In the world of façades, an extensively discussed topic is ‘Façade and Fire’, it is worth understanding some basic principles that make it necessary to have fire protection in façades in the first place including the cavity and chimney effect!

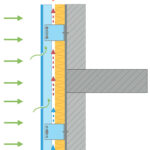

Typically, there are two methods of handling façade waterproofing, face sealed and rain screen. In the case of a face-sealed façade, it depends on 100% of the rainwater that has to be shed, however, due to weathering effects after a few years, seals get cracked creating leakages. These leaks demand periodic maintenance.

A rain screen façade is a kind of two-stage construction; the inner wall is a load-bearing insulated wall that is protected by outer skin. The outer skin protects against rain and moisture and maintaining a space between the cladding and building wall prevents water from infiltrating the building structure. A rain screen is one of the most effective options in the market today if it is designed and installed with an authentic approach.

Why Rainscreen?

There are several benefits of using a rain screen façade over face seal systems:

1. Superior waterproofing

It protects the structure of the building from moisture, rain and condensation through a multi-layer barrier system, and it is less dependent on site workmanship and sealant durability for waterproofing performance.

2. Thermal efficiency

The rain screen cladding helps shade the structure and dissipate the heat. The cavity between the inner and outer screen doesn’t allow heat to transfer into the structure (particularly the heat from direct sunlight), the heat is radiated into the cavity. The warm air moves up and out of the cavity by convection, drawing in cooler air at the base and insulating the primary wall structure.

3. Condensation control

When rain screen façades are properly designed and installed, condensation will form in the cladding cavity (as opposed to within the wall structure!) A rain screen provides for this to be drained or evaporated, thereby preventing damage and mould growth.

4. Long-term durability

Rainscreen façades are less dependent on sealants, and hence are less subject to deterioration over time, and the maintenance cost of dealing with this.

And Why A Cavity?

The key features of a rain screen façade are:

- Outer cladding

- Cavity

- Air/water barrier

The outer cladding is designed to shed the most, if not all of water, and bears the primary impact of exterior weather forces and UV, hence cladding must be durable and of non-porous material.

The air/water barrier is the final layer of protection, preventing any moisture from penetrating the building walls. It may be permeable or non-permeable depending on requirements. All penetrations should be sealed.

The cavity is essential for the effectiveness of the rain screen system. It provides a secondary line of defence against the elements. It serves two purposes:

- Allows drainage of any moisture to penetrate the outer cladding

- Allows air circulation, evaporating moisture from the surface of the air barrier and drying the cavity This plays a significant part in preventing water ingress into the building.

As a thumb rule, a minimum cavity of 25mm should be maintained to allow sufficient air movement. Walls greater than 25m high should have a cavity depth of 1mm per meter in height. For example, a 50m wall with a continuous cavity should have a minimum depth of 50mm. The cavity may be broken and drained at individual floor levels.

Rainscreen Designs

As classified by the AAMA (American Architectural Manufacturers Association), there are two basic types of rainscreen systems:

- Drained, Back-Ventilated (AAMA 509-09)

- Pressure Equalised (AAMA 508-07)

Drained, Back-Ventilated

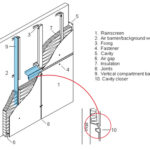

This system is increasing in popularity as a move forward from the traditional face-sealed model. A drained and back-ventilated rain screen has continuous airspace, with openings at the top and bottom of a wall section to encourage air movement.

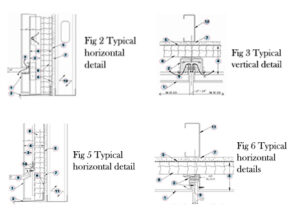

These systems stop well over 90% of the water that could potentially reach the air and vapour barrier of the building. The remaining small quantity of water is then dissipated through the combined action of gravity (drainage) and air circulation (evaporation). Refer to typical details form the CWCT document. (Ref. fig. 2 & 3)

Pressure Equalised

Pressure equalised (Ref. fig. 4, 5 & 6) rain screens are gaining prevalence in Europe & USA as the optimum waterproofing solution. The system relies on a cavity pressure that matches the external air pressures. This is achieved through open joints (ironically!) and compartmentalising the cavity.

The benefit of this system is that as air pressures are equal between the cavity and the external, there is no air movement to force rainwater into the cavity. This does mean, however, that the air and vapour barrier must be able to absorb the wind loads. As such this system is mainly suitable for masonry construction or quality sheathing.

What Is The Difference?

Dfed, Back-Ventilated (AAMA 509-09)

• Water entering the air & water barrier is unlimited.

• No pressure equalised principal

• No need for compartmentalisation Pressure Equalised (AAMA 508-07)

• Water entering the air and water barrier is strictly limited.

• Works on pressure equalisation principal

• Compartmentalisation is a must to control pressure equalisation.

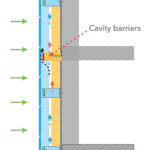

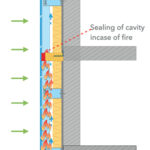

Rainscreen, Cavities And Fire

Of course, the cavity present in the system also acts as a pathway to propagate fire in a fire event which is called a ‘chimney’ effect. This is where intumescent cavity barriers become indispensable (refer Fig. 7). Typically, unused in Indian construction, they have the ability to close the cavity when exposed to significant heat, preventing this airflow and helping to prevent the spread of fire (refer Fig 8). It is always good practice to include a cavity barrier at floor levels – regardless of the cladding.

For an exterior wall to function for waterproofing, condensation, fire, structural, insulation, etc. a holistic design process is required, with decisions not being made based on one single aspect.

Types Of Cladding Materials And Selection

There are a variety of cladding options as natural stone, GFRC, GFRP, Aluminium metal cladding, zinc cladding, copper cladding terracotta clay tiles, high-pressure laminates (HPL), ceramic tiles, ACP, etc. While selecting cladding material we must give attention to the following points:

-

Fire class of material

As per international codes, there are many fire classes out of which fire class relevant for façades are A, A2 & B class. Where class A means non-combustible material, class A2 means limited combustive & class B means fire-retardant material.

-

Tested system

Tested system is needed for every project and due consideration shall be given to fire testing requirements as per relevant codes and project requirements.

Conclusion:

While designing and implementing rain screen/ ventilated façade, we must adopt a holistic approach. Poorly designed and poorly installed rain screen façade without any cavity barriers become a disaster in case of a fire event, there are many examples where the rain screen façade becomes the source of fire propagation due to the use of ACP with polyethene (PE) and the fire spreads rapidly due to the chimney effect in the absence of cavity barriers.

Unlike other countries, India does not have specific norms or regulations pertaining to the use of cladding materials (especially ACP cladding with PE core). As professionals, we need to consider all the precautions to be taken in the selection of the cladding materials as well as to curb the propagation of fire. While designing a rainscreen cladding system the above points should be given importance and engineering judgment to be applied to arrive at an appropriate rainscreen system and also which will be fire-rated.