Q – Could You Tell Us About The Architectural Firm Cannon Design And Its Establishment In India?

Yogesh Jog (YJ): CannonDesign is a globally recognised, forward-thinking architecture firm celebrated for its innovative and integrated design solutions. With 18 offices in major cities such as Chicago, New York, Mumbai, and Boston, CannonDesign offers comprehensive services—including architecture, engineering, interior design and sustainability consulting.

In 2024, CannonDesign was ranked among the top firms worldwide in the World Architecture 100 report, earning distinction across key sectors such as healthcare, education, sports, and science & technology design. At the heart of our practice is Living-Centred Design-our own novel approach to tackling the most pressing challenges of our time. This philosophy empowers us to create solutions that go beyond meeting human needs, thoughtfully addressing the increasingly complex interdependencies across all forms of life. Many of our projects are celebrated for their exceptional quality and enduring impact, embodying our commitment to environments where both people and communities can truly thrive.

CannonDesign began working in India over fifteen years ago and now has a 65-member team in Mumbai. Our local architects and engineers work alongside colleagues from around the world, aiming to bring together global expertise with what’s needed locally.

Q – Could You Please Brief Me On The Journey And Projects Of Cannon Design In India, As Well As The Projects You Are Currently Working On? What Type Of Projects Do You Do More Of?

YJ: Our presence in India began with a defining project – the Tata Medical Centre in Kolkata, which established a new standard for cancer care in eastern India. From there, we built on that foundation with expansive campuses for Tata Consultancy Services in Bhubaneswar and Rajarhat—together totalling more than 3 million square feet. Each project reflects our commitment to energy efficiency and seamlessly blends our global expertise with local insight.

With every opportunity, we strive to craft spaces that are not only highly functional but also fundamentally people-centric. Our core strengths lie in Healthcare, Education, and Science & Technology, and these typologies continue to shape our portfolio. Among recent achievements, the Rivea Vascular Institute in Hyderabad has emerged as a leading healthcare facility, significantly enhancing the patient experience in India. Collaborations with Holy Family Hospital and Jupiter Hospital in Mumbai further reflect our commitment to local partnership and our dedication to delivering thoughtful, effective design solutions.

Q – Tell Us About Some Turning Points In Your Design Firm. Please Throw Some Light On A Few Of Your Milestone Projects And Some Of Your Challenging Projects.

YJ: A significant development in our operations has been the integration of the Mumbai studio into CannonDesign’s global workflow through Single Firm Multi Office (SFMO) projects. These collaborations enable team members to work with colleagues from various offices across North America and other regions. The process involves sharing ideas, methods, and responsibilities between locations, which provides exposure to different design approaches. This experience has contributed to improved quality and technical prowess in projects in India and enhanced planning, coordination, and delivery of work. It has also supported our capability to address complex challenges while following the principles of Living-Centred Design.

In recent years, our team has contributed to collaborative international projects including the Mayo Clinic’s “Bold. Forward. Unbound.” in Rochester, Minnesota, USA; the Kenneth C. Griffin Pavilion at Memorial Sloan Kettering Cancer Center in New York, USA; and Northwell Health’s Petrocelli Surgical Pavilion at North Shore University Hospital in New York, USA, just to name a few. Engagement in these projects has informed and refined approaches applied to work in India. Locally, milestone projects including Tata Medical Centre, Kolkata Phase I and II, Tata Consultancy Services campuses in Bhubaneswar, Rajarhat and Mumbai have provided opportunities to implement these learnings and better understand the local market.

Q – What Is Your Take On Sustainable Practice In Architecture Today?

Akhila Pillai (AP): As an industry, we are getting better, but there is still much work to be done.

Sustainability has been a topic of discussion in the field for some time. Initially, only a small number of architects were actively involved in sustainability efforts. Many firms saw sustainability as something to pay lip service to, but without fundamental changes to the approach of architecture, viewing it as the responsibility of the engineering consultants to deliver on.

Over time, awareness of the urgent impact of buildings on the environment and human health has grown. New dimensions of sustainability, such as carbon, material health and embodied impacts, have emerged. The impact of the façade on building performance and new energy code requirements for the envelope performance has increased the architect’s need to engage with sustainability from the earliest design phases and continue through the detailing.

Thankfully, we have many new digital tools for evaluating multiple aspects of building performance from the earliest design phases, allowing us to shape our designs with sustainability in mind. At CannonDesign, we have been encouraging our teams to think not only of a design concept for the building, but a performance concept as well, and make sure they are compatible, if not one and the same. This is a cultural shift that architecture needs to take for us to transform into a regenerative design practice.

Q – How Would You Define Your Design And Installation Process For Façades And Fenestrations In Your Projects?

AP: Our façade and fenestration design and installation process are rooted in a performance-driven, collaborative philosophy aimed at achieving efficiency, durability, and design integrity.

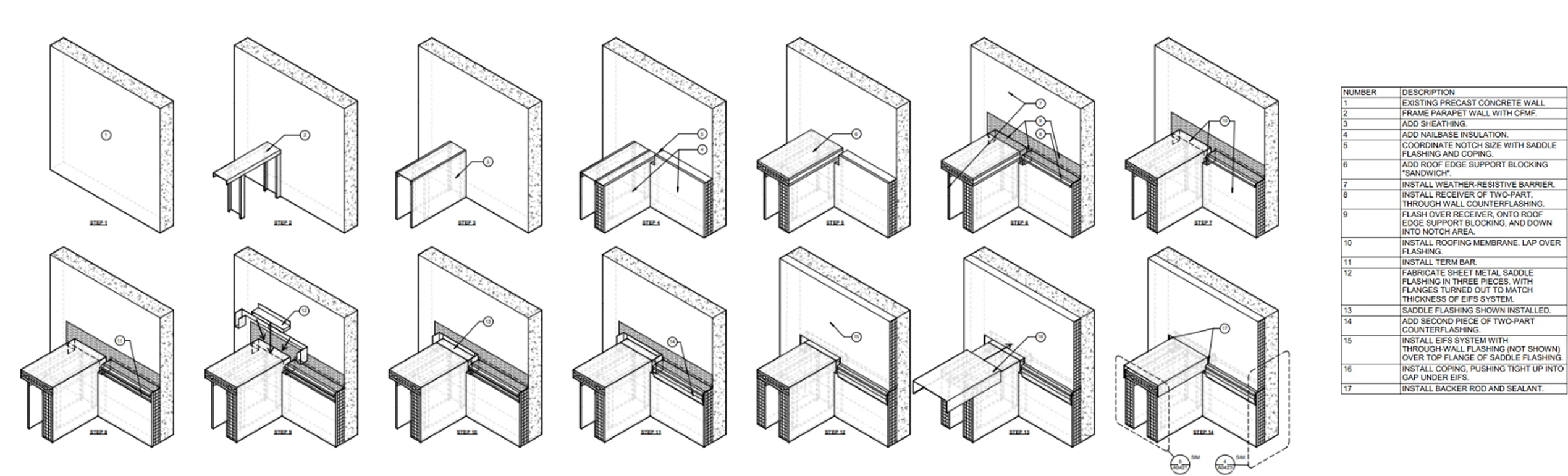

It begins with a clear understanding of the site and its climatic conditions. From there, we attempt to integrate the essential control layers early on – air, moisture, thermal, and vapour barriers – each of them playing a distinct role in protecting the building envelope, ensuring environmental separation, and significantly boosting energy efficiency.

The process thrives on collaborative project delivery models such as Design-Build, Integrated Project Delivery (IPD) and Design Assist, where fabricators, contractors and design teams co-develop solutions using Building Information Modelling prioritise By using BIM and digital twin technologies, we ensure seamless coordination and early clash resolution. We prioritise early engagement with façade consultants, structural engineers, and manufacturers during the schematic design phase, enabling us to align technical detailing and system integration while minimising risks.

Altogether, our approach embodies a sustainable multidisciplinary method that fuses architectural aspiration with constructability and longevity.

Q – Please Talk About Some Of The Most Preferred Façade Materials In India And Globally.

AP: Globally, the façade landscape is shifting toward materials that balance performance, aesthetics, and low embodied carbon. Mass timber systems – such as cross-laminated timber (CLT) and glulam – are increasingly celebrated for their renewability and biogenic carbon storage, often paired with engineered wood-composite rainscreens or thermally broken metal. Prioritising durability.

Prioritising embodied carbon as a key design principle reflects our commitment to the responsible sourcing and construction of materials, ultimately contributing to a more sustainable, eco-conscious built environment.

Mass timber manufacturing produces significantly lower carbon emissions compared to the energy-intensive processes used for concrete and steel, while also being a renewable resource. We are currently working on various mass timber projects across the United States where the design and construction phases demand enhanced creativity, determination, and problem-solving compared to the traditional path.

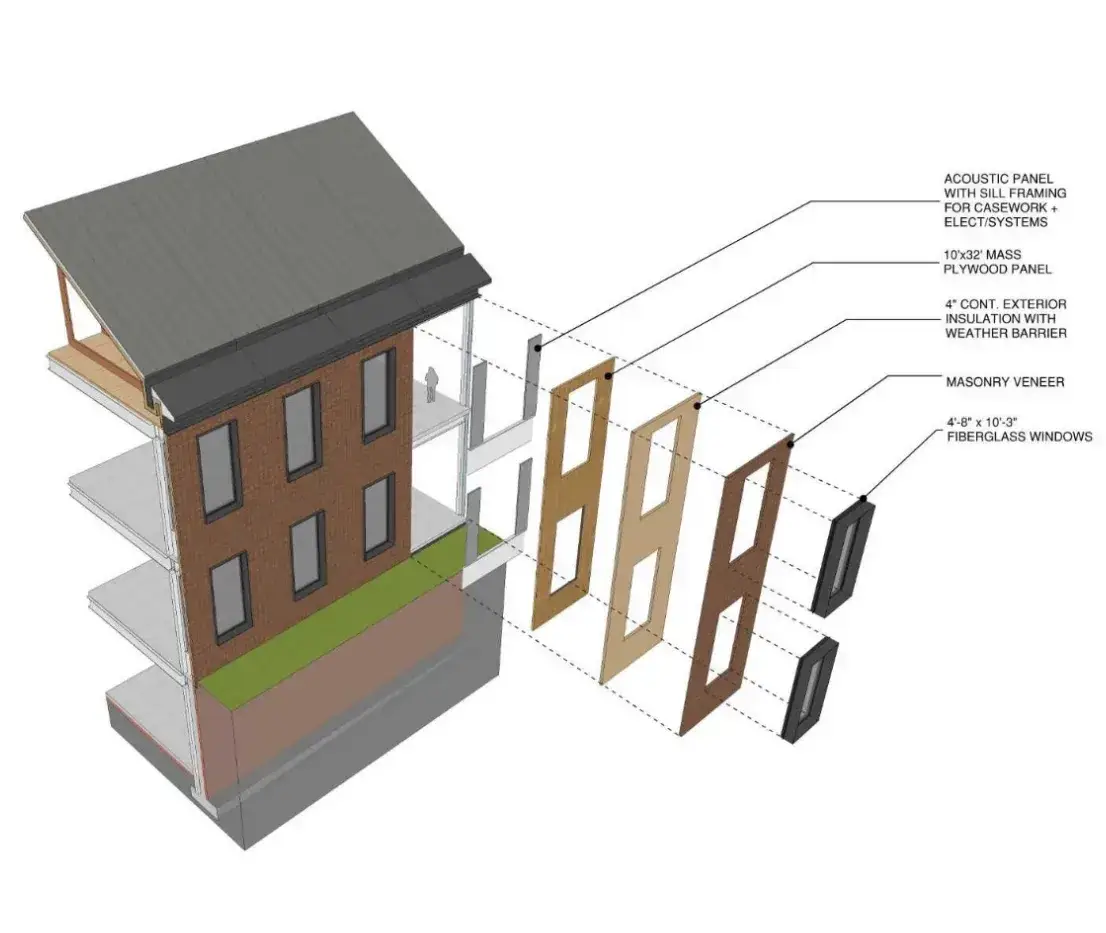

The Washington State University Vancouver Life Sciences Building in Washington, USA, showcases one of the first full-building envelopes made from mass plywood panels (MPP), replacing conventional metal framing and drywall with a sustainable, prefabricated system. This reduced embodied carbon, improved thermal performance, and enabled enclosure in just four days – well ahead of schedule. The exposed wood interior adds warmth and wellness benefits, while meeting LEED Gold standards and demonstrating how innovative materials can enhance both construction efficiency and environmental impact.

Our commitment to Sustainability, Material Impact Initiative and Design Excellence in India is equally strong. Many of our projects already integrate low-carbon, locally sourced materials – such as sandstone for Tata Medical and granite in dry cladding systems – leveraging India’s expanding domestic production capabilities to reduce transportation emissions and support a more resilient, regional supply chain.

Q – Could You Please Brief Me On The Latest Trends In Façade And Fenestration Designs, Materials And Technologies?

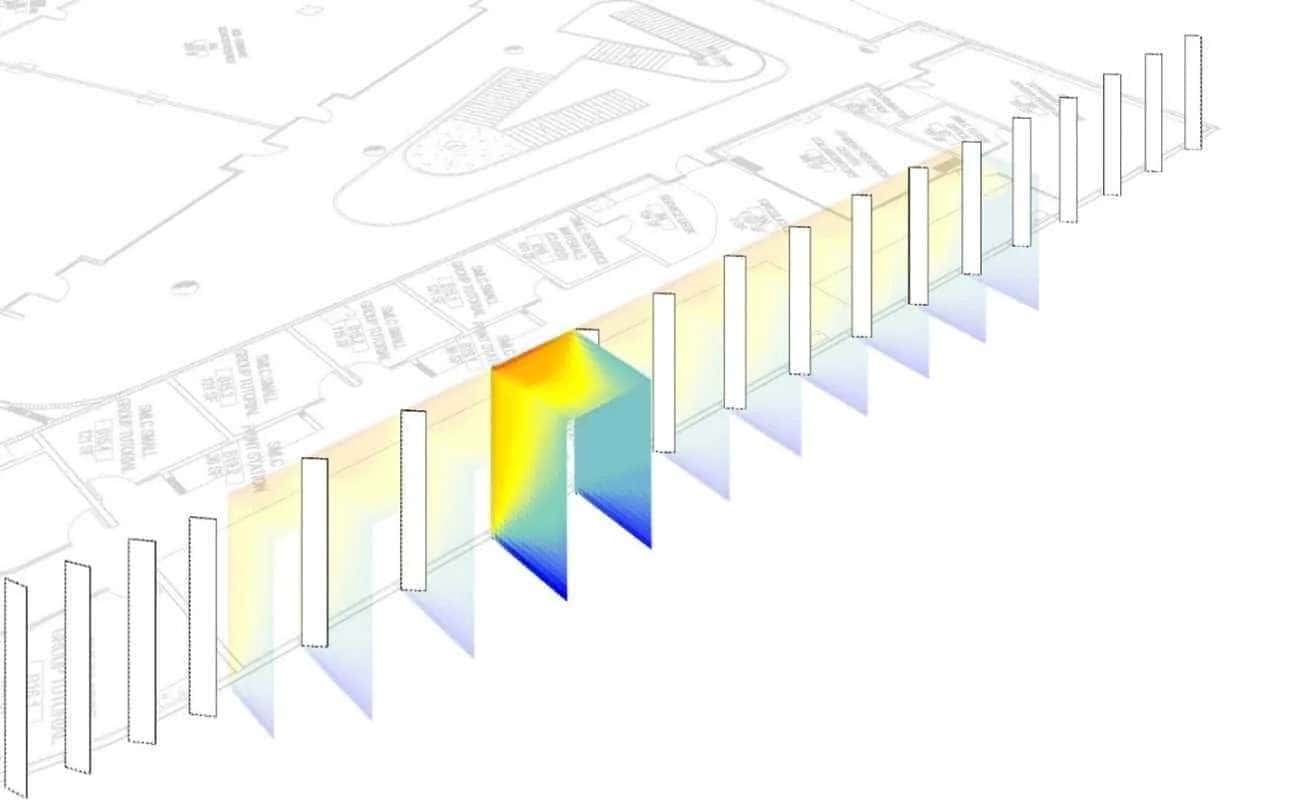

AP: We have been experimenting more with environmentally responsive façade designs, including exterior shading optimised by solar angles, producing unique façade expressions. These façade elements have been designed to shave peak loads, reduce glare, and provide better energy performance. In a recent competition, we were using a faceted façade with building-integrated photovoltaic panels aimed towards the sun to generate energy, while aiming the glazing away from the sun to allow in soft indirect daylight while reducing solar loads.

High-performance glazing – triple panes with low-e coatings and integrated shading devices, while aluminium composite panels with high recycled content and fibre-reinforced polymers find favour where lightweight, corrosion-resistant envelopes are required. Across all these applications, life-cycle assessments guide material selection, pushing designers to weigh transport distances, manufacturing impacts, and end-of-life disassembly potential.

Vacuum insulated glazing (VIG) is an intriguing new technology that a lot of glass manufacturers are making investments to develop product lines of. Consisting of a thin IGU with an evacuated cavity, the VIG units can offer better U-Values than a triple pane unit in a thinner and lighter panel. Though VIG is a more expensive and more specialised product than triple glazing at present, as it becomes more mainstream, it could really upend our current way of thinking about the façade and the limitations of the windows-to-wall ratio.

Leveraging unitised façades, prefabricated components, and mega wall systems allows us to accelerate construction schedules, reduce on-site labour, and deliver higher quality with fewer joints and penetrations.

Q – What Kind Of Software And Tools Do You Use While Designing Efficient And Effective Façades And Fenestrations?

AP: We employ computation tools such as Grasshopper for Rhino to perform iterative building performance analysis. We connect the parametric Grasshopper models to validated simulation engines for energy and daylight through plugins such as Climate Studio and Ladybug tools.

Using this workflow, we can parameterise the physical, thermal, and optical properties of the façade. As we explore different design iterations architecturally, we track the performance of each iteration for a range of environmental performance metrics, including energy, peak loads, daylight, thermal and visual comfort. Looking at the façade designs in an integrated way allows us the opportunity to identify design pathways that address multiple performance concerns simultaneously.

For example, we can make sure we design the façade with the right amount of glazing to provide good daylight and views, but not have an excessive amount that will penalise energy performance, introduce glare, or provide asymmetrical surface temperatures that will cause thermal discomfort. We can look at the operational and embodied carbon of the façade design together, so we don’t end up adding more embodied impact in insulation than we will save in carbon emissions through energy use.

Even though we are initially looking at a large design space, the tools give us the ability to both keep track of all the high-level data on all iterations, yet also drill down into the details. We can extract surface temperatures of the glass, look at hourly results, and perform 2-D thermal transfer using THERM. We are expanding our use of AI to enhance the work we do. Instead of simulating all possible combinations in a larger design space during the initial iterations, we simulate fewer options and then use machine learning to make predictions about the others.

Additionally, as we work on complex projects with intricate geometries, we’re increasingly recognising the need for three-dimensional multi-step details to effectively convey our design intent, show construction sequence, and gather early feedback (Image).

Q – What Are The Key Safety And Security Aspects You Look Upon While Designing A Largescale Project/ High-Rise Building?

AP: When designing a high-rise or large-scale building, fire and life safety is one of the most critical considerations. Stopping a fire before it spreads and effectively managing smoke movement can make the difference between a manageable incident and a catastrophe. Following several tragic fires worldwide, it has become clear that insulation and façade materials must be thoroughly tested for fire propagation. NFPA 285 plays a crucial role in this process, verifying that the entire exterior wall system-from insulation and cladding to air and vapour barriers – works cohesively to limit fire spread and protect occupants.

Resilience is another essential factor. It ensures that the building maintains structural integrity and operational continuity under extreme events such as flooding, seismic activity, high winds, and wildfires. In critical facilities like hospitals or laboratories, resilience is treated as a fundamental design requirement, with all systems – structural, mechanical, electrical, and plumbing – engineered to perform reliably under these conditions. Material selection is a key to minimising this strategy: e.g. assemblies and finishes are carefully chosen to minimise fire propagation, particularly in high-risk areas or regions prone to wildfires.

Façades are also designed and tested for impact, weather, and structural resistance. They need to withstand wind loads, seismic forces, and potential debris impacts while maintaining integrity. This ensures the building envelope protects occupants and prevents hazards such as glass breakage, water infiltration, or structural failure.

Q – Please Brief On Future Façade Technologies, Designs, And Materials That You Wish To See In The Next 20 Years.

YJ: We at CannonDesign have been lucky to have subject matter experts like Regal Leftwich – who is an architect, educator, and author of six books on AI/ML – and who has long explored the link between science, technology, and the built environment. He often shares AI’s future impact and how innovative design can harness its potential.

If I imagine façades twenty years from now, I see them transformed from mere barriers into intelligent, interactive layers – almost like living companions for our cities. These future envelopes will feature surfaces that breathe, harvesting sunlight through seamlessly integrated photovoltaics, and purifying the air using bio-reactive coatings or embedded plant systems. Materials may be grown rather than manufactured – mycelium, algae composites, and other regenerative substances that not only reduce carbon but restore ecological balance. Façade panels will be kinetic, smart glass will automatically adapt to changes in light, heat, and weather, and surfaces will employ AI-driven self-healing technologies, repairing micro-cracks before they’re ever visible.

Through the power of generative design and 3D-printed precision, these façades will balance expressiveness and performance – blurring the boundaries between architecture, nature, and technology. Much like a digital assistant, the façade itself will respond to individual needs, creating personalised environments for each occupant while contributing to a harmonious, sustainable whole. And perhaps most remarkably, façades will sense the presence and mood of occupants – subtly shifting their colour, transparency, or texture to calm or energise us, making our buildings truly responsive to the rhythms of human life.

Q – What Is Your Advice To Young And Upcoming Architects?

YJ: I’d say start by asking yourself why you’re drawn to architecture in the first place. It’s a question I still come back to, even after all these years. Our field moves fast, and it helps to have a sense of purpose – something that keeps you grounded when days get complicated, or projects don’t go as planned. Architecture isn’t just about buildings; it’s really about the people who use them, the communities we help shape, and the lives we touch.

If you are just beginning, don’t hesitate to explore different areas – healthcare, education, public spaces, you name it. Try out various roles too, whether that’s design, research, or talking with clients.

We help shape the lives we touch. If you are just beginning, don’t hesitate to explore different areas – healthcare, education, public spaces, you name it. Try out various roles too, whether that’s design, research, or talking with clients.

Each experience teaches you something new about what you’re good at, what drives you, and the kind of impact you hope to make.

And honestly, staying open to new ideas and technologies matters more than ever. Digital tools, especially things like AI and advanced visualisation, are changing the way we work. Even though these can feel overwhelming at first, they’re helping us solve problems in smarter ways and design spaces that truly respond to people’s needs. The learning never really stops in this field, and I think that’s what makes it so rewarding.