aluplast is one of the leading uPVC window and door profile manufacturing companies in the world. The brand is known for its revolutionary innovations and customised product design across the globe. Last year aluplast group achieved an enormous milestone by turning 40. Ravi Balakrishnan took over the role of Managing Director, aluplast India in October 2022.

We had an opportunity to interact with Ravi Balakrishnan recently. He spoke to us about his company, his new role as the Managing Director of the company, as well as their products, manufacturing facilities, future plans of the company, the future of the industry and much more.

Could you please tell us about your new role as the managing director of aluplast?

I joined aluplast in October 2022. I am quite new to the company, just about 4 months into the new job. aluplast is a German manufacturer, but quite well established in India with a presence in Baroda. The company has been doing very well in the past few years. My role would be to drive the growth and take it to the next level. We have an excellent manufacturing facility, good products, and a great dealer network.

Could you please tell us about the company aluplast, its growth, and its milestones? When was it established in India?

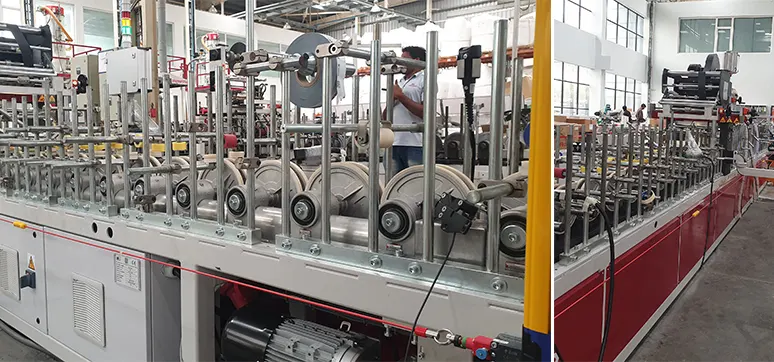

Sure. aluplast, a German company with over 40 years of rich history, is truly a global company now, with family ownership. They are not only present in Germany in a big way, but also in the rest of Europe. A large new plant is now running in Poland and they have acquired a company in the United States of America as well. So there’s a global footprint, which is quite obvious. Coming to India, the sale of aluplast products has been happening for more than 10 years. In 2016, a manufacturing facility was set up at Baroda in India, and since then the brand has been growing quite well.

In India, we have a wide network, having pan-India coverage with our partners. Apart from India, we are also sending our products to Nepal, Bhutan, and all the neighbouring countries. Export is a big market for aluplast. For example, we export our products to Australia, Malaysia, Indonesia, and the Middle East market. A big part of it is produced in India and also partly procured from Germany.

You have been with companies like Saint-Gobain & Schneider Electric in India and abroad earlier. Please brief on your experiences and how is it going to help you in leading aluplast from the helm.

I passed out of Regional Engineering College Calicut in 1993 and have 30 years of industry experience. Fortunately for me, I had the opportunity to work in different domains and different companies handling different businesses. I have a lot of project management experience and have done operational management at the national and global levels.

My last assignment, just before joining aluplast, was in sales and marketing, and product development – i.e., handling, and supplying to the automotive OEMs. So I have been exposed to different markets, industry verticals and profiles. So I think it gives me a more general perspective of the market and how to approach the market with a bit of a different view than an industry veteran who’s looking from the inside. So I would say, I have a larger perspective and hopefully, that should work. I should be able to take the company and the brand forward in a good way with my varied experience.

Could you please tell us about aluplast’s products and those which are launched recently?

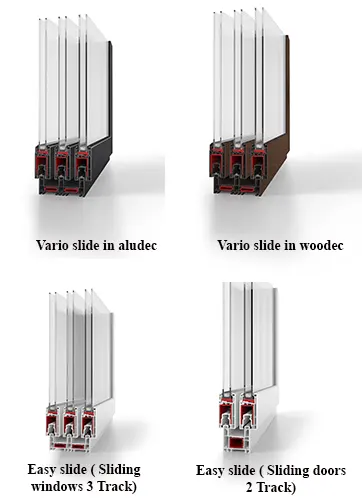

aluplast is into making profiles worldwide and we have partner networks. The partners convert these profiles into windows and door systems. Earlier, the UPC profiles were all white in colour. Now the trend is changing from white uPVC to various colour/ texture options. Now, laminations allow people to choose from more colours and textures. So the touch and feel of uPVC windows are something different.

Today we have laminated products, which can give you the very similar feel of a wood finish, aluminum finish, etc. So you have the best of both worlds. You have a world Class uPVC window in look and feel, at the same time you can have whatever you want – wood/ aluminium/ vinyl finish. This provides a much bigger choice for the customer.

If you ask me which finish is the trend today, it is the wood finish. People are going more for wood finishes for their rich look. Actual wood is the preferred material in many parts of the country. But at the same time, people don’t want to use wood by cutting trees, and it is more expensive compared to uPVC. From a sustainability point of view, uPVC is good since it can be recycled.

Please tell us about the company’s R & D policies and strategies.

We get strong R&D support from our parent company in Germany where most of the new developments take place. And in India, we have a strong manufacturing base with full capability to produce the product. A lot of development happens in Germany, for example, we have now, Energeto where the reinforcement is also made of a plastic material and it can be fully recycled. So it is extremely good for energy performance but at the same time a hundred percent sustainable. When it comes to India, we are progressively upgrading our technologies, and bringing in more and more tools from Germany to boost local manufacturing.

Today, we have the full capability and full range for extrusion, and also the adequate capacity for lamination. So, by bringing in more tools to India, we are becoming more self-reliant. And in the coming days, you will see more and more locally manufactured products available for sale. Technology is also developing with the demand from the industry.

Tell us about some of your iconic projects, partnering with well-known architects, or industry leaders.

We are there from boutique bungalows to high-rise apartments – catering to almost all the segments – residential being the primary focus. But we are also there in institutional sales. Our portfolio includes large and small-scale projects, from Kashmir to Kerala. We have a full range of products catering to the need of architects, adapting to their requirements and styling what they are looking for. As I mentioned earlier, if you want a particular colour or a finish, it is possible now, and that gives much more freedom and choice for the end customer.

Throw some light on technologies for windows that help noise cancellation, ensuring water and air tightness.

Throw some light on technologies for windows that help noise cancellation, ensuring water and air tightness.

People must recognise the significance of windows. It is not just a thing to close or open the inside of a building from the outside environment. There are many other functionalities. And today with the kind of urban setting we live in, one of the biggest challenges is to have a very high level of noise insulation. uPVC window with multiple chambers and multi-locking systems, combined with strong glazing of double glazing units may help in reducing the noise. Laminated glazing can provide very high levels of noise.

Now coming to thermal properties, what is the role of windows in maintaining optimal indoor temperature?

There is no doubt that the uPVC window scores much better in providing the best U-values in controlling heat ingress during summers or insulation during winters. This is a measure of how well the window is insulated, essentially in simple language. This also determines how less is your air conditioning bill is going to be or how much the power consumption by your air conditioner is. To put it simply, with a multi-chamber approach, we can get very low thermal transmission, which means the cold air inside remains cool and the heart outside remains out and you get great indoor comfort.

Considering that the uPVC windows are dustproof, rainproof, and have the best insulation and good thermal protection, uPVC products are the best choice technically. The products like gaskets and other hardware, which go along with the system also help in preventing heat ingress. Tell us about their importance.

We are profile manufacturers and partners who convert them to windows or doors. Coming to gaskets, we co-extruded some of these gaskets to ensure the highest level of quality and proper sealing. It’s also important that you choose the right kind of hardware. There is a variety of hardware available at different price points in the market, but it’s important to choose the right one. Our profiles are compatible with almost all hardware systems available in the market.

One needs to choose the glazing carefully. We have glazing beads suitable for various thicknesses of the glass – from a small thickness (single glazing) to very large double glazing thicknesses. So depending on the requirement and the choice, you have a wide variety of possible selections. In short, the customer has a full choice of picking up whatever he/she wants suitable to the requirement. I would just add that, be careful and choose the right one of good quality.

Tell us about the testing and certification methods of your products.

Testing and certification of any product used in construction are very important. Again, this is one point where, I think, enough is not being done in India. aluplast is well-known for its quality. Since it is a European company, our windows and doors are certified as per European standards. We are now selling in the American, Australian and UK market also, which is governed by different bodies and follow different kinds of standards. Each country has its building code and different regulations. aluplast products are complying with all these requirements.

When it comes to India, it’s a different story. We don’t have an adequate regulatory framework today, which gives a bit of openness for certain ‘not so good quality’ people also to come in and establish themselves in the market. Hopefully, this would be curtailed with a bit more regulations and we are seeing some initial moves in the direction that would take the whole industry to the next level with mandatory high-quality products, confirming certain regulatory requirements. I hope that organizations like UWDMA and BIS are working towards these kinds of regulations and certifications, and soon we should see better quality assurance.

How do you choose windows for projects based on functionality & categories, standards, testing, etc., and how do you gauge the quality of fenestration?

Windows should be selected carefully. Openable windows need floor space, and cannot be used if there is a space constraint. In that case, we can go for sliding windows, which don’t occupy much floor space. If your house is facing a street or a noisy urban environment, or if you are near an airport or a railway station, it could be very noisy. Thus good insulation is very important for doors and windows. When choosing a multi-lock, aluminium profile with a double glaze that might provide very good noise insulation, and you are sure of sound sleep at the night. Considering air-conditioned spaces, a well-insulated door or a window is critical to ensure that your energy consumption is low.

When it comes to institutions or other commercial buildings, everyone wants IGBC Gold or Platinum. Hence, energy consumption is a very critical element to achieve this kind of target. So keeping in mind the sustainability and long-term durability, I think we have to choose the right window and the right door for the application. And our partners are well equipped and trained to assist you to achieve the best. They come to your site, take measurements, and help you with the right selection.

What are the main challenges faced by the uPVC fenestration industry?

India is a growing market and there are a lot of expectations. But when you have too much growth, it brings along some undesirable side effects. One of the challenges is unclear regulations and standards, which allow some people to take shortcuts and do something which is not desirable, and then that sometimes gives a black mark to the whole industry.

So I think it’s important that we maintain quality and long-term durability always in mind. Because the bad name or the bad reputation, which you create is not only for you, but it’s impacting the whole industry. Other than that, I think the industry is well poised for good growth. This we are seeing with rapid urbanisation, most of the large builders need windows that are factory-made so that they are identical and of good quality. And when it comes to smaller apartments, the owner and the architects are very quality-conscious and choosy about colour, texture, finish, and overall build quality. So I think all these things will help us to go to the next level – i.e. quality control and certification.

Tell us about your channel expansion strategies in the market.

aluplast set up a plant in Baroda in 2016. Today we have extrusion lines and lamination lines, and we have almost 25 to 30% excess capacity, which can be additionally catered to based on the growing demands of the market. So we are not immediately in a need of an expansion. Having said that, we have a large tract of land, which is already pre-planned and assigned for the phase two expansion, and there is an in-principle approval from the management to look at the next phase of growth for aluplast India. The question is when to press that button, and that would depend on the market conditions and the market growth.

Unfortunately, 2020 – 2021 was not a nice period due to the pandemic. Now the market is bouncing back in most of the big cities, and tire two and three cities. So there is a lot of growth potential, and we are ready to cater to the market and grow as and when it is required.

What keeps your company ahead of its competitors in terms of services offered? What are your USPs?

aluplast has been a reference for quality, and it has been always at the forefront of innovation, bringing in new technologies and new types of windows. We have been always the best in providing quality products with long-term durability. uPVC by itself is very sustainable, and we have always been at the forefront of sustainability. To summarize, quality, durability, and innovation are the USPs that take us to the next level and keep us at the top.

Where do you see the industry 5 years from now?

Urbanization coupled with more disposable income, people are always looking for farmhouses/ holiday homes or weekend homes. So we look forward to doing a lot more villa projects, slightly away from the big cities or in tier two and tier three cities. So overall, the market is growing rapidly, and not only just in quantity but in terms of quality too.

People are demanding better finishers, more textures, and more functionalities. I think automation is going to be a big topic of interest. Technologies will continue to drive the market positively, and I’m sure, high-quality products with good technology systems will be the need of the hour.