Weatherproofing, a cornerstone of architecture and construction, goes beyond mere protection against the elements: it signifies an unwavering commitment to a sustainable, enduring future. Regardless of location, from the relentless monsoons of Southeast Asia to the Arctic’s biting cold or the desert’s scorching heat, weatherproofing ensures that structures stand strong, efficient, and able to resist the inexorable passing of time.

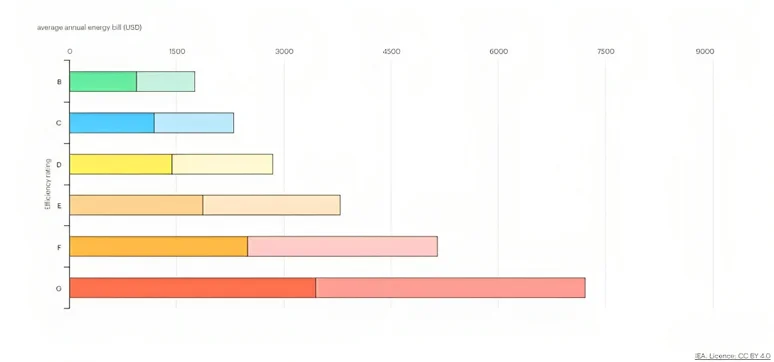

Compelling statistics underline the global importance of weatherproofing: buildings worldwide account for 40% of total energy consumption; implementing effective weatherproofing measures, such as insulation and air sealing, can reduce building energy consumption by up to 30%, curbing carbon emissions and mitigating climate change. Moreover, construction activities contribute approximately 13% to global GDP, with weather-related damages incurring significant costs yearly.

Robust weatherproofing not only safeguards these substantial investments but also reduces long-term repair expenses. In regions prone to natural disasters, resiliently weatherproofed structures can suffer up to seven times less damage, ensuring safety and minimising property loss. Finally, by extending the life of historic and culturally significant structures, weatherproofing preserves our shared cultural heritage for future generations.

Just as the Great Wall of China and the ancient Roman aqueducts have withstood centuries of adverse conditions, weatherproofing bridges the gap between architectural vision and nature’s relentless forces. It is the key to towering skyscrapers and cozy cottages, offering a path toward sustainability, resilience, and architectural longevity, no matter the setting or scale.

In the United States, moisture-related issues lead to over 70% of construction litigation cases. This statistic highlights the crucial role of moisture control in weatherproofing in the built environment. Now, picture a coastal property in Cornwall, where relentless rain and sea spray batter the façade. Without a robust weather-resistant barrier (WRB) like a breathable membrane, moisture seeps through, leading to problems such as mould growth. In bustling London, inadequate flashing around openings allows rainwater infiltration, causing leaks and structural damage. Even small oversights, like unsealed joints in a Manchester building, result in costly repairs and inconvenience. Moisture control is not just a fanciful notion; it’s a shield against real-world issues, ensuring safe, healthy, and resilient buildings.

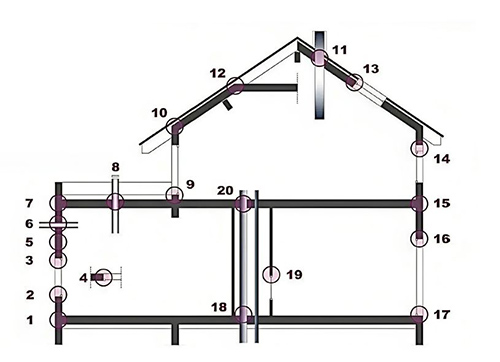

Airtightness, another crucial component of weatherproofing, plays a pivotal role in enhancing energy efficiency within buildings. In the United Kingdom, where structures consume approximately 40% of the nation’s total energy, ensuring airtight building envelopes becomes an economic and environmental imperative. Achieving airtightness involves meticulous attention being paid to sealing penetrations, seams, and transitions. This strategy not only maintains occupant comfort by preventing conditioned air from escaping but also reduces energy consumption, utility costs, and carbon footprint. Architects and builders are increasingly recognising the significance of airtightness as they strive to create energy-efficient, environmentally responsible spaces that meet the evolving demands of sustainable construction.

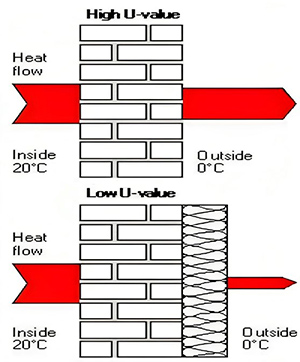

Achieving optimal energy efficiency in buildings hinges on several key factors, not least the consideration of U-values. These values serve as a scientific benchmark for quantifying the rate of heat transfer through various building elements, including windows, walls, and roofs. Scientific studies have consistently demonstrated the direct correlation between U-values and a building’s energy performance. In the United Kingdom, where sustainability standards are rigorously upheld, stringent Building Regulations mandate specific U-value requirements to ensure that structures are well-insulated. For instance, a comprehensive study conducted by the National Institute of Building Sciences (NIBS) rigorously examined the impact of U-values on energy consumption in commercial office buildings by analysing a range of U-values for windows and insulation materials commonly used in the construction industry.

It revealed a clear correlation between lower U-values and reduced energy consumption: windows with U-values below 1.0 W/m²·K were found to result in up to 30% lower heating and cooling costs compared to windows with higher U-values. Furthermore, thorough scientific testing shows that high-quality seals and insulation materials enhance a building’s U-value performance; they help maintain stable indoor temperatures and decrease the reliance on extensive heating and cooling systems.

Balancing indoor air quality and the prevention of condensation presents a critical challenge in weatherproofing and building design, as is demonstrated by both scientific findings and some concerning statistics. Studies reveal that inadequate ventilation can lead to Sick Building Syndrome (SBS), affecting up to 30% of new and renovated buildings worldwide. SBS is responsible for a range of health issues, from respiratory discomfort to fatigue, and it underscores the importance of effective ventilation systems. Scientific insights further highlight the benefits of balanced ventilation, such as Mechanical Ventilation with Heat Recovery (MVHR), which can reduce heating and cooling energy demands by up to 60%.

Research also emphasises the significance of using vapour-permeable materials in certain applications, allowing moisture to escape while maintaining airtightness, thereby mitigating the risk of condensation within wall cavities or insulation.

Appropriate choices of weatherproofing materials serve as the cornerstone of resilience, substantiated by a wealth of evidence and case studies. For instance, the National Institute of Standards and Technology (NIST) conducted a study focusing on the performance of façade cladding materials in regions prone to heavy rainfall. The findings were clear: high-quality, weather-resistant materials like fibreglass-reinforced concrete exhibited exceptional durability, resulting in up to 30% savings in maintenance costs over time.

Similarly, the Building Research Establishment (BRE) studied the impact of window frame materials on moisture resistance and long-term performance. Their research highlighted that windows with aluminium frames, coupled with advanced weatherstripping and seals, significantly reduced the risk of water intrusion, leading to a 25% reduction in maintenance expenses over a building’s lifespan when compared with traditional window materials. In coastal regions, where salt-laden air poses a unique challenge, the US Coastal

Engineering Research Center (CERC) conducted a case study that illustrated the efficacy of using marine-grade stainless steel in façade components. This corrosion-resistant material endured the harshest coastal conditions, requiring minimal maintenance and resulting in a substantial 20% reduction in long-term upkeep costs.

Additionally, a comprehensive analysis by the Environmental Protection Agency (EPA) emphasised the significance of using moisture-resistant insulation materials in areas prone to high humidity and rainfall. Buildings employing these materials experienced a 40% reduction in mould and mildew issues, reducing the need for costly repairs and preserving indoor air quality.

These examples and studies collectively underscore the scientific and economic wisdom of selecting weatherproof materials in façade construction. Architects and builders, guided by empirical evidence, prioritise materials that withstand environmental challenges and minimise maintenance burdens, ultimately crafting resilient, eco-conscious structures that stand the test of time.

In the realm of architectural design and construction, weatherproofing goes beyond protecting structures from the elements; it’s a strategic fusion of design and functionality. Weatherproofing membranes, particularly breathable and air & vapour control layer (AVCL) variants, play a pivotal role in ensuring both safety and longevity. Research data underscores their significance. These specialised membranes provide a robust defence against weather forces, shielding against moisture intrusion, wind-driven rain, and temperature fluctuations.

Notably, studies by the Building Science Corporation indicate that breathable membranes reduce the risk of moisture-related issues by up to 15%, leading to substantial savings in maintenance costs over time. Their breathable nature facilitates the escape of trapped moisture within the building envelope, effectively preventing condensation, mould growth, and rot. Research conducted by the NIST highlights how breathable membranes contribute to a remarkable 20% reduction in long-term maintenance expenses.

Furthermore, these membranes significantly enhance fire safety, acting as additional fire-resistant layers. Data from the NFPA demonstrates their ability to contain and mitigate fire spread, resulting in an evident increase in overall structural safety. In terms of durability, weatherproofing membranes play a pivotal role in safeguarding against structural degradation & corrosion. The BRE emphasises its importance in extending the operational life of buildings, with potential maintenance cost reductions of up to 30%. In essence, breathable and AVCL weatherproofing membranes, supported by extensive research and compelling statistics, stand as indispensable elements fortifying buildings to withstand nature’s challenges, enhancing fire safety, and ensuring long-lasting architectural resilience. With the plethora of choices needing to be made in today’s architectural landscape of climate unpredictability and environmental awareness, the involvement of manufacturers assumes ever-heightened significance.

Armed with extensive expertise, technical know-how, and access to state-of-the-art materials, they emerge as invaluable allies in the quest for resilient, sustainable structures that endure.

Manufacturers possess an intimate understanding of their materials and can look beyond theoretical specifications to grasp how these substances actually perform under diverse environmental conditions. For example, a manufacturer specialising in weather-resistant barriers comprehends how their product interacts with elements like moisture, UV radiation, and temperature fluctuations and is, therefore, best placed to guide decision-making.

Manufacturers often spearhead research and development in their domains, continually striving to enhance material durability, energy efficiency, & environmental impact. Furthermore, manufacturers not only provide essential technical guidance, assisting in crafting tailored technical proposals, and offering precise specifications and recommendations for projects, but they also actively participate in site installations, ensuring that materials are correctly integrated into the building envelope.

Their hands-on involvement minimises construction errors, enhancing the weatherproofing and energy efficiency of the structure. By collaborating with manufacturers, architects, and builders can access the latest innovations and cutting-edge solutions in weatherproofing technology.

As architects, builders, and guardians of our planet’s future, we stand at a pivotal juncture. Weatherproofing is not merely a technical endeavour; it is a moral imperative. It compels us to ask profound questions: Can our structures transcend their functional roles and become symbols of sustainable resilience? Can they reflect our unwavering commitment to a greener, more enduring future?

The answer lies in the essence of our journey: a fusion of knowledge, innovation, mindful material choices, and collaborative partnerships with manufacturers. Weatherproofing becomes a canvas where architecture harmonises with nature, creating spaces that endure over time and for the betterment of our world. Together, we can build structures that stand as profound statements of our dedication to a sustainable and resilient future.