high wind pressure as per the approved design. The planning and execution team from the developers and the engineering company are strong and strategic enough to make such kind of a scrapper project successful.

There are 6 to 7 typologies of windows in this project. The sizes of all the 2254 windows are well planned by the team, which were standardized to manufacture and supply to the site for the installation process. Sejal Intelligent Façade (engineering company) for this project had the scope of work to design, manufacture, supply, and install fenestrations. It was made so easy by strategies like standardizing the size of doors and windows by the project team. All the windows were 100% manufactured at their R&D centre and plant in Nalasopara and dispatched to the site to install with the normally required hardware screws. Apart from windows, the project has a very eye-catching parking façade with a design of a tree shape with uPVC louvres material. The shape of the tree is created in such a way by using different sizes of small to large pieces of uPVC with two different colours.

Quick Facts:

- Project: Sejal-Siddha – Seabrook

- Location: MUMBAI

- Developer’s Name: SEJAL Realty and SIDDHA Realty

- Architect: J P Agrawal

- Height of Tower: 220+ meters

- Product used in the project: Door & windows, Railing, Louver fins, Fire Door

- Commencement Date: January 2022

- Completion Date: February 2023