Please tell us about the company Aludecor and its products. When was it established?

Aludecor, established in 2002, stands as a proud Indian enterprise that excels in crafting metal composite panels. Our journey has been one of relentless innovation and dedication, propelling us to the forefront of the cladding industry both within India and on the global stage.

Our portfolio boasts a diverse array of offerings, encompassing aluminium, zinc, and copper composite panels. In the spirit of continuous progress, we’ve introduced a groundbreaking creation – the Nexcomb honeycomb panels. This remarkable product features the Nexcore honeycomb core, poised to revolutionise architectural cladding by bringing forth a new era of creativity and excellence.

What are the major milestones in the company’s journey?

Aludecor stands as a true vanguard of innovation, consistently leading the ACP cladding industry with pioneering accomplishments. From introducing India’s first double coat, double bake line to unveiling Zinc and Copper composite panels that redefine design, we’ve consistently embraced firsts.

Our commitment to advancing safety and sustainability led us to launch India’s maiden Anti-Bacterial ACPs and develop the nation’s first Fire-rated ACPs with an FR core. The attainment of the globally recognized NFPA 285 certification for our Fire-rated range underscores our unwavering dedication to safety.

Our exclusive partnership with global Zinc leader NedZink showcases our commitment to delivering the best, while our latest feat—India’s pioneering honeycomb Nexcomb panel core— further solidifies our status as industry innovators.

Aludecor’s journey is a testament to innovation, setting a standard that continually propels the industry forward.

Could you please brief me on some of your recently launched products & and the most well-known ones in the market?

Certainly! Our product lineup boasts both recent innovations and well-established favourites that have garnered significant acclaim in the market.

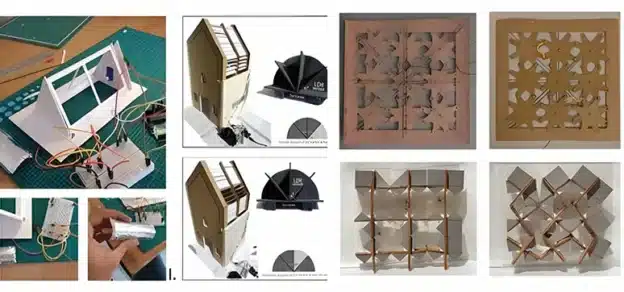

Our latest offering, the Nexcomb Honeycomb panel, is a testament to our ongoing commitment to pioneering solutions. Currently available in aluminium, this revolutionary panel showcases a core structure inspired by the intricate design of a honeycomb. This construction involves bonding a network of aluminium hexagonal cells, creating a remarkably sturdy yet lightweight composite. This innovation, ideal for varied sectors and industries, offers unparalleled creative freedom and the ability to craft visually striking structures. We’re proud to mention that we’re actively working on expanding this innovation to other metals as well, further broadening our range of possibilities.

Please tell us about your company’s manufacturing facilities.

Aludecor takes pride in its modern manufacturing facilities located in Haridwar, India. These cutting-edge facilities serve as the backbone of our operations, enabling the production of an extensive array of products.

All the 3 manufacturing units, nestled in the picturesque city of Haridwar, have played a pivotal role in our company’s evolution and product innovation. Boasting state-of-the-art machinery, advanced testing capabilities with dedicated R&D labs, and top-tier technology, these facilities stand as a testament to our commitment to excellence.

Spanning across an impressive 35,000 square meters, our three facilities in Haridwar collectively house an aluminium coil coating capacity of 22,000 metric tons per annum. This robust setup enables us to cater to diverse requirements while maintaining stringent quality standards.

From producing MCPs (Metal Composite Panels) to Zinc solid panels, Honeycomb panels and core, our manufacturing facilities showcase our dedication to precision, innovation, and meeting the demands of a dynamic industry landscape.

Tell us about some of the iconic projects in which your products are used as exterior cladding materials.

Every project we undertake holds a special place in our hearts, regardless of size or scope. Aludecor ACP sheets have played a significant role in shaping a diverse range of creative projects, both in India and internationally.

Here are some standout examples: Stellar Complex, Ahmedabad: An embodiment of charm and functionality, the Stellar Complex in Ahmedabad designed by the globally renowned Architect Sanjay Puri, stands adorned with our Rustic Series. Its simple rectilinear geometry is complemented by subtle colour tones, while the angular geometry adds a striking contrast to the building’s overall design.

BioWonder, South Kolkata: A true ode to nature, the BioWonder project brings the best of greenery and modern architecture to the city of Kolkata. Powered by Aludecor ACP sheets, the design seamlessly integrates greenery, sunlight, and fresh air, creating a space that allows individuals to thrive close to nature.

Oxygen Business Park, Noida: Our involvement in the Gold LEED energy-efficient Oxygen Business Park in Noida was a remarkable achievement. The industrial yet sophisticated look achieved through Aludecor ACP sheets perfectly complements the glass décor. The fire- rated ACPs by Aludecor have added a focal point, harmonizing all elements seamlessly.

Shangri-La, Bangalore:

Proudly associated with Shangri-La Bangalore, India’s first luxury hotel equipped with full fire-rated ACPs. This landmark project exemplifies our commitment to excellence and safety while adding a touch of luxury to architectural brilliance. Each of the projects we associate, reflects our dedication to transforming architectural visions into reality, providing aesthetic appeal and performance excellence in equal measure.

Please throw some light on the latest materials, technologies and trends in façade cladding in India.

In the dynamic realm of façade cladding in India, several materials, technologies, and trends are shaping the landscape.

Materials: Glass, metal panels, natural stone, terracotta, composite panels, and high-pressure laminates are at the forefront. Among these, composite panels and high-pressure laminates are gaining substantial traction. Composite panels, noted for their lightweight durability, offer an array of options, custom designs, and colours to cater to diverse architectural needs. High-pressure laminates, apart from their wood textures, have become versatile choices for both interior design and external cladding, presenting a wide spectrum of design possibilities.

Technologies: Technological strides are revolutionizing façade and cladding systems in India. Building Integrated Photovoltaics (BIPV) is a prime example, ushering in energy-efficient solutions that integrate solar power generation with building exteriors. Another significant advancement is the infusion of digital printing into cladding materials, allowing for unprecedented design flexibility and customisation.

Trends: The ever-evolving trends in India’s cladding landscape reflect global concerns and emerging design philosophies. Sustainability takes center stage, as architects and builders embrace eco-friendly materials & practices. Innovative and biophilic designs foster a harmonious connection between architecture and nature, enhancing user experiences.

Resilience and durability are paramount, with a focus on materials that withstand the test of time and environmental challenges. Moreover, interactive designs are emerging, responding dynamically to changing environmental conditions and infusing vitality into structures.

In this swiftly changing environment, Aludecor remains dedicated to staying at the forefront of these trends, offering innovative solutions that echo the evolving needs of architects, designers, and builders.

Tell us about the testing and certification methods for your products.

At Aludecor, our commitment to quality goes beyond words – it’s ingrained in every aspect of our products. Just as a chef meticulously selects the finest ingredients to create a masterpiece, we take great care in sourcing top-notch materials, perfecting formulations, and ensuring exceptional performance in each and every ACP sheet we produce.

Our dedication to excellence is unwavering, from the moment we lay the foundation to the final delivery. We’re not content with meeting industry standards – we set our own high bar for industrial excellence and extend that commitment to our customers worldwide. The road to perfection isn’t easy, but it’s one we walk diligently.

Every ACP sheet that leaves the Aludecor factory is more than just a product – it’s a testament to our relentless pursuit of quality. Rigorously tested and meticulously evaluated, each sheet complies with the strict parameters of our comprehensive 204 In-House Tests. Our manufacturing units are buzzing with precision, as we ensure that our products stand up to the toughest scrutiny.

Safety isn’t just a checkbox; it’s our paramount responsibility to you. We want you to use our ACP sheets with complete confidence, knowing that every element has undergone rigorous scrutiny. Our vigilant systems allow us to monitor every phase of development, giving you peace of mind.

We’re not just a name in the industry; we’re a symbol of excellence. Our efforts have been acknowledged globally, as we proudly received the Best Quality Practices Award from the prestigious European Society for Quality Research (ESQR) in Brussels, Belgium. This recognition celebrates our commitment to quality, our innovation-driven R&D, the meticulous testing protocols we follow, our industry-leading practices, and the exceptional products we offer. At Aludecor, quality isn’t a buzzword – it’s our way of life. We’re not just shaping ACP sheets; we’re shaping a legacy of excellence that stands the test of time.”

What are the key factors to consider while choosing cladding materials?

Selecting cladding materials involves evaluating factors such as durability, aesthetics, maintenance needs, environmental impact, local weather conditions, cost, fire resistance, regulations, insulation, installation ease, resistance to pests and decay, and adaptability. These considerations collectively guide the choice of materials, ensuring a harmonious balance between practicality, aesthetics, and sustainability.

What do you see as the main challenges faced by the Aluminium cladding industry?

In the aluminium cladding industry, challenges include poor fabrication techniques that need modernization, regulatory compliance complexities, the imperative for fire safety awareness and FR grade ACP usage, quality control maintenance, sustainability concerns, and the need for technological advancement. Adapting to these challenges is essential for industry growth and innovation.

What keeps your company ahead of its competitors in terms of products and services offered?

At Aludecor, our relentless commitment to innovation and excellence sets us apart from competitors. We thrive on continuous experimentation and innovation within our state-of-the-art facility, ensuring that our products remain at the cutting edge of the industry. Quality and safety are uncompromising pillars of our offerings, bolstered by our unwavering dedication to embracing the latest technology trends.

We pride ourselves on pushing boundaries and breaking barriers, all while considering the socio-economic impact of our products. Our creations aren’t just products; they’re milestones in architecture, contributing to a better world. What truly distinguishes us is our caring approach toward our customers, fostering relationships that extend beyond transactions. This combination of innovation, quality, care, and forward-thinking is what propels us forward, keeping us a step ahead in the competitive landscape.

Where do you see the cladding industry as a whole, and the aluminium cladding industry in particular, evolving over the next 10 years?

Having witnessed over two decades of evolution in the cladding industry, I am confident that cladding is more than a trend – it’s the architectural future, often referred to as the “skin of architecture.”Among the diverse cladding materials available, aluminium stands tall, and ACP remains a favourite choice for design consultants, fabricators, and architects alike.

Ethical practices have guided our journey, and sustainability has emerged as a central theme. By combining innovation with environmentally friendly methods, the aluminium cladding industry is poised for a sustained and impactful presence. As we move forward, the industry will continue to embrace creative opportunities, reshaping urban landscapes and architectural aesthetics. The coming decade will witness cladding’s transformative power, with aluminium at its forefront, contributing to a more sustainable and visually stunning built environment.