“I am in too much grief to talk. What can I say? The work of half my lifetime, very nearly; all my mechanical instruments and scientific apparatus, that it has taken years to perfect, swept away in a fire that lasted only an hour or two. How can I estimate the loss in mere dollars and cents? Everything is gone. I must begin over again.” – Nikola Tesla

A fire broke out in the basement of 33-35 South 5th Ave and swept through the entire structure, including Tesla’s laboratory. Unimaginable records of scientific discoveries vanished into thin air. Fire is all-consuming and doesn’t care about sentiments, and for any safe design of buildings, fire safety should be its priority.

PASSIVE FIRE PROTECTION

Apart from active fire protection which is important, but as the saying goes, “prevention is better than cure” passive fire protection is of greater importance. Any building materials selected shall be carefully examined for their fire reaction properties and fire resistance properties. When active fire systems work once the fire erupts, passive fire system prevents a large fire spread, prevents major damage to building members, and provide enough time for active fire system to work efficiently. As aluminium glazed curtainwall is a non-combustible material everyone assumes that the building is safe when it is not. The gap between a curtain wall and floor assembly is a void, which will be hidden in any building after completion, if that is not closed with appropriate materials, this acts as a chimney where in case of fire, hot gases, smoke, and fire can easily spread from floor to floor.

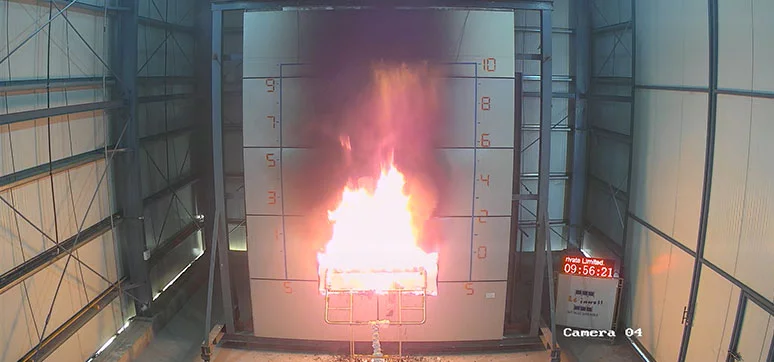

Fire stops or perimeter fire protection systems are designed to protect the building and its occupants from the rising hot, toxic smoke and the rapid spread of fire. Imagine a building without a fire stop or with a bad untested and unverified firestop system in place which can easily give away. When there is a fire accident in one of the apartments, the fire will rapidly grow and damage the false ceiling and expose the void or if there are any nonverified fire stopes. The hot high-temperature smoke and toxic gases will soon rise and spread to the top floors. To make sure that the fire stops and spandrel areas in a building are safe, it shall be tested against ASTM E 2307 and ASTM E 2874 respectively. Both the test methods are similar and done in an Intermediate-Scale, Multi-story Test Apparatus (ISMA)

ASTM E 2307: Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-Scale, Multi-story Test Apparatus (ISMA)

This test method measures the performance of the perimeter fire barrier and its ability to maintain a seal to prevent fire spread during the deflection and deformation of the exterior wall assembly and floor assembly during the fire test while resisting fire exposure from an interior compartment fire as well as from the flame plume emitted from the window burner below.

When the maximum joint width is not equal to the minimum joint width, the fire barrier is subjected to a movement cycle before the fire test, the minimum number of cyclic tests and its rate of movement are specified in the standard. The standard determines the following

- Movement capacity of the perimeter fire barrier.

- Loadbearing capacity if required.

- Ability to resist the passage of flames and hot gases &

- Insulation properties of the perimeter fire barrier.

This standard does not provide the quantity of smoke and other combustion products emitted during its combustion or the flame spread over its surface. This can be evaluated as per ASTM E 84. The fire barrier is installed into a calibrated Intermediate-Scale, Multi-story Test Apparatus. When required, a movement cycle is performed as per ASTM E2307 before the fire test. Unexposed thermocouples are fixed over the fire barrier to determine the ‘T’ rating which corresponds to insulation properties and the ‘F’ rating corresponds to the integrity properties of a fire barrier. Both ratings are provided with respect to time.

A fire barrier with a joint width of 4 inches or less, has a ‘T’ rating of 50 minutes means that the fire barrier has stopped a temperature rise of any of its thermocouples on the surface of the unexposed face of the perimeter fire barrier or adjacent supporting construction from crossing 181°C above the initial temperature until 50th minute of the test. If the joint width is greater than 4inch then the temperature is limited to 139°C. Similarly, a fire barrier has an ‘F’ rating of 55 minutes means that the fire barrier has stopped any flame projection around its boundaries and the passage of flames or hot gases to ignite the applied cotton pad till the 55th minute of the test. If there is any load applied on the perimeter joint, then the joint shall have sustained that load for the duration of the test.

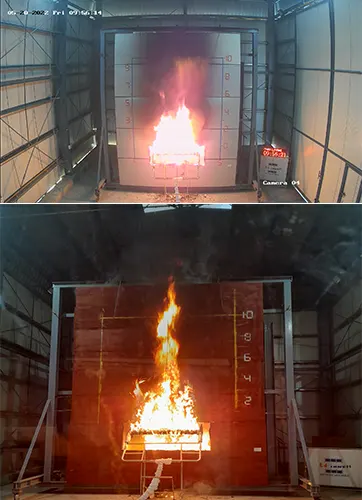

ASTM E 2874 Standard Test Method for Determining the Fire Test Response Characteristics of a Building Spandrel-Panel Assembly Due to External Spread of Fire Using Intermediate-Scale, Multi-story Test Apparatus (ISMA)

This test method evaluates the fire-test response characteristics of a spandrel-panel assembly spanning the intersection of a floor assembly and assesses the spandrel-panel assembly’s ability to impede the spread of fire to the interior of the room or the story immediately above it via fire spread from the exterior of a building and provide a quantitative measure of the fire hazard in terms of an I-Rating, T-Rating, and F-Rating from a specified set of fire conditions involving specific materials, products, or assemblies. This test evaluates the performance of the portions of the exterior wall installed between vertically adjacent window openings in multi-story buildings. This test method addresses the potential for fire to spread to a single story immediately above the room of fire origin and also simulates a fire in a post-flashover condition in a compartment that is venting to the exterior through a window opening.

This test method provides for the following measurements and evaluations:

- The ability of the spandrel-panel assembly to resist the passage of flames or hot gases sufficient to ignite a cotton pad, or be visible to an observer.

- Transmission of heat through, and above, the spandrel-panel assembly using heat flux and unexposed surface temperature measurements.

The spandrel with perimeter fire barrier and floor assembly is fixed to the test apparatus and the burners are ignited as per the standard. During the test when a crack or hole through the test assembly is observed, a cotton pad is employed to determine the integrity of the spandrel panel assembly. “I” Integrity Rating of the spandrel panel assembly is the time at which one of the following conditions first occurs:

- The total heat flux measured by the heat flux transducers reaches 3 kW/m2

or - The occurrence of flames or hot gases on any portion of the unexposed surface of the test specimen is sufficient to ignite the cotton pad.

“T” Rating – The “T” rating of the spandrel panel assembly is the time at which the temperature rise of any of the thermocouples on the unexposed face of the spandrel panel assembly or adjacent supporting construction is more than 181°C above the initial temperature, or the average temperature rise of the thermocouples on the unexposed face of the spandrel panel assembly is above 139°C.

“F” Rating—The “F” rating of the spandrel panel assembly is the time at which visible flame penetration through the building spandrel-panel assembly or around its boundaries, occurs.

CONCLUSION

It is high time to safeguard the building and to look into the safety aspects at its design stage. Since the active fire systems are easily more recognisable in the building, most of the common public only think of the active fire system which is the only method involved in fire prevention or protection. Passive fire protection awareness and its implementation are in greater need today than ever as buildings go vertical and global temperatures go positive.