A designer knows where to add/ remove material, how to use the known resources to defend the unknown circumstances, use the type of material to meet strength, ensure safety and price criteria, make it more durable, energy saving, and apply creativity to solve the problem. The selection criteria for hardware depend on various parameters like safety, strength, aesthetics, cost effectiveness, maintenance, and user friendliness.

Safety

When selecting any hardware, safety should be the top priority. The hardware will be considered as the secondary loading structures in most of the applications like facades, railings, etc. The hardware should have built-in safety features such as fail-safe, safe-life mechanisms, redundant components, and error detection and correction capabilities to minimise the risk of accidents and failures.

Strength

The design of any hardware should have an optimal proportion to the mass of the system and external load (wind, live & point). It should be strong enough to restrict exceptional circumstances, and in such instances, the hardware has to bear the loads and should be durable. Also, if any part of the hardware fails, it should not fail the entire system.

Aesthetics

We need to consider the aesthetics of a system while choosing hardware, especially if the application is exposed, or the system is expected to grow and handle increasing demands in the future. Most of the time, meeting similar requirements of aesthetics and safety would be very challenging, but creativity is a tool to accomplish the requirements of beauty and load bearing strength.

In the current market, a building’s aesthetic views are something that cannot be compromised. Hence, while selecting hardware for the door & window system, visual aspects like colour, texture, finish, overall built quality and aesthetics of the hardware need to be considered in a such way that it should not disturb the overall design of the building.

Cost-Effectiveness

While efficiency and safety are paramount, the cost-effectiveness of the hardware should also be considered. Analyse the total cost of ownership, including initial purchase costs, maintenance expenses, and potential savings or benefits achieved through improved efficiency and safety.

Maintenance

Evaluate the availability of maintenance and support services for the hardware. Prompt technical assistance, software updates, and replacement parts should be readily available to ensure minimal downtime and efficient resolution.

User-Friendliness

The hardware should be user-friendly, allowing easy installation, configuration, and operation. Intuitive drawings, clear documentation, and training resources facilitate efficient usage of hardware and reduce the risk of user errors or accidents on the site. Ensure that the selected hardware complies with relevant regulations, industry standards, and safety guidelines. Compliance with legal requirements and standards is crucial for maintaining operational efficiency and safety.

When it comes to door and window hardware, a lot of other parameters which are recommended to consider is

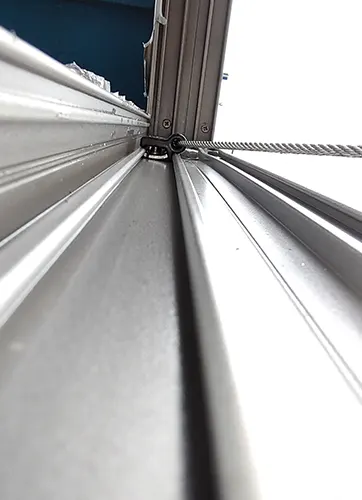

Compatibility of Hardware with Profile Design:

We can increase factory fabrication efficiency by using Euro Groove (20C) groove profiles. It has Advantages as below:

• Punctureless hardware installation: Reduce the production time of windows or doors by avoiding additional machining for hardware installation. Avoid hardware customisation.

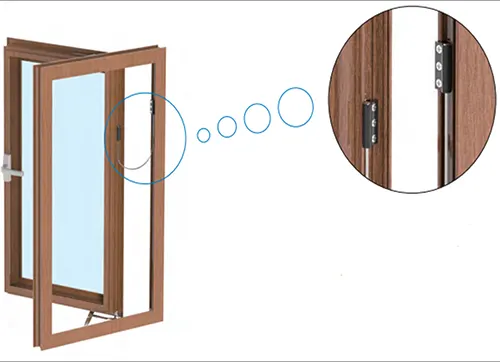

• Calculate the number of locking points: We propose a single-point locking system or multi-point locking system based on wind load and window size.

• Project surrounding environment: Project’s surrounding environment plays an important role while selecting hardware materials. In some cases, if the project is located near the sea area, then it may require special surface treatment and coating to prevent corrosion.

• Selection of hinges: In the case of side-hung casement windows, based on their opening direction and window size, we propose a pivot/ friction hinge.

• For the side-hung open-in window, we recommended using a pivot hinge to achieve the maximum opening and clear view.

• For side-hung open-out windows, we recommended using friction hinges instead of pivot hinges to avoid shutter disengagement due to cyclic motions.

• Anti-fall arrangement: There are various factors by which a window can fail like bad workmanship, hinges failure, calamities, etc. So, to avoid accidents due to such failures anti-fall restrictor can be installed to minimise such incidents.

Aurobindo Kohinoor Hyderabad

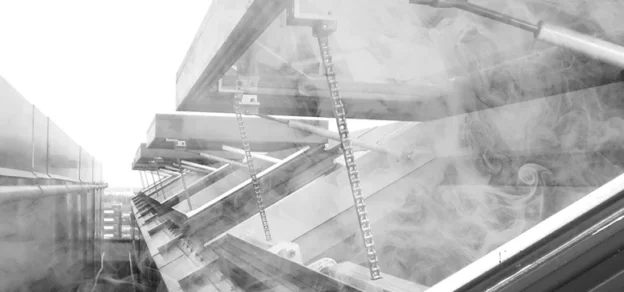

Considering all the key points mentioned in my article, we designed a U-Channel railing for the loading condition of 3.3KPa for the Project developed by the Aurobindo group.

The project started with a different design and ended with a unique and simple hardware solution. The real challenge faced by our “design team” was to provide and fulfill the requirements of the client. It was not so easy to design the hardware for the glass height of 1.1m and 3.3KPa loads. The earlier proposal was more expensive for the client. Our design team provided an optimal, cost-effective, safe solution with 3 different designs. This was saving nearly 23.5% cost of the overall railing budget. Understanding the load paths can help a designer to think about Optimisation and cost-cutting. There were extremely high challenges while designing a U-channel, anchors, and wall brackets. The wind load of 3.3KPa is acting on the 1.2*1.1 Sq m area. In return, these reaction loads were acting on the channel, from channel to anchor.

QUICK FACTS:

• Project: Aurobindo Kohinoor

• Location: Hyderabad

• Client: Aurobindo Realty

• Consultants: FACET Façade Consultancy

• Architectural Hardware used: Kinlong Hardware India Pvt Ltd

• Commencement Date: 3rd May 2023

• Completion Date: 10th June 2023