Architectural hardware has become an important aspect of design – be it façades, doors, or windows. With the entry of international systems, equipment and hardware firms, the Indian architectural hardware for façade and fenestration has also evolved over the years. Technology and its use have increased many folds giving precision to products with quality and sustenance. Along with the use of technology, design has also evolved over the years. Gone are the days of tinted glasses and bulky hardware to hold them. The trend for buildings is towards more transparency over the past few decades.

This story covers the latest trends in architectural hardware, important aspects to consider while choosing architectural hardware, standardisation of window and door hardware systems, key safety parameters to look for while specifying hardware, and quality vs. the cost of architectural hardware. We spoke to many architects and façade consultants regarding these topics. Here are their views and suggestions:

Trends in the Façade, Door and Window Hardware Products

It is not an overstatement to say a building’s façade is its most important element, for both architects and users themselves. Understanding the trends in façade design helps us see the direction of the future façades and advanced and sophisticated technologies in façades, states Manish Kumar, Director, TDS Coetus Pvt. Ltd. In the door and window segments, the introduction of a bigger sash to achieve wider view and access is the trend. “For continued updates, I usually attend seminars and webinars like ZAK World of the façade and follow magazines on façade and newsletters”, adds Manish.

The plethora of hardware for doors, windows, and elevation design constitutes varied options in the market. As a result, the market is currently flooded with products of varying price points, materials and quality. Concerning the current trends, says Ar. Alpana Gupta, Managing Partner at Vijay Gupta Architects, materials with lightweight properties help reduce the dead load on the building, thereby enhancing construction economics. Additionally, in order to reduce energy consumption, one can opt for sustainable materials to fully or partially mitigate the energy requirements of a structure. For a country like India, the aspect of cost sensitivity is crucial where budget constraints drive material selection for design solutions.

Ar. Mohd Shamim Khan, Principal Architect & Partner, Maven Design Studio LLP talks about the need for keeping oneself updated on the latest products. “Architecture is a field where we are witnessing a very rapid change in terms of architectural products in the market. A lot of products are being launched every day so it has become tough for architects to keep themselves updated. So to keep up with the latest trends I spend considerable time in the selection of hardware for my projects which involve market research in terms of product design, performance, technology, pricing, etc.”, says Ar. Khan.

Hardware used in the built space can easily replicate the overall design concepts and our level of appreciation for the environment. “Nowadays I have noticed that architects, as well as clients, don’t like bulky hardware in their buildings/doors/windows. So it can easily be said that minimalism or ‘less is more’ is the latest trend. This trend requires the hardware to be concealed or minimised to be incorporated into the whole system.

Hardware with high-performance specification with a minimal design approach is in high demand”, says Ar. Khan. Architects are barely able to keep up with the façade and fenestration design trends and the latest products available in the market today. Ar. Rahul Mehta, Founder & Principal, Rahul Mehta Architects says, “We see that in the residential space, there is great consumer awareness and sensitivity to window frame sizes, noise cancellation, heat loads and even behaviour w.r.t wind loads. In commercial spaces, we see great awareness now w.r.t heat loads, light transmission, fire safety, etc.

The clients/consumers are expecting more innovations not only in aesthetics but in specifications as well. This is one of the largest challenges as we not only have to keep up with the customer sensitivity and needs but also with the multiple innovative responses vendors have come up with to cater to the new, well-informed, new-age client/consumer. Magazines much like yourselves are one typology of sources that help keep us up to date”.

Pramod Jain, Cofounder & Operational Head, Creative Architects & Interiors believes that innovation is the key to successful and holistic design solutions. The hardware that is currently used in façade, door and windows are based more on functionality, durability and safety rather than on the aesthetic look alone, says Sumesh Sivasankar, Project Head, Acorp Consultants Private Limited. Trend changes based on the main products like façade, door and window, and hence the supporting hardware should be manufactured based on the above-said parameters. The project closure report of a project asks the manufacturer to provide the technical specification with the technical drawings of the product which in fact is like a user manual for the end-user. The Architect or the Designer’s primary responsibility should check the quality and grade.

Today’s façade achievements are about driving design possibilities technically – achieving optimal functionality and high performance, points out Ar. Aashish V Karode, Principal, Design Atelier Architects and Design Consultants. “You may imagine a 15m long glazed façade panel on an edge of a 50th-floor penthouse which requires each pane to have glazing sized with a 2.1m width and 6m high DGU, and the system to be automated for sliding. The installation needs to comply with the relevant codes and be certified on British/ European standards, must also look and feel great, while it performs highly on parameters for security, fire life safety, access, acoustics, weather protection, and energy efficiency. To keep up, you need experts to advise you on the correct products and specifications,” he adds.

The growing emphasis on safety measures has led to an increase in the use of fireproof materials in façades as well as doors to prevent structural collapse and allow safe egress of occupants in case of fire, says Ar. Gupta.

Types and Selection of Windows and Doors

Windows:

The selection of window typology depends on its application, the size of the opening, and the height at which the window is installed.

• Top hung: Broadly used in commercial projects. Can be recommended for high-rise projects.

• Side hung: Mostly used in residential projects. This type of window has size & weight limitations. They are ideal for widths not more than 750mm. Outside-opening windows are not recommended for high-rise projects.

• Bottom Hung: Used for smoke release vents. If the vent size is bigger, then automation is recommended.

• Parallel pop-out: Best window suitable for ventilation as well as smoke release. Depending on the size, weight and OEM’s recommendation automation can be considered as an option.

• Tilt & Turn: This window is finding major applications in private houses/villas. This serves as an option for ventilation when tiled (bottom hung towards inside) and complete opening when side hung (open inside). This requires special hardware.

• Vertical sliding: This window with automation is a perfect option for rooms that do not have balconies. Although proper engineering would be required with regards to glass configuration, shutter size, wind pressure, fixing details, etc. Smaller sizes can be done using manually operated vertical sliding windows with a self-balancing principle.

• Sliding Doors /Patio Doors: Mostly used in residential/hotel/resort projects where is a deck/balcony outside a room

Doors:

• Framed doors/Patch fitting door: single leaf or double leaf/one-way swing or two-way swing

• Revolving door/Automatic sliding doors: Commonly used in commercial entrance spaces

(Vicky L. Vora, Founder & Principal Façade Consultant, V3 Façade Design Studio)

Important Aspects to Consider while Choosing Architectural Hardware for Doors, Windows and Façades

The major aspects to consider while choosing hardware, says Vora, are:

A) Purpose

• Cross ventilation: Top hung/side hung/parallel pop-out/sliding

• Smoke release: Parallel pop-out/bottom hung

• Fire-rated partition: E / EW / EI Grade of fire rating requirement

B) Site location

• Wind pressure varies as per topography. The type and number of locking points would vary accordingly

• Proximity to the saline atmosphere: Hardware should be saline resistant

C) Weight and size of openable

• Type of hinges

• Number of hinges

• Position of hinges

• Manual or automatic mode of operation

D) Altitude of application

• Side-hung windows shall be recommended for buildings that are not high rises. Wear and tear of hardware due to cyclic motions can cause the shutter to disengage which can lead to serious accidents. If these are mandatory for CFO requirements, it would be advisable to limit these typologies only to window requirements as per the CFO. For ventilation purposes, top-hung windows can be an equivalent option.

In addition to the above points, Ar. Mehta stresses aspects like the location of the fenestration, for e.g., the specifications for an exterior door to the entry of a home would vary compared to the specifications for say a service door leading to a kitchen in a hotel. He adds that the material of the system also determines the hardware specifications – for e.g., those for a UPVC window and a sleek aluminium window would vary. Moe over, the selection should be based on the prevalent climatic conditions – The hardware for a façade may vary considering the local conditions such as proximity to the sea due to the probability of corrosion or wind loads or due to extremely hot conditions, and so forth.

The design intent plays an important part in defining the look of doors, windows or façades and their elements. For e.g., if one opts to have an art deco look to the building façade the main door to the lobby may have handles that may be more ornate or hinges that may actually form a part of the aesthetics, adds Ar. Mehta. With increasing building heights, in the ‘post-disaster’ scenario we live in, there has thus been a marked change in the performance criteria being demanded across all fenestration, particularly in relation to fire-resistant hardware and fixtures for smoke ingress prevention, smoke seals, and hardware and windows glazing products, stability and of course strength and longevity- full functionality with cool looks, high standards and low maintenance, adds Ar. Karode.

Chimes Building, Gurugram by Design Atelier – An open design

Chimes Building, Gurugram by Design Atelier – An open design

Functionality is, of course, the most critical aspect of hardware selection on a case-to-case basis, says Ar. Gupta. Another criterion is assessing the life cycle cost of the building and the short-term cost benefit of using a cheaper product. Furthermore, usability, both for the end user and the installation, is also essential. Finally, the visible element of the hardware is chosen based on contemporary or classic aesthetics. Factors like material, sleekness and finish quality are critical as they help enhance the space and gain character and are used to create a cohesive design scheme.

A project by Maven Design Studio LLPAr. Khan

A project by Maven Design Studio LLPAr. Khan

lists the following as the most important aspects which cannot be ignored when choosing architectural hardware:

• Safety

• Performance

• Futuristic design

• Value for money

• After-sale services.

According to Manish Kumar, the facts to look at before choosing the hardware for doors and windows.

• Material chemical properties should analyse according to geographical factors

• Hardware compatibility should check w.r.t. profile going to use

• Façade and door/window system structure design should check w.r.t. static, dynamic load

• Budget is the most important part that helps to understand the amount have to spend on hardware without compromising on the other aspect of the project.

There are many other aspects to be considered while choosing hardware for doors, windows and façades, which are mentioned below by Ar. Sivasankar.

• The suitable product/material for the usage which gives the best performance

• The manufacturer’s reputation and existence in the market

• The quality and grade of the product which results in the durability of the product

• Technical Specification and relevant certifications of the product

• After-sales, service and spare parts availability including warranty

• Department and their approach to the issue/matter

• Spare parts availability and warranty of the product

• Material/product availability in the local market

• Maintenance-free and user friendly

• Time required for rectification by the company technician or experienced carpenter

Design Atelier project – Blackberrys HQStandardisation – A Challenge

Design Atelier project – Blackberrys HQStandardisation – A Challenge

Lack of standardisation of window and door systems considering the design approach is one of the major challenges faced by the architectural hardware industry. The use of high-end technology has grown exponentially, allowing for enhanced hardware design and production with the required quality and sustainability, says Ar. Gupta. Similarly, process-driven solutions also compel us to follow design practices that support the standardised hardware resolving our complexities regarding compatibility and functionality. Engineered solutions such as factory-made doors and windows provide us with much better standardised and certified products.

However, in reality, lack of standardisation results from our construction practices which revel in customisation. Another problem is keeping up with the fast-paced, dynamic market in terms of product design. Standardisation can reduce cost factors, response times, and the need to stock a wide range of parts to some extent. Standardisation can be achieved by setting up guidelines that are accepted by all the stakeholders with regard to how a product can be created and supported. Integration of the latest technology is one key aspect that must be considered, says Ar. Khan.

Ar. Mehta agrees though a certain level of standardisation has taken place in terms of specifications for hardware for certain building user types, it is very broadly done and there is a long way to go in terms of creating standard specifications for all specific locations and function variants within a given building design typology.

A residential project by Maven Design Studio LLP

A residential project by Maven Design Studio LLP

As every project has a different layout design, different floor heights, different structural design, etc., standardising window/door systems is a challenging task. But it is not impossible to achieve. This needs thorough coordination between the façade consultant, the architect and the hardware manufacturers. A thorough exercise is needed between designers and manufacturers to achieve hardware solutions that are best suited for the project, says Vora. Since the planner/ developer of every project is different, it is not possible to design every building in the same way.

Manish Kumar adds that system designers should have enough knowledge to develop aluminium profiles according to the hardware standard. While preparing aluminium profile designing, the system developer and hardware manufacturer need to interact with each other to avoid later consequences, he adds.

Below are a few solutions that can provide some ease in the selection of window/ door systems, adds Vora:

• Proper know-how of the window/door hardware technical data sheets. These documents mention the recommended shutter sizes, weight carrying capacities, grade of material, etc.

• Recommendation of uniform testing standards which the hardware should have received from a recognised authority

• Awareness amongst the manufacturers to clients, consultants and architects of the system’s advantages and limitations

• Seeking assistance from manufacturers during the design stage to ensure the final desired product is executed as planned.

Amity Kolkata by Vijay Gupta Architects

Amity Kolkata by Vijay Gupta Architects

Architectural hardware selection and standardisation are generally left to the realm of architects, project managers, rate analysts, and contractors based on certain specifications and applicable rules/standards. Some of the missing participants are the facility managers and the maintenance personnel. They are the people who actually face the brunt on a regular basis specifically in the case of non-residential building types. Their experience can be of great value, says Ar. Mehta.

Another important direction one could take is to make an exhaustive list of door/ window/façade solution types and their permutations and combinations with respect to various building types and then start putting out applicable hardware typologies against each in the list and have that come across as an approved minimum standard for the said types, though there are agencies which lay the benchmarks for standards. This would eventually lead to simplification of selection and also there in allowing for more availability of stocks in the typologies making long-term maintenance, etc., easier, remarks Ar. Mehta.

On the other hand, Jain believes that most hardware systems and products do follow market standards with respect to design and also come with appropriate and well approved certifications. “While standardised systems enable ease of procurement and execution, they certainly restrict design freedom to a great extent. Even though it is possible to get bespoke and custom-made hardware products and systems in cases where the design demands so, it is a hassle and might shoot up the project cost quite a bit”, adds Jain.

According to Ar. Sivasankar, what we get in the market is standard hardware that only matches the normal/standard doors and windows but when you want a different final product, doors and windows, the hardware should be different too. Their technical/product specifications too will differ based on functionality and appearance.

Ar. Sivasankar suggests a few solutions based on his experience and knowledge:

• A research about the hardware that is not used widely in the market

• Find companies or individuals who do customisation of hardware products

• Understand the hardware products they have manufactured for their clients

• Pay a visit to their showroom for those products which are showcased

• Give your requirements and ask for shop drawings and technical/ product specification

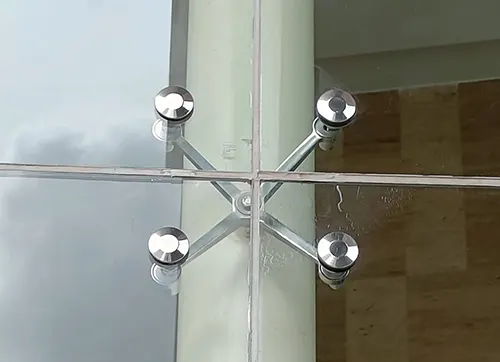

A façade design by Acorp Consultants Pvt Ltd In the custom design space in which we operate, designers have to accommodate more desirable, novel or appropriate ideas criteria, avers Ar. Karode. For e.g., applications that can support super-sized performance glass panels in high-rise façades. To achieve this, we need to use the highest international certification standards; in mind that the standards do not become limited and pose constraints on the possibilities of design. The rising desire for non-standard glass sizes and performance glass poses the challenges of needing specialised hardware to support more ambitious façade applications. Thus architectural hardware reliability, strength and easy applicability have become a big factor in recent glazing achievements.

A façade design by Acorp Consultants Pvt Ltd In the custom design space in which we operate, designers have to accommodate more desirable, novel or appropriate ideas criteria, avers Ar. Karode. For e.g., applications that can support super-sized performance glass panels in high-rise façades. To achieve this, we need to use the highest international certification standards; in mind that the standards do not become limited and pose constraints on the possibilities of design. The rising desire for non-standard glass sizes and performance glass poses the challenges of needing specialised hardware to support more ambitious façade applications. Thus architectural hardware reliability, strength and easy applicability have become a big factor in recent glazing achievements.

Key Safety Parameters to Look for While Specifying Hardware

While selecting any hardware for the projects we must consider the safety parameters on a priority basis and it should never be compromised, points out Ar. Khan. International standards for hardware should be considered while selecting hardware for any location and application. Parameters like fire resistance, security, weather resistance, and performance during any disaster like fire & earthquake, amongst others are important. These parameters cannot be defined or achieved just by going with the look & feel of the product. We must ensure that the product has gone through all the tests, quality checks and certification as per the global standards.

BHEL NOIDA by TDS Coetus Pvt. Ltd.“One of the primary considerations is the planned span’s appropriateness, loading, and frequency of usage. Then comes the corrosion resistance, particularly if used in highly polluted or coastal areas. However, on high rises, the certification for wind loads is equally an important consideration. Furthermore, compatibility with the door/window profile is another critical factor with gasket selection that can be essential to safety since it helps in resistance to smoke and air infiltration and the ability to keep loud noises out”, observes Ar. Gupta.

BHEL NOIDA by TDS Coetus Pvt. Ltd.“One of the primary considerations is the planned span’s appropriateness, loading, and frequency of usage. Then comes the corrosion resistance, particularly if used in highly polluted or coastal areas. However, on high rises, the certification for wind loads is equally an important consideration. Furthermore, compatibility with the door/window profile is another critical factor with gasket selection that can be essential to safety since it helps in resistance to smoke and air infiltration and the ability to keep loud noises out”, observes Ar. Gupta.

For homes, Ar. Karode recommends investing in smart home solutions linked to the IoT- This should cover safety from fire, security, surveillance, alarm, and cover appliances. For high-rises, Ar. Karode and Ar. Mehta recommends hardware compatible to adhere to the applicable fire life safety code like natural smoke control systems, intelligent ventilation, labour safety protection and alarms in unmanned areas. “For example, in addition to the code requirements, we should ensure self-closing fire doors with panic devices and interlocking the multi-level secure and access system with fire alarm interfaces”, he adds.

Hardware should be strong enough to resist static load & dynamic forces and the supreme quality for fire resistance are the two aspects recommended by Manish Kumar.

When do we have to change/replace architectural hardware?

Here is the answer given by Ar. Sivasankar:

• Old-designed hardware that can be easily broken by a burglar/shoplifter

• Due to wear and tear, the mechanism stops functioning

• Materials used to manufacture the hardware can be lightweight

• Sub-standard quality and low grade of the product

• Sagging of the doors and/or windows

• Gaps between the doors/windows and frames

• Poorly maintained hardware

• Non-fire resistance materials

• Clear glass or wooden shutters for windows and/or doors.

Looking at the above-mentioned reasons, the end user has to take a decision while considering the safety parameters. They can be:

• Upgrade the hardware based on current technology

• Materials to be used of first-class quality and grade 1 components

• Gaps between doors/windows are to be of an allowed measurement

• Fire-resistance products to be used

• Use of toughened glass or metal shutters for windows and/or doors

• Testing of windows, doors & façades in extreme weather conditions

• No extra load of profiles to be used on façade, windows and doors

• Purchase materials/products recommended by National Building Code 2016 that suit to Indian environment.

According to Pramod Jain. Knobs, hinges, latches, levers and locks are gadgets that enable the functionality of a building, and an optimum investment in them yields great dividends. In order to ensure safety, factors such as performance, durability, certification, quality, material and the design mechanism are emphasised. For example, if we consider hinges – it is crucial to look into their durability with respect to how strong it is or what alloy it is made up of. Similarly, a good certification ensures maximum safety, hence authorised and licensed attestations need to be checked.

A project by Rahul Mehta Architects – corridor with classic handles and panelled doors

A project by Rahul Mehta Architects – corridor with classic handles and panelled doors

Key Safety Parameters

• Number of locking points: Parameters like window size, wind pressure, etc., determine whether a single point or multipoint locking arrangement is required

• Type & number of hinges: Shutter weight is one of the prime factors which determines the type and number of hinges to be used. The position of these hinges also plays a vital role.

• Stay arm: In many applications, the restricted opening is recommended in order to ensure the window after opening can be brought back to close condition with utmost ease.

• Stopper in sliding windows: This ensures when the shutter is accidentally moved it should not bang at the extreme ends and cause injury

• Performance mockup test: It determines the performance of the window hardware for design wind load as well as for proof load conditions

• Anti-fall system: This can act as a secondary safety accessory that holds the shutter and avoids its fall, in case it disengages from the window frame

(Vicky L. Vora, Founder & Principal Façade Consultant, V3 Façade Design Studio)

Quality Vs Price

The context of reasonable price is a vague subject in India. Quality hardware is expected to ask for a premium over sub-standard products. As façade consultants, says Vora, we propose precise specifications and a minimum of 3 makes for every item which is used on a façade. Having more than one option gives the contractor/client to negotiate better and get better hardware solutions for the project. Value engineering and optimisation can be done on other aspects of façade design. This exercise can bring you reasonable savings without compromising on the safety and other technical aspects of the façade design.

A project by Rahul Mehta Architects – matching doors and windows with Georgian bars and concealed handles

A project by Rahul Mehta Architects – matching doors and windows with Georgian bars and concealed handles

Ar. Mehta suggests that it would be great if one could explain the types and costing (in terms of what goes into putting a product out there in the consumer market) of hardware from the very grassroots in the industry so that it can help the next crop of designers and engineers better guide their clients. Quality products that are ANSI BHMA certified have an associated price, while they are not cheap, they must meet the performance criteria of each product under test conditions, notes Ar. Karode.

“Our solution to this is to always suggest looking at criteria beyond merely the performance features of a product; We recommend tested and certified products where the strength and operational efficiency performance of each product is measured and graded against the baseline international standard”, he adds. Due to a lack of proper standardisation of the products, and less investment in innovation & research, manufacturers are not able to create a segment of the products that is cost-effective without compromising the performance & reliability of the product, says Ar. Khan.

Pramod Jain, observes that one of the major reasons for the price hike is the transportation cost imposed by the foreign manufacturing companies. This issue can be resolved if the Indian government can fund and help set up new companies within the country itself, just as the ‘Make in India’ campaign intends to do. Ar. Sivasankar, too agrees that the Indian manufacturer has to build the same product equivalent to that of a foreign product with an economical rate/price. Also, the Indian manufacturer can have a business tie-up with his abroad collaborator to manufacture the same in India which obviously will have an impact on the rate/price of the product.

The Architectural Hardware Industry can be regulated if we implement manufacturing, installation, and maintenance standards, says Ar. Gupta. We should find a balance between customisation and cost-effectiveness. Since customisation has a direct impact on economies of scale, thus raising the cost of manufacturing. Volumes are being driven by construction across all sectors, which should address the issue of high costs and low budgets that plague the selection of quality hardware. Similarly, engineered fenestrations help to standardise products and increase their affordability.