As a veteran in the field of sealants, PU foams, and building hardware accessories, I can truly give you my in-depth understanding of what India has witnessed in the past couple of years and the future of the façade & fenestration industry in the coming years.

PU FOAMS AND SEALANTS

I would like to break up the subject of sealants and PU foams first… The humble beginning of the sealant industry: Use of Silicone mainly started with Silicone structural glazing way back in the early 1990s. Silicone is a ‘must-have’ for every façade, door, and window, aka fenestration. The revolution in the silicone industry came with the advent of uPVC doors and windows in the early 2000s, and now, after two decades, it is mandatory to use the same in every door and window installation.

The organised aluminium system companies also shaped the use of silicone sealants. This has also urged the unorganised aluminium door and window industry to a large extent to make sure to use Silicone sealants, acrylic sealants, and PU Foams for all installations across the country.

In particular, a fenestration includes a complete system with all mandatory components, including profile, glass, gasket, sealant, anchors, fasteners, and reinforcement. They all go together as one to complete the system.

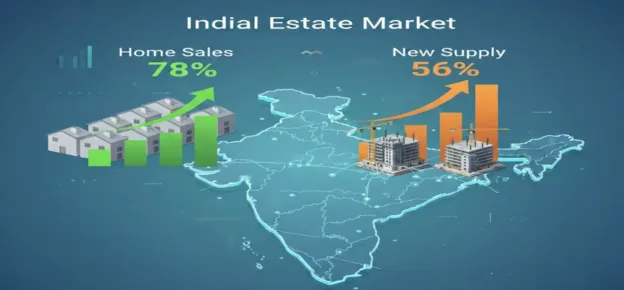

Thousands of pieces of training organised for industry members, along with demos on proper installation/use of all these products, have shaped the sealant and fenestration/related industries in India. Looking ahead, the construction industry in India will take a long forward leap in the coming years. Projects and retail sectors are expected to keep growing through the decade, and I see that the growth of sealants is directly proportional to the same.

Quality is a top performer and will need to be maintained by all manufacturers at all times to have enduring products with high performance. I also see great scope for new technologies like MS Polymers and Advanced PU to come forward in the industry sooner. India is a dream shaping up, and sealants are a form and function of the same; growth can only be positive.

ARCHITECTURAL HARDWARE

As far as building hardware and accessories are concerned, for the longest time, the same was always imported from China and other parts of the world and still is. Going forward, the forward drive towards ‘Make in India’ is going to take shape very aggressively, and it is expected that top-quality uPVC/ Aluminium door and window hardware will be produced in India, not only for the domestic market but also for exports.

The consumption of quality hardware is likely to double every year, and the industry size is expected to grow by more than 30 % year on year, as more and more doors and windows will need safer and more secure hardware, which in turn means more hardware per window and door in terms of cost and value.

India is on a growth trajectory, and we welcome this change and will support the industry like we have been doing for the past few decades.