Sometimes referred to as rain-screen or cladding systems, ventilated external wall systems are an increasingly popular façade option for both new-build and refurbished mid to high-rise buildings. They not only offer a huge array of design options and finishes but also a practical construction method for temperature and moisture management. However, the cavity created between the external cladding and the internal insulation layer can present an issue when it comes to passive fire safety.

ADDRESSING CONFLICTING PRINCIPLES

In daily use, the cavity is vital for ensuring that any moisture penetrating the external façade can drain away through the gap left between the exterior and the insulation layer. In addition to preventing issues with dampness or mould, the airflow within the cavity allows the whole system to stay cool in warm weather and warm in cooler weather, as well as providing some acoustic benefits. But, in the event of a fire entering the wall construction, this open cavity can present a risk. If not carefully considered, the void will act like a chimney, drawing flames, smoke and heat up the building. This then makes it more likely for a fire to spread into multiple floors, putting lives and property at risk.

To prevent this, the cavity needs to be closed off using cavity barriers— blocks of fire-resistant material, which seal the cavity to create compartments that contain the fire to an area of manageable risk until the fire is extinguished. In many regions, this is a legal requirement when using a ventilated façade, with heavy fines for non-compliance.

Standard cavity barriers are labelled ‘full-fill’ products, meaning they are fitted directly between the internal and external layers to completely seal the cavity. This makes them ideal for vertical applications in ventilated façades as they can help to maintain the air pressure within compartments, preventing the fire from spreading horizontally around the building. However, in a horizontal application, they would prevent the system from effectively ventilating or draining away rainwater, leading to dampness within the building envelope.

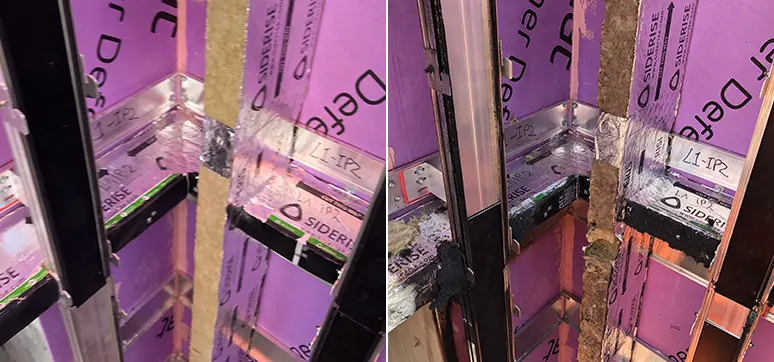

To resolve this, open-state cavity barriers were developed. These include an integral intumescent material that rapidly expands in reaction to high heat (around 130°C). This enables them to be fixed to the internal cavity wall, leaving the ventilation gap open to allow for free vertical movement of air and drainage day-to-day (sometimes referred to as the ‘cold state’). However, in the event of a fire, the intumescent expands in a matter of seconds until the void is fully closed and a robust fire seal is formed.

PRODUCT PERFORMANCE

Cavity barriers have a crucial role to play in fire safety, and they must be carefully tested to ensure they meet the necessary fire resistance performance. Both the test standards and the pass and fail criteria are often dictated by local regulations or project-specific guidance. However, there is understandably some difficulty in using the standardised tests to determine the performance of open-state cavity barriers, because the time taken for the gap to close would initially lead to a technical ‘fail’, even though the moment the intumescent is activated fire integrity and insulation is established. To help resolve this issue, the Association for Specialist Fire Protection (ASFP) produced a Technical Guidance Document, TGD 19.

This outlines the test configurations and failure criteria for the testing of open-state cavity barriers and the pending prEN 1364-6 standard, which is being developed specifically for cavity barriers. The test is based on the existing EN 1366- 4 linear joint seal test (using the principles of EN 1363-1) but modified with upstands to better replicate the cavity construction and allows 5 minutes for the intumescent to close the gap.

Note that, even with the inclusion of cavity barriers, systems can fail if the external rain-screen façade allows the fire to spread up the outside of the building causing the cladding to move, break down or come away. Any malfunction with the cladding would likely leave a path for the flames to spread up and over the cavity barrier and up the cavity. Therefore, it is crucial to always refer to the latest regulatory advice for façade design and specification and to ensure high-quality workmanship at every stage. Large-scale system testing is also imperative.

UNDERSTANDING THE SYSTEM

Whilst small to medium-scale tests can ascertain a product’s performance, and therefore general suitability for the purpose it is marketed for, it is only through large-scale testing that we can fully understand how complete assemblies perform in their intended application. All the system components are examined together, providing data on how the different products interact, along with the impact of details such as joints, gaps, and penetrations on the overall fire performance.

Large-scale testing is particularly vital for passive fire protection products such as cavity barriers which are reliant on their ability to maintain their fit within the void Siderise has participated in and sponsored many large-scale system tests where the test assembly uses their RH and RV Cavity Barriers and CH-CB Closed State Horizontal Cavity Barriers between the inner structure and external wall finish when under the thermal load of a fire. The two main globally applied large-scale system tests that evaluate the fire propagation characteristics of ventilated facades are NFPA 285 and BS 8414.

NFPA 285 Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components

This American National Fire Protection Association (NFPA) standard is a reaction to a fire test of a complete external wall assembly. It is used as the typical path to compliance in India. It looks at how exterior wall assemblies and panels, used as components of curtain wall assemblies that are constructed using combustible materials or that incorporate combustible components, can contribute to the propagation of fire. It can be used for both non-loading and load-bearing constructions, although there is no requirement for a live load during the test. The results from this test only apply to the exact system being tested.

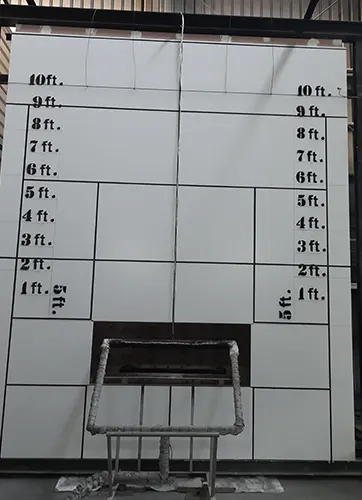

The fire exposure duration for NFPA 285 is 30 minutes with a 10-minute observation period. It takes place on a 14ft wide x 18ft high, two-storey rig simulating a straight façade elevation with a window opening on the first floor.

It uses two gas burners as the fuel source– one inside the lower floor which is ignited first, and one outside directed towards the top of the window opening which is ignited five minutes later. This is designed to simulate a flashover scenario, exposing the construction to flames for 30 minutes.

A system will pass this test if it can demonstrate that it does not propagate flames either vertically or horizontally within determined parameters (10ft above the top of the window or 5ft horizontally from the window centreline), or that the temperatures recorded by specifically placed thermocouples within the wall assembly do not exceed 1000°F during the test.

BS 8414

This test standard was originally developed by the British Research Establishment (BRE) and was revised in 2020 with significant changes. It is separated into two parts:

• BS 8414-1:2020 Fire performance of external cladding systems. Test method for non-loadbearing external cladding systems fixed to, and supported by, a masonry substrate

• BS 8414-2:2020 Fire performance of external cladding systems. Test method for non-loadbearing external cladding systems fixed to and supported by a structural steel frame

It can be used to test rain-screen cladding and external wall insulation systems. Results from the tests can be used to determine whether the system successfully meets or fails to meet the performance criteria for classification in accordance with BR 135 ‘ Fire performance of external thermal insulation for walls of multi-storey buildings’. The test results are only applicable to the exact system tested.

The test assembly comprises a 9.7m high rig, including a 1.5m wide wing with a 90° internal corner, and with a re-entrant angle of 90°. A wooden crib is the fuel source, and the test is designed to simulate a post-flashover fire scenario in a room with a total heat output of 4500MJ over 30 minutes at a peak rate of 3 ±0.5 MW. Recent research has suggested that the actual heat output is significantly higher than this. The test runs for 60 minutes, with an observation after 30 minutes. The fire is then put out safely and the rig is left to stand for a further 30 minutes to see what happens to the build-up after having been extinguished, to observe if the materials reignite, disintegrate and fall, or smoulder.

Regardless of whether NFPA 285 or BS 8414 is chosen, it is essential that testing is conducted by an accredited third-party testing house, and that the full report includes explicit detail about the tested system components and is openly accessible on the manufacturer’s websites or via their technical teams.

SAFE FAÇADE, SAFER BUILDING

Whether full-fill or open state, cavity barriers whose performance has been properly verified through independent product and system testing are a vital part of any ventilated façade system, ensuring protection without compromising their fundamental purpose.

For more information, please email: technical.services@siderise.com or visit www.siderise.com