The Growth of Hardware Market in India

Before the pandemic, the architectural construction hardware and glass product market in India experienced steady growth due to several factors, including rapid urbanisation, infrastructure development, and an increasing focus on modernisation and aesthetics in buildings. The market saw a rise in demand for products such as door and window fittings, hinges, locks, glass façades, curtain walls, and other related hardware. The Covid-19 pandemic had a temporary setback on the construction industry as a whole, including the architectural hardware and glass product segment.

Post the initial impact of Covid-19, the architectural construction hardware and glass product market in India began witnessing a resurgence. The following are the driving factors for this revival:

• Increased demand for residential construction due to rapid urbanisation

• Commercial development with a desire for modern and visually appealing structures.

• The Indian government’s continued emphasis on infrastructure development, including programmes like “Housing for All” and “Smart Cities Mission”

• Railways and airports, healthcare, and educational facilities are expected to drive the demand for architectural hardware and glass products in the post-Covid era.

• Besides new construction, renovation & retrofitting projects also contribute to the growth of the construction hardware industry. As older buildings and structures require repairs, upgrades, & modernisation, the demand for construction hardware products such as door and window hardware, locks, hinges, flooring and other fittings increases.

Construction activities are closely tied to overall economic growth. When the economy is expanding, there is an increased demand for construction projects s leading to a rise in the demand for hardware. The architectural hardware industry is influenced by international trade patterns. Increased globalisation and cross-border construction projects create opportunities for hardware manufacturers and suppliers to expand their reach and cater to a broader market.

The Indian government’s ‘Make in India’ initiative has encouraged domestic manufacturing of hardware products. This has led to the establishment of manufacturing units by various global suppliers in India, contributing to the growth of the hardware market. The growth is further fueled by the growth of e-commerce platforms in India, which added benefit to the growth of the hardware market.

Challenges Faced by the Industry

Major challenges faced were supply chain disruptions (leading to delays in material procurement and delivery); labour shortages, and economic slowdown. The pandemic’s impact on the economy resulted in reduced investments and delayed projects, affecting the overall demand for architectural hardware and glass products.

1. Cost of raw materials: Unavailability and unaffordability of raw materials can be a significant hurdle for hardware manufacturers. Fluctuating prices of raw materials, such as aluminium, steel and glass, impact the manufacturing cost and overall profitability.

2. Technology and innovation: Adapting to new technologies and innovation is crucial for staying competitive in the hardware manufacturing industry. Some manufacturers may face challenges in adopting advanced manufacturing processes, machinery, and automation due to cost constraints or a lack of awareness about the benefits and implementation strategies.

3. Competition from imports: India imports a significant portion of its hardware and building materials, including façade, door and window products. Imported products, often from countries with lower production costs, can pose intense competition for domestic manufacturers, especially if they are unable to match the price and quality offered by imported alternatives.

4. Customer awareness and perception: Educating customers about the benefits and quality of domestic hardware products can be a challenge. Some customers may perceive imported products to be superior in terms of quality, leading to a preference for foreign brands.

Market Trends

In response to market trends and rising consumer demand, several new materials and products have been introduced in the architectural hardware and glass industry.

Smart façades: Integration of technology in façade systems is gaining popularity. Smart façadess can incorporate features like self-cleaning surfaces, dynamic shading systems, and embedded sensors for real-time monitoring of environmental conditions.

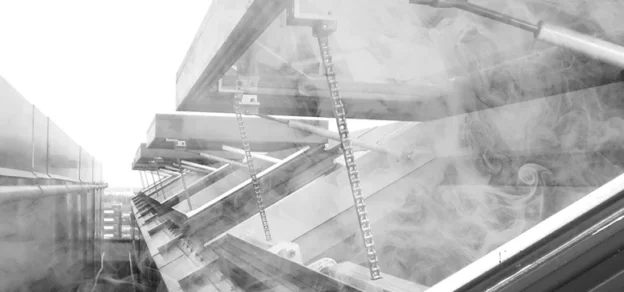

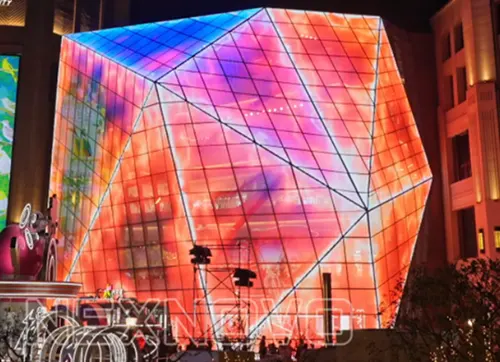

Dynamic façades: Dynamic façade systems can adapt to changing environmental conditions. They may include movable elements or technologies that adjust the façade’s appearance, such as shape-shifting materials or panels that rotate to control sunlight and ventilation. LED façades: Digital façades often utilise LED (Light Emitting Diode) displays to create vibrant and high-resolution visual content. These displays can be embedded within the façade or mounted on the exterior surface of the building, allowing for the projection of dynamic graphics, videos, animations, and other media LED-integrated railings: LED-integrated railings incorporate lighting elements within the railing system. These railings can enhance safety by providing ambient lighting in dark environments while adding an attractive visual element to the space.

Architectural mesh: Architectural mesh is a versatile material used for applications such as façades, ceilings, sunscreens, and space dividers. It offers various patterns, textures, and transparency levels, allowing architects and designers to create unique and aesthetically appealing structures. Integrated technology: Integration of technology within architectural hardware is on the rise. For example, smart home automation, door locks and access control systems are becoming smarter, allowing for keyless entry, remote control, and integration with home automation systems.

Standardisation & Certification

Standardisation & certification provide a common framework for the industry, promoting interoperability and compatibility. When products adhere to recognised standards, they are more likely to be accepted and used by architects, builders, and other stakeholders. This promotes market acceptance and increases market opportunities for manufacturers.

Here are some ways in which standardisation & certification help the industry:

Quality assurance: Standardisation and certification ensure that construction hardware and glass products meet specific quality standards. By adhering to standardised specifications and undergoing rigorous testing, manufacturers can demonstrate that their products are reliable, durable, and perform as expected. This helps to build trust among customers and reduces the risk of product failures or defects.

Safety and compliance: Standardisation and certification ensure that construction hardware and glass products meet safety requirements and comply with relevant regulations. For example, standardised hardware such as locks, hinges, and handles are designed to withstand specific loads and ensure proper functionality. Similarly, certified glass products, such as windows and doors, are tested for factors like impact resistance, fire resistance, and thermal performance, ensuring they meet safety standards.

Interoperability and compatibility: Standardisation allows for interoperability and compatibility between different construction hardware components. When hardware products adhere to common standards, they can be easily integrated and used interchangeably in various construction projects. This simplifies installation, maintenance, and repairs, as builders and contractors can rely on standardised components that fit and function together seamlessly.

Market access and global trade: Standardisation and certification facilitate market access and promote global trade in the construction hardware and glass products industry. By complying with recognised standards, manufacturers can demonstrate their product’s quality and compliance to international buyers, expanding their market reach. Certifications issued by reputable bodies enhance credibility and enable easier entry into foreign markets with strict regulatory requirements.

Consumer confidence & reputation: Standardisation and certification help to build consumer confidence in construction hardware and glass products. When products carry certifications from reputable third-party organisations, it assures customers that the products have undergone rigorous testing and they meet quality and safety standards. This enhances the reputation of manufacturers, strengthens brand image, and promotes customer loyalty.

Innovation and advancements: Standardisation provides a framework for innovation and advancements in the construction hardware & glass products industry. By setting common benchmarks and guidelines, standards encourage manufacturers to develop new & improved products that meet the evolving needs of the market. Standards also facilitate the introduction of sustainable practices, energy-efficient designs, and technologies that enhance product performance.

Future Demands- Vision 2030

The commercial and residential sectors offer prospects for growth in the global door and window industry. With a CAGR of 3.8% from 2016 to 2021, the worldwide door window market shipments were predicted which reached $231.3 million in 2021. According to a survey by Lucintel, the global door window market is anticipated to expand between 2022 & 2027 at a CAGR of 4.9% and $308 million in value and volume. Through 2025, window demand in India is anticipated to expand at the quickest rate of any significant market, at 11% annually. Growth will emerge from a weak base in 2020 brought on by the epidemic, the Russia-Ukraine war, and Inflation in raw material prices.