Cladding in construction is a material applied on the exterior walls to provide a skin or layer. It provides a degree of thermal insulation and weather resistance and also improves the appearance of buildings. Cladding can be made of any of a wide range of materials available in the market, including wood, metal, stone, brick, vinyl, and composite materials that can comprise aluminium, wood, stones, blends of cement and recycled polystyrene, etc.

The wall cladding market in India is still evolving and the future for the same definitely holds much promise with the high demands in the construction industry. In this edition’s cover story, we discuss the trends in cladding materials and technologies, intelligent and responsive cladding solutions, future cladding materials and designs, testing for the wall clads for strength and durability, standards and norms while procuring and installing cladding materials, and much more.

4 Key Trends In Exterior Wall Cladding

Building cladding is the exterior skin, or envelope of a building, and includes all moisture barriers and siding materials used to cover the outside of the structure. If you want to add wow factor to your building, then you will need to think carefully about specifying the best cladding and external finishes. Over the years, cladding has become a preferred solution for giving a protective layer and identity to both residential and commercial buildings.

There is a marvellous range of materials out there to fire the imagination, from traditional stone and brick finishes to shiny metallic finishes. In trends of cladding material, brick wall finishes, brick slips, uPVC cladding, wood cladding, stone tiles, metal cladding, fibre-cement are available in the market, says Ar. Jasvinder Lal, Architect, Design2Occupancy Services LLP.

Current claddings portray inclination towards following trends to select an apt cladding material, points out Ar. Gaurav Goel, Principal Architect, Studio Parametric Curiosity India. Firstly, cladding material properties that define the visual and performative aspects of the cladding are vital. The material can be aesthetically pleasing, but if it fails to perform in extreme climates and fire scenarios, it would not be the best choice. Secondly, lighter-weight claddings are trending due to the lesser weight upon application to the existing structure.

Rapid assembly and cost-effective local manufactured materials for cladding are in trend. Due to the fast and easy assembling of the cladding modules, there is a decline in construction time and labour costs, whereas if materials are local and mass-produced, they are cheap and economically viable for a project. According to Ar. Lal, the key factors influencing cladding selection are colours and textures, cost-effectiveness and sustainability.

Colours & textures: Material and colour are one possible starting point for façade design. The façade of a building plays a key role in making a great first impression. They also express the personality of its occupants and the space it holds inside.

Cost-effective cladding: Cost-effectiveness is right up there among the top considerations while choosing from a large range of available options. The durability is of greater importance too. Initial cost plays an important role when looking for the best cladding solution. The cost-effectiveness of cladding depended upon the number of factors to consider when weighing up types of cladding. The location of the building is important, but also thermal efficiency, fire rating, and the sustainability of the materials. Sustainability: Sustainable choice in eco-friendly building exterior cladding includes wooden cladding, rock panel, super-thin steel, and solar concrete.

According to Ar. Nilesh Gandhi, Principal Architect, Metadesign (I) Pvt Ltd, from mid-50’s to late last century, the exterior envelope consisted of majorly natural materials like brick and stones, not specifically as cladding materials but the core material. This got completely overshadowed by the dot com boom in the early part of this century, with glass becoming the preferred choice. We see a strong trend of ACP, across structures.

The key trends, according to Ar. Gandhi, are:

- Glass (cost-effective or sustainable only if used correctly)

- Aluminium composite panels

- Stone cladding (expensive, lot of colours and textures, sustainable only if used appropriately

- Texture paint / Marble chips (most cost-effective, most sustainable, variety of colours and textures).

According to Alex Joseph, Sr. Vice President – Marketing, Greenlam Industries Ltd., the latest trends in materials ruling this space is High Pressure Laminate Cladding (HPL). The reasons for the same are:

a. HPL provides a sustainable solution and is used in isolation or in a combination with ACP or glazing or both. This range comes in a variety of colours, patterns and textures. Some of the finishes that bear a stylish and polished look include suede and high gloss.

b. HPL clads are all fire-retardant by default and are intended for severe outdoor conditions, for instance, applications involving long term exposure to strong sunlight or extreme cold weather. This single variant, which is the highest performing grade as per the standard provides a foolproof solution for all types of applications.

According to Joseph, HPL maintains its superiority over ACP, metal or dry clay based cladding solutions available in the market for the following reasons:

1. ACP, though competitive and aesthetic, the surface is too soft to resist impact loads and tend to develop irreparable dents. This product suffers from other issues like colour fading over prolonged use and calls for replacement. The replacement does not assure colour matching on all occasions.

2. Terracotta clay tile dry cladding is made with clay tile and the aluminium substructure in isolation or in combination with glass. This is a more expensive option than ACP and the colour options are limited. The material is brittle and carries the perils of being so.

On the other hand, metal cladding like zinc & copper is quite expensive than any other material available. However, aesthetically it looks good and different types of surface finish can be achieved with limited colour options, adds Joseph.

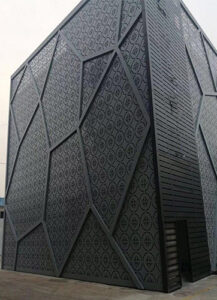

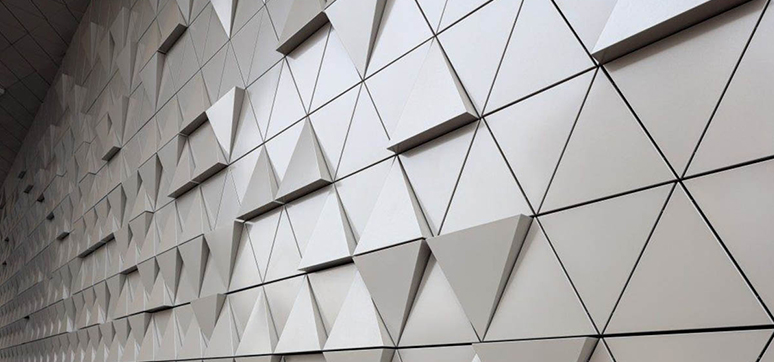

Shankho Chowdhury, President, Decoratives Division, CenturyPly notes that digitally printed HPL panels, which can be customised according to the need of the customer, is one of the key trends. With this option, one can simulate any image or impression on the panels which suits the requirement. Different kinds of new and pioneering installations like under-cut or hinged applications are also in trend. The other key trends are customised perforations with a background LED lighting scheme, and non-linear, sloped & tilted installations, adds Chowdhury.

Gaurav Sanghavi (Co-Founder) of Pentaspace Design Studio, spoke about the 4 key trends:

1. Perforated, parametric designs are the trends in façade panelling. Taking into account sun paths, wind directions, shading coefficients, etc.; Façades are screens, which can be shaped with multiple algorithms to make it more sustainable and efficient. Vibrant colours are the new norms of expressive façades.

2. Fibre-reinforced materials exhibit high thermal insulation and corrosion resistance, making them cutting edge over the traditional materials. These properties of the fibre-reinforced polymer are gaining huge traction in the façade material market.

3. Vegetation – Vegetated walls, landscape walls, and vertical gardens are few of the green façade techniques that are gaining huge prominence in the façades market.

4. Solar cells – Photovoltaic cells or solar cells are quite prominent in building energy-efficient building façade.

Cost and scalability are the two primary factors of new façade technology to be successful and accepted commercially.

Use Of Cladding Technologies & Materials To Regulate Daylight & Ventilation

Exterior façades allow natural daylight indoors. The daylight needs to be controlled so that it is useful, without creating glare or other unwanted outcomes for occupants, notes Ar. Lal. Smooth, even, glare-controlled daylight passing through translucent glazing provides numerous benefits to people, from energy conservation to reduced reliance on electric lights.

Only if the cladding is the core or the envelope, it will have an impact on daylight, observes Ar. Gandhi. If the cladding is a transparent material, the visual light transmittance (VLT) of the glass will impact the daylight or the privacy. If the building envelope material is porous, it will impact the ventilation. Automation, motorised or movable or interchangeable envelopes can regulate the daylight, ventilation and privacy parameters, he adds.

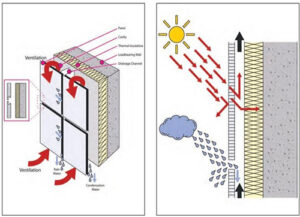

The façades also contribute towards enhancing a building’s thermal performance, says Ar. Lal. Firstly, the ventilated façade panels provide a (small) benefit to the U-value of the wall behind due to the fact that they shield the building from direct wind and sun. Secondly, the large panel format and the resulting shielding effect help to reduce the number of thermal bridges – anything that goes through the wall’s outer insulation layer – thus, maximising the performance of the insulation.

Ventilated cladding system creates a gap in between the wall and cladding product lining, providing a layer of air cushion that acts as a thermal barrier by regulating the sunlight, says Chowdhury, also making the building more energy-efficient. Terracotta façade System is a kind of new curtain wall system, adorned with terracotta panels as a decorative surface and functions based on the main screen principle. It is a perfect and smart combination of traditional materials and modern architecture, featuring large format panels, functionality and a complete provide privacy.

According to Ar. Harsh Pote, Co-Founder, Pentaspace Design Studio, parametric designs are now evolving in 3-dimensions and this gives us the ability to regulate light and ventilation in said space. According to him, the façade is not skin anymore. It is a membrane, which reacts with the outside algorithms, which then translates into design and creates a comfortable interior space.

Most Preferred Cladding Material

Demand for the cladding solutions market can be credited to the high growth of the construction industry across the globe. Demand for fire-resistance, thermal resistance, and water resistance, soundproof cladding systems are growing in the market. Innovative, eco-friendly cladding materials are preferred in the market as a consumer is becoming more environmentally concerned, observes Ar. Lal. For more than a decade, glass, stone, wood, metal/ACP has always been the traditional choice of material for exterior cladding.

Ar. Goel and Ar. Gandhi too agrees with the dominance of the said materials. The reason for choosing these materials is their cost, availability, easy installation and variety of choices in terms of colour and texture to customise a façade. Ar. Gandhi adds that these materials are preferred primarily on account of speed of construction, ease of availability of manpower labour, and maintenance. More importantly, it is the “westernisation” leading to this domination, he adds. According to Ar. Pote, glass, aluminium, zinc, copper, exposed concrete panels, sandwich panels, etc. are most preferred since they are cost-effective.

In the case of commercial buildings, primarily ACP, clay tile, glass, HPL cladding or a mix and match of these materials are being widely used, adds Joseph. For residential purposes – stone, HPL cladding, ceramic, fibre cement boards, Korean and wood amongst others are usually preferred. Nowadays architects tend to utilise contemporary moderate material to make a straightforward, uncluttered façade, notes Ar. Lal.

With regard to materials, metal cladding offers excellent options. He too agrees that zinc titanium, aluminium, claddings materials are dominating the industries. Apart from standard systems, these offer customised façade options as well. Further, the Zinc- Titanium alloy is a material that can be folded, bent, curved and profiled into customised panels to meet the design intent of the architect.

Days were there when exterior grade HPL was used to be confined within a certain kind of applications, says Chowdhury from CenturyPly. But now more and more people are yearning for the authentic wooden, stone or abstract look for their façades and the demand of the exterior grade laminate is increasing considerably.

Why HPL for Cladding?

ACP cladding

- Degradation of the core material (recycled LDPE*) and ultimate failure of the panel

- Delamination

- Paint finish is not durable, comes away from the aluminium substrate

- ACP Product is highly susceptible to dents and torn off corners

- Contributes in of ozone layer depletion & maximum in global warming

- Shade variation is a common phenomenon

- Colour gets faded easily, especially in oceanic climates

- The sealant fluxes out of its place and gives a patchy look on the panels

Stone & ceramic tiles cladding

- Stones are expensive

- Labor-intensive installation process

- Heavy & fragile

- Tiles are prone to crack and drop away

- Prone to algae and fungal attack

HPL Cladding

- No distortion even in extreme climatic

- Highly UV resistant with almost no shade fading even after years of installation

- Resistant to extreme weather conditions

- Suitable for installation as a ventilated façade system

- Colour stable – optimal lightfastness

- Self-supporting

- Impact-resistant – wind and other elements

- Scratch resistant

- Fire retardant

- Easy & rapid installation

- Low-cost maintenance

- Heat insulation and wall protection – protects buildings from excess temperature in summer to excess cold in winter & aiding removal of heat and moisture from rain or condensation

- Lightweight compared to any rocky product

- Suitable for all exterior cladding applications

(Shankho Chowdhury, President, Decoratives Division, CenturyPly)

Cladding Material For Future Facades

Although the traditional wet façade elements such as bricks, stones, and wood are still widely used and have a ready market, futuristic new-age elements and composites, including ceramic, vinyl, fibre cements, are rapidly gaining ground. Technological advancements and novelties in the industry are aiding in evolving consumer preference. “We have seen that currently HPL cladding and stone veneers are few of the most popular cladding options in India. Other than this, metal claddings are also in trend for most commercial buildings and factories. Using fibre cement as a cladding element is still a new concept in India and we believe it has a huge scope and its market is growing rapidly,” says Chowdhury.

Joseph too agrees that metal cladding is gaining popularity. According to Ar. Goel, Glass takes the leading position as the trendiest future cladding material. “These days, glass can be manufactured to specific energy standards along with moulding it to organic shapes including double curvature skins. Such workability along with mass manufacturing and fast installation makes it a material for future that is open to further design experimentation,” adds Goel.

Precast wall panels, if developed well to address Indian conditions and challenges, can prove to be trendy and can be termed as the future of façades, says Ar. Gandhi. The most futuristic cladding materials are those that can be crafted into a unique pattern that would otherwise be impossible with traditional materials, points out Ar. Lal, like cladding material with a unique geometric patterned design. It should be stable, lightweight, and can withstand the rigours of the natural environment, for instance, Prefa FX12 panel, fiber C3D cladding, Venetian glass bricks, etc.

According to Ar. Sanghavi, photovoltaic cells on façades are the new trend so that the buildings can generate energy and can become self-sustainable in power requirement. But, at present, the system seems to be very expensive. As the costs decrease, these on-site power systems will be integrated within the glass skin and these façades will become local, nonpolluting energy suppliers to generate enough energy. Ar. Sanghavi adds that the green façade created by green walls and urban farming, which makes the structure self-sufficient and creates a healthy microclimate, could be the future trend.

Intelligent & Responsive Cladding

Chowdhury notes that in the last two decades, the areas of advanced materials and technologies have progressed rapidly. New research on nanomaterials, biomaterials and smart and intelligent composites imitating natural nanostructures and processes are tried almost every day within the radical technologies. In the architectural field, and especially in the sector of building cladding, only a trivial amount of such advanced technologies have settled. As an alternative to the traditional mechanisms and techniques, architects and civil engineers are nowadays using enhanced composite materials to provide crafted and efficient façades.

An intelligent cladding is one that is responsive to the requirements of the occupant, organisation, and society. It is sustainable in terms of energy besides being lowly polluting in terms of emissions and waste, healthy in terms of wellbeing for the people living and working within it, and functional according to the user needs, notes Joseph. This can be achieved by deploying an appropriate, reliable and proven technology. A cladding or envelope, which breathes and adapts is agile, and is responding to the climate and nature is intelligent and responsive, observes Ar. Gandhi.

Cladding materials that respond to the sun and wind to maintain favourable thermal comfort along with optimal light levels and energy consumption can be referred as intelligent and responsive, says Ar. Goel. Such cladding systems are generally kinetic and adapt to different configurations based on the weather data obtained by electronic sensors. On the contrary, some smart materials like thermo bimetals have also been explored for such intelligence in façades recently, adds Ar. Goel. These alloy metals deform themselves from the sun’s heat and allow more ventilation into the buildings without any need for sensors by using their mechanical expansion properties.

Agreeing with Ar. Goel, Ar. Lal adds that the ability for a building envelope to change and adapt its configuration relative to the sun (either by blocking its rays to prevent overheating and/or glare or by allowing them to penetrate for passive heat gain and/or daylighting), has been a primary source of formal and technological innovations in intelligent building skins. The need of the hour is “Smart Buildings” or “Intelligent Buildings”. “Intelligent Façade” plays a key role as it is essential in making it truly smart and it is the primary defensive line for the building against the environmental and climatic variation, points out Ar. Sanghavi. Responsive building façades facilitate interaction between the environment, the indoor space and the occupant in a meaningful way. High-performance envelopes are assessed based on energy optimisation and reduction in the use of resources and their inhabitants.

Smart Cladding Technologies & Sustainable Buildings

A rapidly changing environment is affecting building users as well as building performance. Despite the fact that the climatic characteristics have variable parameters, traditional façades are largely static; so, we use large amounts of energy in order to control internal comfort. The application of smart materials technologies in the field of architecture mainly depends on the ability of these materials to change their shapes and characteristics based on passive form, under the influence of external stimuli such as humidity, temperature, solar radiation, light, air movement and pollution, says Ar. Lal.

Presently, building design criteria focuses primarily on sustainability as people are mostly looking for eco-friendly cladding solutions. Therefore, cost-saving materials could help reduce the carbon footprint and save energy, are creating more demand with each passing year, says Joseph. Apart from this, a flexible system with respect to façade design like louvers with MS fabrication techniques and similar processes can be a smart cladding solution. Lastly, non-flammable and codeapproved materials also apply to retrofit for the need to ensure the energy efficiency of the building, he adds.

According to Ar. Goel, smart cladding technologies can be of greater value than just shielding the built structure. Many R&Ds are taking place in the smart cladding domain to meet sustainable and energy performance goals. Some materials that are innovative and smart include algae bioreactor panels that generate heat and electricity from producing algae in double glass façades, vertically integrated greenhouse modules (VIG) that provide for landscaping vertical surfaces for heat insulation and evaporative cooling, vertical farm cladding systems that provide food using hydroponics, and pollution-eating concrete panels that consist of Titanium dioxide to stick pollutants in the environment to its surface.

Ar. Gandhi concludes that sustainable buildings can’t be made by smart claddings alone, however, cladding technologies can play an important and crucial role in defining the sustainability quotient of any building.

The Following Tests are Performed on Cladding Materials:

- AAMA 501.1-17 – Standard test method for water penetration of windows, curtain walls and doors using dynamic pressure

- AAMA 501.5 – Test method for thermal cycling of exterior walls

- AAMA 508 – The test is to evaluate the ability of the wall cavity to achieve pressure-equalisation with the exterior

- AAMA 509 – Test and classification method for drained and back ventilated rain screen wall cladding systems

An efficient cladding can also help maximise thermal performance, improving the energy efficiency in the building. (Ar. Jasvinder Lal, Architect, Design2Occupancy Services LLP)

Testing Of Cladding – Norms And Standards

According to Ar. Pote, the norms and standards to be followed is the one by the Bureau of Indian Standards (BIS). Generally, the cladding material, which is selected, is based on the test and quality certificate provided by the vendors. If further quality control is required, independent labs have to confirm the materials test the physical samples.

However, both BIS standards and Energy Conservation Building Codes (ECBC) have not been formulated for clads at the moment. However, the use of cladding materials does not affect adversely in maintaining the WWR of the building, says Joseph. For cladding materials, the U-factor and SHGC are important criteria, those are governed and mandated by ECBC as well. The ECBC norms specify that a building can be up to 60% covered with glass, in which case a superior quality glass is preferred that is good for thermal performance, notes Ar. Pote. ECBC standards are incorporated in the design by making the simulation model in the software’s, which help the project to make it energy efficient.

All parameters of the façade are checked, and solutions are created to check the maximum efficiency. BIS standards for cladding materials follow the British norms of material classification for fire safety, to be rated as Class 1 as per BS 476 part 7. The testing depends on the material chosen for cladding – Bricks, stones, panels, glass, fabrics, metals, all have specific compression, tensile, weathering, tests and standards that need to be followed, says Ar. Gandhi.

Expert’s conduct testing on a variety of products and cladding materials, both at the pre-construction phase for design validation and on-site. Cladding and façades are tested for air leakage, water penetration, and structural characteristics including racking.

Apart from meeting the mechanical and dimensional stability tests, the products are tested for water absorption and boiling water resistance, says Joseph. Tests are conducted to verify their resistance to colour change on exposure to artificial weathering and resistance to climatic shock which predominantly indicates the performance characteristics of the product upon prolonged exposure. The product should also pass the fire behaviour requirements (Clads supplied by companies including Greenlam conform to EN 438- Part 6 standard and meets the requirements of EDF which is the highest-rated grade in this class).

Chowdhury spoke on different official and Government approved norms and standards stipulated for different kinds of cladding members. For exterior grade high preferred laminates, the most preferred and globally accepted standards are EN-438, Part 6 and ASTM-E84.

Is Aluminium a Highly Combustible Material?

Aluminium itself is a non-combustible material with good thermal conductivity. It is only when combined with flammable materials such as a polyethylene core or a wet paint finish that aluminium claddings can pose a fire hazard. Solid aluminium cladding is usually made from extruded, powder coated aluminium, which dissipates heat, and if it is exposed to fire for a long period it will melt, not burn, preventing the spread of flames.

Powder coatings will also only char, again keeping flames from moving rapidly across the surface. Solid aluminium contains no combustible materials or core, and is, therefore, a far safer cladding option for residential buildings. On top of this, solid, powder-coated aluminium has the added advantages of being a flexible, lightweight, and corrosion-resistant cladding type.

Solid aluminium contains no combustible materials or core, and is, therefore, a far safer cladding option for residential buildings. On top of this, solid, powder-coated aluminium has the added advantages of being a flexible, lightweight and corrosion-resistant cladding type. (Ar. Jasvinder Lal, Architect, Design2Occupancy Services LLP)

Choosing Fire-Safe Cladding Material

When we talk about fire-safe materials, natural materials form the first choices – like clay tile, stone or HPL organic cladding materials. Metals and metal composites should be avoided because during a fire, the metal layer will conduct heat in either direction and may start melting depending on the nature of fire, simultaneously releasing toxic gases when metal composites burn. They may also release droplet which acts as carrier of fire and spread the flames to newer vicinities. Hence, a cladding material that does not ignite easily, emit obnoxious smoke and droplets should be chosen, says Joseph.

Façade engineers designing fire-safe cladding systems need to know the fire properties of the material being used and their key reaction to fire like ignitability, combustibility, flame spread, and reactions of droplets and smoke, says Ar. Pote. Emphasising the importance of fire-resistant materials, so that a façade must not propagate fire, it must also not let the fire or heat travel from one area to another and it should not disintegrate in the presence of fire for a reasonable amount of time, he adds.

Two important parameters that define the performance of fire-safe façade materials are their combustibility and smoke production. If façade material is combustible, it will contribute to the spread of fire to other parts of the building. Façade materials may also produce toxic smoke which causes more deaths, and the toxic content of the smoke will depend upon the materials that they are fire safe or not.

Ar. Lal comments on the international standards: Those which are widely referred for cladding materials are EN 13501, ASTM E84, BS 476 Part 6 & 7 and BS 8414. These standards specify fire and smoke spread characteristics and acceptable norms with testing standards. He points out that the bedrock of all modern fire regulations is confining it to a single floor. A fire spreading from one floor to the next completely undermines all the elements of protection and control that make egress routes and firefighting viable.

Composite cladding and ACPs have, up until recently, been hailed as a cheaper alternative to other cladding products. These are flammable materials, combusting easily as soon as it is hit by fire, and thus allowing flames to race up the sides of buildings. Solid aluminium is a safe alternative. According to Chowdhury, consumer awareness on fire resistant cladding is growing rapidly in India and this is imparting a positive impact on the market. Evolving requirements are influencing the available choices of fire-retardant cladding options which are not combustible.

At present, the market has varied variants of fire retardant cladding materials like EN-438 and ASTM-E84 (Flame spread & smoke development index) qualified HPL panels, which also comes with Green-guard certification. This qualifies these products to be used in ‘Green Buildings’ and in other delicate environments such as schools and healthcare institutions. NBC part IV specifies the fire code for India, with calorific values and the applications, along with CBRI Roorkee, certification, which can be benchmarked for selection, adds Ar. Gandhi.

Innovative Cladding Solutions for the Future Façades

The innovative façade designs will be interactive, the environment is responsive as well as cost-effective – like drawing moisture from outside to collect water, capturing solar energy to the building self-sustainable. Façades could filter the polluted air and provide fresh air for the occupants. The façade could warm or cool the building depending on the climatic condition and requirement. We might see façades, which could expand, and contract as per the space requirement. Façades could be reused from an old building to new construction. Some of the future façades systems are:

Façades generating power or photovoltaic glass unit (PGU): Façade captures solar radiation and turns it into energy. Thermally dynamic façades or Phase change materials (PCM): These façades can respond to variations in outdoor conditions. TDF use phase change material wherein a layer of salt crystals capture the heat radiated by the sun and release it back to the environment during non-operational hours.

Biomimicry in façades as living buildings: The envelope of the buildings in the future may react to external stimuli, opening and closing throughout the day through a system of cellular openings that allow natural light and ventilation to pass. Façades enhancing the outdoor environment controlling microclimate impact: Growing vegetation can create a positive microclimate around the structure, which helps in reducing the temperature around it.

Façades enhancing indoor environment leading to fresh air: With growing pollution around the world, using green walls on the façade can filter all the potential toxins in the air acting as an air purifier.

Façades addressing fuel crises by creating building façades by using algae: The technology of BIQ building algae panels are used to generate power by burning the algae on the façade to generate alternative energy sources.

Façades addressing food crises or Hydroponics: The increase in urban sprawl is reducing the farmlands. This technique, where urban farming is done on the façade of the built for, not only makes the building self-sustaining, but also has numerous advantages like controlling pollution and creating a healthier microenvironment.

(Ar.Gaurav Sanghavi, Co-Founder, Pentaspace Design Studio)

Future Exterior Cladding Designs And Materials

The global scenario of the building façade industry is undergoing several changes and developments in terms of performance deliverables. Going beyond mere aesthetic appeal, architectural designing elements are now concentrating more on the essential functionalities like energy conservation, fire safety, lessening of chemical emission etc., which have become extremely crucial around the world. Architects are deploying cladding materials to optimise their capabilities. Green composite materials like high pressure laminates and other less known elements are being adopted for ventilated façade solutions and help projects achieve high levels of building sustainability certifications, says Chowdhury.

The future of cladding lies in products with non-superficial and intrinsic features which reduces or eliminates negative impacts and can create positive impacts, on our climate and natural environment. There is a bright future for cladding design and materials ahead due to cutting edge research and innovation happening today. Traditional dogmas of façade are dealt with innovative solutions to produce new ways of protecting buildings. Moreover, the rapid development of computational power coupled with mechatronics and robotics holds a new future for façades. Artificial Intelligence (AI) is another field that has been explored in the built environment today. Therefore, future façades are likely to be comprised of materials that can facilitate more interactive façade systems that are integrated with the power of sustainability, technological innovation and material science, predicts Ar. Goel.

Considering the global warming scenario, cladding is going to be the most important product for any building. Amidst constantly changing weather conditions, the nature of the material should be a bad conductor of heat, and it should be a ventilated façade system. Therefore, clay tiles along with seasoned wood or wood composite and HPL cladding should be the sought after material in the future, says Joseph. Ar. Gandhi is sure that static fenestrations or façades will be a passé. And the buildings will be more mobile and dynamic.

Moveable, rotatable, louvers, fins, and shading devices that move in sync with the sun/ rain, will become common. Glass windows no more shall be glass but once that generates solar energy. Would also like to see the use of earthen and generic natural materials that have lived the test of time, and ones with a high life cycle, in line with the life of the structure. Materials that self-degrade and just need to be replaced without the need to take care of disposal to landfills, would be interesting, notes Ar. Gandhi. Fabrics could also make an entry into façades!

CONCLUSION

The cladding systems market is projected to grow from USD 224.4 billion in 2018 to USD 292.5 billion by 2023, at a CAGR of 5.44% from 2018 to 2023, says a report by Markets and Markets™. Demand for the cladding solutions market can be credited to the high growth of the construction industry across the globe. Factors such as increasing residential and non-residential construction and infrastructure activities, its high durability, and ability to enhance the aesthetic appearance of the buildings drives the demand for cladding systems. Based on materials, ceramic cladding systems dominated the market.

We need to develop cladding technologies and materials with future perspectives. By 2050, it is anticipated that there will be an extra two billion city dwellers across the globe and the consensus is that sustainability can only be achieved if both developed and developing countries take the same, or a similar, course of action. The year 2050 will mark a generation of internetnatives adults who will have lived all their lives engaging with smart devices and materials. They will have experienced technological breakthroughs that will redefine how human beings will interact-not only with each other, but with their surrounding environments too.

The innovative façade designs will be interactive, environmentally responsive as well as cost-effective like drawing moisture from outside to collect water, or capturing solar energy in order to make the building self-sustainable. The façade could warm or cool the building depending on the climatic condition and requirement. We might see façades, which could expand, and contract as per the space requirement. Façades could be reused from an old building to a new construction. There is no limit for imaginations and ideations.