Design for fire safety is still in a nascent stage in India. There is now a growing demand for ‘fire-rated materials’ among the decision-makers in the Indian construction industry, particularly pertaining to the façade. The recent spate of fire accidents both on a national and international level has fueled the discussion further. Many of these mishaps were preventable if only a few basic principles of firesafe design were included in the façade design. This article aims to shed some light on some of the key aspects of fire safety in façade design.

Fire Standards And Testing Methodologies

There are many well-known standards and testing methodologies which are followed across the world when it comes to fire safety in façade design. Some of the notable ones are as follows:

• National Building Code (NBC 2016) of India: NBC provides guidelines for glazing selection in buildings. Excerpts from Part 4 – Clause 3.4.10.2 of NBC pertaining to glass selection can be summarised as below:

1. For fully sprinkler enabled buildings with fire separation of 9 m or more, tempered glass in a noncombustible assembly shall be used

2. For buildings which are not sprinkler enabled, 60- 240 minutes fire rated glass is recommended for the external façade.

• EN13501-1:

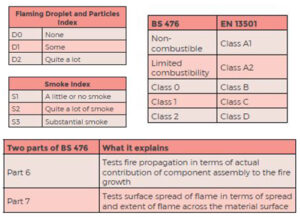

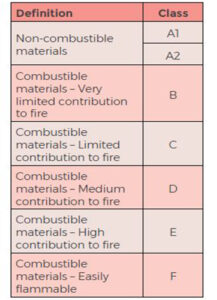

This European standard provides classification of building materials in terms of their reaction to fire. Materials are classified in terms of Class A1, A2, B, C, D, E and F ranging from non-combustible to most combustible. In addition to this, the standard also classifies material in terms of ‘flaming droplets and particles’ during the first 10 minutes of exposure denoted by ‘d’ and ‘smoke propagation’ during the first 10 minutes of exposure in terms of ‘s’.

Consider, for example, a hypothetical cladding material of Class A2 s3 d2. The fire performance of the material can be understood as follows:

A2 Non-combustible

S3 Produces substantial smoke

D2 Produces quite a lot of flaming droplets and particles

It can be seen that even when a material is non-combustible, it can perform badly in the event of fire if it causes high levels of smoke or produces lot of flaming droplets.

All the three parameters listed above are to be seen together to select the right cladding material in terms of fire resistant properties.

• BS8414:

This is a British Standard which provides technical specifications explaining the fire performance of external cladding systems.

• BS 476:

BS 476 is a British standard that provides information on fire tests to be carried out on building materials and structures. It has 2 parts: Part 6 and Part 7.

The classification of materials in terms of BS 476 can be juxtaposed on the classification of materials in terms of EN 13501 to arrive at equivalent classification of materials as shown below:

• NFPA 285:

This a standard fire test method for evaluation of fire propagation characteristics of exterior wall assemblies containing combustible components provided by the National Fire Protection Association (NFPA).

Materials

One of the common misconceptions in understanding the fire behavior of the façade materials is encapsulated by the following statement: ‘I need a material with 2-hours fire rating’. While this is a perfectly fine thing to ask for when discussing glass partitions, it is not how the fire performance of a cladding material is defined. Although glazing and cladding together form the elemental units of façade design, their performance parameters vary.

- Glazing:

Typically, tempered glass has better performance against fire than annealed glass. Tempered glass can withstand double the temperature threshold that annealed glass can withstand. Also, even when tempered glass breaks or shatters, it breaks into many small pieces which are relatively less harmful than annealed glass which breaks into large shards with sharp edges.

However, there are glasses specifically meant for fire protection also. These are generally used in places where compartmentalisation of spaces is required. These are called fire-resistant glasses and they fall into 3 categories as follows:

Integrity (E): This is the most basic type of fire-resistant glass and as the name suggests, this type of glass provides integrity to the partition. It prevents flame and hot gases from reaching the non-fire side for some time.

Radiation control (EW): In addition to preventing flame and hot gases, the EW type of fire-resistant glass also prevents heat reaching the non-fire side to some extent. It allows people to pass through on the non-fire side for a certain specified amount of time.

Insulation (EI): The EI category provides the highest level fire-rating since it also helps maintain the temperature of the nonexposed side at reasonable levels for a specified period of time. This is in addition to preventing passage of flame and hot gases. These are available in many performance ratings such as 30 minutes, 60 minutes and 90 minutes fire rating. Nevertheless, for façade applications, generally tempered glass is suggested along with other fire-safe design features.

- Cladding:

The common method of classification adopted for cladding materials is based on the European Standard EN – 13501 – 1. As shown in the table below, cladding materials are classified in to the following 5 types based on their flammability:

Class A1: These cladding materials have the highest performance in terms of fire protection. They are non-combustible and are made up of totally inorganic materials such as concrete, stone, fired clay and ceramics. One of the disadvantages of these panels is the dead load which makes them a potential danger in the event of falling from heights.

Class A2: Cladding materials belonging to this class are also noncombustible but they are generally composite materials such as some types of high pressure laminates (HPL), aluminium composite panels (ACP) with mineral core and a few types of plasterboards. These are lighter in weight compared to A1 category but come with a price and the options available in India are limited.

Class B: Combustible materials which make very limited contribution to fire are grouped under Class B category. There is a plethora of options available in this category in Indian market. Most of the aluminium composite panels (ACP) and high pressure laminates (HPL) available in India fall under this category. These panels when used with non-combustible insulation offer superior fire performance to buildings.

Class C and Class D: Class C and Class D make limited to medium contribution to fire respectively and are combustible. In general, these 2 categories are also not preferred in façade design due to their risky nature. Composite panels made of organic materials without fire retardants generally fall under this category.

Class E and Class F: These 2 classes of materials easily catch fire and are not considered in façade design.

Installation Methodology

Method of installation adopted is as important as selecting the right material as per the above specifications. There are various cladding methods adopted in India ranging from wet cladding to dry cladding.

Generally dry cladding methodologies involve fixing the cladding panels to a structural frame fixed to the building. This results in a cavity between the building and the cladding material. Fire breaks need to be provided to prevent the chimney effect in order to deter the fire from spreading from one floor to another vertically and from one room to another horizontally. In addition, the provision of a minimum 10% of total openable vision glazing is required to mitigate the effect of smoke built-up in the event of fire.

India’s Lesson From The UK

After the Grenfell accident, there has been a lot of discussion about fire safety of cladding materials. Incidentally, the cladding material that was used in the Grenfell tower during the infamous fire accident of 2017 was ACM panel with an unmodified polyethylene (PE) core. The Ministry of Housing, Communities & Local Government (MHCLG), UK, commissioned testing the behavior of non-ACM (Aluminium Composite Material) cladding materials. The Expert Panel that undertook this study made a few recommendations1 and the points related to cladding materials are summarised below: • ACM panels with unmodified PE filler pose significant fire hazard on residential buildings at any height and should be removed.

- ACM panels with fire retardant PE filler when used with rigid polymeric foam insulation presents significant fire hazard for residential buildings over 18 m or buildings at any height where residents need significant assistance to evacuate and these systems should be remediated.

- HPL systems with panels of Class C s3 d2 or Class D s3 d2 does not meet the functional requirements of the UK building regulations and are to be remediated.

- HPL systems with panels of any class with combustible insulation on residential buildings over 18 m or buildings at any height where residents need significant assistance to evacuate should be remediated.

Conclusion

A system is only as strong as its weakest element. This applies to fire safety of buildings as well. Fire safety in design starts with the selection of right materials. But testing the system and adopting right installation methods are also important in achieving fire safety at a holistic level. It is understood that the aforementioned materials and installation practices come with a cost. Only when there is a conscious effort from building designers, builders, operators and end users, can fire safety become an integral part of design and fire tragedies like the Grenfell incident can be prevented in the future.

References

https://www.gov.uk/government/publications/building-safety-advice-for-building-owners-including-fire-doors