In a conversation with Sreenivas Narayanan Technical & Compliance Director – Middle East & Asia Pacific, Siderise Insulation, he talks about Siderise’s evolution, its products, projects and its contribution to improving fire safety in buildings. Here are the excerpts…

Can you provide an overview of Siderise’s history and the evolution of your solutions over the past 50 years?

Siderise started its life in 1972 as a distributor of acoustic materials. However, we soon became aware that the standard materials available on the market could not always meet the specific requirements of our customer base. So, in 1979, we opened our first manufacturing facility. This allowed us to develop more progressive acoustic options and bespoke product designs for a mix of construction markets.

After success in this field, we expanded our offering in 1991 with another manufacturing facility dedicated to the development and production of passive fire protection solutions for the building envelope. However, again, we did not want to simply replicate what was already available on the market. Recognising the limitations of standard spray on fire seals and horizontally fibered fire barriers – and understanding the need for reliable fire-safe constructions – we engineered an innovative dry-fit stonewool Lamella solution with a patented manufacturing process.

In essence, this involves laterally compressing vertically oriented fibres and heat-bonding foil to the ‘cut’ face of the fibres under factory-controlled conditions. The foil and the pre-compression are critical to the mechanics of effective fire-stopping. From this strong foundation, we continued to grow the business through mergers and active globalisation to meet the growing demand for fire, acoustic and thermal solutions for this rapidly evolving worldwide market. This included embracing new technologies to help improve building safety. Fifty years on from our acoustic beginnings, Siderise is now one of the world’s leading construction product manufacturers of high-performance passive fire protection solutions for the building envelope, operating across the UK, Europe, the Middle East, the US, India, Asia Pacific, and beyond.

How has the Siderise brand and range of passive fire safety products gained international recognition?

At the heart of our global reputation is the dependable performance of our factory-engineered products and systems. This is verified by intensive fire testing to national, European, and international standards at a product and system level, as well as part of large-scale façade constructions. Whilst universally recognised standards are of unquestionable importance, we also take into consideration regional standards and undertake testing to satisfy localised compliance criteria.

We also advocate for independent certification where possible, even though it’s not always mandatory. We use accredited bodies such as ICC-ES to evaluate our products and were recently issued with our ESL-1524 listing for CW-FS120 – the first curtain wall perimeter firestop manufacturer to get this listing. This essentially means that we can obtain approval from local authorities in the MENA region as it is deemed to comply with the applicable sections of the International Building and Saudi Codes (IBC and SBC) for compartmentation in curtain wall applications.

We are also committed to fulfilling the requirements of regional AHJs where the approval process for certified acceptance varies from country to country. Take the Malaysia Fire and Rescue Department (BOMBA) for example, or the Singapore Civil Defence Force (SCDF). This ensures code compliance— and beyond— across different applications in multiple regions. It doesn’t stop there; we have a strong network of in country partners spanning the globe whose local knowledge and on-the-ground expertise have been invaluable enabling access to Siderise products and systems.

However, we do not only export products but an ethos. Our offering is underpinned by a core value of ‘integrity in all we do’. This includes openly providing trusted product information to the market, commitment to building competency within the workforce, and sharing our knowledge and experience with the industry. It is this mix of quality manufacturing, thorough testing, and supportive service that sets us apart in the global market, and why international architects, consultants, façade contractors, and other stakeholders have confidence in specifying and using our products.

Can you elaborate on the class-leading fire protection, noise control, and thermal insulation capabilities of Siderise’s products?

We are always looking to push the performance of our products to the next level – typically far beyond the minimum requirements of code and regulation to ensure the safest possible solution. It raises the bar and creates a higher playing field to help drive the industry toward best practices. One example is the current development of a product that aims to fulfill both thermal and fire performance criteria in curtain wall façade applications. Designers and specifiers are often presented with conflicting principles when it comes to energy efficiency and fire safety considerations. So, we wanted to address this with an innovation that functions as both a fireboard and thermal insulation.

This will also streamline the source and supply process for buyers by providing a complete system under one warranty from a single manufacturer, with the confidence that each component is compatible. Furthermore, much of our business is in curtain walling so in addition to our passive fire protection offering, we offer a range of solutions for managing sound in these building types.

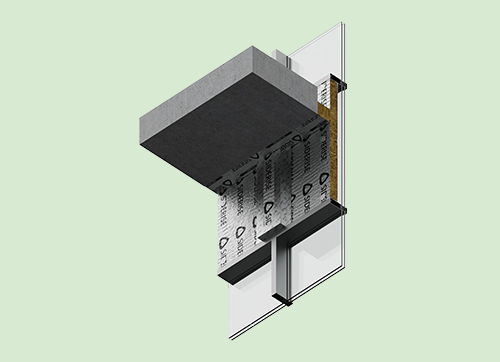

Our Siderise CW-FS Curtain Wall Firestop is another fine example. We were the first, and currently, we are the only manufacturer, to produce a perimeter barrier solution that has been tested to EN 1364-4 in a façade construction with mechanically induced pre-test movement cycling to EAD 350141-00-1106. It is clear how crucial this is when we consider that curtain wall façades and floor slabs can move a lot due to forces such as wind loading, seismic activity, and thermal stress. Installed between the façade and the slab edge, it is therefore vital to ensure that perimeter fire seals can withstand this constant deflection, whilst maintaining a tight fire seal against both elements to ensure effective compartmentation.

Nevertheless, we have recently gone one step beyond as the first-ever manufacturer of holistic curtain walling compartmentation systems outside of the US to test for ASTM E2874. Released around three years ago, this is a standard that aims to address a huge issue that has been lingering in the industry for some time – how do you assess leap-frog risk?

In summary, this new test method seeks to help specifiers evaluate the performance of a spandrel construction in terms of auto-exposure and fire resistance. At this time, it is not an obligatory requirement of any jurisdiction yet, despite the cost, we wanted to test one of our protected spandrel systems to gain a deeper understanding of performance.

How does Siderise support customers and specifiers with technical expertise? Can you provide examples of the support services offered?

Accurate specification and installation are key to successful passive fire protection. To support this, we are committed to nurturing technical excellence, which is why we have wrapped our product and systems portfolio in a comprehensive and free-of-charge technical services offering throughout the construction journey, from concept and design to sign-off and handover. We currently have four regional offices with in-house expertise at both a national and international level, with over a third of our entire global workforce technically trained. Combine this with the expert local knowledge of our partners and we have a wider reach with the ability to support more stakeholders.

Our highly trained competent engineers in our technical services team have an intrinsic understanding of how our products work and what makes a safe building. With a huge amount of test data and experience at their fingertips, they provide detailed advice and assistance on specification, detailing, engineering judgments, compliance, and even bespoke product or systems development that comply with various performance criteria, depending on the application.

To help bridge the gap between design and as-built performance, our Site Services team provides site managers and installers with invaluable insight into potential practical challenges whilst helping to ensure the fire safety strategy is not undermined. This includes toolbox talks, project-specific training, and benchmark installations, which all assist in ensuring instructions and method statements are fully understood.

The team also provides an inspection service to ensure our products are installed as intended. This can be done in person or digitally using our free Siderise Inspection App, which allows installers to send photographic evidence and installation data directly to Siderise engineers to review. This makes it simple to record the progress and quality of installation of standard Siderise firestop, cavity barrier, and acoustic barrier systems before they are concealed by the façade.

The report generated by the app provides a valuable visual record of hidden elements of construction once the build is complete. This means it is clear exactly what’s in the building and how it was installed which can be passed over to the building owner at sign-off and used to inform any future maintenance or building work.

In what ways has Siderise contributed to advancements in fire protection, noise control, and thermal insulation in the construction industry?

Collaboration and knowledge-sharing are fundamental when it comes to progress, especially around a subject as complex as passive fire safety or as misunderstood as acoustics. We have created a bank of educational resources to help construction professionals build and consolidate their knowledge, from interactive online learning modules (Deep Dives) for specifiers, to hands-on onsite training for installation teams. We also take the insights we have gained from our test data and project involvement and use them to actively participate in key technical committees and trade associations activity to help drive the global construction industry towards better solution performance and competency standards.

Additionally, as an Officer of the Construction Products Association (CPA) in the UK and Chair of its Marketing Integrity Group (MIG), our CEO, Adam Turk has taken a lead role in advising regulators and legislators on the emerging ‘Code for Construction Product Information’ (CCPI). This new code is voluntary and aims to improve the marketing of construction product information so that it is clear, accurate, up-to-date, accessible, and unambiguous. Naturally, we have signed up for the code because in line with our core value of ‘integrity in all we do’, we believe in the open sharing of trusted information.

Of course, reliable information and competency are intrinsically interlinked – training someone to be highly competent and giving them unreliable information does not make sense, nor does giving reliable information to someone who does not have the competency to use it. It is our duty as experts in this safety-critical field of construction to provide trusted product information to the market and share our knowledge and insight to help build competency and raise the bar for a safer global built environment.

Can you discuss any recent innovations or advancements in Siderise’s solutions?

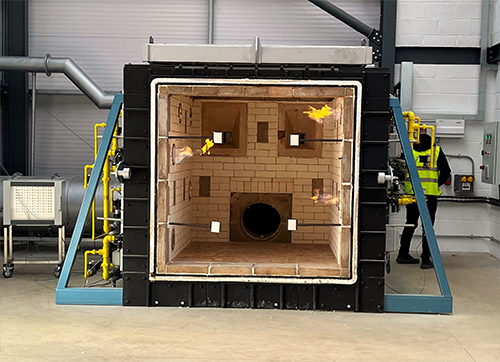

We have invested in our R&D capacity with a new £1 million Global Innovation Centre. Operational from January 2023, the center marks a huge step forward for us, raising our profile as a diligent and dedicated manufacturer of life-safety critical products. Featuring a specialist fire test furnace – the only one of its kind outside a dedicated fire testing facility – the ability to test products to any published fire test curve to BS, EN, ASTM, UL, and ISO standards will allow us to not only conduct our own research and quality control testing in house but also to expand our bespoke solution offering, helping to develop passive fire protection systems for even the most unusual projects.

We are in the process of seeking UKAS accreditation to ISO 17025 to verify that it operates with technical competency and generates valid results, with the goal of making fire safety performance testing more accessible across the industry. We are also seeking to embrace new advancements in service-related technology, such as the development of the next-generation Siderise Inspection App or embracing AR technology to view and position 3D design models of our systems, transforming the way people consume and interact with information.

How does Siderise ensure that its insulation products meet or exceed industry standards and regulations?

Whilst not always compulsory, testing to the correct standards and gaining third-party certification are the best ways of assessing and verifying the performance of passive fire protection products, and ensuring true compliance with any regulations or best-practice standards. There are often multiple tests on the market, but testing to standards that offer a more accurate indicator of real-life performance in line with the real-world demands of the application can be considered much safer.

As mentioned earlier, we have partnered with world renowned certification bodies – including UL, Intertek, IFC, ESL and Certifire, ICC ES – to ensure all our tests are independently checked and verified. Gaining certification is a rigorous process, usually involving reviewing product test data against appropriate standards and requirements, and submitting product samples for analysis and as comparative samples. Factory visits and audits may also be carried out randomly, certification will be withdrawn, and re-testing required if any significant changes are observed. Any certificates that have been achieved are always uploaded to our website for specifiers to assess and use.

As mentioned earlier, we have partnered with world renowned certification bodies – including UL, Intertek, IFC, ESL and Certifire, ICC ES – to ensure all our tests are independently checked and verified. Gaining certification is a rigorous process, usually involving reviewing product test data against appropriate standards and requirements, and submitting product samples for analysis and as comparative samples. Factory visits and audits may also be carried out randomly, certification will be withdrawn, and re-testing required if any significant changes are observed. Any certificates that have been achieved are always uploaded to our website for specifiers to assess and use.

Could you provide some examples of notable projects where Siderise’s solutions have been successfully implemented?

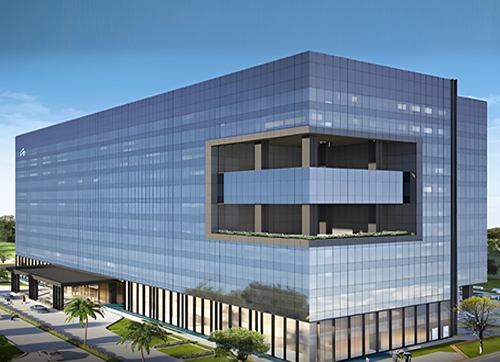

Our robust portfolio of properly verified passive fire protection has led to specification on some of the world’s most iconic and innovative buildings. For example, in Dubai, our products have gone into many of the skyscrapers that dominate the city’s famous skyline, such as Boulevard Heights, Fountain Views, Al Fattan, and Merano Tower along with the Mobility Pavilion Expo 2020 and more recently Uptown Tower.

We are also currently working with the project teams on the stunning 360m Ciel Tower – the world’s tallest hotel. Across India, we have completed over 200 projects with our distribution partner, Allarch, including Three Sixty West – a notable residential and hotel tower in Mumbai. Elsewhere, we have Assima Tower in Kuwait, Samsung Biologics in Korea, MOL in Hungary, Lusail Plaza, Doha, Al Amein Towers, in Egypt Sanofi EVF in Singapore and the TK Office Tower in Cambodia with plenty more projects underway!

What specific challenges are associated with insulating cladding systems, and how does Siderise address those challenges?

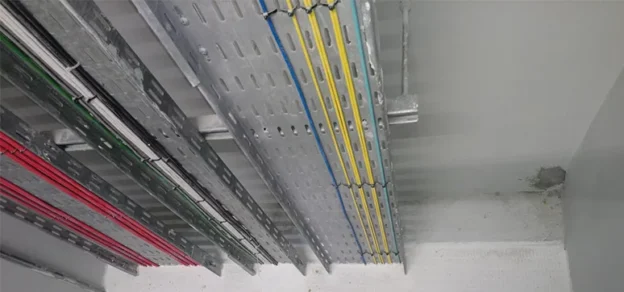

From a fire safety perspective, one of the key challenges when it comes to protecting cladding systems is the frequent requirement for a ventilation gap between the insulation and the cladding. This is to allow any moisture that penetrates the external façade to drain away. In addition to preventing issues with dampness or mould, the airflow within the cavity allows the whole system to stay cool in summer, and warm in winter, and provides some acoustic benefits. However, this open cavity can present a fire risk if not carefully considered. If a fire entered the wall construction, this void would act like a chimney, drawing the flames, smoke, and heat up the building and causing the fire to spread to multiple floors.

To prevent this happening, in many countries there is a legal requirement for the cavity to be closed off using cavity barriers. Yet this directly conflicts with the idea of a ventilated cavity. To address this, we developed our open-state Siderise RH Cavity Barriers. These include an integral intumescent material that rapidly expands in reaction to high heat (around 130°C). This allows them to be fixed to the internal cavity wall, leaving the ventilation gap open to allow for free vertical movement of air and drainage day-to-day (sometimes referred to as the “cold state”).

However, in the event of a fire, the intumescent expands in a matter of seconds until the void is fully closed and a robust fire seal is formed.

We are always collaborating with partners in the industry to conduct large-scale tests in different configurations with different materials and the dataset from these tests means that we can learn a lot about specific challenges and find new ways of overcoming them safely.

How does Siderise ensure the compatibility and integration of its insulation solutions with different cladding materials and systems?

Again, testing is key here – particularly to standards that allow us to understand how our products will be used in real-life applications. This includes submitting our products to be used within large-scale façade systems tests, such as NFPA 285 and BS 8414-1 and -2, and in system tests for specific applications such as ASTM E2307 and EN 1364-4 for the perimeter fire seals used within the spandrel zone of a curtain wall façade. These comprehensive tests offer a clearer understanding of the fire resistance in terms of not only how our product performs but how it will interact dynamically with other components and materials within the façade under fire conditions.

In light of recent incidents involving cladding related fire hazards, how does Siderise contribute to improving the fire safety of cladding systems? These incidents have very clearly demonstrated that doing ‘just enough’ is never enough and that fire safety must be at the heart of every stage of the construction process, especially in high-rise buildings. As global experts in passive fire protection, we believe we have a key part to play, acting as a trusted project partner from concept to handover. With our robust testing approach and investment in ensuring technical excellence, we are equipping design and construction teams across the globe with the cutting-edge solutions and tools they need to ensure the highest safety and performance standards possible to protect buildings and all who use them.