The cladding aims to withstand external weathering and offer durability and sustainability to the building façade. The choice in design and material of a façade is determined by factors such as the size and type of building, its geographical location, weather conditions it is exposed to etc. Energy efficiency is the main concern, besides its appearance. Today, the market offers a variety of materials for façades with abundant choices in designs and patterns. Large-size porcelain tiles and high-pressure laminates are in trend for their aesthetic value and sturdiness.

Exterior Clad Laminated (ECL) high-pressure laminates and porcelain wall clads are used for the majority of structures. The products have anti-graffiti properties and offer flexibility in installation. These are high-grade and high-pressure compact laminates. Inspired by the colours and patterns of natural wood, the 6mm thick, laminates come in over 200 designs in grainy bark style or plain wood patterns. Mount matt finish laminates give an antique, subtle appearance to the façade. The UV coating of the full-bodied ECL gives extra protection against harsh solar rays and extreme climates.

For overall façade design, the following general parameters should be considered:

- Architectural requirement

- Thermal performance to be achieved (U-value, g-value, layer temperature)

- Flexibility (adjustable performance)

- Interaction strategy with HVAC systems (extract rate, natural ventilation)

Apart from these parameters, the following specific parameters have a significant impact on design and façade performance:

- Loads

- Maintenance (interior or exterior)

- Investment vs. running costs

Cladding Materials

The primary function of cladding is to split the indoor environment of a building from the outside in such a way that the outdoor environment will not affect the indoors. It is also useful for regulating light penetration and controlling the radiation and conduction of heat from the sun and prevents interiors from getting faded and dull. Additionally, sunshades and louvred panels allow for reflected light to enter the building which enhances comfort.

Considering Indian climatic conditions, one needs to choose cladding having the following properties:

• Resistance to corrosion: Cladding materials have high corrosion resistance like aluminium and steel and they should be properly treated with hot dip galvanising and epoxy or PU paint.

• Cleaning and maintenance: The cleaning cycle of the external building envelope should be ascertained while selecting cladding. Select a material that will attract less dust and with minimum horizontal surfaces. Flush seal systems must be avoided and nonbleeding sealants may be used for weatherproofing. A façade that is ventilated and insulated can save up to 70 per cent on energy costs for heating or cooling.

Cladding of a building ensures that the internal temperatures are maintained at ideal levels, reducing both the cost burden of HVAC, its impact on the ecology and the protection from water permeation. Many parts of the country experience heavy rains and cladding serves as a coat that reduces the infiltration of water into the primary structure.

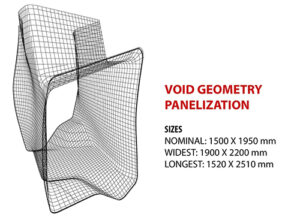

Façades are designed with passive and active ventilation, such as double-skinned façades that allow the warm air to rise and exhaust from the void between the two skins. Additionally, for high-rise buildings where windows cannot be opened due to high wind pressures, passive ventilators are the solution, which can be opened and closed.

The level of acoustic attenuation of the cladding material is decided based on the type of external and internal environment, with respect to the frequencies and amplitude of the ambient noise and sounds. Laminated double-glazed units having varying glass thickness, with acoustic PVB are the best choice for acoustics.

There are varieties of cladding materials/ systems used these days, such as wood, concrete, glass, aluminium solid sheet, aluminium composite panels (FR grade A2), natural stones, stainless steel, terracotta, high-pressure laminates (HPL), copper cladding, zinc cladding, fibre cement board cladding, Corian cladding, GFRC, etc.

a) Glass: Glass selection is the most time-consuming item, which needs to consider the following:

i. Selection parameters should be clearly defined, viz colour, U-value, light transmission, etc.

ii. Look for the ideal combination of DGU or laminated or both

iii. Select proper interlayer film depending upon usage, internal or external

iv. Select glass processing as per requirement viz tempering, heat strengthening, heat soaking, etc.

v. Selection of face to be fitted in case of frit glass

b) HPL (High-Pressure Laminate) is popular for exterior cladding, as it can be exposed to the combined action of sunlight and atmospheric agents including rain, hail or wind. These are not affected by thermal shocks and have the ability to withstand extreme climate changes. Further, these reduce the amount of water that is absorbed and provide protection against chemical or air pollution.

c) Aluminium: The following points may be considered during finalising the aluminium extrusion:

i. Alloy and temper selection depending upon usage and bending

ii. Powder coating specs 2603/2604/2605 depending upon the location of use

iii. Clearly define the acceptable dimensional tolerance criteria

d) Zinc cladding is an innovative system that has qualities like long-lasting, malleable, flexible and aesthetically appealing.

e) Stainless steel wall cladding is commonly used in today’s buildings creating a striking architectural effect. Unlike most other types of façade material, stainless steel is available in an array of finishes, patterns, dimpled, textured, embossed and coloured finishes. Some of these aspects enhance durability and prevent wear and tear in high-traffic areas. Stainless steel is an incredibly versatile material, it can be rolled, folded or pressed into almost any shape. It is also one of the most robust and sustainable materials due to its superior corrosion resistance and is recyclable.

Consider the following points for steel cladding:

i. Define the grade of steel

ii. Specify the coating required, viz. galvanising, sandblasting, PU coated with minimum dry film thickness expected

iii. Specify the dimensional tolerances expected

iv. Ensure all critical weld tests are witnessed by professional third-party QC

v. Get a sample approved for the external finish of architecturally exposed steelworks

vi. Always select proven brands for external application of cladding works

vii. Sizes should be optimised prior to ordering so as to reduce the wastage

Consider stainless steel anchors for all externally exposed anchors and fasteners. GI can be used for internal concealed application. Ensure minimum embedments are carried out as specified and if the structure has having big tolerance, then better to have longer lengths. Specify the hardness and elongation criteria for the gasket. Prefer EPDM over PVC gasket. Ensure the dyes are checked with respect to extrusions and are approved by the designer.

f) Stone & porcelain tiles: Consider the following points while choosing stone and porcelain tiles for the building envelope:

i. Ensure the entire materials are supplied from a single block

ii. Veins should be in one direction

iii. Colour variations in natural stone should be benchmarked with acceptable criteria

iv. Emphasis to be given to getting smooth edges

v. Ensure criteria for tolerances in holes and grooves are clearly defined

New Materials For Building Envelope And Glazing

Continuous innovation in cladding materials towards performance has been able to deliver new products that are efficient, economical and attractive. These include:

• High-strength hollow block masonry units using natural mineral-based geopolymers help reduce the load on the building at the same time give a better thermal performance.

• Light, responsive façade that breathes. This façade is made up of a series of faceted fiberglass rosettes, which open and close in response to the temperature of the façade thereby avoiding excess heat from ingressing the building.

• Double screen façade made from special tiles that can clean the air around it. UV light-activated free radicals from the tiles destroy any existing pollutants from the air leaving it cleaner for the people inside the building.

• Dynamic façades using modern technology, which transforms itself in response to the changing sun positions, lighting conditions and functional requirements.

The world is moving towards dynamic façades with endless possibilities, which are energy efficient. Traditional products like stone and aluminium composites are not enough to take care of the emerging needs of architecture as there is a continuous demand for materials that can provide appearance, and performance and take care of extreme Indian climate, dust, humidity and pollution.

The cladding industry in India has developed a new range of cladding products, which are sustainable and are available in a wide design range of colours, shapes and sizes. Demand for more efficient, responsive façades has led to the replacement of conventional glazing with a new generation of high-performance, intelligent façade system that meets the comfort, performance and environmental parameters.

The material palette of façades is evolving rapidly, ranging from ceramics, multilayer aluminium/ metals, to ETFE (ethylene tetrafluoroethylene copolymer) cushion fabric, multilayer ETICS (external thermal insulation cladding system) to green vegetated façade systems. New generation façades are self-cleaning, environmentally dynamic, information sensitive and communicating. The new generation hi-tech glass is transparent (but photo chromatic), lightweight (but strong), safe (without additional processing) and energy generating.

The fully responsive parametric façades are non-static, but kinetic addressing varied issues including sustainability, power generation, and vertical farming. The façades, far from being static elements are getting responsive and communicative. However, the biggest challenge is to balance the cost to performance. The façade is a living organ like our skin, which will respond in real-time to its surroundings and will be capable of adapting to it. The façade will be able to heat and cool itself and the building will no longer depend on artificial climate management. There are interesting glass products available, including PV modules, di-chronic glazing, glazing with integrated louvres, intelligent glazing systems, and electrochromic glass that changes from clear to opaque in a second.

Curtain Glazing System

Transparency, sustainability and protection from heat make glass an attractive façade material for high-rise buildings, where the need is for lightweight but strong material. Glass weighs less than concrete, offers views of the outside, and is sustainable too. New glass products have many benefits such as solar control and advanced thermal insulation. These have a coating that protects against UV rays penetrating the interiors and offers energy efficiency, and minimum visual glare. The glass can be engineered to provide maximum daylight indoors while keeping the interior cool.

Curtain glazing is a versatile cladding option with glass as the primary material. In modern high-rise buildings, the exterior walls are often suspended from the concrete floor slabs, curtain walls and precast concrete walls. The curtain wall is characterised by coloured and spandrel glass, a grid of aluminium caps, stainless steel, and stone spandrel covers. The curtain glazing is designed to resist wind and earthquake loads, air leakage, and excessive heat loss.

Installation of DGU (Double Glazed Unit) is preferred as it makes the curtain glazing system one of the most efficient insulators against heat loss, energy efficient and has high aesthetic value. Its disadvantages are that it is relatively expensive and there are issues of safety and glare.

Double Skin Facade

The building form, the height of the high-rise, high wind velocities and pressure differences on the external façade, are the prime issues in the design of the façade.

A double-skin façade is the preferred for following reasons:

- To decrease the U-value of the façade below 1.0 W/m2K;

- To enable permanent activation of the shading system to prevent increased cooling loads and high wind loads

- To ensure ventilation through controlled openings in the external skin.

A double-skin façade helps to reduce the pressure differences in a building in the façade cavity. For example, the dynamic wind pressure, which is the result of the gust, can be reduced by closing the openings in the external façade. The external double-skin façade consists of single glazing with uncoated white glass and the lowest possible iron oxide content.

Together with reflective shading, this configuration ensures that a maximum percentage of the solar radiation is reflected back to the outside and does not contribute to the heating of the interior space. The internal façade is constructed with gas-filled thermopane glazing (U-value = 1.1 W/m2K., g-value = 60%) which is the true thermal boundary of the skin. The double skin façade is characterised by ascending air currents as a result of the solar heat gain and the transmission losses. Ideally, a horizontal thermal gradient should develop in the air cavity in hot weather conditions, with relatively high temperatures between the single glazing and the shading system and lower temperatures between the shading system and the thermopane glazing.

The supply-air façade offers the advantage that the transmission losses through the thermopane glazing are regained with the supply air. The solar gains pre-treat the supply air, and the external glass skin offers protection during ventilation in rainy weather. The double-skin façade can serve as a quasi-fresh air stack, eliminating the need for air stacks in the building. This is a considerable advantage in high-rises. The air temperatures in the space between the façade layers may be considerably higher than outside temperatures in hot weather, which can be a disadvantage. To tackle this, it is important to integrate it with the ventilation system, exhaust air system and subsidiary air-conditioning.

Selection Of Glazing

The term “glazing” has a very wide range of meanings in architectural vocabulary, including transparent, translucent and opaque material in its range. Low-maintenance glass is only a commercial term. There are coatings available that reduce the dust accumulation on the glass surface and thus require less maintenance. The market has a variety of options for glazing materials, which can be selected considering the following:

• The direct sunlight diffused through the material or transparency,

• The amount of light that comes through or visible transmittance,

• The amount of radiant heat transmitted through the material measured by the solar heat gain coefficient

• The amount of heat from the air that will pass through the material, measured by the U-value of the assembly.

The supporting system or assembly design should be done considering factors such as available sizes of glazing material, span, the structural strength of the assembly, ease of installation, maintenance and pleasing aesthetics. A glazing material with a low Solar Heat Gain Coefficient (SHGC), low U value, high visible transmittance, and appropriate transparency based on location and layout would be ideal. Other factors to consider are the strength of the glazing material, maintenance, resistance to breaking or cracking and how the material will age over time.

In India, the major problem with skylights is the potential greenhouse effect in the space enclosed rather than heat loss. Along with the orientation of the skylight, heavy tinting of glass or polycarbonate glazing also reduces daylight, contradicting the prime objective of having a skylight. During the selection of glass or polycarbonate glazing, it is critical to optimise light versus heat gain characteristics. Glazing should be primarily of Low E Glass (low emittance). DGU (Double-glazed units) with thermal barriers are a must in extremely hot climates. Ceramic fritting and staining are other kinds of treatment options for façade glazing.

Glass installation should be done skillfully. Due to thermal stress, glass breakage occurs when there is a temperature variance in different parts of the glass. It is most common in large pieces of sealed insulating glass with heavy heat-absorbing or reflective coatings. The outside of the glass heats up more than the inside as the coating converts radiant heat from the sun into sensible heat. The outer glass expands and bends and when held in place in a rigid assembly, it cracks. As the breakage is not covered by the manufacturer’s warranties, it should be considered at the design stage itself.

Fenestration

Fenestrations protect the inhabitants in a building from the natural elements wind, rain, sound, fire, termites, humidity and security issues. For high-rise buildings in particular, the wind loads play a significant role in dictating the structural strength and in determining the thickness of the cladding material and the support structures used. All these parameters must be considered and their impact calculated prior to the fabrication of cladding panels. The wind load is calculated as per IS 875. Additional static profiles (hurricane bars) are chosen according to the requirement as per the IS norms.

The profiles are designed for using double glazing and if natural shading is not provided, thermal control glass is used. When selecting windows for energy efficiency, it is important to consider their energy performance ratings. This will help the selection of windows with both low U-factor and low SHGC to maximise energy savings in climates with cold and hot seasons. Whole unit U-factors and SHGCs are considered rather than centre-of-glass (COG) U-factors and SHGC. Whole-unit numbers more accurately reflect the energy performance of the product. When properly selected and installed, energy-efficient windows can help minimise heating, cooling and lighting costs. Improving window performance involves design, selection and installation.

For the Indian climatic conditions, uPVC profiles, which are multi-chambered, should have a minimum 2.5 mm thickness. 18 mm thickness of clear glass and multi-locking system hardware is recommended. These systems are tough to withstand intensive solar radiation, extreme heat and humidity. This means no discolouration and deterioration of the uPVC window and door system for many years. Also, with a multi-chamber design, superior sound control and thermal insulation can be obtained. It also removes the possibility of air, water, and sound leakages with its twin sealing gaskets.

Sustainable, innovative, reliable and aesthetically pleasing door/ window systems for both internal and external applications, combine a mix of form, function, ease of use, security and performance. The solution should allow natural light to ingress while keeping weather, noise, dust, rain, air and pollution out. Residential and commercial spaces have different requirements in terms of design, use function and performance.

Fittings need to be of higher specifications and must be able to prevent accidents due to strong winds. There can be a stay arm for windows called anti slam stay arm, which is very useful to prevent window shutters from shutting with force due to strong winds. There is a growing trend for ventilated façades. High-density laminates are one of the most preferred choices for ventilated façades where there are dead walls. Ventilated façades give a cooling effect to the dead wall of the structure and allow the structure to breathe, which is essential for all RCC structures for longevity.

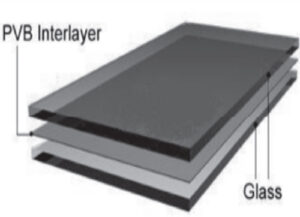

Laminated Glass

There are two types of laminated glass:

- PVB Lamination

- EVA Lamination

A range of laminated glass with specialised PVB interlayers provides a high level of security and safety. It eliminates the need for grills or shutters and gives the ability for crystal surveillance.

The Breathing And Green Facade

The breathing and green façade in a high-rise structure aims to create green spaces closer to the users. The offices overlooking the gardens are equipped with openable windows to allow the fresh breeze from these greens. Façade planting creates a microclimate, which is less prone to heat gain from solar radiation than metal or mineral-clad surfaces. Evaporation effects result in temperatures that tend to be lower than those in the surroundings. Wind-resistant plants can also be employed as windbreaks.

This idea has been pursued by the Malaysian architect Ken Yeang with his “green” façades, for example on the Menara Boustead Tower in Kuala Lumpur. The green wall with deciduous climbing plants, can reduce the solar gain inside the building, reduce the street noise and reduce energy load. It also produces a stack effect between the planted façade and the building exterior, channelling the heat away from the building. The façade vertical garden can be seen from the outside of the building as well as from the inside.

The system is made up of two main elements: the planter and the trellis. The dimension of the long, continuous planter is 1 meter deep and 1.4 meter-wide to the façade. It is made of lightweight concrete and is wide enough for easy access by maintenance staff. The trellis consists of an aluminium structure composed of horizontal mullions and slats. The waterproofing consists of gravel and a geotextile mesh laid over 2-millimetre thick fibreglass.

The planting medium consists of 70% earth, mixed with 10% river sand and 20% compost. The structural system is designed to account for the additional loading of the green wall soil, water and other loads (people, wind, seismic, etc.). Green walls should be protected from high wind speeds, wherever possible, and especially potential vortex shedding at building corners and other hazard-prone areas. Sufficient space should be allowed for the planting to grow without interruption, and also for maintenance staff to work.

Building Envelope As An Environment Moderator

The building envelopes are designed to communicate an image of contemporaneity. This must be conceived by understanding the complexity of the economy, ecology, climate and technology which together act as environmental moderators. A skin system aims to achieve sustainability as well as synthesize various facets of a project such as materiality, constructability and budget. It focuses on performance and spatial optimisation. All façades are composed of two orders, the first one is the main structure attending to all static conditions and the other is the structural system.

The precast panels can be made of steel, concrete or lightweight GRC sandwich panel systems. Curtain walls can be thermally insulated and supported on a self-supporting aluminium façade system which is self-cleansing and easy to maintain. For example, the bronze strips, an alloy made of copper and tin, under weathering exhibit a warm auburn colour on their surface. After oxidation of the surface, the material shows a dark-brown anthracite colour.

Conclusions

Cladding and glazing serve many purposes in creating a controlled internal environment, protecting the building from external conditions, preventing the transmission of sound, thermal insulation and the appearance of buildings. Cladding maintains privacy and security of exteriors, provides access to ventilation and a hygienic environment and prevents the spread of fire. Its properties like termite resistance, waterproofing, environment friendliness, and wide range of colours and designs make cladding a trend.

Exterior cladding plays an important role in structural stability. It helps in natural ventilation, sun screening and dissipating heat absorption. It helps to absorb water during rainfall and keep out rain infiltration and keep the building secure and safe. A properly tested, installed and maintained cladding also provides fire safety.