In the rapidly evolving landscape of modern architecture and construction, the significance of testing has emerged as a cornerstone for ensuring the safety, functionality, and longevity of high-rise buildings. The integration of glass, fire safety in building façades, and hardware components within these towering structures has ushered in a new era of innovation and design. However, with innovation comes the imperative to rigorously test these elements to meet stringent standards and regulations. This article delves into the pivotal role that testing plays in guaranteeing the integrity of the glass, fire safety, and hardware in high-rise buildings, safeguarding lives and elevating the standards of contemporary urban living.

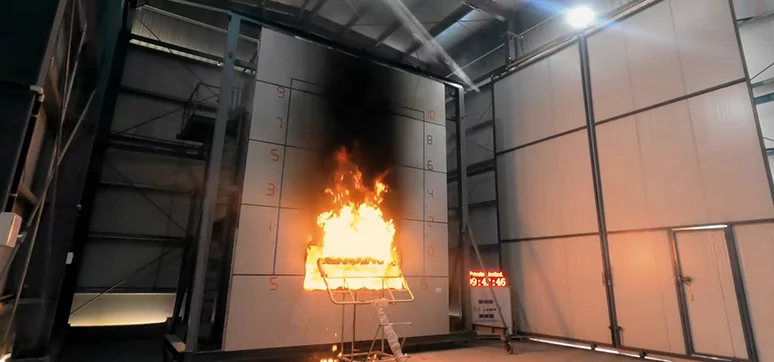

1. NFPA 285: Enhancing Fire Safety in Building Facades

The NFPA 285, developed by the National Fire Protection Association, serves as a vital fire testing standard specifically designed to evaluate the fire performance of exterior wall assemblies in multi-story buildings. This test is essential for ensuring that the building façades can withstand and prevent the spread of fire, enhancing overall fire safety. Let’s delve into its benefits and its significance for the industry.

Benefits of NFPA 285:

- Comprehensive Fire Safety Evaluation: NFPA 285 provides a thorough assessment of how exterior wall assemblies react under fire conditions as a system. It considers factors such as heat transfer, flame propagation, and smoke generation, offering a comprehensive evaluation of fire safety. Simply put, it’s the weakest component in the system that will fail first. So even if a Fire rated cladding material is used the system holding the cladding could be the weakest link.

- Realistic Fire Behaviour Simulation: By simulating a fire scenario that could occur in a real-world situation, NFPA 285 offers insights into how the façade materials, insulation, and construction methods interact when exposed to fire. This helps identify potential weaknesses and fire propagation risks.

- Prevention of Fire Spread: The test ensures that fire does not rapidly spread along the exterior of the building, minimizing the potential for a fire to engulf the entire structure. This is crucial for safeguarding lives, property, and neighbouring structures.

- Industry Best Practice: Adopting NFPA 285 as a standard practice showcases a commitment to industry best practices. It enhances the reputation of architects, builders, and developers by prioritizing the safety of occupants.

Industry Advantages:

-

Accredited third-party laboratories offer objective assessments of glass performance Safer Building Designs: Implementing NFPA 285 ensures that building façades are designed with fire safety in mind. This leads to safer structures that are better equipped to contain and resist fire incidents.

- Informed Material Selection: Architects and designers gain insights into the fire performance of different materials and assemblies. This empowers them to make informed decisions when selecting façade materials, balancing aesthetics with safety.

- Regulatory Compliance: As building codes continue to evolve, compliance with standards such as NFPA 285 becomes more crucial. Structures that meet these requirements have a competitive edge and face fewer challenges during regulatory reviews.

- Risk Mitigation: By undergoing NFPA 285 testing, potential fire hazards can be identified and addressed during the design phase, reducing the risk of costly modifications or even litigation in the event of a fire incident.

In conclusion, NFPA 285 serves as a critical tool for evaluating and enhancing the fire safety of building façades. Its benefits extend to improved building design, safer structures, and adherence to industry regulations. By prioritizing fire safety through standards like NFPA 285, the construction industry contributes to the overall safety and well-being of occupants and communities.

2. Performance Testing of Processed and Float Glass: A Lens to Quality and Safety

Processed and float glass, fundamental to modern construction, plays a multifaceted role in architectural design and functionality. As these glass types find widespread applications, it becomes imperative to subject them to thorough performance testing. This testing, conducted by accredited third-party laboratories, ensures that the glass meets stringent quality, safety, and performance criteria. Let’s explore the significance of this testing and its role in elevating glass quality.

Importance of Performance Testing:

- Functional Validation: Performance testing assesses whether processed and float glass meets the intended functional requirements. This includes factors such as strength, durability, thermal insulation, and optical clarity.

- Safety Assurance: Glass breakage poses serious safety risks. Performance testing evaluates the glass’s behaviour upon impact, ensuring it shatters into safer granules or retains structural integrity, thus minimizing potential hazards.

- Energy Efficiency: Glass influences a building’s energy efficiency. Performance testing measures thermal insulation properties, aiding architects in selecting glass that optimizes heating and cooling needs.

- Aesthetic Excellence: Glass’s visual quality is vital for both interior and exterior applications. Performance testing verifies its colour accuracy, clarity, and absence of distortions, enhancing the aesthetic appeal of buildings.

Benefits of Third-Party Accredited Testing:

- Unbiased Evaluation: Accredited third-party laboratories offer objective assessments of glass performance. Their independence ensures impartial results, instilling confidence in manufacturers, architects, and end-users.

- Specialized Expertise: These laboratories possess specialized knowledge and cutting-edge equipment for comprehensive testing. Their expertise guarantees thorough evaluations covering all facets of glass performance.

- Regulatory Compliance: Accredited labs adhere to international standards, ensuring that glass meets industry-specific requirements, building codes, and safety regulations.

- Quality Assurance: Third-party testing demonstrates a commitment to producing high-quality glass. It fosters trust among consumers, architects, and manufacturers, leading to enhanced product acceptance.

- Innovation and Improvement: Feedback from accredited laboratories drives innovation. Manufacturers use insights from testing to refine glass materials and designs, leading to improved performance and functionality.

In conclusion, performance testing of processed and float glass is pivotal for ensuring safety, energy efficiency, and aesthetic appeal in modern buildings. Third-party accredited testing adds objectivity, expertise, and adherence to standards, ultimately contributing to the overall quality and safety of the built environment.

3. The Significance and Advantages of Durability Testing for Window and Door Hardware

Window and door hardware form the backbone of building structures, facilitating functionality, security, and aesthetic appeal. Ensuring the longevity and performance of these hardware components is essential for both building occupants and the construction industry as a whole. Durability testing serves as a key mechanism to validate the reliability and resilience of window and door hardware. Let’s explore the importance and benefits of these tests.

Importance of Durability Testing:

- Safety Assurance: Window and door hardware contribute to building security. Durability testing ensures that locks, handles, and hinges remain functional over time, reducing vulnerabilities and enhancing occupant safety.

- Long-Term Reliability: Buildings are long-term investments. Durability tests identify potential points of failure, enabling manufacturers to design hardware components that can withstand extended usage and environmental stresses.

- Regulatory Compliance: Building codes often mandate specific performance levels for window and door hardware. Durability testing ensures compliance with these regulations, instilling confidence in the reliability of hardware products.

Benefits of Durability Testing:

- Performance Validation: Durability tests subject hardware components to real-world usage scenarios, confirming their ability to endure repeated cycles of operation. This validation assures the functionality of hardware in actual building applications.

- Lifespan Prediction: Durability testing provides insights into the expected lifespan of hardware components. Manufacturers and builders can use this information to estimate maintenance schedules and plan for replacements when needed.

- Quality Improvement: Identifying weak points during durability testing allows manufacturers to refine designs and materials. This iterative process results in higher-quality hardware products with enhanced durability.

- Innovation & Design Enhancement: Durability tests may uncover opportunities for innovation. Manufacturers can explore new materials or mechanisms that improve the overall performance and resilience of their hardware.

- Market Differentiation: Hardware that has undergone durability testing stands out in the market. Manufacturers can leverage this distinction to showcase their commitment to quality and attract customers who prioritize reliable solutions.

- Reduced Liability: Ensuring hardware components meet or exceed industry standards through durability testing reduces the risk of liability in case of hardware-related failures.

In conclusion, durability testing for window and door hardware is integral to ensuring their long-term functionality, safety, and reliability. By subjecting hardware components to rigorous testing, manufacturers, builders, and end-users benefit from improved quality, compliance with regulations, and increased confidence in the performance of these essential building elements.