Doors and door hardware are often overlooked during the design process for new construction or renovation projects. While minimum functionality and code requirements are typically considered, little attention is given to how well they will function over time. Instead, more focus is placed on the aesthetics and finish of the door and its hardware. Unfortunately, this lack of attention to functionality can result in ongoing challenges for the staff responsible for maintaining building accessibility and security.

The hardware components play a significant role in the overall performance and aesthetics of windows & doors. This article will explore the generic selection criteria for hardware in windows and doors, with a specific focus on technical aspects. By considering these criteria, homeowners, architects, and builders can make informed decisions that meet their particular requirements.

The Indian market today has a variety of products for architects at different budgets to match project or customer requirements. The availability of designs is only limited by our imagination as many manufacturers can also custom-make hardware to specific needs. Modern hardware manufacturing has become very innovative with new equipment and processes, enabling the use of better materials, coatings and finishes such as PVD / shining chrome. With the residential sector being a large consumer of builder hardware, the rise in housing units augurs well for the builder hardware industry.

1. Material Selection:

One of the primary considerations in hardware selection is the choice of materials. The materials used in hardware components greatly influence their durability, resistance to corrosion and overall performance. Stainless steel is a popular option due to its strength and exceptional corrosion resistance. It is often the go-to choice for exterior hardware as it can withstand harsh weather conditions. Brass, with its elegant appearance, is often preferred for interior applications but requires regular maintenance to prevent tarnishing. Aluminium is lightweight, durable, and corrosion-resistant, making it suitable for interior and exterior hardware

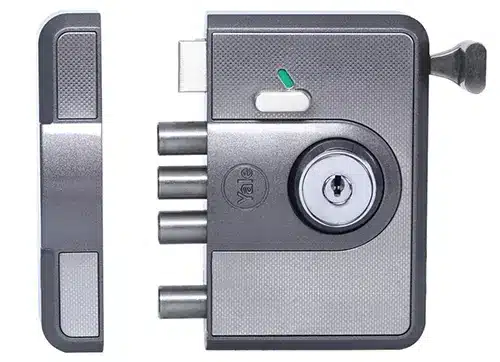

2. Security Features:

Windows and doors serve as entry points to a building and ensuring their security is paramount. The hardware components selected should provide robust security features to safeguard against unauthorised access. Window hardware should include reliable locking mechanisms, such as multi-point locking systems, which secure the window at multiple points along the frame. These mechanisms not only offer enhanced security but also improve the overall sealing of the window, reducing drafts and increasing energy efficiency.

Door hardware should include high-quality deadbolts, latch bolts, and

reinforced strike plates to prevent forced

entry

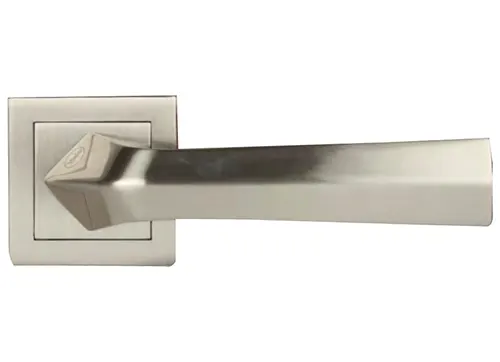

3. Functionality and Ease of Use:

Hardware components should offer smooth functionality and ease of use to enhance the overall user experience. Hinges, handles, and locks should be designed for effortless operation. Hinges should be sturdy, allowing windows and doors to open and close smoothly without squeaking or sticking. Handles should have an ergonomic design, ensuring a comfortable grip for users of all ages and physical abilities. Locks should be easy to engage and disengage while providing the necessary security. Additionally, the hardware should be easy to install, adjust, and maintain, facilitating hassle-free operation over the product’s lifespan.

4. Energy Efficiency:

In today’s environmentally conscious world, energy efficiency has become a crucial consideration in hardware selection for windows & doors. Energy-efficient hardware helps minimise heat transfer and air leakage, contributing to reduced energy consumption and lower utility bills. Weatherstripping and gaskets play a vital role in sealing gaps and preventing drafts around windows and doors. Additionally, selecting hardware that supports the installation of double or triple glazing can significantly enhance the energy efficiency of windows, as these glazing options provide better insulation properties.

5. Compatibility and Versatility:

Hardware components should be compatible with various window and door types to ensure flexibility in design choices and easy integration into different architectural styles. Whether it is casement, sliding, tilt and turn, or folding systems, the hardware should offer compatibility with these different configurations. This allows homeowners and builders to choose from a wide range of window and door options without compromising on hardware functionality or aesthetics. Moreover, the hardware should be adaptable to accommodate additional features such as motorised operation or smart home integration, providing enhanced convenience and functionality.

6. Durability and Maintenance:

Windows and doors are exposed to various environmental conditions, including sunlight, rain, and temperature fluctuations. Doors installed in facilities located in coastal areas or other high-moisture environments face unique challenges due to the corrosive nature of saltwater and high humidity. To ensure the longevity and functionality of doors in such conditions, it is crucial to consider corrosion-Resistant materials. Therefore, hardware components must be durable and resistant to corrosion and wear. High-quality materials and finishes ensure the longevity of hardware, minimising the need for frequent replacements. Regular cleaning and lubrication of moving parts are essential to maintain functionality and prolong the lifespan of the hardware.

The anticipated level of use is a crucial factor to consider when selecting doors. Residential applications typically involve fewer cycles per day, usually around 20, and the doors are expected to have a service life of 30 years or more. In contrast, commercial applications experience higher traffic, often with hundreds of cycles per day. However, even in these demanding scenarios, a well-chosen commercial-grade door can still provide a service life of 25 to 30 years. It is important to avoid installing a residential-style door in a commercial setting, as it would likely suffer premature failure, lasting only a fraction of the expected lifespan, often less than five years.

Conclusion

Selecting the appropriate hardware for windows & doors is essential for ensuring their functionality, durability, and security. Homeowners, architects, and builders can make informed decisions by considering the generic selection criteria discussed above. Material selection, security features, functionality and ease of use, energy efficiency, compatibility and versatility, as well as durability and maintenance, are all critical aspects to consider when choosing hardware for windows and doors. By prioritising these technical aspects, one can enhance the overall performance and aesthetic appeal of windows and doors while ensuring the long-term satisfaction of all stakeholders involved.