In modern architecture, with its evolving designs, materials, and complex structures shaping urban landscapes, ensuring fire protection poses a challenge. The integration of glass façades and other glazed structures presents both technical and commercial hurdles for designers. However, an increasingly employed solution to address these challenges is performance-based fire safety design.

Understanding the Challenges

Architectural advancements, environmental concerns, and the integration of renewable energy technologies like photovoltaic panels pose significant challenges to fire safety in modern buildings. Traditional fire safety standards often struggle to address these complexities, highlighting the need for a more adaptable framework. Performance-based fire engineering emerges as a viable alternative, offering a comprehensive approach tailored to the unique characteristics of each building. By prioritising safety targets through flexible and innovative solutions, performance-based design strategies empower architects and engineers to navigate the intricacies of modern architecture while upholding fire safety standards.

Performance-Based Fire Safety Design

Performance-based design in fire safety allows for the customisation of fire protection measures, departing from prescriptive codes and standards. Widely adopted in Europe, this approach offers flexibility in addressing challenges in complex buildings where standard methods may prove inadequate, such as with glass façades.

In this iterative process, fire safety engineers and designers follow key steps outlined by organisations like the Society of Fire Protection Engineers (SFPE) or NFPA. They commence with a comprehensive analysis including various factors such as fire risks/load, materials, occupant characteristics, and evacuation strategies. This detailed analysis covers the unique needs and vulnerabilities of each building individually.

Subsequently, engineers establish performance objectives based on the analysis findings, delineating specific targets for fire safety measures. These objectives form the basis for designing customised solutions that optimise safety while considering architectural and functional requirements.

Advanced tools such as computational fluid dynamics (CFD) simulations are frequently utilised to model fire behaviour and evaluate the effectiveness of proposed measures. Occasionally, fire testing may also be conducted. This enables engineers to anticipate fire spread, assess structural exposure to heat and smoke, and evaluate occupant evacuation in various scenarios. Additionally, the operational conditions of fire services can be analysed.

Throughout the design process, collaboration with architects, builders, and stakeholders is mandatory to ensure that proposed solutions align with project goals, regulatory requirements, and budgets.

Utilising Performance-Based Design for Façade and Glazing Design

The benefits of Performance-based design for façade and glazing design (complex buildings) can be listed as follows:

- Customised Solutions: Performance-based design enables engineers and architects to tailor fire protection measures to the specific characteristics of the façade design, considering factors such as material composition, construction methods, and unique architectural features.

- Fire Modelling and Analysis: By using advanced tools like computational fluid dynamics (CFD) simulations, engineers can model fire behaviour and analyse how different façade configurations may influence/ prevent fire spread, smoke movement, and heat transfer, enabling the identification of potential fire risks and the development of targeted mitigation strategies.

- Material Selection: Performance-based design allows for the evaluation of various façade materials in terms of their fire resistance properties. Engineers can assess factors such as smoke production, and structural integrity under fire conditions to inform material selection and fire resistance decisions.

- Integration of Active and Passive Fire Protection Systems: Performance-based design facilitates the integration of both active (e.g. sprinkler and water mist systems) and passive (e.g. fire-resistant materials, compartmentation) fire protection measures within the façade design, enhancing overall fire safety performance.

- Evaluation of Evacuation Strategies: Engineers can assess how façade design impacts evacuation procedures in the event of a fire, considering factors such as exit routes, accessibility for emergency responders, and the effectiveness of wayfinding systems.

- Continuous Monitoring and Adaptation: Performance-based design allows for ongoing monitoring and adaptation of fire safety measures as building use and occupancy conditions evolve over time, ensuring that fire protection strategies remain effective and compliant with regulatory requirements.

In summary, performance-based design provides a flexible and proactive framework for addressing fire safety concerns in complex building façades. By integrating advanced analysis techniques, material science principles, and innovative design strategies, engineers and architects can create façades that not only enhance the aesthetic appeal of buildings but also prioritise the safety and well-being of occupants and property.

Practical Examples – Fire Rating of Glazing

IFAB has been involved in projects where performance-based fire safety design has enabled comprehensive safety assessments of complex buildings. As many buildings incorporate automatic firefighting systems, their benefits have also been utilised in glazing dimensioning. The typical fire rating of glass depends on its ability to fulfil different fire protection criteria, categorised under fire rating classes such as E and EI.

- E Classification: The “E” classification signifies integrity only, maintaining its integrity during fire exposure, preventing the passage of flames and hot gases for a specified period but lacking insulation against heat transfer (radiation).

- EW Rating: The “EW” classification includes both integrity and heat insulation properties. It signifies that the building element can maintain its integrity and provide a certain level of insulation against heat transfer when exposed to fire.

- EI Classification: The “EI” classification denotes both integrity and insulation, maintaining integrity and providing insulation against heat transfer, preventing flames and hot gases from passing through while restricting heat transmission for a specified duration.

E, WE and EI classifications are vital for ensuring fire safety in buildings, particularly in areas where fire resistance is very important. Architects and engineers select the appropriate fire-rated glass, based on building codes and regulations, to meet specific safety standards and protect occupants & property in the event of a fire. While EI-rated glasses are favoured for most projects due to their enhanced properties, E-rated glasses offer architectural benefits with minor compromises.

Alternative solutions have been sought as performance-based design allows for diverse technological applications. One example is using the presence of an automatic firefighting system to compensate for the limitations of E-rated glass to meet EI requirements. This approach has gained interest in projects with architectural complexities or challenges in using EI-rated glass, especially in buildings equipped with water mist firefighting systems. Water mist systems, having very effective cooling capabilities, effectively suppress fires by atomising water into tiny droplets, extracting heat and lowering temperatures. Whether for firefighting, cooling or protecting important structures, water mist systems provide an active fire risk mitigation in fire safety engineering.

IFAB has been engaged in test programmes and result assessments for performance-based design, experimentally testing glass with firefighting systems. Figure 1 illustrates a test for a glass façade according to DIN4102, but using a water mist curtain outside the furnace/glazing to provide additional cooling and blocking heat transfer (radiation). In this specific test, normal E-rated glass fulfilled EI requirements, resisting the design temperature curve for 60 minutes without cracks. Additionally, the heat radiation limit of 15 kW/m2 was met in the fire tests, which was approved by an independent certification organisation.

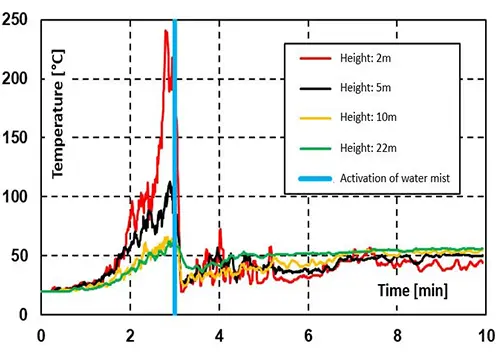

Performance-based design, supported by tools like computational fluid dynamics (CFD) simulations, enables the assessment of complex structures’ fire safety. For example, IFAB conducted CFD analysis for a complex atrium in Germany, evaluating whether glass in the atrium wall could be replaced with less fire-rated glass using sprinkler or water mist systems. The selection of a water mist system, due to its superior cooling capacity, was determined through pre-studies defining the critical temperature for the atrium glass façade as 85°C. A comprehensive assessment, including fire load measurements and validation simulations, confirmed the effectiveness of the chosen strategy. CFD simulations demonstrated that maximum temperatures on the glass surface remained below critical values, with the activation of the water mist system effectively mitigating fire risks throughout the atrium.

The simulations were even carried out with a conservative approach defining that the mist system shall not influence the heat release rate by suppressing. Using a “Freeburn” scenario, the water mist system was challenged in the most conservative way. The maximum temperatures are shown in Figure 2.

Conclusions

Performance-based design enables the customisation of fire protection measures, departing from prescriptive codes and standards in the case of very complex buildings. Engineers conduct thorough analyses, establish performance objectives, and create tailored solutions, ensuring effectiveness across different scenarios. This approach provides flexibility in addressing fire safety concerns in complex buildings, particularly those with complicated façades. It enhances overall fire safety performance through customised solutions, fire modelling, material selection, and integration of active/passive fire protection systems. Another example is the Printing Media Academy in Heidelberg, Germany. This is one of the oldest examples in Germany where active systems, such as water mist, were used as a mitigation method to obtain the building permit for this complex structure