When it comes to the system windows as a choice of product for fenestration, some of the key factors that influence its performance are hardware, resistance to water seepage, and ruggedness against stormy weather. From the user’s perspective, hardware is the closest matter which influences their perception of the quality and performance of the fenestration product. Also, hardware is the part of the system which is most complicated from functional and engineering perspectives.

However, often the single criteria for the fabricators for the selection of hardware is price and the rest of the parameters are neglected. The intention here is to give insight into such areas of hardware which need to be considered, along with the price, for the right selection of the hardware based on product design context. So, let’s explore one by one.

A) FUNCTIONAL REQUIREMENTS:

Grossly following are further sub-classifications that are considered from the functional perspectives. The number of operational cycles with their specified capacity: Normally dynamic hardware such as hinges, locks, and rollers are checked for failure by setting up a test rig. This test rig facilitates the load application as per the designated capacity of the hardware and is operated repeatedly until it fails. Normally, if you consider 3 times a day you open or close your windows, this counts approximately 1000 cycles a year. If you warranty 20 years of window life, then you should have hardware that is tested for 20,000 cycles.

Various load-carrying capacities based on the type of hardware:

Depending on the type of fenestration such as sliding or casement, every sash/ shutter has certain weights, which are often borne by hardware elements. It is crucial to check the hardware manufactures technical manual for an appropriate selection guide or consult the hardware supplier’s technical support. Inadequate weight capacity, such as underweight carrying will result in the low life of the hardware, and overweight carrying capacity will ask for more price and thus not make it an optimum priced offering.

Wind load-specific requirements:

This specific requirement is more relevant in casement shutters compared to sliding shutters. Often besides structural failures, it is observed that the hardware is also a prominent source of failure when it is tested for positive and negative wind load test cycles. So, you should make sure the hardware stands the wind loads for which the fenestration product is designed.

Security and anti-theft features:

In some cases, mostly in-ground and ground +1 properties, especially if grills are not provided, safety is assumed by default with the applied hardware and glass. Glass is often vocally bold in its terms of specifications so that the security and safety both are taken care of. However, you must also be sure it is the case with hardware. There are standards like PAS24 which can be further referred for the same.

The number of locking points in the case of locking systems:

Generally, all locking solutions, whether casement or slider can be grossly divided into a single point and multipoint locking. The selection of locking points depends mainly on the performance against wind load and security aspects. Another factor influencing this is the size of the window or door. Normally, slider windows (small to medium) sizes use a single-point lock, and for casements – irrespective of size – preferred is multipoint locking solution. Sliding doors have a mixed solution of single and multipoint locking, however, sliding doors, if budget allows then, should have multipoint locking solutions. Based on the specification of the window/door a technical consultation can be sought from the hardware suppliers.

Geolocation of the site and environmental conditions where the windows door will be installed:

This refers mainly to the corrosion of the hardware and directly affects the quality and life of the hardware. For example, if the site is near the coastal area, then the hardware should have anti-corrosive construction of material. In the same way, some areas may have extreme temperature cycles. i.e., at night, it may be very cold, and in the day higher temperatures. You must make sure hardware is designed/ tested and the supplier assures better functionality to such conditions.

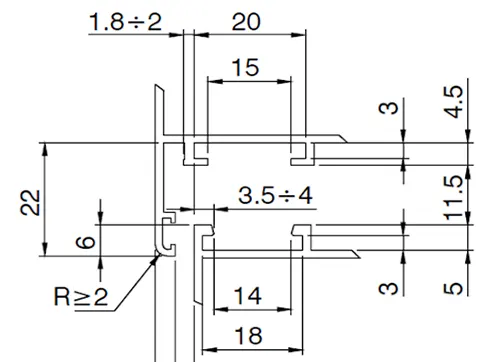

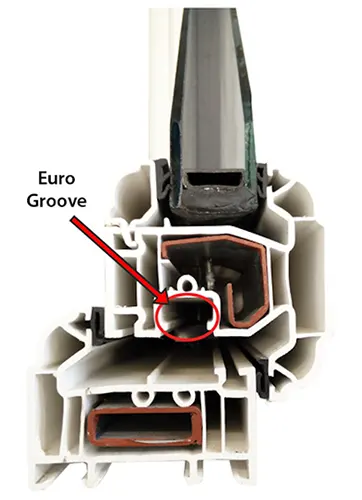

Interchangeability of the hardware with other competitive brands:

A very critical aspect of the windows and doors is the interchangeability of the hardware with other brands. Normally, profile systems have a standard groove which is generally accepted by all major manufacturers. There are certain standards that also define these grooves. All the hardware should be selected around this groove, this helps in achieving flexibility and cost competency. One such groove is Euro groove type 1. Most Indian hardware suppliers follow this for aluminum and a similar groove exists for the uPVC profile systems as well.

B) QUALITY, MOC, AESTHETICS, AND OTHER REQUIREMENTS:

The following are the few points that need to be considered regarding quality, MOC, and aesthetics.

Constructional quality of the hardware:

More precise manufacturing tolerances better the functional experience of the hardware. The quality of the build and finish also has a strong relationship with aesthetics and user experience and in a way with the life of the hardware. Always whenever possible a short consumer survey is to be done to gauge the user likeness and user experience which will help select the optimum hardware solution.

Material of construction (MOC):

This has a direct relation to the cost and quality of the product along with its life. The MOC of the hardware should be optimum enough so that quality referring to function and user experience is not compromised and not extreme as well where the cost will be too high, and the product is over-engineered. To assess this, one should always ask for the MOC of all the hardware components so that there is a clear picture of how optimum the hardware solution is. For example, a multipoint locking handle may have an aluminium casting or brass. Selection depends on the solution offered category (retail/project) and the cost sensitivity of the window door solution offered.

Aesthetic and ergonomic considerations:

Form, colour and surface finish must be a choice to differentiate from the competition and this also compliments the aesthetic language of the profile system used. Ergonomic considerations such as the grip shape, grip confidence and comfort must be appropriate or with excellent quality. The force required to crank also should be within the limit as per ergonomic specifications. A test report or a written declaration on ergonomics will help establish more user confidence in the solution you are offering.

Form, colour and surface finish must be a choice to differentiate from the competition and this also compliments the aesthetic language of the profile system used. Ergonomic considerations such as the grip shape, grip confidence and comfort must be appropriate or with excellent quality. The force required to crank also should be within the limit as per ergonomic specifications. A test report or a written declaration on ergonomics will help establish more user confidence in the solution you are offering.

Cost, service, and lifetime warranty of the hardware:

Cost is the parameter that always becomes the single most influential factor. However, evaluation for the right choice should have considerations as mentioned above. The service warranty is another important criterion that should be considered along with cost parameters.

A simple matrix of evaluation can be built as below for the right selection of the hardware. Each parameter can be given points from 1 to 10 — 1 is the least and 10 is the most favorable. Then the sum of these points will yield the most suitable and optimum hardware solution.

Conclusion:

To select the best-fit solution for hardware one should look beyond the cost and consider other parameters as well. This will deliver a better solution in terms of windows and doors without changing or affecting other product parameters.