A meticulous pre-execution phase is crucial for the success of any façade project. Every detail, from design validation to material handling, plays a pivotal role in ensuring that the façade system meets the highest industry standards. Below is a comprehensive guide to the critical considerations before façade execution begins, emphasizing technical accuracy, structural integrity, and quality control.

Key Considerations Before Façade Execution – A Quality Control Perspective

- Organisational Structure For Site Coordination

A well-defined organisational chart is essential for ensuring smooth coordination and effective communication across all teams involved in the project. The chart should clearly outline roles and responsibilities from senior management down to the supervisors, facilitating seamless collaboration between departments.

Departments To Be Included:

- Design: Responsible for finalizing and verifying the design, including all structural and aesthetic aspects of the façade system.

- Safety: Ensures that all safety protocols are followed on-site, conducts risk assessments, and makes sure that safety standards are met at every stage of the project.

- Project Management (PM): Oversees project timelines, budgets, and resource allocation, ensuring that all aspects of the project are progressing as planned.

- Quality Control (QC): Maintains quality standards throughout the project, conducting inspections, testing, and ensuring that all materials and installations meet the required specifications.

- Planning: Coordinates the scheduling and logistics, ensuring that all activities are carried out on time and resources are allocated efficiently.

- Store: Manages material inventory and ensures that all materials are delivered, stored, and handled correctly, preventing delays or damage.

Having a structured organisational chart ensures clarity in roles and responsibilities, minimizes miscommunication, and helps the team quickly address any issues that arise during the execution phase.

- Design-Related Documents and Preparations

- System Design Considerations

- Wind Load Analysis: Detailed wind load calculations should be based on local climatic conditions, ensuring that the façade can withstand extreme wind pressures.

- Structural Integrity: Calculations for the entire façade system, including anchors, supports, and attachments, must ensure that the system meets the required safety margins per local building codes.

- Thermal Break System Design: The thermal break system should be chosen or designed based on the project’s performance requirements, including energy efficiency, insulation, and condensation control. The selected or designed system must align with the project’s thermal performance standards, addressing both energy conservation and structural demands. It should be compatible with other façade components to minimize thermal bridging and optimise overall system performance.

- System Design Considerations

- Design Documentation

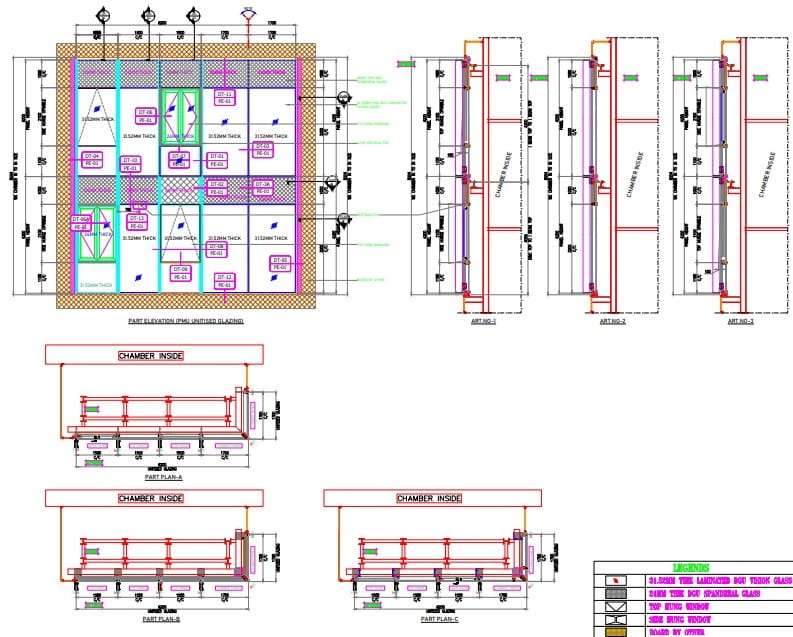

- Concept And Shop Drawings: All design documents, including structural details, glazing specifications, and material finishes, must be reviewed and finalized before fabrication.

- Survey Reports: On-site surveys should be conducted to validate the alignment of the façade system with the building structure, ensuring that tolerances are maintained during installation.

- Hardware Data Sheets: All hardware specifications—such as anchors, fasteners, and seals—should be technically vetted to ensure compatibility with the façade system.

- Material Procurement Plan

- Procurement Scheduling: Ensure that material procurement aligns with the floor closure schedule, ensuring that materials for corner panels, doors, openables, and standard panels are available well in advance.

- Just-In-Time Delivery: A robust logistics plan should be in place to ensure the timely delivery of materials, particularly critical components like glass and framing systems.

- Early Procurement Of Corner Panels, Doors And Openables:

To avoid complications during installation and maintain quality standards, materials for corner panels, doors, and openables must be ordered early and be available on-site. Delaying material procurement for these components can lead to alignment issues, misfitting, and quality compromises during installation.

Key Considerations:

- Advance Material Ordering: Ordering materials early ensures availability for smooth execution. Delaying procurement can result in rushed installation and quality control challenges later on.

- Complete Material Planning: Ensure all corner panels, doors, and openables are ordered and fabricated ahead of time, along with standard panels, to avoid last-minute shortages and coordination issues.

- Accurate Fabrication: Early procurement allows for precise fabrication and avoids misalignment that could arise from missing or delayed components.

- Seamless Integration: Ensure that all materials are available and fit within the design for proper integration with structural elements, preventing delays and rework.

- Performance Mock-Up – Façade Testing

- Mock-Up Testing: Full-scale mock-ups are essential for validating the design, installation procedures, and material performance. They help identify potential issues with system integration, aesthetic consistency, and functionality before full-scale execution begins. Mock-ups should serve as the reference point for the entire project, setting quality standards and confirming that all systems and materials perform as intended.

The mock-up test should be conducted as per the consultant’s recommendations. For example, the Water Stone project by Brookfield, tested at Winwall Testing Laboratory in Chennai on 3rd September 2024, underwent a comprehensive sequence of tests to verify the façade’s performance under various conditions.

The Following Tests Were Carried Out:

- Pre-loading: +900Pa

- Air Infiltration: +300Pa

- Static Water Penetration: +300Pa

- Dynamic Water Penetration: +450Pa

- Structural Performance: +/-1800Pa

- Repeat Air Infiltration: +300Pa

- Repeat Static Water Penetration: +300Pa

- Repeat Dynamic Water Penetration: +450Pa

- Seismic Racking: +/-10mm (5 cycles, Horizontal Movement)

- Vertical Inter-Story Displacement: +/-10mm (5 cycles, Vertical Movement)

- Repeat Air Infiltration: +300Pa

- Repeat Static Water Penetration: +300Pa

- Repeat Dynamic Water Penetration: +450Pa

- Repeat Static Water Penetration: +600Pa

- Repeat Structural Performance: +/-2700Pa

- Seal Degradation Static Water

These tests simulate a range of real-world conditions to assess the façade’s performance in terms of air and water infiltration, structural stability, and overall durability. All performance standards should be documented and verified to meet local and international building codes. Successful testing of the mock-up ensures that the façade design, materials, and installation methods will deliver the desired results during full-scale execution.

- Visual Mock-Up (VMU) Before Full-Scale Execution

Visual Mock-Up (VMU) is a crucial step in the pre-execution phase to ensure that the façade design is visually accurate before full-scale execution begins. It allows the design and quality teams to validate the appearance and aesthetic details of the façade, providing an opportunity for adjustments before installation.

Key Benefits of VMU:

- Design Validation: VMU offers a high-fidelity visual representation of the façade, ensuring that the final product will match the initial design intent.

- Material & Finish Verification: The VMU helps confirm that the selected materials, finishes, and colors are consistent with the design specifications.

- Alignment With Structural And Architectural Elements: VMU allows the design team to ensure that thefaçade aligns correctly with the building’s architectural features.

- Simulating Installation Process: The VMU helps visualise the installation sequence, aiding the team in identifying potential conflicts or issues.

- Client and Stakeholder Feedback: It serves as a tool to ensure all stakeholders are aligned with the final appearance of the façade.

- Glass Technical Considerations for Quality And Performance:

- Glass Selection: The glass type, thickness, and performance should be specified in collaboration with the structural consultant and architect to meet both aesthetic and structural requirements.

Key Considerations:

- Quality Assurance and Certification: Ensure that all glass components are sourced from certified manufacturers and meet relevant international quality standards.

- Edge Deletion, Glass Thickness, Spacer Color/Type, and Argon Gas Check:

- Edge Deletion: Proper edge deletion is necessary to ensure optimal adhesion between the glass and frame.

- Glass Thickness: Select glass thickness based on structural load requirements and safety standards.

- Spacer Color/Type: Ensure the spacer used between glazing layers is compatible with the design and meets durability standards.

- Argon Gas: Verify that argon gas is properly sealed within double-glazed units (DGUs) to enhance insulation and energy performance.

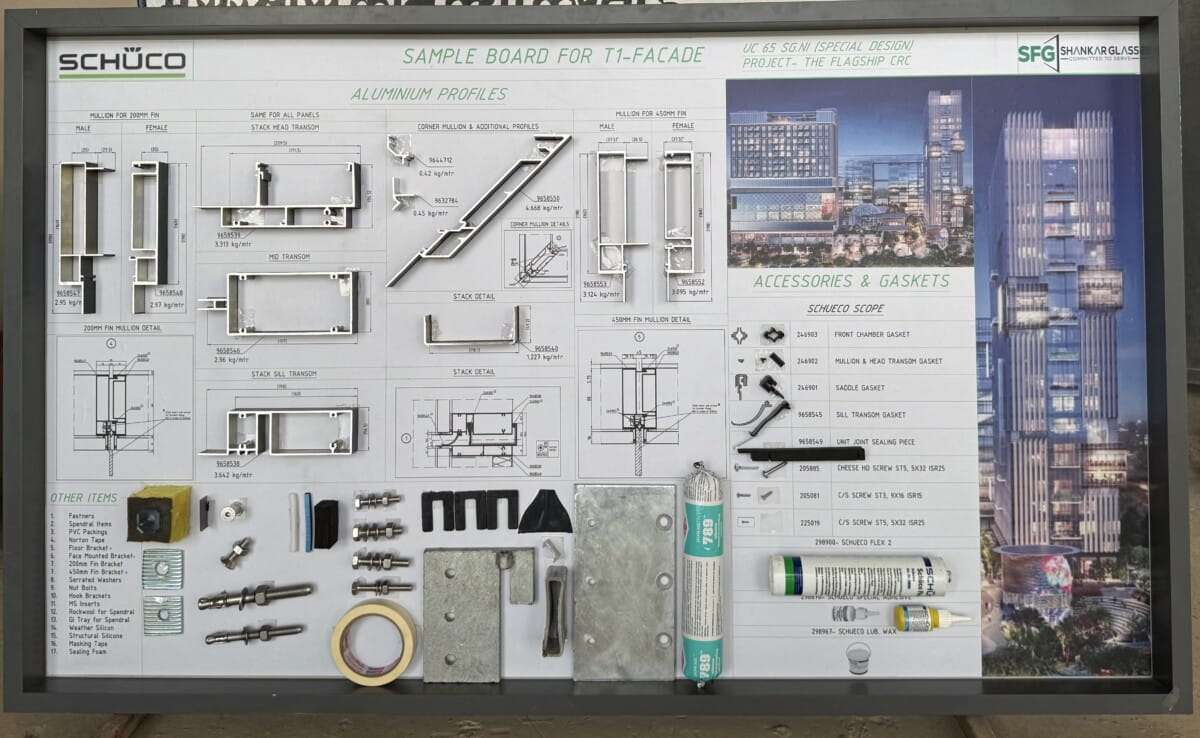

- Sample Boards for Quality Control

The Sample Board plays a critical role in setting the quality benchmarks for façade materials and finishes. It allows the design team, client, and quality control team to verify the materials and finishes before large-scale production and installation.

Key Points:

- Material Selection: The sample board helps to visually confirm the material, finish, and color selection.

- Texture and Finish: Sample boards should include full-scale mock-ups of the façade materials to examine texture, gloss, and finish.

- Validation: The sample board allows all stakeholders to approve materials and finishes before they are used in the façade installation.

- Glazing Room Requirements For Optimal Glass Quality

Key Considerations:

- Dust-Free Environment: Maintain a dust-free zone to prevent contamination of glass surfaces.

- Temperature Control: Control temperature and humidity to prevent thermal expansion or contraction that could affect the glass quality.

- Handling Procedures: Follow proper handling and storage procedures to prevent damage to the glass during installation.

- Store Management: Material Handling and Protection Effective store management ensures that materials are stored, handled, and delivered correctly, reducing the risk of damage before installation.

Best Practices:

- Material Segregation: Classify and organise materials based on their type and size to facilitate easy access.

- Controlled Storage: Store materials in dry, temperature-controlled environments to prevent degradation or damage.

- Packaging of Panels: Panels should be carefully packaged using protective materials to safeguard against scratches, impacts, and any form of damage.

- Delivery Standards: Ensure that the delivery of materials follows industry best practices with secure transport to avoid damage during transit.

Key Considerations During/After Façade Execution – A Quality Control Perspective

While working on high-rise façade projects, façade engineers have encountered and overcome several challenges in ensuring the success of these installations. In this part of the article, the author shares some key considerations from his own experience, focusing on quality control and technical challenges faced during the execution and post-execution phases.

- Powder Coating and Extrusion Profiles

One of the first steps in ensuring a successful façade system is the inspection of powder coating on extrusion profiles before fabrication begins. From my experience, quality control at this early stage is critical. Dry Film Thickness (DFT) must be checked to ensure uniformity across all profiles. Any discrepancy in the coating can lead to future issues with aesthetics and performance, especially for high-rise buildings exposed to extreme weather conditions.

- Protection Of Powder-Coated Profiles

After the profiles are powder-coated, it is crucial to wrap them with protection film. This simple step significantly reduces the chances of scratches, dents, and other physical damage during transport and handling. However, the protection film should not be removed until after installation, once all cleaning and floor activities are completed, ideally 45-60 days before final handover.

- Fabrication Checklist And Approval

Before fabrication is considered complete, a detailed checklist must be followed. This checklist should cover the following:

- Dimensional checks.

- Material quality verification.

- Hardware compatibility.

Having faced challenges in past projects, I’ve realised that it’s essential to ensure all components meet the correct tolerances and specifications to avoid delays during installation.

- MS Inserts and Fixing Details Approval

One key challenge I’ve encountered in my work is ensuring that all MS inserts and fixing details are approved by the consultant and system provider well in advance. If there are any discrepancies or delays in approval, it can affect the structural stability of the façade and delay the entire installation process. Ensuring all fixings are approved early helps avoid issues later on.

- Glazing Room and Glass Handling

In a high-rise façade project, glazing room conditions can make or break the quality of the final installation. From my experience, ensuring a dust-free environment, controlling temperature and humidity, and using the right handling equipment (like suction lifters) for glass panels are essential practices.

Key Tests In The Glazing Room:

- Butterfly Test: Ensures the glazing system can withstand high wind loads, critical for high-rise façades.

- Deglaze Test: Verifies the resilience of the system when subjected to external forces, ensuring the glass doesn’t detach.

- Relative Test: Checks the movement between the glass and the frame, which is crucial for the durability and safety of the façade.

- Detailed Post-Fabrication

Checklist

After fabrication, I have found it very helpful to maintain a comprehensive checklist to confirm that:

- The fabrication aligns with design specifications.

- All components fit perfectly and are in the correct sequence for installation.

This step is crucial to minimise the need for rework and to ensure that the panels are prepared for the next stage in the process.

- Floor Bracket Inspections

As a project manager on high-rise façade projects, I can’t stress enough the importance of performing a detailed inspection of the floor brackets before installation. These components play a significant role in ensuring the façade is securely fixed to the building. Any misalignment at this stage can result in critical issues later, which could affect both structural integrity and aesthetics.

- Pull-Out Test for Anchors

One of the most challenging but essential aspects of façade installation is ensuring the anchors are strong enough to withstand the forces they’ll face. Pull-out tests should be conducted on all anchors before installation to verify their load-bearing capacity and ensure that they can maintain the façade’s stability under extreme conditions.

- Subsurface Alignment and Pond Testing

In my experience, the alignment of the sub-sill is one of the most crucial aspects of ensuring that the façade performs as expected. The sub sill must be aligned according to the survey results. After sealing the joints, I’ve found that conducting a pond test ensures there are no leaks, making it an essential step before moving forward with further installation.

- Pre-Lifting Checks And Safety Protocols

Before lifting panels into place, it is critical to carry out comprehensive checks to ensure everything is ready. I’ve worked on numerous projects where safety protocols were rigorously followed before any lifting operations began. This includes:

- Verifying that the panels are secure and free from defects.

- Ensuring lifting equipment is functioning and safe to use.

- Making sure the workforce is well-trained in safety norms to avoid accidents.

- Gasket Cross-Checking and Waxing

Cross-checking gaskets before lifting is a step that I always ensure is performed thoroughly. Gaskets are vital for ensuring the system’s integrity, and applying wax to them helps the panels slide smoothly during installation. Missing this step can lead to friction, resulting in installation delays or even damage to the panels.

- Cleaning Before Lifting Panels

In my experience, cleaning is one of the most underrated but crucial steps. Before lifting panels into place, it is vital to ensure that both the panels and the installation area are clean. This minimises the risk of any debris being trapped between the panels, which could damage the surface or interfere with the sealing process.

- Panel Alignment Post-Installation

Once the panels are installed, it’s crucial to check their alignment. All panels should be aligned according to the approved stack height and vertical grooves. Misalignment can affect the façade’s appearance and lead to significant challenges in both quality and structural performance later on.

- Pond Testing After Installation

After each installation cycle, I always make sure to conduct a pond test. This test helps to ensure that the installation is watertight, preventing leaks that could cause significant damage in the long run.

- Post-Installation Checklist

I always advocate for a detailed post-installation checklist. This checklist is essential for verifying that the installation is complete, the façade system is secure, and all components are functioning correctly. This checklist should be reviewed by the quality team, PMC, and the client to ensure full satisfaction before handover.

- Complete Record Keeping of All Reports

Maintaining comprehensive records of inspections, testing, and approvals is crucial. These records serve as a reference for future maintenance and inspections and can also provide proof of compliance with regulations.

- Handover and Final Cleaning

Before the façade system is handed over to the client, a final cleaning is necessary to ensure the façade looks pristine. This includes removing any installation debris, dust, or other residues from the system to make sure it looks as intended.

- Maintenance

Finally, I always emphasise the importance of creating a maintenance plan for the client. This plan should include:

- Regular cleaning schedules.

- Periodic inspections of the seals, gaskets, and hardware.

- Recommendations for maintaining the system’s performance and appearance.

Conclusion

Working on high-rise façade projects has given me a deep understanding of the technical, design, and quality control aspects contributing to a successful installation. By focusing on these key considerations during the post-execution phase, we can ensure that the façade system meets all structural and aesthetic requirements while maintaining long-term performance.

Every detail, from powder coating inspection to post-installation maintenance, plays a significant role in the success of a façade system. I hope sharing my experiences helps others understand the complexities and challenges of high-rise façade execution and how quality control is paramount to ensuring the desired results.