Could you please tell us about your journey in the field of architecture? How did you think of becoming an architect? What do you enjoy most about your profession?

My career in architecture so far has been fulfilling and dynamic. I am from a family of building contractors so, from a very young age, I was drawn to the intersection of creativity, problem-solving, and making. Architecture has provided the perfect outlet for that passion. The idea of shaping spaces and contributing to the built environment always fascinated me.

What I enjoy the most is the opportunity to bring a vision to life, creating something tangible and enduring whilst addressing the functional needs and aspirations of the people who inhabit those spaces. Every project is a unique puzzle and requires a deep understanding of the context – historical, spatial, environmental, social, and economic – as well as collaboration with the community and various other stakeholders. The diversity of these challenges keeps me engaged and motivated.

What do you think is the role of a façade or building envelope in the sustainability enhancement of a building?

In the face of the climate crisis and the subsequently urgent need for the construction industry to align with sustainability goals, the role of a building envelope is paramount. Its significance is not only vital but evolving rapidly, making the ‘fabric first’ approach crucial in our efforts to reduce carbon emissions and conserve energy.

Decarbonisation is a multifaceted challenge and requires a mosaic of solutions. The building envelope is the first line of defense against external elements and is thus at the forefront of this transformative journey. The ‘fabric first’ approach puts emphasis on optimising the building fabric. This process spans from increased thermal performance and airtightness, carefully assessed solar control and natural ventilation, user comfort, and fenestration orientation to thoughtful material selection such as the use of circular materials. The goal is not only to address operational carbon but also the embodied carbon within the construction materials.

It has become critical to develop methodologies to assess and quantify the carbon emissions – embodied, operational, and whole-life carbon – on our path to a carbon future by 2050. Technological advancements and analytical tools will play a pivotal role in navigating these complexities by enabling a data-driven analytical approach to inform sustainable building practices.

Please tell us about any interesting ongoing or recently completed projects at Woods Bagot.

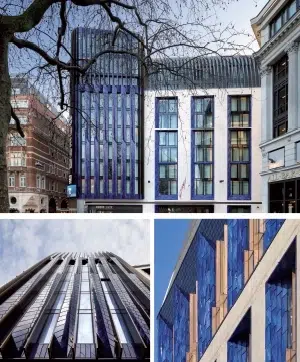

I am particularly fascinated by The Londoner Hotel project, especially its façade composition. The hotel ingeniously slots into a dense and bustling urban setting, leveraging the site potential both above and below ground, to deliver significant value to the community.

Notably, the project boasts a BREEAM Excellent rating and features one of the world’s deepest ‘habitable’ basements that accommodates two cinema screens, as well as various hotel amenities and staff spaces.

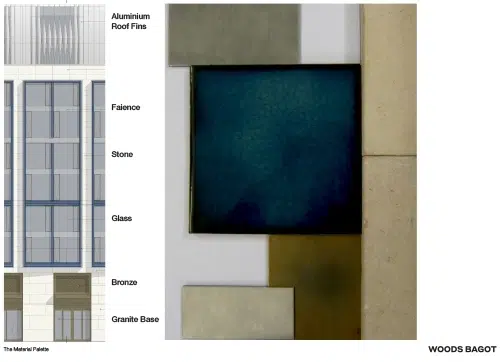

Interestingly, as part of the planning consent requirements, the project was required to contribute to the local community in some form of public artwork. Rather than treating this as a mere add-on, our approach involved working in collaboration with locally based artist Ian Monroe. Together, we conceptualised and integrated a captivating public artwork into the building’s fabric which resulted in a dynamic undulated royal blue terracotta façade to the tower, positioned to mark the entrance to the building and the alternating patterns of glazed tiles activating the window reveals that enhances the overall aesthetics thus delivering a layered public realm experience.

Composed of 15,000 bespoke individually handmade tiles, the façade serves as a homage to the area’s tilemaking history. The material palate is contextual, nodding to the numerous glazed brick insertions that characterize public buildings in the area.

Composed of 15,000 bespoke individually handmade tiles, the façade serves as a homage to the area’s tilemaking history. The material palate is contextual, nodding to the numerous glazed brick insertions that characterize public buildings in the area.

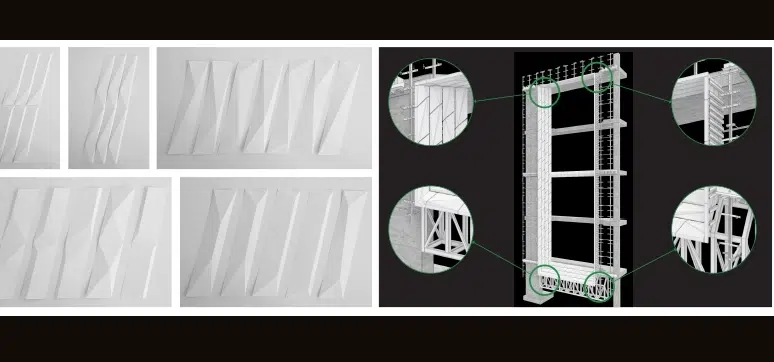

To overcome the challenge of executing the complex façade composition, The Londoner required extensive coordination between our extremely talented in-house digital design specialists, the project engineers Arup, consultants, and off-site fabricators.

Optimisation Approach

The process began with Monroe’s hand-drawn sketches and papercut models, experimenting with colours, shapes, and arrangements. Using digital design tools, we optimized the geometry of the tiles – size, weight, and thickness, and coordinated the metal subframe design, and the mechanical elements, without compromising the design intent.

The process began with Monroe’s hand-drawn sketches and papercut models, experimenting with colours, shapes, and arrangements. Using digital design tools, we optimized the geometry of the tiles – size, weight, and thickness, and coordinated the metal subframe design, and the mechanical elements, without compromising the design intent.

The Londoner is an artistic triumph that features incredible craftsmanship that extends from its ground floor to its roof. Intricate and complex, this level of artistry would be challenging to achieve manually and so was made visible and tangible through collaboration amplified by digital tools – making it a technological feat too.

- Project Name: The Londoner

- Location: London

- Client: The Edwardian Group

- Architect: Woods Bagot

- Engineering: Arup

- Faience manufacturer: Darwen Terracotta and Faience

- Materials used for façade & and fenestration: Portland Stone, Faience, Aluminum

How has the integration of Building Information Modeling (BIM) impacted the process of façade design in building projects, and what key advantages or challenges have emerged as a result?

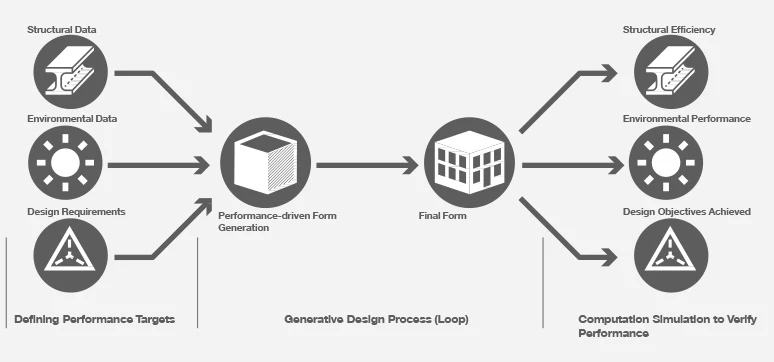

Building Information Modeling (BIM) and advanced computational analytical methods have significantly transformed the process of façade design in building projects. BIM has provided a holistic and collaborative platform that enhances communication and coordination amongst the design team subcontractors and various other stakeholders involved in the design and construction process. BIM has presented the scope for reasoned decision-making, increased efficiency and accuracy, and has facilitated Design for Manufacture and Assembly (DfMA) in the design and delivery process.

A comprehensive three-dimensional digital model allows a more accurate representation of the façade’s intricacies, enabling better visualisation and understanding of the design and components, material performance and optimisation, clash detection and coordination, construction tolerances and sequencing, and enhanced construction process – thus considerably reducing the margin for errors.

Nevertheless, the BIM process presents several challenges. These include legal, contractual, and data security concerns, along with time and cost investment relative to the project scale, as well as competency and training requirements. One common challenge we frequently encounter is the interoperability between softwares used by different stakeholders. To mitigate this, we emphasise clear communication and ascertain early agreements on standards and processes through the BIM Execution Plan (BEP). However, there are always lessons to be learned, particularly in managing extremely complex geometries carrying complex data within the BIM environment, which can potentially impact productivity. The most important thing is to communicate clearly, early and continually.

As technology continues to advance, what emerging trends or innovations do you foresee in the intersection of BIM and façade design, and how might these developments influence the future of building design and construction?

Building Information Modeling (BIM) in façade design holds exciting prospects for the future of building design and construction, ranging from enhanced visualization and construction methodologies to the integration of cutting-edge technologies and cloud-based workflow.

As technology continues to advance, several emerging trends and innovations are likely to shape this intersection. With the ongoing shift towards sustainability and circular economy, smart façades, advanced simulation and analytical methods, supply chain integration, advancement in DfMA, and Modular construction techniques for high-performing façades, BIM can play a pivotal role in the seamless integration of these interventions. These trends and innovations will not only streamline the design and construction process but also contribute to the creation of more empathetic, user-centric, sustainable, efficient, and visually striking buildings.

What is your vision for 2030? What kind of cities would you like to see?

To answer a complicated question as simply as possible, my vision revolves around placing people at the heart of urban development. In envisioning cities for 2030, I see a profound shift towards people-centric design interventions. I imagine cities where every aspect of urban design is guided by a deep understanding of community needs and aspirations. This entails reimagining urban spaces as places that prioritise the well-being of people, emphasising health, happiness, and interconnectedness of communities- with easily accessible and inclusive amenities, green spaces and cultural hubs that foster a sense of belonging.

One piece of advice you would like to give to aspiring architects?

To embrace a mindset of continuous learning and curiosity and take every opportunity to expand your knowledge – whether through formal education or hands-on experience.

In this ever-changing landscape, a commitment to learning not only enhances your professional growth but also empowers you to contribute meaningfully to the transformative and creative process of shaping the built environment sustainably.