Why every Façade Engineer should lead by example?

Flicking through paperwork and rushing for approval of submittals are not the case when trying to condense the risk of a catastrophe, particularly in façade fire safety. Never has there been a time more important than today for façade engineers to be at the forefront in mitigating deficiencies found during the construction phase of a high-rise building that may pose fire-related harm to people and communities.

Stakeholders have a fundamental responsibility as a whole to fully underscore the importance of driving responsible, trustworthy, and ethical work with safeguards that mitigate risks and potential harms to individuals and our society.

An imperative call: Façade fire safety in high-rise buildings

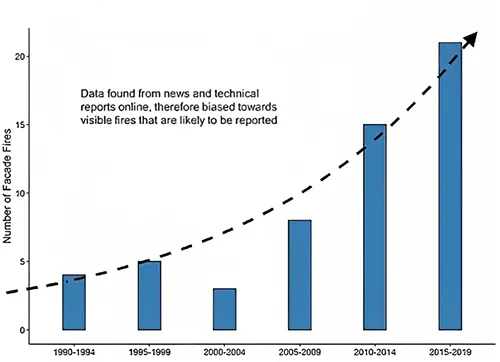

As the number of high-rise buildings continues to grow in cities around the world, so too does the importance of Façade Fire Safety. According to NFPA (National Fire Protection Associate), highrise buildings pose many unique challenges not found in low-rise buildings.

Façade fires in high-rise buildings are extremely dangerous, as they can spread quickly and be difficult to contain; with hindsight, a Façade engineer’s crucial ongoing effort will help engage other parties in taking a comprehensive approach while collectively committing to ensure consistency in design. This effort builds on considerable aspects practised by façade engineers to root out bias in the design drawings and on-site installations. Façade engineers are able to explore how the technical analysis parameters align with the principles and practices of on-site installation works.

This allows for real-time evaluation which provides critical information that would mitigate many hazards, especially the ones posed by the propagation of fire. This may include identifying deficiencies found in the design drawings & installation works which will enable the responsible parties to take further steps early in the construction phase.

Also, it is important to consider looking through previous fire incidents to learn from the failures & successes, strengthening the evaluation further and saving the client valuable time and budget. A performance-based design such as Computational fluid dynamics (CFD) software and Finite Element Analysis (FEA) models many different fire scenarios to reach the required level of safety of the high-rise buildings and façade elements respectively.

The Façade Engineer Blueprint: A Roadmap for Façade Fire Safety in high-rise buildings

From principle to practice, identifying the protective measures includes principles that will advance the façade engineer’s vision of façade fire safety.

The following principles include:

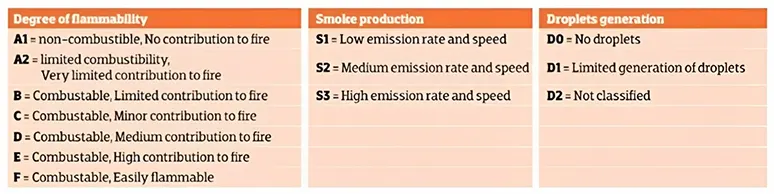

• Fire-resistant materials According to EN 13501-1 Classification A1 materials used on façades should be non-combustible, adhering to any foreseeable possibility of fire hazards. The number of combustible components contributes to the spread of the fire which includes but is not limited to the supporting & framing systems and their accessories, inner plasterboard skin, sealants, waterproofing membrane, and the infill and cladding material.

The following fire rating standards should be met by ASTM E84.

1. The fire reaction of a material is measured against a number of criteria including seven classification levels:

• Flame spread index (FSI): indicates the speed a flame travels across the surface of a material. Measured between 0-25.

• Smoke Development Index (SDI): measures the smoke a material emits as it burns. Measured between 0-450.

• Fire resistance rating: indicates how long the material can resist as a measure of time (ASTM E119)

• Ignition temperature: the minimum temperature causing self-ignition of a material

• Flaming droplets/particles: small particles of burning material that may ignite other materials

Also, a “Full-scale Façade Fire Propagation Test” can be conducted for non-load bearing façades, rain screens & insulated wall systems as classified by BS 8414-1.

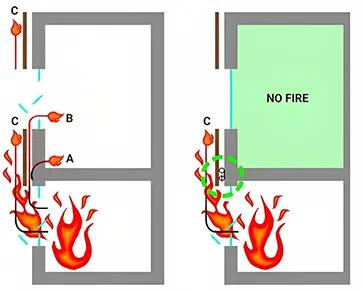

2. Fire barriers and fire stops

Fire barriers and fire stops should be UL-classified material. Their functions are similar but differ in their manner of workability. Their functions are to prevent the spread of fire and smoke that might leapfrog from one story to another. Fire stops in particular are sealants that seal the gaps and openings while fire barriers are physical insulation materials used to block the fire from spreading.

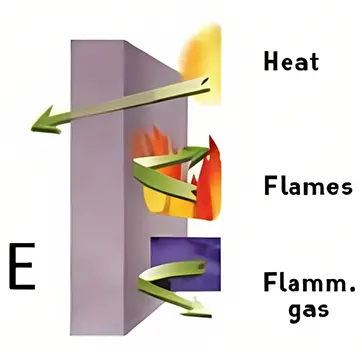

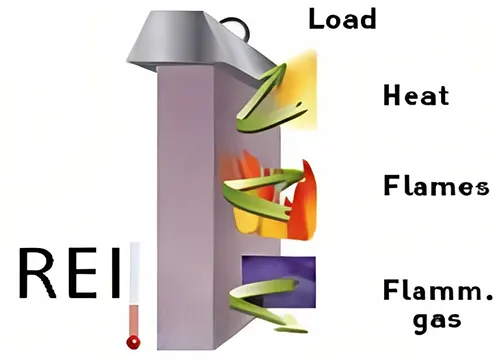

Fire barriers should be placed according to the manufacturing recommendation in a vertical and horizontal fashion to prevent and contain the spread of fire and smoke. Rain screen systems for example as in the figure shown, are cavity-based systems that can rapidly propagate fire in an unpredictable manner if kept uncontained. Here physical fire barriers play their role.

Meanwhile, fire stops are applied on gaps between floor slabs or the façade. The gap must be filled with fire sealants or fire-intumescent material that reacts and expands upon contact with heat preventing smoke and fire from one compartment to another. An accredited third-party body should commission the application of the fire barriers and fire stops and verify that they are maintained in a continuity manner.

The following EI rating standards should be met in accordance with BS EN 13501-1

• The fire resistance of a material is measured against a number of criteria:

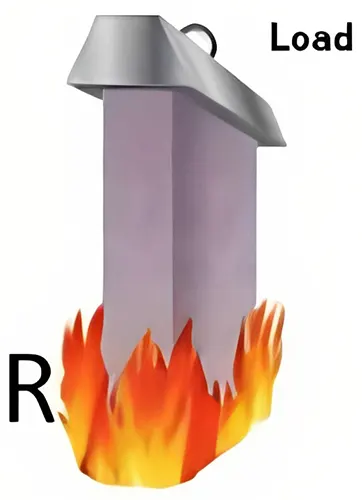

• R – supporting capacity

The capacity of a material’s mechanical fixation to resist fire without losing its structural strength. For example, “R120” implies that for 120 minutes of fire exposure, the system will still retain its structural integrity

• E – Integrity

The capacity of a material to prevent the passage of fire and hot gases from one compartment to another. The same applies here as “E120”

• I – Insulation

The capacity of a material to prevent heat transfer from one compartment to another

According to the European classification, the minimum requirement for cavity barriers should have an EI rating of at least 30 minutes.

3. Fire risk assessment

An intrusive investigation and condition surveys should be conducted to identify any unknown defect found during the design and construction phase. These defects may pose a fire risk.

The defects include the miscoordination of joint detailing with adjacent elements, poor installation works, and mechanical detailing in fixing the insulation and façade panels. Not to mention, these defects may compromise the integrity of the fire-resistant material being used. So, a remediation scheme should be taken into consideration and reported to the construction team to avoid future repetition.

Adopting an early holistic approach with many active parties will ensure workmanship is carried out at utmost quality and efficiency. Closely working with architects, engineers, and fire safety experts will ensure robust adequacy to protect occupants and the building from potentially unavoidable fire incidents.

4. Other safety protocols

This aspect demands greater input from specialists such as fire engineers who are eligible to recommend fire safety plans and active systems such as fire sprinklers that have the capability to extinguish flames and cool down hot surfaces. In addition to that, detection and alarm, suppression systems, egress strategy & emergency systems are necessary to implement for highrise buildings. In conclusion, I believe there is still a lot that needs to be done to further understand the façade fire safety nuisance, especially in high-rise buildings. Going beyond testing the material to checking its interaction with other elements under different circumstances or delivering a smooth collaborative manner between parties will reassure clients (and other parties) that the bespoke solutions are of the highest levels of safety and compliance.