Architectural hardware is the backbone of the fenestration industry. Whether it is the harmless small window opening in your completely secured restroom or even a large span opening in facades, the hardware around it is what defines how long the operable is going to perform. When we mean performance, it is measured by several parameters including water, wind and even the sheer functionality of the product, besides a few other lookouts that each building brings out.

From the time when hardware used to be just another item to close on the BOQ (bill of quantities), to the present days when it is closely looked upon by leading developers, architects and façade consultants as the saviour of the operable in extreme conditions, the role of the product has been magnified to a large extent.

Whether it is the conventional top-hung operable façade or a sliding door, the hardware is expected to function on a variety of parameters which include measuring up to:

-

Parallel Opening Window 1.2 mts x 2.4 mts DGU at IB Blu, Mumbai The weight of the operable (nowadays requirements exceed 400 Kgs on certain requirements, even though the more volume-based may go up to a maximum of 180 Kgs).

- The size of the panel – conventional sizes now reach 1.5 m x 3m in façades top hung and 1 m x 3 m in sliding doors.

- Resistance to wind pressure

- Water penetration

- Working cycles

While deciding on the kind of hardware to be used in operable, it is of utmost importance to consider a variety of factors beyond what is listed above. Safety plays an important role and the opening dimensions/ application of the operable should account for the occupants of a building, especially children. Today the new age hardware has solutions where the openings can be restricted with child safety measures in place.

Ventilation in homes plays an important role too and while we have always been used to opening windows outwards to their maximum capacity, today you have the option of selecting restricted openings to let air in, save on air conditioning costs and yet inhibit access from the outside. This also comes in handy for night ventilation without compromising on security.

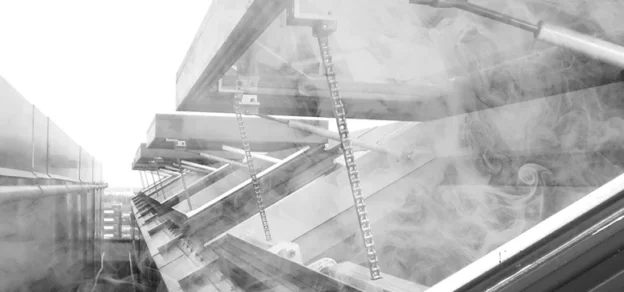

So be it a villa where you need to have access to your sliding window from the inside and yet also be able to lock/open it from the outside to a pivoted window, which allows cleaning of the glass from both outside and inside from the comfort of your room, or a parallel opening façade panel which allows the plain of the façade to remain the same, yet allows ventilation from all four sides and stretches window dimensions beyond imagination (may I add quite useful for smoke ventilation too), the industry has it all. To top it, there are solutions for bottom-hung vents today for up to 4.2 m height and 350 Kg and top-hung vents up to 3 m height and 250 Kg, tested to 10,000 cycles.

As dimensions increase and demands go up in terms of safety even in terms of fire norms, the inclusion of automation solutions for both natural ventilation and smoke vents has witnessed a sea change. Not only are these systems integrated with the Building Management System (BMS), but they are also equipped to offer concealed electronic locking multi-points.

While buildings continuously grow taller and modern homes turn to automation, it would be very unlikely that the fenestration industry did not gear up to this aspect. With hardware solutions now available to automate windows at the touch of a button or shall I say at the hands of a remote control unit or even at the touch of an iPad, the hardware has truly come around a complete circle.