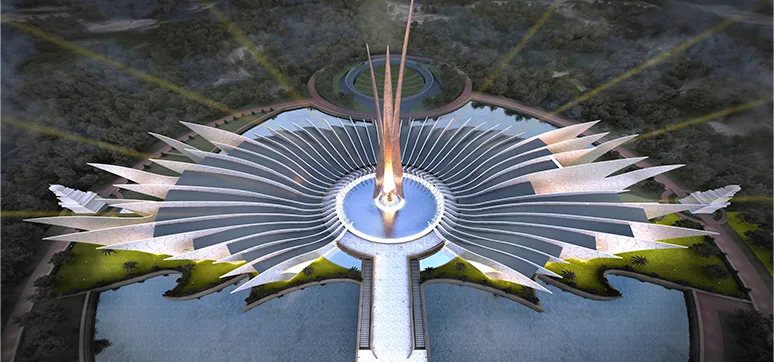

CJ Blossom Park, Suwon, South Korea

By:

CJ Blossom Park in Suwon, South Korea, designed for one of Korea’s largest companies, consolidated the corporation’s previously disparate pharmaceutical, biotechnology, and food products businesses into a single location.

The building’s architecture, which was designed by the Yazdani Studio of CannonDesign, is inspired by CJ’s brand identity—defined by a three-petal blossom. These are represented by three elliptical towers of differing heights, each housing one of CJ’s divisions. The towers rise around a central atrium that cultivates interconnectivity and engagement with fluid circulation and natural light.

An outer-pleated perforated screen wraps around the entire complex and shades the floor-to-ceiling semi-unitized glazing, providing an even distribution of light deep into the building. By carefully coordinating pleat folds and screen densities with building orientation and program elements, this secondary skin enabled the team to place full-height glazing around the entire perimeter of the building without negatively impacting thermal performance.

With a wealth of diffused daylight, the circulation was placed at the perimeter, separated by a glass wall from the laboratories at the centre within each tower. In this way, there is visual connectivity between different disciplines within the building, and the laboratories benefit from panoramic views and natural light. A complete approach to daylighting was achieved with the provision of glare-controlled exterior and daylighting sensors in addition to the large central atrium. Flexibility, efficiency, and comfort are afforded throughout each floor by a chilled beam system for temperature controls.

A detailed solar study led to the optimisation of the perforations to control the incident solar radiation around the building. Perforations range from 30% to 50% at 2-3% intervals based on the orientation to reduce solar heat gain where needed while still maintaining high levels of natural daylight. This enables the building to save energy, reducing the output of carbon dioxide and other greenhouse gases, ultimately helping to reduce the carbon footprint of the building.

The design of this sophisticated double-skin facade with the perforated screen wall came with the challenge of its maintenance. Working in tandem with the façade maintenance vendor, the team designed a Building Maintenance Unit (BMU) system where the automated façade access system runs along tracks on the roof with the carriage dropping from telescoping arms within the space between the veil and the exterior glazing. With over 14,000 panels and well over 1,000 unique panel types, the complex veil form with varying densities presented a challenge to the design, fabrication, and installation efforts. Once the form was resolved, emphasis was placed on detailing and alignments, enhancing the fluidity, and tying together the discrete elements.

Quick Facts:

- Project: CJ Blossom Park

- Location: Suwon, South Korea

- Client: CJ Cheiljedang Corporation

- Architect: Yazdani Studio of CannonDesign

- General contractor/ construction manager: CJ E&C

- Other Consultants: Iljin, Thronton Tomassetti, ARUP

- Executive Architect and Engineers: Heerim Architects & Planners

- Materials used for façade & fenestration: Unitised glazed aluminium curtain wall without vertical mullions between the floor and the ceiling, folded perforated painted aluminium plate panels on a steel frame and outriggers, and point-supported glass on glass fins.

- Commencement Date: 2010

- Completion Date: 2015

Top Stories

Quanex Building Products to Acquire Tyman in $1.1 Billion Transformative Deal

By: Abdul | May 2, 2024

BIM’s Integration with Emerging Technologies such as AR and VR Presents Exciting Opportunities for Architectural and Façade Design

By: Abdul | May 2, 2024

The Future Impact of Artificial Intelligence on Façade Access Gondolas

By: Abdul | May 1, 2024

Façade Systems Market Size is Estimated to Reach USD 398.8 Billion by 2029

By: Abdul | April 16, 2024

Improving Sustainability Alongside Fire Safety – Can We Deliver?

By: Abdul | April 16, 2024