Glass in architecture has been used in façades and as a construction material for many years. The invention of steel and plate glass in the late nineteenth century made possible an imaginative leap – the transparent steel framed enclosure – which underpinned the development of architecture in the twentieth century. Glass perhaps, is the only material that has seen continuous technological advancement since its first use as a building material. This is evident from the vast range of glasses now available to clad the buildings depending on the usage and budget. In this article, we present are view of today’s available architectural glass types as well as their characteristics and potential for future development of glass as a structural material.

In the past few decades, the use of glass in buildings has remarkably increased. As a result, several transparent buildings have been constructed. The flexibility or versatility of glass keeps on increasing as experts find new applications to this paramount building material. Now it is being used for building delicate looking fenestrations on facades as well as complex architecture. With the advent of green technology in construction, glass is constantly undergoing transformation. Solar power glass, switchable glass projection screens are a few of the newer uses. This is one material to look out for!

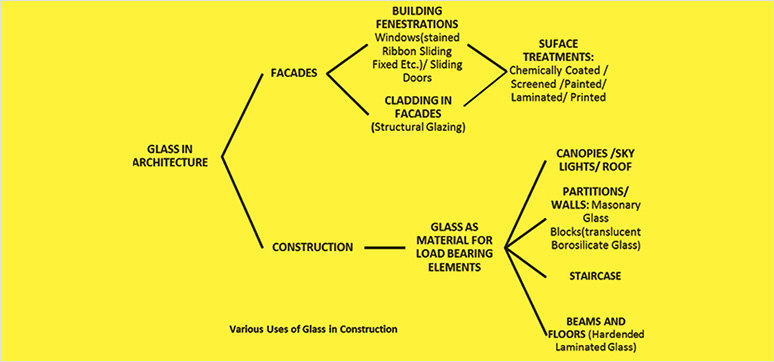

In Façades, says Anup Naik (Director, Space Matrix Architects & Planners), glass has scaled itself from mere windows to structural glazing, wherein the glass technology has contributed to various glass types from laminated, printed, painted to chemically coated and screened the choices are numerous depending upon the requirements. Curtain walling, structural glazing, bolt glazing or spider glazing, fin supported glazing, cable glazing and suspended glazing – are available according to the customer’s specifications. As a construction material, the application of glass has manifested from glass masonry walls and glass blocks to canopies, skylights and roofs, and as load bearing elements.

In recent years, designers have begun to use glass more in structural applications. Instead of panes of glass being supported on metal beams and columns, glass is now being used to support itself through glass structural members. Drawbacks of glass, such as privacy issues, can be resolved by the usage of technologically advanced forms of glass like frosted/ translucent glass.

Advantages of Using Glass as a Structural Element

Glass is a critical material for any building envelope in the contemporary architecture. This could be because of its lightness of weight, visual porosity, thermal comfort, acoustic insulation, ease of installation and safety, says Abhishek Bij, Associate and Lead Designer at Design Plus Architects. It is the only mainstream material that provides multiple variations in all the mentioned parameters.

Mukesh Jaitley (Director-Projects, The Wadhwa Group) mentions that developers are using glass to bring in efficiency and enhance the aesthetics of a structure. Lightness of glass results in the reduction of the structural load. Its transparency allows maximum natural light, resulting in reduced consumption of electricity. If glass, with correct specification of reflectivity and thermal insulation properties, is used, it will definitely help in efficiency. Lastly, glass façades and roofs provide unobstructed views and help to make it an interactive building envelope.

Since glass has the ability to absorb, refract or transmit light, says Architect Indrajit Kembhavi, Principal Architect of Kembhavi Architects, it can be made transparent or translucent to add extraordinary beauty to the building and increase visual connectivity between the building and its surroundings. Glass holds the capacity to transmit up to 80 per cent of available natural day light in both directions without any yellowing, clouding or weathering, adds Kembhavi.

Deben Moza (Joint CEO & Executive Director, Project Management Services, Knight Frank Property Services Pvt Ltd.) points out that the properties of glass including its very high compressive strength, resistance to corrosion,

recyclability, and reduction of energy consumption also adds to its demand. With the advancements in glass coatings, there is tremendous increase in demand for sleeker structures – structures having more light, and with an argument of being ecofriendly in all conditions.

For Deepak Dinesh Prabhakaran, MD, PNC Architects, it also protects the building from the vagaries of nature, and serving as a surface for branding and advertising of digital and other media. In addition to its transparency, these properties add to the demand for glass in construction.

Glass with high selectivity ratio is the key, says K P Nagaraj, Associate Vice President, Regional Head – Infrastructure, Infosys Limited. Glass that reacts to change in environment and occupant preferences ensures that light and heat transmission parameters are adjusted to provide maximum thermal and visual comfort to occupants throughout the day all year. A façade (due to variant solar insolation) can be designed for different specifications from bottom to top with varying fenestration area and percentage, shading strategies and selection of glass type (heat resistant glass near top and high visibility near base) making the envelope interactive.

According to Rajendra Kumar, Founder and Principal Architect, Architect Rajendra Kumar & Associates, a good double layered glass acts as a good insulator. Lower heat-loss is achieved by introducing multiple glazing layers, gases and low-e coatings.

In future, glass used in the façade will have integrated solar cells and it will be used for generating energy. This will change the definition of building envelope completely, says Kapil Handa, Managing Principal, Studio DRA LLP. PV cells can be mounted on the blanket area of the façade and this can generate power.

However, India being a tropical country, the usage of glass is not necessarily environment friendly in all cases due to the varied environmental conditions as compared to colder climates, opines Deben Moza. Hence, the use of glass should be minimal to prevent heat.

Rajendra Kumar reminds that energy efficient glass is the only solution for energy conservation. For a building with larger glazed areas in façades and roofs, and entirely glazed façades, the key driver for energy-saving is energy-efficient glass. In hot climate, reliance on air conditioning, is mitigated by the use of advanced solar control glass, allowing the sun’s light into buildings, while blocking much of its heat. In cold climates, low-emissivity glass reduces heat loss, while allowing high levels of valuable free solar gain to heat buildings without significant loss in natural light. However, in the summer, unless combined with solar control glass, it can become uncomfortably hot, says architect Rajendra.

Various uses of glass in construction

K P Nagaraj from Infosys says that choice of glass has to be part of the integrative approach. By choosing a high performance glass, one can reduce the cooling requirement due to lesser amount of heat. The key is to select glass with low solar factor (direct heat reduction), low U value (indirect thermal heat reduction) and optimal light transmission.

The correct choice of glass can help to reduce the capital outlay, running costs and associated carbon emissions of buildings.

Types of Architectural Glass

The skylines of Indian metros are dotted with highrise buildings clad in glimmering glass, spelling out affluence and style, but there’s much more to glass than just that.

Broadly, architectural glass can be classified into Annealed, Heat Strengthened, Toughened, Laminated, Coated, and Patterned. Each of these can be further classified into sub categories depending on more subtle variations and manufacturing patents.

Mindspace at Airoli East, Navi Mumbai by K Raheja Corp

Annealed glass or Float Glass is the basic flat glass product that is the first result of the float process. It is also known as soda lime glass. This type of glass is produced without internal stresses imparted by heat treatment, i.e. rapid cooling, or by toughening or heat strengthening. It is common glass that tends to break into large, jagged shards when subjected to a relatively small temperature change or mechanical shock. It is primarily used in making canopies, shop fronts, glass blocks, railing partitions, etc., and often used in double-glazed windows. Building codes in many parts of the world restrict the use of annealed glass in areas where there is a high risk of breakage and injury, for example in bathrooms, indoor panels, fire exits and at low heights in schools or residences.

Heat-strengthened Glass is a semi-tempered glass which retains the normal properties of ordinary float glass. It is similar to tempered or toughened glass except that the cooling is done slower than toughened glass, but faster than annealed glass.

Heat-strengthened glass is about twice as strong as annealed glass. It is valued for its mechanical strength which makes it a good choice for vertical vision spandrel areas and for laminated sloped glazing.

Toughened Glass is chemically or thermally treated float glass, to increase its strength as compared to normal glass. It is far more resistant to breakage than simple annealed glass. Tempering of the glass puts the compression in the outer surface while tension remains in the inner side, therefore at the time of breakage, instead of splintering into jagged shards, which is less likely to cause injury. Toughened glass has extremely broad applications in products for buildings though it may have distortions with low visibility. It can be used for exteriors and interiors, such as glazing for building façades, glass sliding doors and partitions in houses and offices,glass furniture such as table tops, and many other products.

Vijayawada Airport by Studio DRA LLP

Laminated glass is made of two or more layers of glass with one or more ‘interlayers’ of polymeric material bonded between the glass layers. In the event of breaking, it is held in place by an interlayer, typically of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), between its two or more layers of glass. This reduces the safety hazard associated with shattered glass fragments, while there are security risks associated with easy penetration. Laminated glass produces a characteristic ‘spider web’ cracking pattern when the impact is not enough to completely pierce the glass. The interlayer also provides a way to apply several other benefits, such as colouring, sound dampening, and resistance to fire, ultraviolet filtering, and other technologies that can be embedded in or with the interlayer. It is primarily used in glass façades, aquariums, bridges, staircases, floor slabs,etc. It also plays a big role in overhead glazing like skylights, glass ceilings and roofs.

Mixed use development of Glazed Glass and other Material

The 42 – The Tallest skyscraper in Kolkata

Pushyamitra Londha, Senior Associate Architect, Architect Hafeez Contractor on his project:

Glass these days is an integral part of many façades and roofs. This material can be easily shaped and installed, creating structures which are gripping and dominating. With regards to the luxury residential project ‘The 42’ at Chowringhee, Kolkata, which is touted as the tallest tower in the eastern India, we wanted to give a 360 degree view of the city’s skyscape from the windows. In the project, we have incorporated Double Glazed Units which provides air gap between two glass panes in order to reduce the heat loss and gain. Normal glazing can cause immense amount of heat gain and upto 30 per cent of loss of air conditioning energy. Green tinted energy efficient glass can reduce this impact and avoid glare and lower UV radiation, thus providing an ambient comfort inside each apartment.

The balcony railing is uniformly designed at 1.5m high with a glass balustrade and stainless steel hand rail for safety purposes. Moreover, we have used clear laminated sentry glass railings in all balconies to get a clear view of Kolkata city, which are also toughened providing safety, if any glass breaks due to any unforeseen reasons.

The unique building height of the 42 demands specialised solutions when it comes to the windows and the façade. Double glazed, high precision aluminium windows and glazing system with partially fixed and partially openable shutters form the overall structure.

Surface coatings can be applied to glass to modify its appearance and give it advanced characteristics and functions available in today’s flat glass products, such as low maintenance, special reflection/transmission/ absorption properties, scratch resistance, corrosion resistance, etc. AIS, for example, adds sun shielding properties through various coating mechanisms. Another example of coated glass is Mirrored Glass/ Reflective glass, where a metal coating is applied to one side of the glass. The coating is generally made of silver, aluminium, gold or chrome.

Tinted glass is manufactured by adding a dye at the molten glass stage. It is used primarily to minimize solar heat gain and glare and allows for increased control of energy usage. Spectrally selective glazing is a low-e variant, which is able to differentiate between ultraviolet, daylight, and infrared. It allows only the desired rays to penetrate through. This is a mature technology and spectrally selective glass is available with major manufacturers. Gas-filled glass panel is a low-e variant, which is an insulated glass unit (IGU) filled with inert gases, that reduces the U-factor. Argon is the most popular gas fill, while Krypton offers greater energy efficiency.

Patterned glass is flat glass which has a pattern or texture impressed on one or both sides in the process of rolling. The most common method for producing patterned glass is to pass heated glass (usually just after it exits the furnace where it is made) between rollers whose surfaces contain the negative relief of the desired pattern(s). It is typically used for functional reasons, where light but not transparency is desired, and the patterns are accordingly subtle. However, it has also at times been fashionable as a design feature in itself, in such cases often displaying more prominent patterns.

A project by PNC Architects

Extra clean glass is hydrophilic i.e., the water moves over it without leaving any marks. It has a photocatylitic character too. Since it is covered with Nano particles that attack and break dirt, making it easier to clean and maintain.

Chromatic glass has a dynamic film coating, which either reflects or absorbs light, by means of a low voltage charge. This type of glass can control daylight and transparency effectively by reversing the charge. It can switch its behaviour from allowing light through to blocking its passage. When a current is supplied, they darken and when electricity is withheld they become clear. It is available in three forms- photo chromatic, thermo-chromatic and electro chromatic.

It has largely been used in areas which are sensitive to light, like in hospital ICU’s and Labs.

Thermo-chromic laminated glazing (TLG) enables the regulation of daylight by dynamically adapting to the continuously changing climatic conditions. TLG aids (usually just after it exits the furnace where it is made) between rollers whose surfaces contain the negative relief of the desired pattern(s). It is typically used for functional reasons, where light but not transparency is desired, and the patterns are accordingly subtle. However, it has also at times been fashionable as a design feature in itself, in such cases often displaying more prominent patterns.

In addition to the said types, there are more varieties of glass used for construction: Wired glass is formed when fine twisted hexagonal wire netting or mesh is inserted during the process of rolling. It may be patterned, smooth rolled or ground and polished and is used primarily in fire rated windows, doors, skylights and applications requiring a safety glazing material.

Extra clean glass is hydrophilic i.e., the water moves over it without leaving any marks. It has a photocatylitic character too. Since it is covered with Nano particles that attack and break dirt, making it easier to clean and maintain.

Platina at Bandra Kurla Complex, Mumbai by Wadhwa Group

Chromatic glass has a dynamic film coating, which either reflects or absorbs light, by means of a low voltage charge. This type of glass can control daylight and transparency effectively by reversing the charge. It can switch its behaviour from allowing light through to blocking its passage. When a current is supplied, they darken and when electricity is withheld they become clear. It is available in three forms- photo chromatic, thermo-chromatic and electro chromatic.

in reducing the energy requirements of a building and providing thermal comfort. Neither electrical power nor driving unit is required.

Smart Glass with Suspended Particle Devices: In this type of smart glass, a thin film laminate of rod-like nano-scale particles is suspended in a liquid and placed between two pieces of glass or plastic, or attached to one layer. When no voltage is applied, the suspended particles are randomly organized, thus blocking and absorbing light. When voltage is applied, the suspended particles align and let light pass. Varying the voltage of the film varies the orientation of the suspended particles, thereby regulating the tint of the glazing and the amount of light transmitted. SPDs can be manually or automatically “tuned” to precisely control the amount of light, glare and heat passing through, reducing the need for air conditioning during the summer months and heating during winter.

Glass bricks are hollow glass units or blocks of glass shaped to work as bricks. These blocks are joined using silicon sealants to obtain a seamless finish. The two outer, exposed surfaces may be smooth or textured.

Balancing the Right Amount of Glass Usage in a Structure is the Key Ar. Reza Kabul, President, ARK Reza Kabul Architects

How does glass help in making an effective and interactive building envelope? What are the advantages of using it as a structural element?

Ar.Reza Kabul, Director,

ARK Reza Kabul Architects

Pvt. Ltd.

Glass is a versatile material, filtering in natural light into the structure and providing a visual connect between indoor and outdoor spaces. Predominant in the retail segment, it also extends to the residential and commercial segment where a one-way visual connect is required. The use of highly reflective glass and DGU glass assists in reducing the heat transfer within spaces. It also makes the building look lighter.

Design optimization is determined by a balance of three key factors: functionality, aesthetics, and economics. Balancing the right amount of glass usage in a structure is the key to making the structure cost effective.

Please tell us about the use of different glasses in façade construction?

Flat glass is extensively used in railing and window façades. Warm bended glass is ideal for curved façades and bay windows. Cold bended glass is more practical for façade construction as it is gradually bent on site at room temperature and installed there and then.

How can we improve the safety, efficiency, and appearance of glass buildings?

Consulting experienced personnel during the design ensures safety right from the construction phase to the utility phase. The efficiency and appearance of a glass structure can be constantly improvised by attaining the right balance between the need, functionality and aesthetics.

Please tell us about the latest technologies to alter transparency of glass?

Smart Glass is an impressive innovative technology which switches the sheet from transparent to opaque. There are two variants to this technology: electrically adjustable and non-electrically adjustable. One such structure that uses this technology is the EDGE in Melbourne, where a cube is suspended from the 88th floor of the tower, and it switches from transparent to opaque, giving the people inside the cube a view of the city.

What is the potential for future development of glass as a structural material?

Size and scale is one of the key factors for the future use of glass as a structural material. There is a huge demand for larger sizes with smaller sized support sections. This will help span greater heights, which can be used to withstand the wind pressure in tall buildings.

How do you think India can further develop standards to help safe and effective application of glass as structural products?

The use of trained expertise helps a lot in the process of safe and effective application of glass in structures. Similar to architects and structural engineers, façades engineers too need to be involved in the design process.

Kanakia WallStreet, Mumbai

Choose the Glass Carefully

Shabbir Kanchwala, Sr. Vice President, K Raheja Corp

In the Indian market, usage of glass is growing, with prominent supplier companies like Saint Gobain manufacturing performance glass to suit the Indian climatic conditions and emerging trends. Architects are specific about getting the required look and aesthetics for the structures. The option of unconventional shapes and dimensions only goes further to complement it. Apart from being unconventional and aesthetically pleasing, glass walls provide unhindered views. They allow light to pass during daytime and prevent extreme heat from entering the building, thus, reducing power consumption. The type of glass is carefully selected keeping in mind certain factors like applicable load, usage and location of the structure. The design requirements and calculations of the structure also play an important role in determining which type of glass has to be used.

The flat Glasses are largely used as float glasses in façades, while the warm bended glasses are used in exterior railing and façades where substantial amount of bending is required. The usage of cold bended glasses is limited. Tempered glasses can be used to increase the safety of glass buildings. In order to further enhance it, the use of laminated glasses is suggested. Solar controlled, single low-e and double low-e are recommended to improve the efficiency. However, the appearance depends on what combination of shades of glasses one selects.

Glass is a non-combustive material. In the event of fire, glass shatters in seconds allowing smoke to escape, hence evading casualties due to suffocation.

There are different standards in developed countries like America, Europe etc. for glazing works. These are mainly devised based on applicable weather conditions prevailing in that continent. In India, there is lack of a relevant code for glazing which is something that needs to be worked on.

Mindspace properties in Airoli, Navi Mumbai by K Raheja Corp

Fire Rated Glass is a laminated glass with an in tumescent layer that is specially engineered to withstand extreme levels of heat, restrict heat transfer and prevent passage of smoke and flames. Prominent application includes data server rooms, partitions, doors & windows, façades, smoke screens etc.

Bullet Proof Glass is made with laminated glass along with polycarbonate sheets, the bullet proof glass is a strong but optically clear armoured glass used for safety from bullet penetration. This type of glass is majorly used for doors and windows of buildings with high levels of security requirements.

Almost all types of architectural glass used across the planet are available in the Indian market. However, there are two drivers that determine the extent of use are necessity, and economics. While the know-how is not yet up to the mark in the Indian market, the consumer is up to date on advancements and the latest products, and ensure availability via dealers.

A project by Space Matrix Architects & Planners

Design Optimisation with Glass

Glass has become a favoured feature in buildings, since it reduces the weight on the foundations and makes way for a lighter building. Its modularity has added to the construction speed, says Anup Naik of Space Matrix. However, before incorporating glass in construction, certain factors likedesign requirements, applicable load, etc., need to be calculated to choose the right type of glass, says Mukesh Jaitley of Wadhwa Group.

As on date, architectural glass is mostly used on façades as stick glazing, structural glazing and unitized glazing. It is used as a structural element only in architectural components such as canopies, in clear shop fronts as fins, and as balustrades, railings and other internal building elements. Cost plays a major factor in the use of glass as a major structural element.

While selecting glass for a project, architects and engineers face a lot of challenges:

- Life span

- Necessity and visual appeal

- VLT (visible light transmittance), solar heat gain coefficients, U and R values

- Availability of colour and texture

- Buildability and performance

- Project budget.

Every project carries a special theme which works with the design philosophy at every step. The decision of selecting a glass also has to resonate with the same fact in a measurable manner to control the final outcome.

According to Deben Moza, the design aspect of any building resides on few factors; the most important one is management of the ‘sun path’. In an Indian context, it is important for the building orientation to be in alignment with the solar path, which is a deciding factor in most cases for the designing of the façade glazing.

The optimization of design vis-à-vis glass can vary from being extremely scientific or equally intuitive, says Abhishek Bij. For example, if the sole purpose of a certain commercial façade is purely based on the balance between thermal comfort and estimated cost, then software simulations fed with manufacturer’s specification can suggest the ideal product. If geometry is the overriding decision maker, then the optimization process resolve the geometry such that most double curved glass panels are eliminated.

One of our current projects, Saily international Sports Complex, uses several combinations of structural glass from Saint Gobain to achieve the desired thermal comfort and the mosaic pattern on the façade,” points out Bij.

PNC Architects – bedroom villa exterior

The latest trend in Architecture is prefabrication and modular design, and glass and aluminium are the sought after materials in this area, since they are high precision materials that can be prefabricated, engineered and pre-processed easily. “The key here is focus on its material properties, the design methodology and its failure mode. With the advancement of technology and the science of building, it is important to have clarity on the application of bent glass, single curved and double curved glass. The focus here should be on safety, operation and maintenance”, observes AnupNaik.

Building Geography, Geometry & Curved Glass

Glass is a very flexible material in terms of application in various areas, thanks to all modern technologies available to treat it in different manners. According to Indrajit Kembhavi, glass, being a lighter material, tends to occupy lesser volume of space, and apply lesser structural load, thus helping in optimization of the design.

In addition to the location, typology of the building and existing climatic conditions of the site, the existing acoustical conditions around the site also play a vital role in deciding the amount of glass which can be used in a building.

Selection of glass and aluminium for curved structural elements depends on several factors like the aesthetics of the façade, load-carrying capacity of the structural members and amount of visibility required within the building. It also depends to a large extent on the cost factor.

The curved glass has unbeatable design aesthetics and should have been architect’s first choice in the areas where it can be used. However, says Kapil Handa, architects tend to avoid curved glass, since it is prone to undulations and is more refractive by nature. Because of the costs of curving etc., it still remains quite prohibitive and finds its usage in very limited areas. The industry is yet to bring down the costs.

According to Nagaraj, when curved façade is desired, first try to use flat glass panels arranged in an appropriate array to give the impression of curvature. This is done because it avoids the additional processing involved in curving the glass panels. It is very essential to ensure proper detailing of the frames, glass and the clearances required for expansion/contraction when the façade is of a complex shape.

Use of Flat, Warm-Bended and Cold-Bended Glass in Façade Construction

The arching of glass creating curved glass makes it highly load resistant in most cases. When done properly, arching minimizes deflections also, points out Deben Moza. The use of moulds to bend the glass by raising the temperature to the limits of 580 to 600°C (and above) is the hot bending technique, which on cooling creates the bended glass. The hot bended glass created by manufacturers requires lamination for all architectural applications, where the manufacturers are expanding the limits of radius, angle, thickness, girth and coatings, in order to offer architects and designers the larger sizes and greater possibilities.

GTM Residency Tower with tinted glass for thermal comfort by Design Plus Architects

Cold bending technology is a much recent advancement in the fabrication process where by means of external pressures (frame) one can attain the desired geometrical arching. Cold bending can be carried out after the glass is already tempered. By doing so, the glass adopts the mechanical properties of safety glass. This is used for slight bending of glass. Cold bending can be attained in a factory or at the construction site as well.

According to Abhishek Bij, hot bending is much more expensive than cold bending. “In fact it is so expensive that I would always avoid suggesting hot-bending if I can get away solving the geometry with flat or cold bent glass”, he adds. Glass probably bends more than most people can imagine. Within limits, which conservatively isat approximately 1:1,000, this property allows cold forming, drastically reducing the energy required to achieve curvature. Cold-bent glass in a single pane recovers its original flatness when released. This means that cold bending requires a closed frame that holds it in place; this method is better suited to gentle curves and large scales. While cold bending is feasible with either single panes, laminates, or insulated glazing units (IGUs), the long-term integrity of IGU aluminium spacers, moisture seals, and structural silicon can be another constraint on the amount of bending.

In hot bending, the manufacturer uses moulds, which allow the glass to adopt the desired form. The glass is bent solely by gravity or with mechanical bending equipment. It is preferred to laminate this glass for it architectural application.

Cold bended glass is used for double-curved surfaces while warm bended glass is used for single surfaces. In some applications a mechanical bending process is applied on thinner cross sections of glass.

For bent laminated glass, the glass sandwich is bent with the desired number of glass sheets in the interlayer, then autoclaved. Since the glass is laminated, it fulfils all the safety glass requirements. The key benefit of this process is the possibility of making very flexible shapes.

Prabhakaran of PNC Architects observes that The Omniyat Building by Zaha Hadid is a fine example for the usage of glass in flat, warm and cold bended form. “However, my personal preference is definitely for flat glass – keep it simple and straight,”

he adds. The value of bended glass can only be appreciated in iconic projects, and not in run of the mill developments.

Atmosphere at Mulund West, Mumbai by Wadhwa Group

Improving the Safety of Glass Buildings

By using the right glass, architects can improve the efficiency and safety of buildings. Inappropriate products such as poor quality glass or framing material that is used in some buildings, largely due to ignorance and cost, leads to safety concerns in the long run. Each material presents its own limitations, which must be dealt with during the design process, opines Deben Moza of Knight Frank. The use of adequate materials improves the safety of transparent structures during exposure to fire by increasing the fire resistance of glass elements or by slowing down the development of thermal strain in them. Glazed façades come with a challenge of cleaning and adds substantially to the upkeep cost of the structure.

Fire resistance of glass can be enhanced as you climb the glass type hierarchy, says Ar. Bij. This is apexed with specific fire resistant glasses, where laminated glass is sandwiched with an intumescent layer.

Safety is of paramount importance here. There is nothing more important than ensuring the safety of human life, observes Nagaraj from Infosys. As of now there are no stringent safety norms for use of glass in buildings. Use of laminated glass must be made mandatory, if not voluntary for certain applications. The next best can be toughened glass

which is 4 times stronger than normal annealed glass and breaks into small crystals on impact. Use of fire rated glass has to be ensured at least in critical areas as specified by National Building Code (NBC). Openable panels should constitute at least 10 per cent of total façade area. Rather than opting for glass-box like design, architects should ensure that window to wall ratio is optimal. All the recent Infosys buildings have around 35 per cent WWR, says Nagaraj. This will ensure both enhanced appearance and efficient envelope, good natural lighting and comfortable interiors for occupants.

Deepak Dinesh Prabhakaran of PNC Architects, like Nagaraj from Infosys, agrees on having stricter norms and codes which have to be constantly updated based on performance and usage feedback. Strict implementation of code compliance and maintenance by owners should be mandatory.

Potential for Future Development of Glass as a Structural Material

Trends in the global architectural glass market are essentially driven by two things – building regulations and architectural fashions. With more and more countries pledging to cut their carbon emissions, energy efficiency is increasing becoming a key factor in glazing, says Deben Moza.

Ar. Kembhavi adds that the demand for recyclable, self- cleaning, fire-resistant, heat-insulating materials, makes glass a versatile product for construction. Hence, the potential for future development of glass as a structural material is very high.

Nagaraj of Infosys expects that dynamic glasses will enter the next level of development and application. More and more properties of glass will be controllable. Unobstructed view of exteriors also requires that the structural systems like Aluminium frames be developed and designed accordingly.

A new imaginative leap has taken place recently by architects and structural engineers investigating the potential of using glass structurally, informs Ar. Rajendra Kumar. The glass element may simply resist wind load, or it may carry its own weight, or support live loads of people walking and leaning on it. To the structural engineer, the issues of most concern will be properties of strength, stability, stiffness, along with durability, robustness and buildability.

Deepak Dinesh Prabhakaran also predicts that there is a very good potential for glass to develop into the structural material of choice across various typologies and geographical locations. With technology advancing in leaps and bounds, it will soon be structurally sound to use in a large scale and volume.

Glass in Media Façades

Serving as a surface for branding and advertising of digital and other media, the façade could be converted into a leasable area, and obviously, it garners more attention against the skyline. Today‘s technology allows for the glass surface to be communicative through display of information.

Usage of glass instead of concrete on the façade increases the speed of construction. Also, because glass is the most recycled material in the world, the supply is plentiful and non-detrimental to the environment.

Development of Standards to Help Safe & Effective Application of Glass

Standards enforced in developed countries, for usage of glass in specific areas of building, building, are sadly not adhered to in India, says Nagaraj. Kapil Handa observes that India has always been dependent on an adopted version of British standards, which at some stage started to be known as IS codes. In the meantime, in the world over there was a huge advancement in the codes which allow for greater flexibility in the material usage. America and Australia in particular now have much more stringent as well as flexible rules that allow proper usage of glass as structural elements. Like Nagaraj, Kapil also feels the biggest back draw in the industry comes from the state bodies who do not comprehend the importance of the codes for the health and safety of the users.

Paras World School with Sun shield Coated Glass, designed by Design Plus Architects

As an industry, advices Deben Moza, the ideal approach would be of integration, wherein the designer, manufacturer and the installer take the onus of designing and integrating the various components and ensure adherence to safety standards. Consultants who advice on façade designs are few and are involved only in certain large projects.

Deepak Dinesh Prabhakaran advocates that the standards are becoming all the more important for India as it becomes one of the major producers, inventors (and not remain as users), and Importers. The “Make in India” campaign should extend to the manufacture of high quality building materials in the country. We need to become contenders in the global market, and there is a long way to go to do so, adds Prabhakaran.

Since India is a tropical country, one of the major issues to be considered is the amount of heat being trapped by the glass which indirectly increases the electricity loads and causes warming up of the space, observes Kembhavi. Recyclability of the glass should also be considered as an important criterion. In addition to the above factors, the issue of privacy should also be given due consideration as India is a country with a pre-dominantly conservative society.

Prescriptive norms specifying right use of glass need to be developed. Laminated toughened glass needs to be made mandatory for high raise buildings. Use of annealed glass has to be avoided. These are just pointers but there is a long way to go.