In recent years, the building construction industry, including the design and construction of exterior façades, has strongly focused on sustainability needs and environmental factors. Exterior wall design must offer a healthy and comfortable space to live, work and play while using the least energy and also achieving demanding sustainable expectations.

Combining this challenge with the fast pace of today’s construction and the need for less costly and easier-to-install designs, we find that new materials (and combinations of materials) are constantly being introduced into exterior wall assemblies. Let’s not forget that these exterior assemblies must also be aesthetically pleasing. With the challenging balance of these demands, the need for these “sustainable” exterior façades to also have adequate fire-resistant performance is often left out of the discussion.

Progress with Sustainable Façades

In recent years, major progress has been made in achieving exterior façades with improved sustainable attributes. Some examples include the use of:

• Insulation and other materials to achieve improved thermal properties – towards lower energy use for buildings

• Exterior wall component materials with low volatile organic compounds

• Recycled content in exterior wall component materials

• Photovoltaic (solar panels)

• Low-carbon building materials

These and other sustainable efforts have complimented the design and implementation of exterior wall construction focusing on building envelope performance and comfort for a building’s inhabitants.

Building Envelope Performance – A Comfortable Space

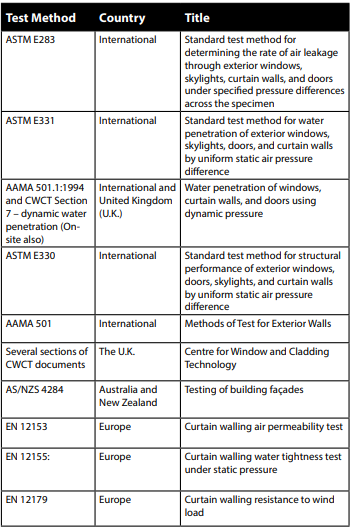

Alongside the growing attention on sustainability, building envelope performance considerations include attributes such as thermal performance, air leakage, water vapour permeability, resistance to water penetration, UV resistance, sound transmission properties, wind load resistance, etc. In most areas, these performance characteristics are driven by local codes and regulations. Table 1 lists some of the more popular test standards and their respective title.

The result of these building envelope performance demands is the use of insulation products with higher thermal properties, increased use of water resistive barriers, air and vapour barriers, use of rain screen systems, and adequate verification of structural adequacy. These standards and procedures are used frequently in architectural specifications, and tests are usually performed on pre-construction mock-ups to assess the wall’s expected performance.

Newer Technologies

The exterior façade industry continues to explore new materials and methods of construction to meet the demands of a sustainable and comfortable environment. We see retrofit construction on existing buildings, the use of building-applied photovoltaic (solar) panels (BAPV), and green façades using natural foliage. Additionally, there are now adaptive façades, such as dynamic shadings, active ventilation systems, and chromogenic façades that automatically change colours.

Fire Performance — International Exterior Wall Test Considerations

With the intense focus on sustainability, achieving comfort for the occupants, and the introduction of newer technologies, exterior wall fires are still occurring globally at a concerning rate. Since the Grenfell Tower tragedy in London, there has been a renewed emphasis on understanding the fire testing requirements for compliance of exterior façades globally. There have also been adjustments to testing standards and code changes in many countries to strengthen fire performance compliance. Regulatory reform has advanced in many countries to ensure that roles and responsibilities are better defined.

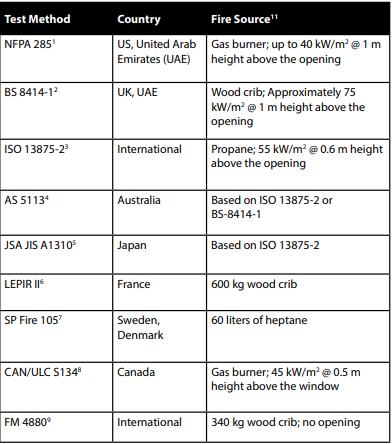

Many prominent full-scale exterior wall fire test methods are solidly embedded into codes and regulations. For example, in the United States (U.S.), the International Building Code (IBC) and NFPA 5000 refer to NFPA 285 as the main fire test method for evaluating fire spread on exterior walls. Recent changes in NFPA 285 address testing of joints and seams and clarify the window detail for the tested assembly. In addition, Annex B was added to this standard outlining detailed guidelines for engineering decisions for substituting components and materials based on an actual NFPA 285 test.

One remaining challenge is that several varying methods are implemented in different countries that may not have the same scope or deliver the same outcomes. It is essential to understand the methods used to qualify a product or system to ensure it is suitable for use in exterior wall construction. Table 2 lists some test methods and the countries where they are typically enforced. This is not intended to be a comprehensive list, as other methods are being developed.

Sustainable and Fire Resistant (SAFR)

Several years ago, fire protection specialists set out to examine this balance of sustainable façade design fire-resistant performance. Specifically, the Fire Protection Research Foundation published a report called Fire Safety Challenges of “Green” Buildings and Attributes (2020)10. Green building design elements that could lead to increased fire safety hazards were identified in the report, and best practices for mitigating fire risks were explored. Based on this study, fundamental recommendations were put forth to advance the idea that buildings and communities could be Sustainable and Fire Resistant (SAFR). The recommendations include:

Several years ago, fire protection specialists set out to examine this balance of sustainable façade design fire-resistant performance. Specifically, the Fire Protection Research Foundation published a report called Fire Safety Challenges of “Green” Buildings and Attributes (2020)10. Green building design elements that could lead to increased fire safety hazards were identified in the report, and best practices for mitigating fire risks were explored. Based on this study, fundamental recommendations were put forth to advance the idea that buildings and communities could be Sustainable and Fire Resistant (SAFR). The recommendations include:

• Integration of “green” (sustainable) attributes of buildings into fire incident reporting systems

• More robust and appropriate test methods for the assessment of material and system performance

• Integration of fire performance considerations into sustainable materials and technologies

• Strong risk and performance assessment methods and tools where data are lacking.

• Better tools for holistic design and performance assessment

• Transition to more holistic, socio-technical systems approaches for building regulatory systems

• Further development and outreach advocating for SAFR-building concepts

Note: The above fundamental SAFR recommendation is from the Fire Protection Research Foundation report, Fire Safety Challenges of Green Buildings (2012)11 and Fire Safety Challenges of ‘Green’ Buildings and Attributes (2020)

Certification Approach

To strike a balance between sustainable and fire-resistant construction, it is imperative to know that the installed systems comply with the most current model codes and standards. There’s an increased use of combustible materials and components to meet these demands, which means achieving fire-resistant design requires careful attention to the products used and how they are installed.

To strike a balance between sustainable and fire-resistant construction, it is imperative to know that the installed systems comply with the most current model codes and standards. There’s an increased use of combustible materials and components to meet these demands, which means achieving fire-resistant design requires careful attention to the products used and how they are installed.

The Grenfell Inquiry Phase 1 Report12 states, “The widespread use of combustible rain screen cladding panels and insulation on the exterior of buildings and the introduction of new kinds of building materials in external walls may have increased the risk of similar fires, but improvements in the regulations relating to fire safety and the requirements for testing and certification of materials, which will be a particular focus of attention in Phase 2, should be capable of mitigating that risk in the future.”

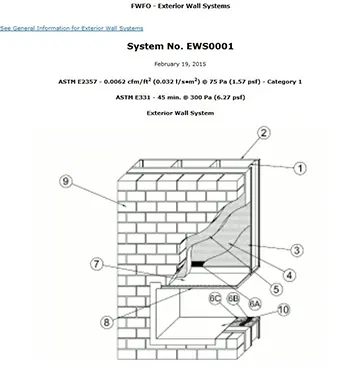

Toward this objective, UL Solutions uses a certification approach to demonstrate compliance with one of the prominent fire test standards in the U.S., NFPA 285. This public database illustrates complete wall system designs and details how individual components are evaluated as part of a system. This approach meets the needs of manufacturers, architects, specifiers, and code officials by providing an accessible, no-cost, and up-to-date method of determining compliance with a code. The illustrated designs within the UL Solutions certification reflect the precise details of a compliant assembly.

Certified wall systems and components are published in the Product iQTM online database in the categories Exterior Wall Systems and Exterior Wall System Components. Examples of wall system components available through Product iQ include various types of cladding, insulation products (including foamed plastic), water-resistive barriers, air-resistive barriers, laminates, sheathing, and composite panels.

References

• NFPA 285. Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies. NFPA, 2019

• BS 8414-1. Fire performance of external cladding systems-Part1: Test methods for non-loadbearing external cladding systems applied to the face of a building. BSI 2015

• ISO 13785-2. Reaction-to-fire tests for façades –Part 2: Large-scale test. ISO, 2002

• AS 5113. Fire propagation testing and classification of external walls of buildings, 2016

• JSA JIS A1310. Test method for fire propagation over building façades, 2019

• LEPIR II Test. Large-scale Fire Performance testing of construction systems for façade CECMI (French committee for the evaluation and the classification of products and elements of construction as a regards fire hazard – under the French Ministry of Internal Affairs directives), 2013

• SP FIRE 105. Issue 5. Large-scale testing of façade systems. SP Boras Sweden, 1994

• CAN/ULC-S134. Standard Method of Fire Test of Exterior Wall Assemblies. Underwriters

• Laboratories of Canada, 2013

• FM 4880, Class 1 Fire Rating of Insulated Wall or Wall and Roof/Ceiling Panels, Interior Finish Materials or Coatings, and Exterior Wall Systems FM Approvals, 2010

• Meacham, B and McNamee, M. Fire Safety Challenges of “Green” Buildings and Attributes. Quincy, MA. The Fire Protection Research Foundation, 2020

• Meacham, B; Poole, B; Echeverria, J; Cheng, R; Worcester Polytechnic Institute. Fire Safety Challenges of Green Buildings. Quincy, MA. The Fire Protection Research Foundation, 2012

• Grenfell Tower Inquiry Phase 1 Report; https://www.grenfelltowerinquiry.org.uk/