The word façade originally comes from the Italian word “facciata”, and is defined as the outside or all of the external faces of a building. The term is frequently used to refer just to the main or front face of a building.

Along with the roof, cladding is one of the most important elements of a building, since it acts as the primary barrier against external weather elements that could damage the health of the structure, such as rain, snow, wind, frost, sun, etc.

Because of this, it is very important to choose a façade system that protects against these risks whilst helping to achieve lower energy consumption, reduce maintenance costs and improve comfort for the inhabitants.

Contemporary homes are unique for their incorporation of multiple architectural styles. While they feature the minimal adornment, open spaces and large windows of modern homes, they are also characterized by free-form composition not found in modernist architecture.

With today’s technology, architects are no longer limited to linear forms. For this reason, contemporary homes tend to incorporate dramatic curves and seemingly impossible proportions.

Another main feature of many contemporary homes is eco-friendly, sustainable design and smart-home technology that reflects a response to today’s climate-change emergency. For instance, contemporary homes are often constructed of natural and recycled materials.

There are many products available in the market for contemporary façades.

-

-

- Precast concrete panels

- Natural stone/granite/tile

- Stucco

- Fibre cement panels

- Terracotta

- GRC/GFRC/FRP

-

One prominent solution to many of the above cladding materials is using aggregated Portland cement boards as base substrate and then jointing and finishing substrate with a cement-bound, synthetic resin-enhanced basecoat. This basecoat provides a seamless surface for the final texture/paint/coating. This technology is used in various applications in façade like:

Exterior Drywall –

Cement board is a superior alternative to traditional construction methods such as brick walls or AAC blocks. A typical exterior drywall consists of exterior grade cement board + basecoat along with interior grade Gyp boards from the internal side of a stud frame. Insulation is filled between the external and internal board cavity for various levels of fire rating and acoustic insulation.

Direct Applied Exterior Finish Systems –

DEFS are relatively new wall cladding systems utilizing polymer-based products with various sheathing boards which function as a substrate. These systems generally do not have an insulation component, although, in one case, the substrate also serves as insulation.

Exterior Insulation Finishing System –

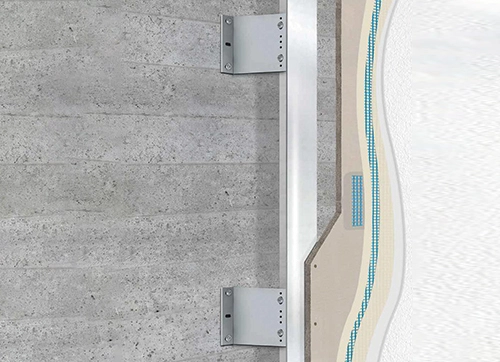

An Exterior Insulation Finishing System (EIFS), also known as EWI (Exterior Wall Insulation System) or External Thermal Insulation Composite System (ETICS) is a type of cladding system that provides exterior walls with an insulated finished surface & waterproofing in an integrated composite material system. Put another way, an Exterior Insulation Finishing System/External Thermal Insulation Composite System can be defined as an ideal energy-efficient thermal wrapping or façade insulation applied to the exterior surfaces of a building which is then finished with a long-life, decorative and protective wall coating that can be installed on any type of construction.

We will find many different companies worldwide offering different solutions for various façade cladding options in cement boards. Some manufacture almost all components like Cement board/insulation/ vapour barrier & finishing basecoat. Some manufacturers specialize in manufacturing independent components like substrate board/basecoat. Eventually, a façade system installer provides a final solution to clients based on site requirements. Clients will always have a wide range of products/ manufacturers to choose the required system as per their requirements.

There are various advantages of the above system:

1. Fire resistant – Almost 100% of components of DEFS are non-combustible hence it is practically very safe to be used in façades.

2. Thermal insulation – With more and more usage of air conditioning, energy saving in buildings become very important. Various insulation methods inside DEFS/EIFS buildings can be made more energy efficient.

3. Acoustic insulation – Exterior drywalls can be used to achieve various levels of acoustic insulation

4. Design freedom – With flexible cement boards and top basecoat, practically any design/height and shape can be achieved using the DEFS system. There are many exterior-grade textures/coatings available by many reputed brands for clients to choose from.

5. Lightweight – Reducing the weight of the façade system also reduces concrete & steel consumption hence reducing overall construction cost.

6. Faster – Exterior drywalls are at least 4 times faster than conventional construction methods, hence buildings like hotels/malls/hospitals can be constructed faster to generate revenue for clients much in advance.

7. Leak-proof/mould-free surface – With top basecoat technology buildings become crackproof and leakproof hence increasing building-like and making the façade look younger for many years.

8. Better finish – As the boards are installed over blockwork using steel frames, the plum and line of the façade are very much smooth and flat as compared to RCC/ Blockwork.

9. Green construction – Construction of exterior drywall requires only 5% construction water as compared to block work. Also, cement boards are only 12mm thick which requires less energy spent during manufacturing and transportation to the site, making exterior drywalls a very good solution in green buildings.

Case Study – 1

Oberoi Flight Kitchen Services Sahar, Mumbai

During the design brief meeting, the client shared his experience with Ar. Parag about challenges of Masonry construction in steel building. Ar. Parag with his vast experience in PEB buildings found a solution for this problem by using Exterior Drywalls with Moisture barriers and avoiding joinery between Steel beams to wall partitions. Wall heights varying from 3Mtr to 5 m were another challenge for construction.

MRWL team worked on various details of joints, groves, and junctions to make sure that façade looks neat and clean and is well protected against any seepage and leakage issues. Architects also used cement boards innovatively to create contrasting bands over exterior drywalls both horizontally & vertically.

QUICK FACTS:

- Project: Oberoi Flight Kitchen Services

- Location: Sahar, Mumbai

- Client: Oberoi Hotels

- Architect: M R Warekar & Associates

- Other Consultants: Tata consulting engineers

- Architectural Hardware used: Light gauge steel frames and USG cement boards

- Commencement Date: Nov 2019

- Completion Date: July 2020

Case Study – 2

SD Imperial Edge IV Tardeo, Mumbai

When we came on board for this project, the application was for a simple exterior drop beam to be created at the slab edge on typical floors (23rd to 49th). During the first phase of installation, both architect and clients realised the versatility of the seamless finish achieved by DUROCK boards also reducing the total weight of the façade system. During phase 2 construction system was used to construct dummy beams and columns, projected box cladding, soffit ceiling and a grand entrance gate arch.

When we came on board for this project, the application was for a simple exterior drop beam to be created at the slab edge on typical floors (23rd to 49th). During the first phase of installation, both architect and clients realised the versatility of the seamless finish achieved by DUROCK boards also reducing the total weight of the façade system. During phase 2 construction system was used to construct dummy beams and columns, projected box cladding, soffit ceiling and a grand entrance gate arch.

Overall 20000Sq.Ft of cement board dry cladding was used, after painting the entire cladding just merged with exterior India’s first premium flagship Apple store constructed is Positioned on a prominent corner of Jio World Drive, BKC. Ground + 1st floor is designed for retail space and has a huge glass façade for more visibility walls and RCC surface making the entire façade look very settled and smooth. Not to mention construction was done much faster compared to GRC.

QUICK FACTS:

- Project: SD Imperial Edge IV

- Location: Tardeo, Mumba

- Client: Shapoorji Pallonji & Dilip Thacker Group, SD Corp

- Architect: Hafeez Contractor

- Other Consultants: Façade India testing

- Architectural Hardware used: PPGI frames & USG cement board

- Commencement Date: Jan 2020

- Completion Date: Dec 2020

Case Study – 3

Apple Flagship Store BKC, Mumbai

India’s first premium flagship Apple store constructed is Positioned on a prominent corner of Jio World Drive, BKC. Ground + 1st floor is designed for retail space and has a huge glass façade for more visibility walls and RCC surface making the entire façade look very settled and smooth. Not to mention construction was done much faster compared to GRC. and natural light.

India’s first premium flagship Apple store constructed is Positioned on a prominent corner of Jio World Drive, BKC. Ground + 1st floor is designed for retail space and has a huge glass façade for more visibility walls and RCC surface making the entire façade look very settled and smooth. Not to mention construction was done much faster compared to GRC. and natural light.

On the 2nd floor above Canopy is their office space, where, apart from the glass façade clients needed a rain screen façade system to give this façade a more settled look and feel, a layer of insulation was added between cladding & block work for a better thermal comfort for the occupants.

The entire cladding was also wrapped with a TVYEK membrane to manage water ingress behind the cladding. There was also a curved wall cladding in the façade where a smooth curve was essential to give the premium look to the façade.

QUICK Facts:

- Project: Apple Store

- Location: BKC, Mumbai

- Client: Empty TC India

- Architect: Fosters + Partners

- Other Consultants: BES

- Architectural Hardware used:AZ150 Coated steel frames and

USG cement boards - Commencement Date: Sept 2022

- Completion Date: Jan 2023

Case Study – 4

Chalet Hotels – Commercial Phase 3 Powai, Mumbai

This commercial building is 3rd building within the Chalet Powai hotel complex. It’s a PEB building constructed by L&T. The Architect wanted a picture frame around the glass façade, a total of 170m long cladding per floor around the glass façade and their requirement was to have this in seamless finish with texture paints. This cladding also acts like a soffit and will have very interesting façade lights post-sunset.

This commercial building is 3rd building within the Chalet Powai hotel complex. It’s a PEB building constructed by L&T. The Architect wanted a picture frame around the glass façade, a total of 170m long cladding per floor around the glass façade and their requirement was to have this in seamless finish with texture paints. This cladding also acts like a soffit and will have very interesting façade lights post-sunset.

Façade gets an unobstructed view from Powai Lake. A specially designed DEFS system along with the customised PPGI frames solution reduces cladding weight. The façade looks very natural but at the same time, it provides good protection for the structure from weathering. This is a masterpiece in making and installation will be complete by Oct 2023.

QUICK FACTS:

- Project: Chalet Hotels commercial Phase 3

- Location: Powai, Mumbai

- Client: Chalet Hotels (K Raheja Corp)

- Architect: PG Patki Architects

- Other Consultants: AXIS FAÇADE

- Architectural Hardware used: PPGI frames & USG cement boards

- Commencement Date: JULY 2022

- Completion Date: Ongoing

CONCLUSION

Whether you are in the process of a new construction or refurbishing an existing façade, getting the right building materials is essential. Exterior drywalls/cladding and ceilings must be stable and durable during different weather conditions and the drywall system offers that stability.

Drywall can be used for the construction of regular walls and ceilings but also as a façade cladding material. It can be removed and installed easily and can be cut in all sizes. It is manufactured faster and this makes a difference to the energy costs during their construction. Most important is the finish one achieves with cement board cladding. Exterior drywalls are a very familiar construction technology worldwide and slowly many Indian developers are also using this world-class technology to build faster and better.