The architectural hardware market for windows, doors and façades has not only grown over the past few years but has also become significant in contribution to the end product. This niche market has been growing at about 16- 17% per annum, largely driven by higher consumer demands. The burgeoning retail market and the need for a more sound insulated environment around your home or commercial space leads to a higher demand for quality hardware. The average cost of hardware for an operable façade panel itself has increased by over 25% due to more stringent demands.

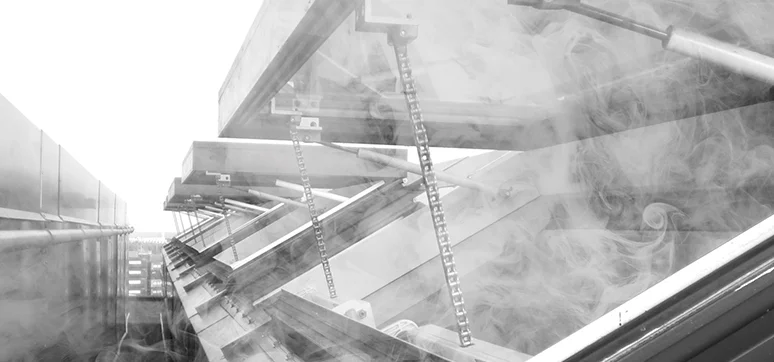

The growth is driven by a few major factors that include vertical growth, more attributed to high wind pressures, increase in fire-related incidences, etc., which demand windows that open automatically when smoke is detected. Also, sound insulation is another factor, which is largely driven by hardware and by glass.

Hurdles Faced by the Industry

The biggest hurdle I would point out would be standardisation. Since the industry is in a turn-around phase with norms still setting in, I am sure every hardware manufacturer faces the challenge of developing a project or system or specific market or even specific client-driven hardware that may not have a future in the long term. The way forward is simple; standardise the elements around the window, be it sizes or the profile itself.

Demand for Products

A growing market, as we are in, brings forward a demand for a huge variety of products. Vertical sliders are one such product that has started to gain momentum in the market. Specific markets like Mumbai face challenges with fire and this leads to an absolute growth in the automation of vents for smoke. Parallel openings present a very niche market, which is sure to grow considering the huge benefits the product offers including uniformity of airflow in the building, smaller carbon footprint and less CO2 within a building, not to forget the large sash weights the product can carry.

Need for Standardisation and Certification

Standardisation is the key. This will bring so much semblance to the industry; be it the reduction in manufacturing costs, improvement in the finished product, site concerns getting eliminated, uniformity in buildings and even an overall sense of a “feel good” look for the cities. Certification will lead to an even playing field for all contributors in the market.

Architectural Hardware Market in 2030

I would probably say that there are a few keywords on this. Standardisation coupled with certification should be set in by then; local manufacturing is something that definitely has the scope and I do see Indian players bringing on standard systems that will lead to volume growth of the market. The signs already exist for a very exciting decade ahead!