Sharing our view on trends and challenges in the context of 2020 runs the risk of being too focused in the short term on developments with regard to EXPO 2020 in Dubai. We are currently in a situation where many projects are focused on EXPO 2020 with a fixed and inflexible schedule of delivery aligned with the start of the event. All the pre-planning and activity leading up to this is on a fixed schedule. In addition, many projects need to be completed, not only out of the original schedule but additional projects as planned. The developer’s efforts to limit cost increase due to tight execution plans are very strong. A key consideration is an agility and flexibility in delivering on budget and on time while meeting EXPO 2020 requirements successfully. But of course, there is a wider perspective on the façade industry in terms of trends and challenges.

Looking back to 2018 leading up to the present and looking to the future, we can see a significant increase in third party service assignments. These assignments are driven by both the façade fabricators as well as main contractors. This is not so much a trend as is a result of the changing market conditions, as also hopefully addressing Priedemann’s advocacy to the market ‘to better control the execution of a project’. In multiple events during the last years, in particular, in many of the ZAK World of Façades events, we tried to educate the industry on the benefits of a REAL third-party execution compliance control service.

Why do we emphasize “REAL”? Because we can still see many, as we like to call these- ‘alibi assignments‘ to just comply to a clause in the specification, while the actual services seem to be in many cases just a token in nature or a tick mark in a checkbox. A third-party service is first and foremost the independent compliance control between design/execution and the specification with respect to the Issued for Construction (IFC) documents and the contractual agreement. The service shall ensure that the client gets delivered what he contracted for. Ideally, such a service is carried out in a proactive and solution-driven way to avoid delays, conflicts and frustration between the parties rather than just with a pass/ fail approach.

However, if there is a lack of knowledge and understanding of façade design, a party may not be able to conduct the simple task of understanding and therefore approving a design, let alone guiding an improvement. We have observed many cases of a standard-rejection stamp, by simply listing all specification clauses to be complied with no ‘marked up’ at all. Such services are not worth even the small fee paid by a client and will not lead to any improvement in design or quality of execution.

This approach ensures timely approvals and execution. Furthermore, it raises the quality of the design and the executed façade – a result we owe to our clients and to society. It becomes even more crucial at a time when the Dubai market lacks sufficient qualified façade fabricators to carry out the numerous projects being launched. Newcomers enter the façade market and less renowned players arise. Many have a good base and opportunity of becoming a qualified fabricators and clients get more confidence when these fabricators are associated with a façade consultant who can guide them proactively in their design and execution process.

When it comes to trends in terms of façade material, we have seen countless presentations of kinetic and responsive façades, adaptable materials, building integrated photovoltaics and even bioactive materials and we are sure, many of them will play an important and active role in the future of façade technology. Individual projects are executed in specific regions with a budget and require completely different localized views of investment strategy and Return on Investment (ROI).

Al Salwa Investments LLC is setting a trend in the market not only by its outstanding design quality of ICD Brookfield Place Tower – Dubai, designed by Foster & Partners but also by highly valuing third-party services. The client, together with their main contractor, Multiplex – Ssangyong JV, demands not only detailed reviews of façade design, calculations, material and installation but also a proactive role in the early design development phase. This approach avoids time-wasting rejections and ensures the design is headed in the right direction from an early stage.

Priedemann is playing an active role as our team of façade experts carries decades of experience and knowledge in design and execution on global markets. Not only do we take each job seriously, we do not fear taking responsibility on a decision or on an approval, and we give solutions driven advice in the form of notes and remarks as a value addition beyond our contracted assignment of specification compliance control.

Façade Lab – Workspace

Priedemann is an active participant in the development of such new façade technologies through the activities of our Façade-Lab. The Façade-Lab was established in 2009 by the partners of Priedemann. It is a center of excellence for research and development in the core area of building envelope. The objective is to develop sustainable façade technologies until the prototype stage, to optimize it to be ready for the market and to present these innovations to the target market with partners from industry, science and research. Another focus of the Façade-Lab is the development and promotion of integrative and interdisciplinary construction processes in order to form the design process, the construction and the operation on a holistic perspective.

Façade Lab Innovation project

In 2014, the Façade-Lab, together with partners from the industry developed a façade system which we believe is a trend setter in the industry. With the aim of a ‘highly transparent façade’ – a classification which is very challenging to achieve under the German energy saving regulations, a team was formed to find a solution. By joining forces with partners from Schueco and Warema, a normal passive building envelope was transformed into an active building component, reacting dynamically to changing environmental conditions.

Façade Lab – Showroom

As a result, cooling energy needs could be reduced by up to 20 per cent and the user comfort could be increased. This high-performance façade is based on a unitized system of two different elements.

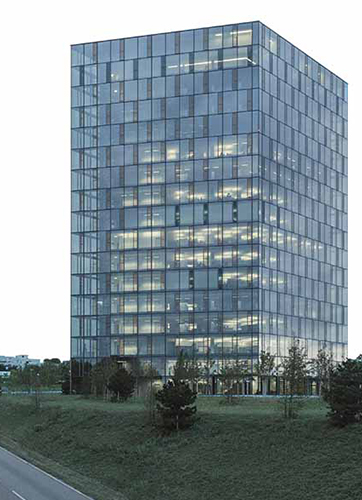

Case Study Festo Automation Center

The façade is the main part of the new eye-catching 67 m high landmark Festo Automation Center within the Festo campus, visible from everywhere in the metropolitan region of Stuttgart. The façade elements consist of one parallel opening window and a fixed glazing element. The smallest element measuring 0.70 x 4.00 m set a new standard in manually openable windows and the technology of electro-chromatic glazing. The larger façade element is 2.70 x 4.00 m large and is carried out as one fixed glazing panel. With a high quality sun control glass, a good view from the inside is still ensured. To counteract glare, an internal blind is nevertheless needed. At the Festo Automation Center, this mandatory blind is used to create a new type of air-exhaust façade. Thanks to new technical innovation and an optimization process within the planning phase, the textile blind creates an exhaust air corridor between the blind and the glazing. Through this space, the exhaust air from the office space is sucked off taking with it the heat from solar radiation captured by the blind within this corridor.

Thanks to this combination of façade engineering and building services, this façade element also features a dynamic g-value, lowering the cooling demand inside and creating higher user comfort – thanks to similar surface temperatures throughout the office. The façade systems mentioned above ensure that already in the first summer since the Automation Center went into operation in July 2015, the inside temperature never exceeded 26°C, even at outside temperatures of up to 40°C. Besides higher energy efficiency, the increased user comfort and enabling high job performance, the single skin unitized façade was created with a depth of only 75 mm of glass construction, increasing the usable floor space in the building. In order to keep this newly generated absolute view clear at all times, a new cleaning robot was used for the Automation Center. Powered by vacuum technology, this robot can move along the whole façade like a gecko by itself cleaning it in only one day. The new Festo Automation Center façade is built like a conventional single-layer unitized façade, but because of a lot of highly designed and developed details and a smart controlling of the building services, a highly innovative, efficient and sustainable façade could be realized.

While incorporating all the green design, innovation, automation, efficiency, sustainability requirements in the region, it is also the perfect solution for the climatic conditions and design trends:

- Conventional façade components are used, which are all available in the region

- Glare control by blinds is widely standard, it is required and available

- The façade is highly transparent when the weather allows it

- Glare is controlled automatically if required, which at the same time improves the insulation property of the façade

- The required AC system is in any case built-in in all buildings in the region and can be easily adjusted to the need of the cavity suction.

- It is suitable even for refurbishments of façades and would improve performance without occupying more space than a conventional façade

We believe that such a smart and innovative approach as well as a proactive third-party approach with the ability to take responsibility is setting a trend in the region for 2020 and beyond.