Why to Choose Fabric Façade?

By:

The fabric façade concerned in this article is the one used as an architectural façade feature, sun glare control and LED screen outside of the existing building envelope façade. According to up-to-date market experience, stretched fabric façades share in the façade market has grown significantly against traditional hard material ones.

Why is that? Below are the major factors:

Dead Loads Erosion: Fabric is approximately 100-times lighter than the glass this will not only reduce dead load reactions but will also make the installation cheaper, faster and much more environmentally friendly (fewer machines). In addition to that, the cost of structural steel & its foundation needed for fabric façade is dramatically lower than the hard façades.

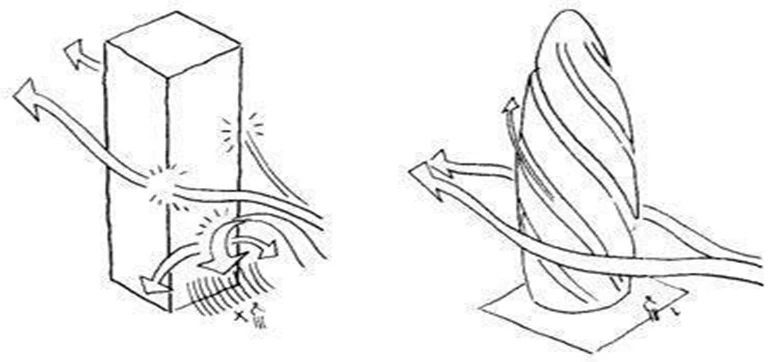

An endless variety of color, openness, shapes & sun glare control: At an affordable cost, fabric façade can be of any color or printing pattern. The possibility of having solid or open mesh fabrics with a wide variety of shading coefficient makes it easy to the sun glare lovers to enjoy day light at their preferred comfort levels. The energy saving is immensely enhanced with enhanced shading coefficient. Unlike hard materials, the fabric can take any curvature or any shape by its nature.

Best LED reflection screen: Stretched fabric is still offering best screen experience. Since the early days of cinema, silver lenticular (vertically ridged) screens, which are made from a tightly woven fabric, either natural, such as silk, or a synthetic fiber, that’s why until our days, some are still referring to the cinema industry as “Silver Screen”, it was in simple words one of first modern stretched fabric applications.

Fire safety: Unlike what inexperienced mindset may think about fabric, we can safely state that fabric fire behavior is not less safer than any other hard façade. Perhaps it is famously known that some kinds of fabric are classified as non-combustible such as PTFE for instance, yet even other kinds of B-class, such as ETFE and PVC are behaving safely too, but with different philosophy as following:

- Does not spread flames (fire will only impact its origin panel),

- Fabric self-extinguish itself in fractions of second (once the fire source is removed),

- The amount of smoke is not significant at all specially when fabric is used as an exterior feature,

- A load of fire in fabric case is significantly less than hard façade.

Durability: As like any other material, if you choose the right quality fabric materials, fabric fabricator, and abide with the preventive maintenance recommendations, then the fabric façade life expectancy is not less than any hard façade. Generally speaking, fabric life expectancy is ranging between 25 to 35 years, depending on its components, the way of application and location. Nevertheless, even after 25 or 35 years, if you wish to change the façade color, printing, shading coefficient (make a brand new look of the new façade) that is unquestionable, and without any doubt feasible on fabric façades exclusively.

Mimicking Nature Hazza Bin Zayed Stadium, Al Ain, UAE

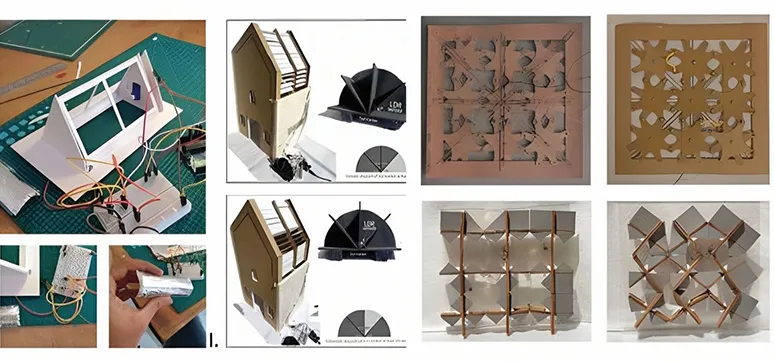

Fig, 1 & Fig. 2: Facade-Mockup-(Fabric-Option-Inspection)

Fig, 1 & Fig. 2: Facade-Mockup-(Fabric-Option-Inspection)

Inspired by the palm tree trunk, the national tree in Arabian gulf countries, the stadium outer façade was designed to cover inner envelop with additional outstanding palm trunk look and at the same time reducing sun glare and heat on inner envelop while allowing it to breath. The 612 panels façade with approximate 92 different sizes and inclination was preliminary intended to be made into hard materials such as GRC (glass fiber reinforced concrete) or with fabric as an option. The shape of each palm trunk panel is curved to mimic nature and therefore the intention to use GRC was to make sure that inspired shape is fully satisfied or simply molded.

Eventually, the conclusion was to make a fabric panel mock up and inspect its viability against GRC (refer to Fig.1 and Fig. 2). The fabric would be stretched on a steel frame with an intermediate arch (refer to Fig. 3). After mock up inspection, the decision was obviously to confirm fabric option for the following reasonsFig.3: Façade Mockup (view from inside)

- In terms of shape, the fabric succeeded to mimic the intended shape by using a metal frame with an intermediate arch and then stretch PTFE fabric on it. Actually, from a far distance like 30m and more, you can’t say certainly that the façade is made of fabric. Refer to fig, 4 and Fig. 5.

Fig. 4 Hazza Bin Zayed Stadium, Al Ain, UAE – Façade After Completion

Fig. 4 Hazza Bin Zayed Stadium, Al Ain, UAE – Façade After Completion - Fabric option cost was half of GRC for the following reasons:

- Lighter fabric panel requires less effort and time for installation

- Lighter fabric panels provide a very low dead load on the main steel diagrid

- frame which indirectly reduced the cost of the main steel structure and foundations.

Fig. 5 Hazza Bin Zayed Stadium, Al Ain, UAE – Façade After Completion

Fig. 5 Hazza Bin Zayed Stadium, Al Ain, UAE – Façade After Completion - The QA/QC control and fabrication of fabric is significantly much more flexible and easier than molding and controlling 92 different GRC molds.

- The LED light reflection on fabric is well known guaranteed pleasure. The Hazza Bin Zayed Stadium is the home of Al Ain Football Club, one of the leading clubs in the UAE Pro League. Designed by Pattern Architects, the 25,000 seat FIFA class football stadium introduces a new approach to sports architecture in the Gulf region by embedding Al Ainʼs identity into the very fabric of the design.

QUICK FACTS:

Project: Hazza Bin Zayed Stadium

Location: Al Ain, UAE

Client: Al Qattara

General contractor: BAM International

Membrane façade contractor: Taiyo Middle East LLC

Architect: PATTERN UK

Other consultants: Schlaich Bergermann Partner, Taiyo Middle East LLC

Materials used for façade: PTFE fabric SHEERFILL-V, Saint-Gobain USA

Commencement date: September 2012

Completion date: July 2014

Top Stories

Foster + Partners Wins the Competition the New Xicen Science & Technology Centre

By: Abdul | April 9, 2024

A Symbol of Architectural Brilliance & Cultural Significance

By: Abdul | April 8, 2024

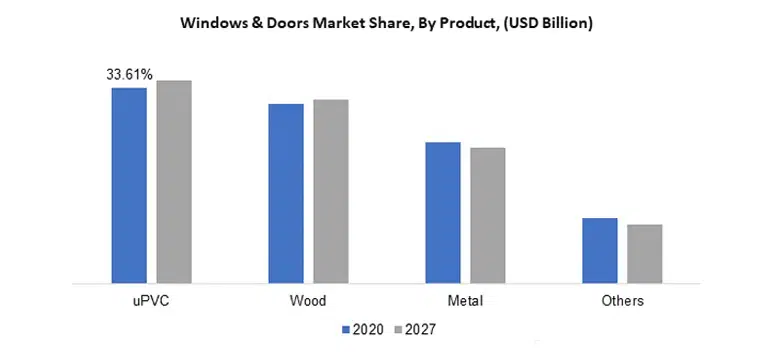

Explosive Growth Ahead: The Rising Demand for uPVC Doors and Windows in India | uPVC Doors and Windows Market in India 2024

By: Abdul | March 20, 2024

Alumil India is Expanding Across South, West & North Markets

By: Abdul | March 18, 2024

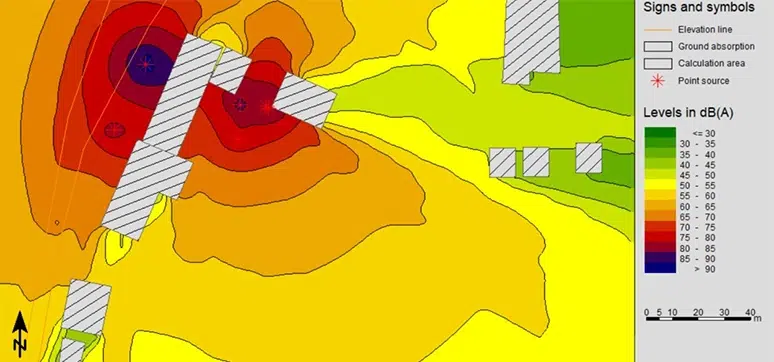

Exploring the Role of Acoustics in Architectural Façade Design

By: Abdul | March 6, 2024