In an interesting interaction with Karan Shah Founder & Partner, PEGO Hardware sharing about their journey and milestones, their product range and architectural hardware industry at large in India.

What leads to the origin of the brand PEGO?

The organisation has always worked very closely with window manufacturers. In 2007 I happened to visit the fenestration exhibition ZAK and I realised that there was a tremendous vacuum in the architectural hardware availability in India. The fenestration industry in India was also taking off at that time with demand being there for architectural hardware solutions. It made me dig deep into this and that lead to the origin of PEGO in 2008. With initial years spent in aluminium hardware, the organization slowly ventured into uPVC Door & Window Hardware in 2012 and started adding more products to its portfolio. And then the rest is history.

Over the years there have been people and a lot of window manufacturers who have shown lot of confidence in PEGO and extended their support during this long journey. This has helped us in learning and adapting to this ever-changing industry. You had launched a podcast show “Beyond Windows with Karan Shah”.

What was the idea behind it?

Beyond Windows was an idea that came during the first COVID lockdown in 2020. We all had a little more time in hand and while going through a podcast I wondered why not do something similar with fenestration industry experts. The idea was shared with a few people within the industry and they happily agreed to be part of it. And then there was no looking back and we managed to run 14 successful episodes which dig deep into the personal lives & journeys of some of the tallest people from the Indian fenestration industry. I hope this would have inspired a lot of people in our industry to learn from these stalwarts and connect better with them.

At some point of time, I do wish to do season 2 with the icons from the Aluminium fenestration industry. What is your biggest strength?

On the personal front, my biggest strength is my love for doors & windows. A strong understanding of hardware applications gives me an edge to innovate & provide the right solution for our customers & address their needs. This when coupled with a motivated team, work doesn’t seem like work. Our interactions with customers contribute to our knowledge, which has helped us in developing the products as per industry needs. We are open to taking a leap in introducing new concepts since our ideas come from consumer needs itself.

Our technical understanding of profile systems helps in developing and providing solutions to our customers at the designing stage of the profiles itself. I can confidently say that our range of products backed by the availability of the same is what really helps us in delivering in time. For customers, PEGO stands for Innovation, Durability, Consistency, Availability & Service. And this we have earned over the years and will continue to be our biggest strength.

With no strict standards in place for door & window hardware and there Fenestration Hardware of high durability being no entry barrier, how does PEGO address the growing competition in the market? Does this put threat to the architectural hardware industry?

Your question itself puts a serious threat with respect to the very existence of uPVC & Aluminium windows & doors, not only for the architectural hardware. If the end consumer feels disheartened due to failure of hardware within few months or years, then we have created one more enemy for the industry. It is for this reason that associations & organisations are working tirelessly with BIS to get standards in place for doors & windows along with all its auxiliaries.

With no entry barrier and accountability, the industry is bound to get an influx of various kinds of products. Cheap is not always good, nor expensive is always good. Hence efforts have been made by us to inform, update, train and educate various stakeholders about the various parameters with respect to hardware so that there is informed buying from them. It does require time, effort and resources, however, it is essential. However, customer appreciation, loyalty and references are intangible yet biggest assets, which can never be traded. This has been one of our biggest strengths. Successful delivery of projects is what has added to our brand over time.

What was the idea behind creating the Application Centre?

Our Application Centre at our head office in Sahibabad has been the biggest value addition which has helped us in sharing our latest innovations with our customers. It gives them the opportunity to witness the application of the product along with a touch and feel experience. Understanding of the product becomes far easier than just showing the product otherwise.

We at PEGO are having in-house testing machines to test the life cycle testing of products and we invite customers to our facility to witness the same. Transparency helps in the building of trust with clients. Along with this our manuals, videos and other informative tools help customers in further understanding of the installation of the hardware.

We have seen increased demand for premium solutions like Sliding folding, lift & slide, and tilt & turn windows. Does PEGO have such solutions? If yes, what technical support is provided by the company to its customers?

PEGO has all the solutions mentioned by you. Even with such solutions we are always pushing the boundaries and trying to upgrade them in terms of aesthetics and functionality.

We have created animated video manuals for a lot of our offerings like sliding folding, tilt & slide, and lift & slide explaining the step-wise process of installation of these hardware making it easier for customers to manufacture these systems. We further have an in-house technical team to assist customers with any technical support on-site. The technology has helped in sharing details even from a remote location. These measures have increased the demand for premium and more complex products.

Further, all our hardware offerings are segregated into smaller systems like casement windows, sliding windows, casement doors & sliding door templates to further provide focused information to window manufacturers. For aluminium, we have templates based on the profile systems, which makes life very easy for window manufacturers in identifying the correct hardware Architects, consultants & window manufacturers are constantly looking for new out-of-the-box solutions for architectural hardware.

How critical it is to evolve and innovate & what are the challenges faced along with this?

For any industry, it is very critical to evolve with time and innovate themselves before becoming obsolete. Everyone wants a change and hence the shelf life of even hardware products has reduced with time. We at PEGO take great pride in taking the leap and constantly coming up with innovative products to address the industry needs.

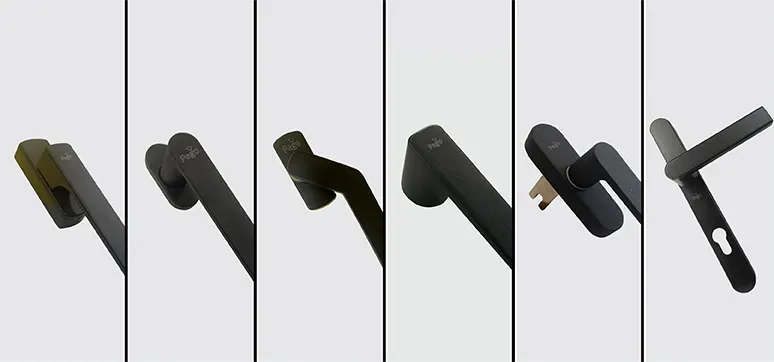

Currently, the trend seems to be moving towards minimal, straight-line hardware designs. The concept of one family hardware design has gained more relevance now than ever before. At PEGO we have been focusing on this for the past 4 years and have been successful in creating many family of hardware designs to ensure uniformity in aesthetics in one home.

While innovating, it is important to ensure that the durability, performance & functionality of the product is not compromised. Also, it is important to note that the idea is to improve the customer experience and make things easier and simpler for them. When these aspects are covered, most often it results in an innovative solution, which has a lasting impact. We at PEGO follow a very customer-centric approach to developing hardware and fulfilling customer needs.

‘Inpsired By Design, Powered By Quality’ – the tagline of our brand is at the focus point of everything we do at PEGO. Most of the innovations at PEGO have come from customer solution-based requirements, and that has been a winning edge for us. I am proud to say that lot of firsts in the architectural hardware have come from PEGO in India.

The traditional hardware needs to be changed with more aesthetical and solution-driven handles which are in sync with the profile system design. It requires a strong awareness of the profile system and the application requirement. Because of PEGO’s strong presence in both Aluminium & uPVC hardware, we have managed to use the best of both the worlds and evolve hardware solutions accordingly.

Do you think the industry is early/ late in introducing these innovative architectural hardware solutions? Is there greater acceptance for such new innovative architectural hardware solutions?

Five years back, I would have said the industry was probably not ready for innovative solutions. But because of the global exposure and world-renowned fenestration leaders also pushing for such alternatives, the acceptance of such solutions has been phenomenal. Ease of information, lots of exhibitions and events, social media & world becoming one big continent in the end, have made strong demands coming from the architects, consultants and end users for such solutions. I also strongly believe innovation is the best way to distinguish oneself from others more when standardisations aren’t there at a bigger level.

Are there clear demarcations with respect to growth forecasts precovid and post-covid for PEGO?

The change has primarily been the duration of forecasts. From yearly it has become quarterly forecasts. My answer to this question will be very specific to only the fenestration industry in India. The splurge in demand posts the first lockdown has been more than what any of the pandits had predicted. It has made us all realise that while the nature of lockdowns will remain uncertain but the business will remain intact and positive.

In the last financial year, we have witnessed 45% growth YoY. I can say that it would not be very different in the current year as well. And I can confidently say it is not true for only our organisation but the fenestration industry in India at large with the percentage being a bit different. While the bottom line has been hurt significantly because of fluctuation in raw material prices but the growth of the topline has helped in keeping the organisation healthy

What is the focus area for PEGO in the next financial year?

We are very much aligned with the demand and need of the fenestration industry. We have already introduced one family complete hardware solution. We are coming up with more designs on the same concept.

With lines blurring between the hardware for uPVC & aluminium, we are using our strength of presence in both the verticals and giving the best of both worlds to our customers. We are focusing on reinventing some of the concepts to provide a more robust and aesthetically superior experience to customers. COVID has accelerated the demand for automation. The COVID protocols are here to stay means the demand for smart windows will remain. Further certain areas where accessibility and operation of windows are difficult, smart windows will only make it easier. We are dedicated to introducing viable and lasting solutions in this vertical. Further, as an organisation, more effort and time is going to be spent on strengthening our manufacturing capability & processes.

How do you see the fenestration industry and the architectural hardware industry evolving in India?

I believe the fenestration industry in India has evolved rapidly in the last five years compared to the previous 10 years before that. And I strongly feel we are at an inflection point where the next five years are going to have an even bigger impact.

The reach has now been made to tier 3 cities and small districts and villages. So it means the market base has increased considerably thanks to the overall boost to infrastructure projects. This coupled with a bigger presence of international brands, thrust to the manufacturing sector, and global exposure for better products have all propelled the growth. Yes, all along the challenges would come from inferior products flooding the market but I also feel the experience of end consumers in terms of good and bad will automatically mature the market in the long run. Also hopefully new guidelines from BIS would further help in ensuring parameters are being defined for doors & windows including the hardware.

There would be consolidation and entry of big corporate houses which would further push the growth of this industry. We have already witnessed activities in this direction.

How well aware do you think the decision-makers are in general about the availability of the hardware products for fenestration, their functionality & categories, standards, testing, etc.? And how do they gauge the quality and functionality of the same?

Rome was not built in a day. We still are taking baby steps in this and have a long way to go. Unfortunately, the pace is slow. And because of incomplete knowledge about the products & standard requirements we have seen the inferior final products at times, which gives industry also a bad name. Various associations, window manufacturers, hardware companies like us, and various other auxiliaries are taking steps to educate and share more information so that there is informed buying. BIS is also working closely with the industry to come up with the guidelines.

Expensive is not always good, nor cheap is the best way to invest in anything. We keep pushing through our certificates, testing machines, product detailing and standard requirements so that customers have more information. We keep sharing these through conferences, workshops, manuals and presentations so that they start asking these questions when buying the product. All these would only help the industry to be much stronger going forward.

What do you see as the main challenges faced by the architectural hardware industry?

The non-presence of formal and forceful guidelines and standards is the biggest worry for not only the hardware but for the entire fenestration industry at large. Till the time these are made compulsory we will have to deal with the influx of inferior products which would hurt the quality products in the short term and the industry at large in the long run.

Fluctuation in base metal prices is another big hurdle being faced by the industry. What has been witnessed in the past 2 years is an unprecedented and ‘never seen situation. It makes the closing of big projects more difficult and is a time-consuming exercise. Further such situations make discussions on prices a consistent part of conversations, which uses a lot of resourceful time and reduces productivity.

Third, the lack of awareness and knowledge regarding these standards among the decision-makers is also a big challenge. Product cycle tests, product composition, plating or powder coating thickness, certificates, salt & spray test; these aren’t the most common questions asked, and rather the information which we as hardware providers need to explain shows we have a long way to go to ensure that there is informed buying by the window manufacturers or final consumer. With awareness activities being conducted by associations and various stakeholders I am optimistic that things would get better with time.